Medem AGDS-M User manual

1

00253

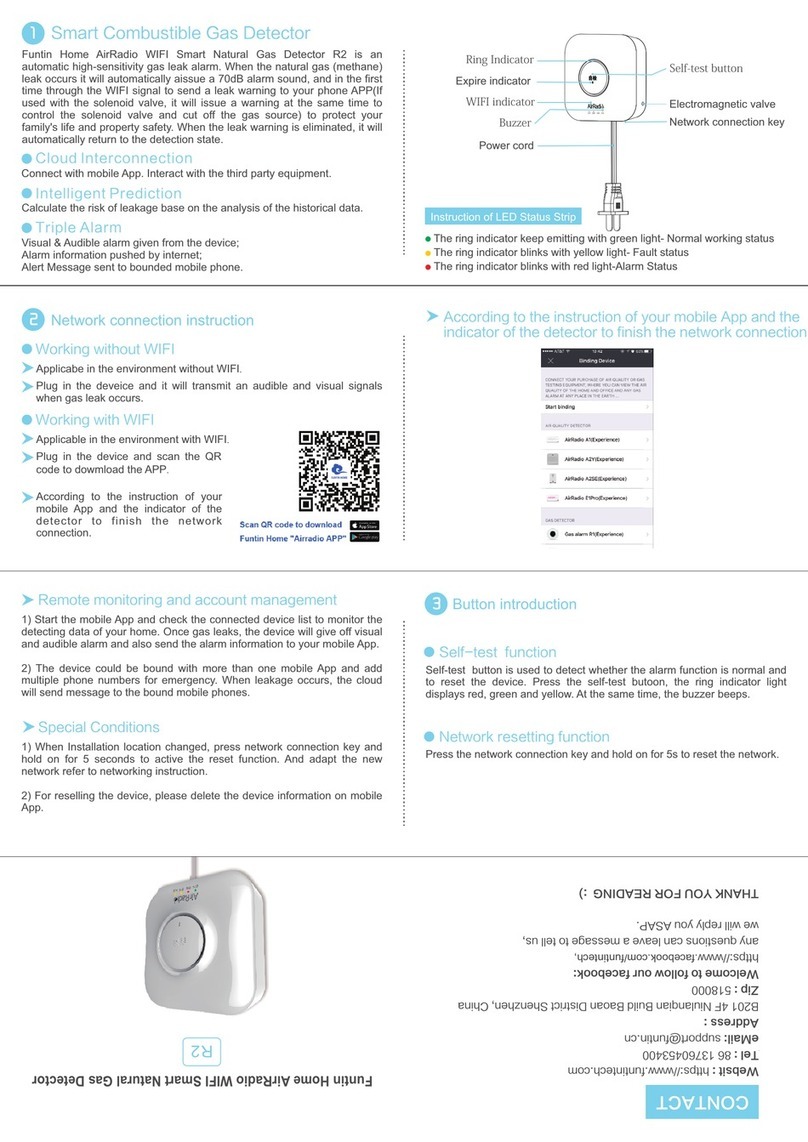

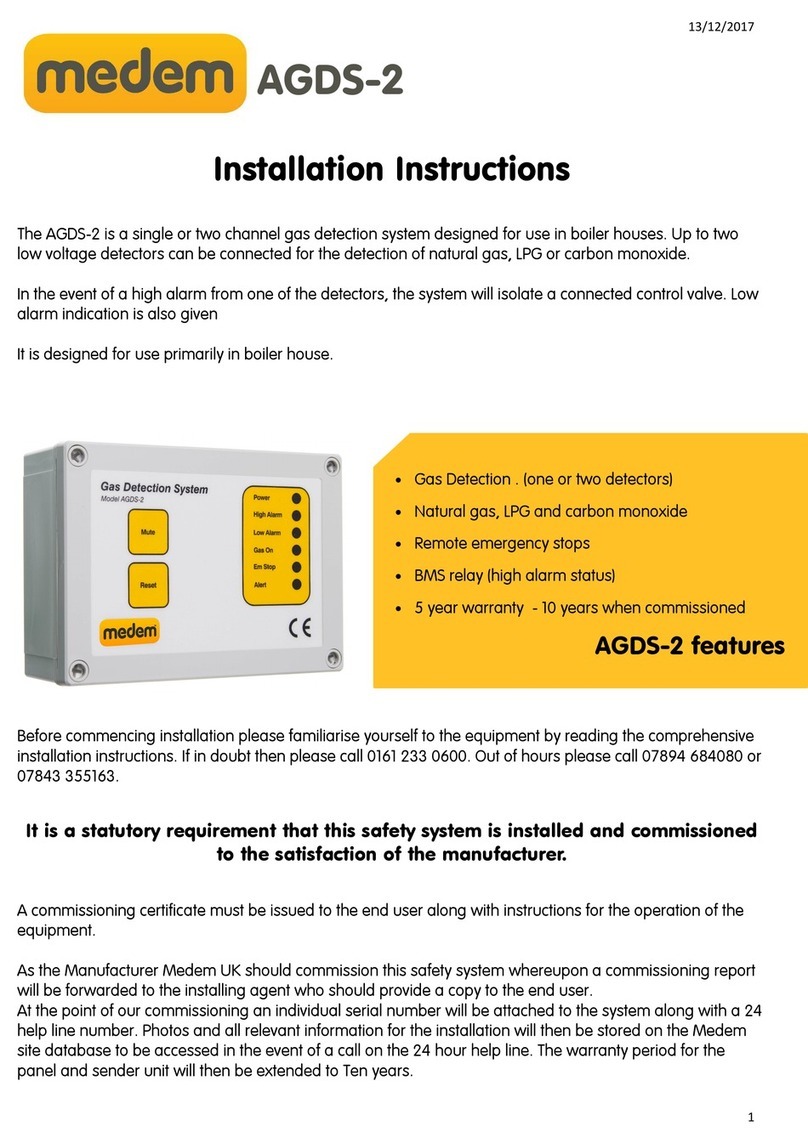

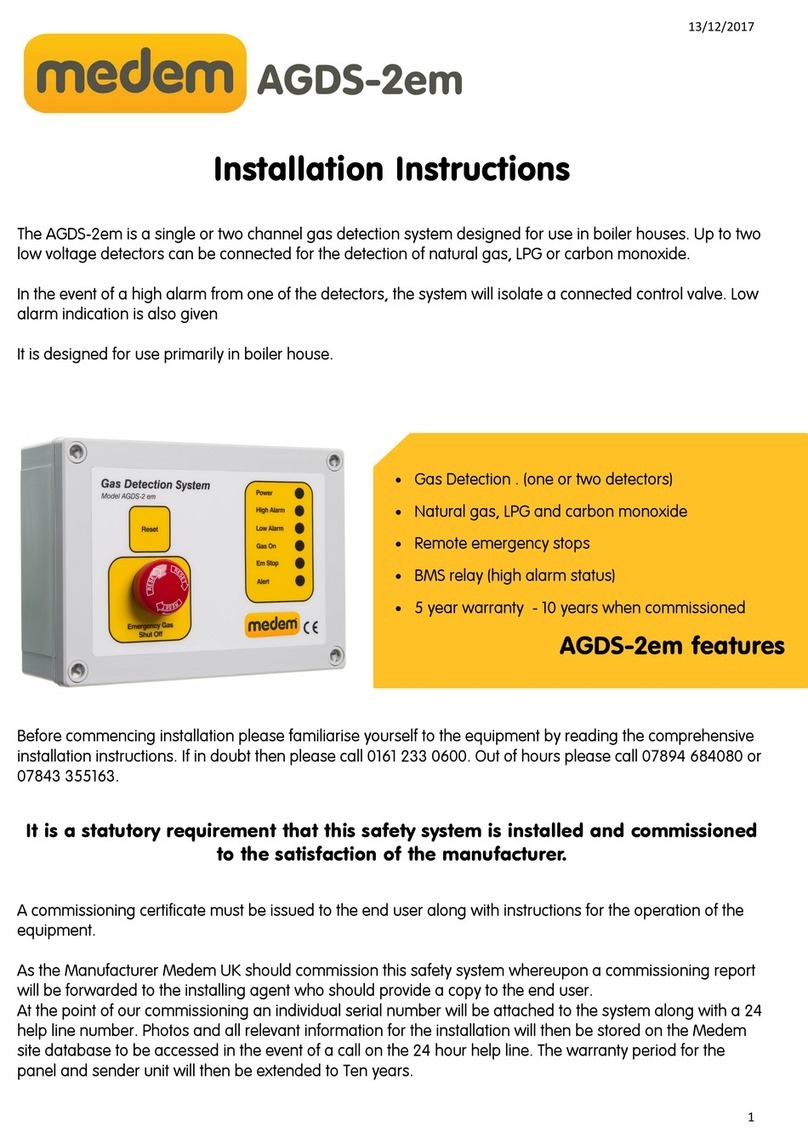

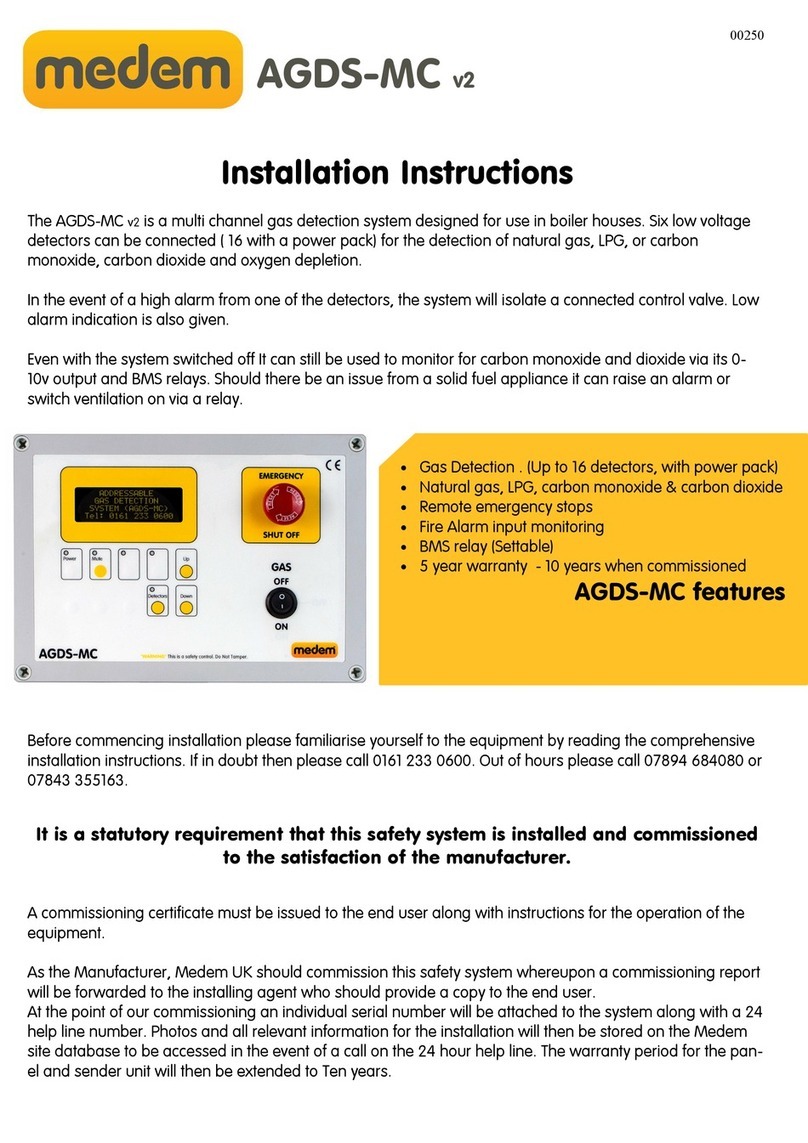

AGDS-M

Installation Instructions

The AGDS-M is a four channel gas detection system. Up to four low voltage detectors can be connected for

the detection of natural gas LPG CO CO2 and Oxygen.

In the event of a high alarm from one of the detectors the system will indicate locally and provides contacts

for remote monitoring or to activate a beacon/sounder or fan.

The system will automatically reset after the target gas detected has fallen below its alarm level. Low alarm

indication is also given.

Before commencing installation please familiarise yourself to the equipment by reading the comprehensive

installation instructions. If in doubt then please call 0161 233 0600. Out of hours please call 07894 684080 or

07843 355163.

It is a statutory requirement that this safety system is installed and commissioned

to the satisfaction of the manufacturer.

A commissioning certificate must be issued to the end user along with instructions for the operation of the

equipment.

As the Manufacturer Medem UK should commission this safety system whereupon a commissioning report

will be forwarded to the installing agent who should provide a copy to the end user.

At the point of our commissioning an individual serial number will be attached to the system along with a 24

help line number. Photos and all relevant information for the installation will then be stored on the Medem

site database to be accessed in the event of a call on the 24 hour help line. The warranty period for the

panel will then be extended to Ten years (detectors warranty is two years).

