9

00250

Detector Infor ation