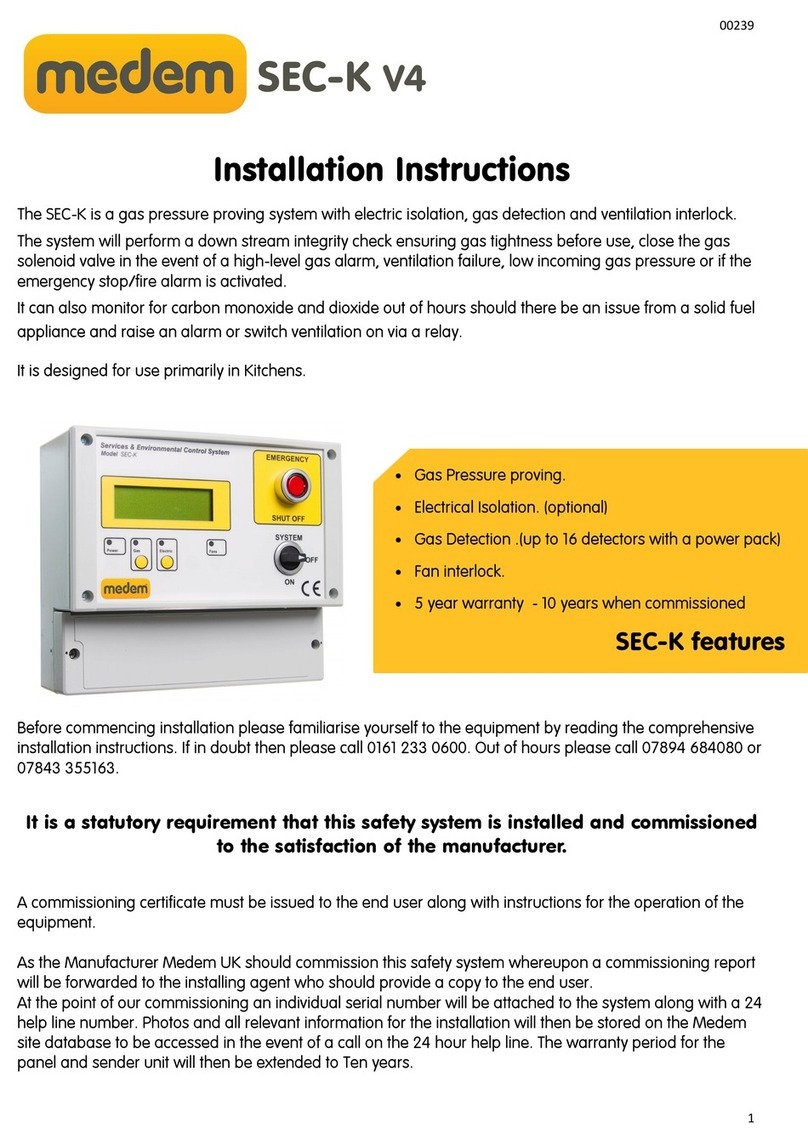

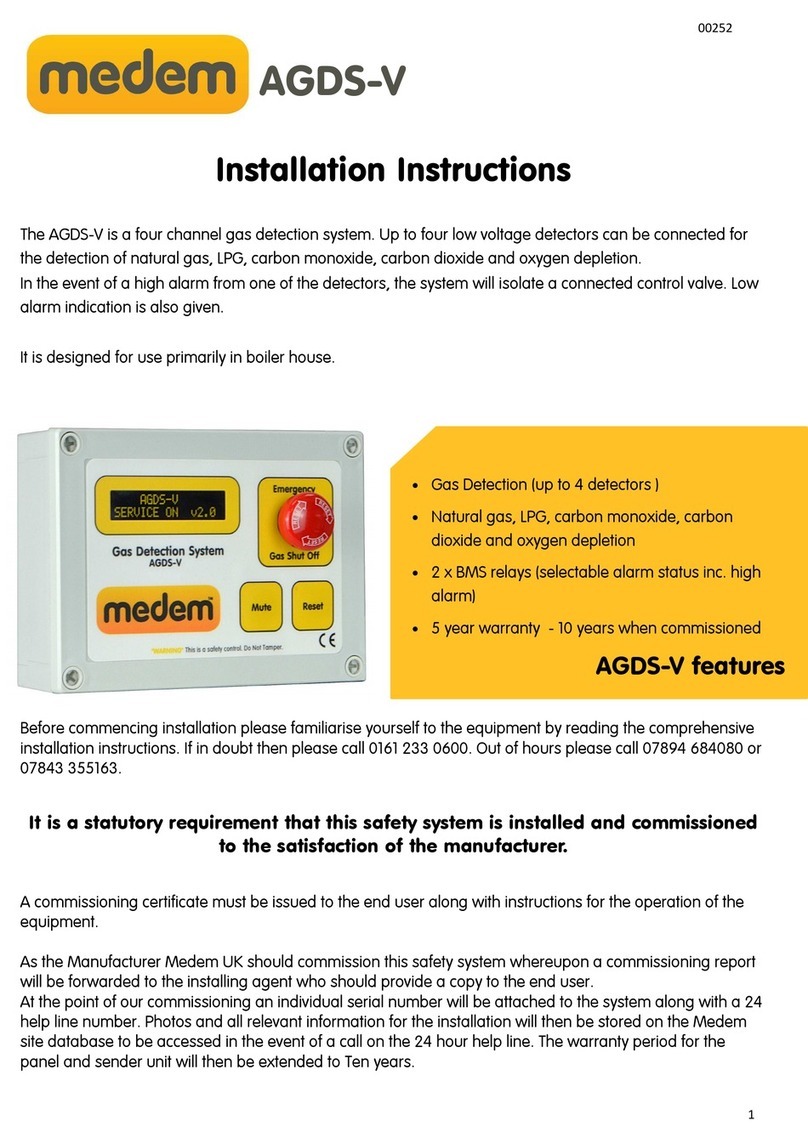

• Gas Detection (up to 4 detectors )

• Natural gas LPG and carbon monoxide

• 2 x BMS relay (selectable alarm status inc. high

alarm)

• 5 year warranty - 10 years when commissioned

AGDS-M features

2

00253

System description

AGDS-M

A Mute button to mute the internal tone

B Reset button for resetting and opening the valve after an alert/alarm condition.

A B

The AGDS-M is a gas detection system designed to monitor the atmosphere for target gases. The system comprises of a mains

powered panel capable of operating up to four sensors either combustible or Carbon Monoxide gas or a mixture of both. The

sensors are pre-calibrated by Medem (UK) Ltd such that they only require to be connected to the panel and functionally tested.

The system is designed to auto reset from a high alarm condition after the target gas has fallen below the alarm level.

In the event of a high alarm from one of the sensors the system will indicate locally and provides contacts for remote monitoring

The system will automatically restart after a power failure.

Control Panel

The front of the panel has the following controls and indications:

Mute button for the internal toner.

Reset button for clearing an alert

LCD display:

For displaying system status during both installation and normal use also for displaying diagnostics

3

00253

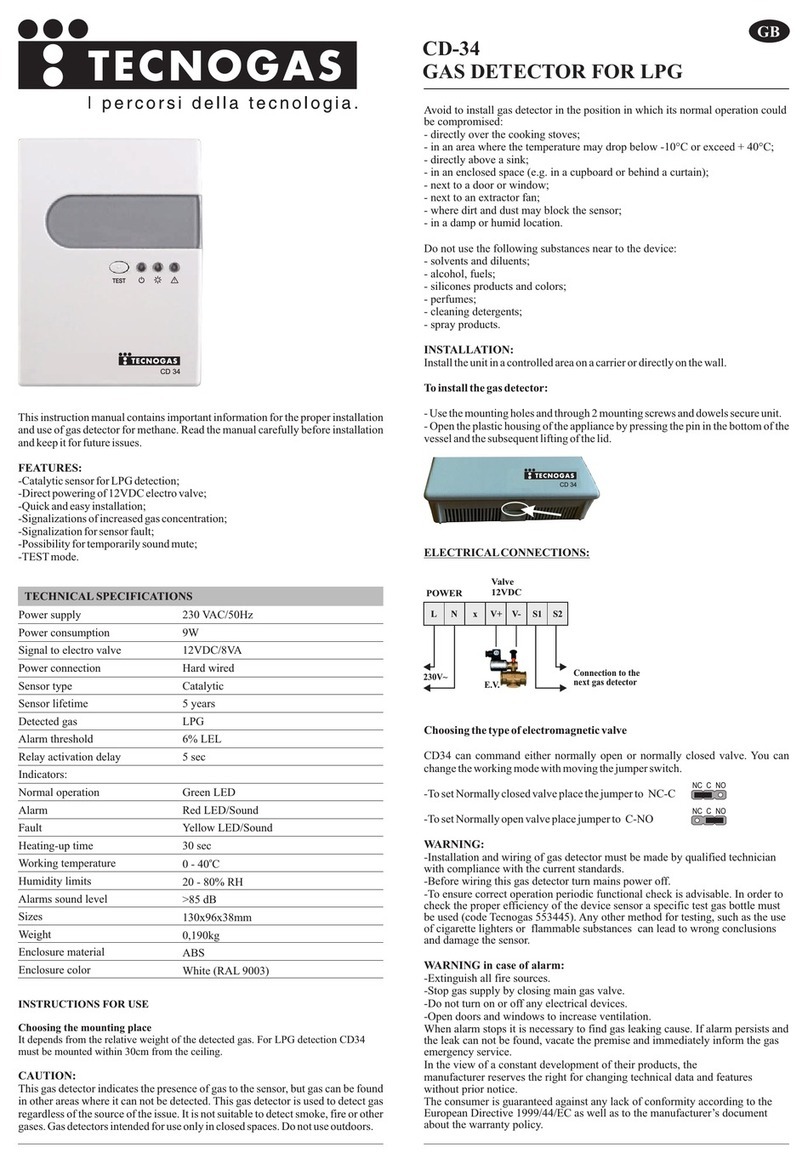

Main features

AGDS-M

Connections to panel: marked on board

1. Live & Neutral 230 volt supply from 3amp switched fuse spur

2.

3. Earth connection terminals

4. AUX 1 BMS Relay

5. AUX 2 BMS Relay

6.

7. Fire Alarm Panel connection (requires N/C volt free contact in the Fire Panel)

8. Power connections for detectors Methane LPG CO CO2 Oxygen Temperature

9. Comms connections for detectors Methane LPG CO CO2 Oxygen Temperature

10. Panel Mode switches (factory set do not alter)

11. Internal tone on/off

12. Spare

13. Learn field device button press once only when all detectors are connected and powered.

14. Display detector information 1 & 2 on screen

15. Display detector information 3 & 4 on screen

16. BMS Relay setting (see page 4 for details)

Power at 230

volts from a

3amp fused spur

16

1 2 3 4 5 7 8 9

10

11

12

13

14

15

17 18

19

Medem

Gas detectors

Multiple

connect in

parallel

Fire Alarm

Requires a volt

free NC contact

Earth Connections not

shown

230v Supply

3Amp Fused Spur BMS Relays

See table on page 4 for

settings.

4

00253

System Settings

AGDS-M

Status

A 1 A 2 A 3 A 4

EM Stop - ES OFF OFF ON OFF

Fire Panel Active -FA ON OFF ON OFF

High Alarm - HA OFF ON ON OFF

Low Alarm - LA ON ON ON OFF

Gas On/Off OFF OFF OFF ON

Detector Fault - DF ON OFF OFF ON

Generic Fault (ES FA HA LA DF) OFF ON OFF ON

There are two mains rated relays 4 & 5 for connection to a BMS or sounder/Beacon. Each relay is able to be set to

report one of the status in the table below.

Max switching 230 volts 5amp’s

4, 5 & 16. BMS Relays and setting switch

Notes.

It is recommended that all systems are commissioned aer installaon by Medem UK. This will e tend the warranty period from 5

years to 10 years and ensure the system is working as designed.

Please see warranty condions that came with the main panel

16

Learn Dets.

Any gas detectors connected to the system will require “learning”. First ensure all detectors are set to a

unique ID address using the selector switch on the detectors themselves (address’s 1 to 4). Having

addressed each detector press the learn Dets button (13) the system will scan and store any connected

detectors.

Shows Dets 1&2 3&4.

To verify that all detectors have been successfully learnt use the Show Dets buttons 14/15 to verify the

detectors are connected correctly.

13, 14 & 15 Learn and Display Detectors

13

14

15

5

00253

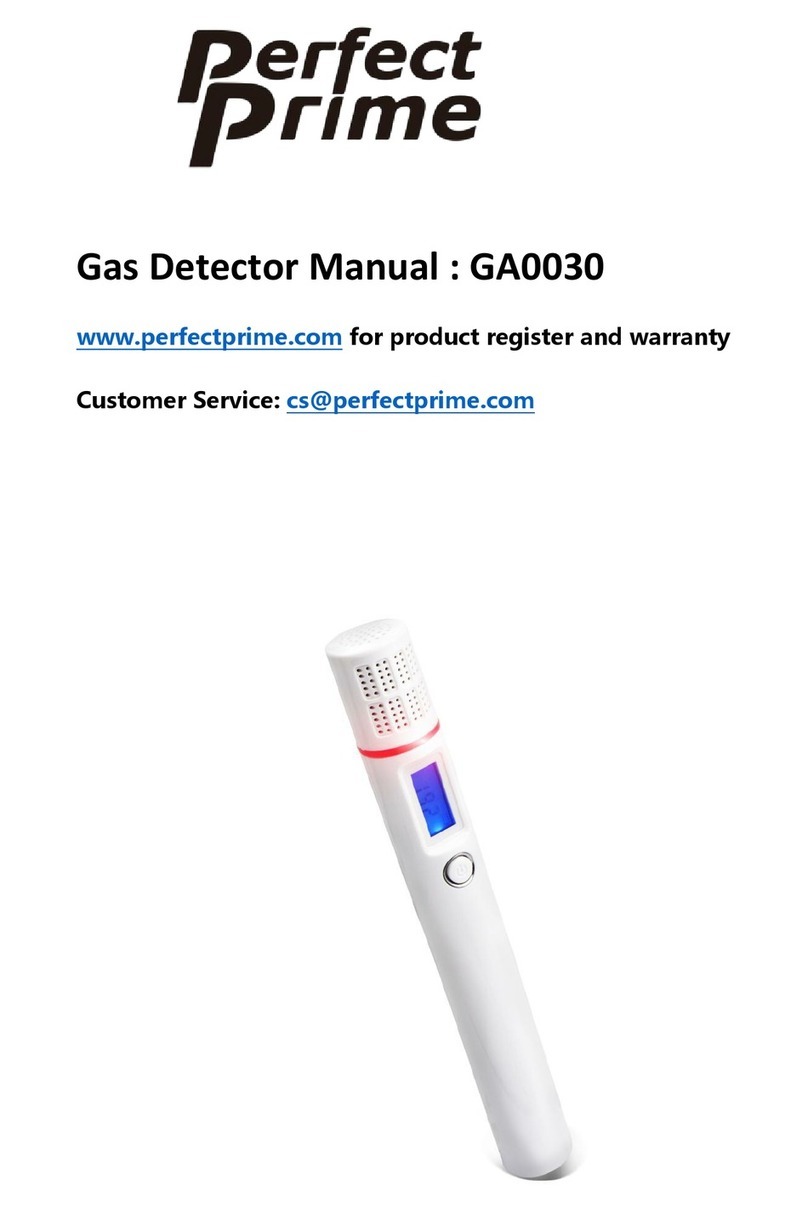

Gas Detection

Gas Detectors

IMPORTANT - Gas Detectors should not be installed until all building construction or painting work etc.. Is completed as these

works can effect the sensitivity and longevity of the detectors.

Ensure that the protective cover labels (RED) are removed only

after the completion of all building work and the system has

been commissioned by the Medem engineer.

The labels are required to be removed for the detectors to

operate but removal before the completion of works risks

contaminating the sensor element.

The system is capable of operating a mix of up to 4 detectors of different types.

The detector types are:

• Carbon Dioxide.

• Carbon Monoxide.

• Combustible gases (Methane Propane).

• Oxygen depletion.

Detector location will vary dependant on the individual characteristics of the target gas that is being monitored for. See the gas

detectors own instructions for more guidance.

AGDS-M Detector Information

+VE supply & Comm’s

From either the main panel or an

extender.

Detectors are wired in parallel and can be

connected to one another daisy chain

Address Selector

Each detector must be set to its own

address 1-4 and then “learnt” using

button (13 see page 4)

Connection and addressing

Status LED

All current wiring regulations must be followed with reference to running low and mains voltage cables together.

The maximum cable length between a detector and the control panel should not exceed 100 metres if the distance between

the main panel and the detectors is greater than 20metres a 1mm screened cable must be used on the +VE 0v terminals

Gas detectors require a four core screened Belden type security cable or 600v rated BMS cable (max cable length of

100meters.)

Remote emergency stops and thermal links require a two core screened cable.

Warranty will be void if Fire Protection Cable or cable over 1mm dia. is used on the SELV side.

When addressing gas detectors CO &

CO2 detectors must be numbered

before natural gas detectors.

6

00253

Detector Information

Detector location will vary dependant on the individual characteristics of the target gas that is being monitored for.

The descriptions below describe the position for each detector after considering these characteristics.

For proper function care must be taken not to site a detector in a “dead space” or in the flow of any ventilation.

Natural Gas/Methane

Natural gas detectors should be mounted at high level on a wall approximately 150mm from the ceiling height and avoiding

corners and potential dead air areas.

Natural gas detectors should not be mounted below the height of the top of a doorway for example. This is because as the gas

is slightly lighter than air it will rise filling the room from the ceiling down and will spill through the top of a door opening into the

next room. If the detectors are mounted below this height then it will take longer the gas to reach the detector.

LPG /Propane

LPG gas is heavier than air so detectors need to be mounted at low level 100mm from the floor consideration should be given

to any potential mopping or wet floor height.

Carbon Monoxide

Carbon Monoxide is similarly weighted to air so detectors should be mounted between 1 to 2 meters from the floor.

Carbon Dioxide

Carbon Dioxide detectors should be installed so they monitor the general level of CO2 within the area. They should be mounted

above standing head height and between 1m and 3m from the potential source. Care should be taken so they are not located

close to the edge of a canopy or in direct flow of the supply or extract ventilation.

For additional information or guidance on site specific requirements please don’t hesitate to contact us.

Each detector has its own Bi-Colour LED which is used to indicate the status of that detector.

Not Lit: No power/comm’s. These a four wire units and all connections are required check the polarity of both the

power and the comm’s (MA/MB) terminals are correct.

Flashing Green: Detector is warming up the detectors will flash green on power up for 90 seconds while the sensor

elements stabilize. The system will ignore any detectors while flashing.

Solid Green: Detector is powered and active. Note: The detectors will still require correctly addressing (using the address

selector pot) and learning by the system using button (13 see page 4).

Flashing Red: Low level alarm. All detectors have both a low and high level alarm low level alarms serve as a warning

that an unsafe condition maybe building and gives chance to intervene before loss of gas service.

Solid Red High level alarm. An unsafe level of the target gas have been reached and the system will isolate the

gas supply. The cause of the alarm will require identifying and resolving before the gas supply can be re-

established.

After installation a simple bump test can be performed by using an appropriate level test gas in order to check operation. Full

testing and calibration checking takes place during a Medem commissioning.

AGDS-M

Detector Location

Detector Indications

7

00253

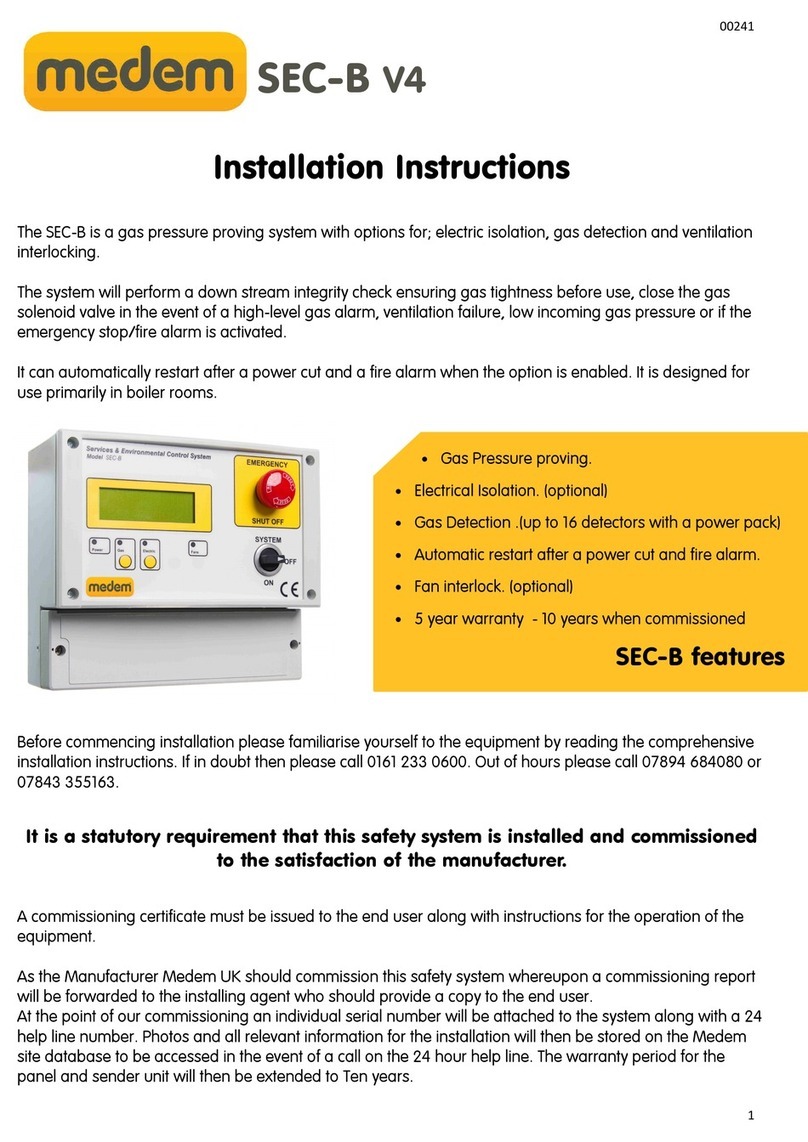

Remote stop buttons

AGDS-M

To EM Stop connections in the

panel

Use terminals TB2 A & C Use terminals TB2 A & C

Remote stop buttons can be connected to the panel terminal

marked as “EM STOP” (number 6 ).

The remote buttons must be wired as shown in order to provide a

“closed contact” for the control panel.

If thermal links are to be installed these should be wired

in series with the EM stop buttons

To EM Stop connections in the

panel

Indicator bar shows when

pressed

Normal EM-Stop Activated

Multiple Stop Buttons

Single Stop Buttons

Resetting (indicator bar)

The stop buttons supplied by Medem are of a “Push Glass key resettable” style when activated a yellow indicator bar will

show and the unit will require resetting using the key provided.

Multiple stop buttons are wired in series.

If thermal links are to be installed these too should

be wired in series with the EM stop buttons

Use terminal TB2 A & C

8

00253

Warranty

AGDS-M

Medem (UK) Limited

Project House

19 Dallimore Road

Manchester

M23 9NX

Tel: (0) 161 233 0600

Fax: (0) 161 233 0601

Web: www.medem.co.uk

E-mail: sales@medem.co.uk

Medem UK Warranty

Terms & Conditions

1. The warranty is a parts warranty and Medem UK Ltd will not cover or accept any labour or

other expenses that may be incurred in the process of changing faulty product.

2. All panels and sender units are covered by a five year warranty.

3. Gas detector units and other remote detectors carry a two year warranty. Installation of the

detectors should not be undertaken until all building and construction work is completed.

4. Gas solenoid valves carry the original manufacturers warranty though as the supplier

Medem UK will exchange faulty valves for return to the manufacturer.

5. Where a Medem UK engineer (or another company appointed by Medem UK) commission

and installed system then that system will carry a ten year warranty. This applies to the

main panel and the sender unit. At the time of commissioning a security label with a serial

number will be attached to the main panel box. photographs and a comprehensive record

of the installation will be held by Medem UK.

6. Where a warranty claim is made then where appropriate a written order to attend site

must be provided to Medem UK A cost for labour and travel to site will be prepared as a

quote. The cost must be included in the order.

7. Where it is found that the installation and/or the quality of workmanship has contributed to

or wholly caused the failure of the product then we reserve the right to charge the whole or

a proportion of the cost of the faulty item.

9

00253

It is essential that the installation of the AGDS-M is carried out in the order given

below to ensure the correct operation of the system.

First read the system description sheet before following the

instructions below

1. Connect any additional EM stop buttons or thermal links in series to the terminals marked “EM stop” (6)

2. Each detector/device has a rotary address switch each switch should be set to a different number 1-4. Then connect the gas

detectors to terminals marked “detectors” on the panel. Detectors are wired in parallel. “Daisy chain” (08 & 09 )

3. Connect fire alarm ensure volt free n/c (7)

4. Ensure any BMS connections are made to the relays (4 & 5)

5. Connect the 3 amp fused spur 240 volt supply to marked terminals.

6. Once power is connected to the panel the detectors will flash the green LEDs for 90 seconds after which the LEDs will be on

continuously.

7. Press the “learn field button” (13) this is on the main circuit board on the right hand side just over half way up the board

pressing this once allows the panel to learn how many and which type of detectors are fitted.

8. Press and keep pressed the “display detectors1-2 or 3-4” button whilst checking on the display that all the detectors have

been recognised by the panel.

9. At this point press the “reset” button the panel will open the gas valve.

Checklist

AGDS-M

Please do not hesitate to call for advice on the

following number:

0161 233 0600 office hours

In the event of any alert the system will always give a reason on screen as to the

cause.

Common messages you may receive are shown below with further explanation.

If you require any help or if anything is unclear then please contact technical support on 0161 233 0600

messages

Detector fault

The system believes it has lost connection to a detector on address XX verify detector addresses and press the “learn button” (23).

Verify all connected detectors are being registered by using the “Show Dets” buttons 14 & 15. If you have no detectors connected to

the system pressing the learn button will clear the error message.

Other Medem Gas Detector manuals

Medem

Medem SEC-B User manual

Medem

Medem AGDS-2em User manual

Medem

Medem SEC-L v4 User manual

Medem

Medem AGDS-2 User manual

Medem

Medem AGDS-2em User manual

Medem

Medem AGDS-2em v2 User manual

Medem

Medem AGDS-MCM v2 User manual

Medem

Medem AGDS-MC v2 User manual

Medem

Medem AGDS-MC User manual

Medem

Medem SafeAir User manual

Popular Gas Detector manuals by other brands

Osaka

Osaka DG - IP21 - LINK instructions

Dräger

Dräger Polytron 6100 EC WL Instructions for use

Riken Keiki

Riken Keiki 04 Series Operation manual

RKI Instruments

RKI Instruments 35-3010RK-07 manual

FIBARO

FIBARO CO Sensor FGCD-001 user manual

Industrial Scientific

Industrial Scientific TANGO TX2 product manual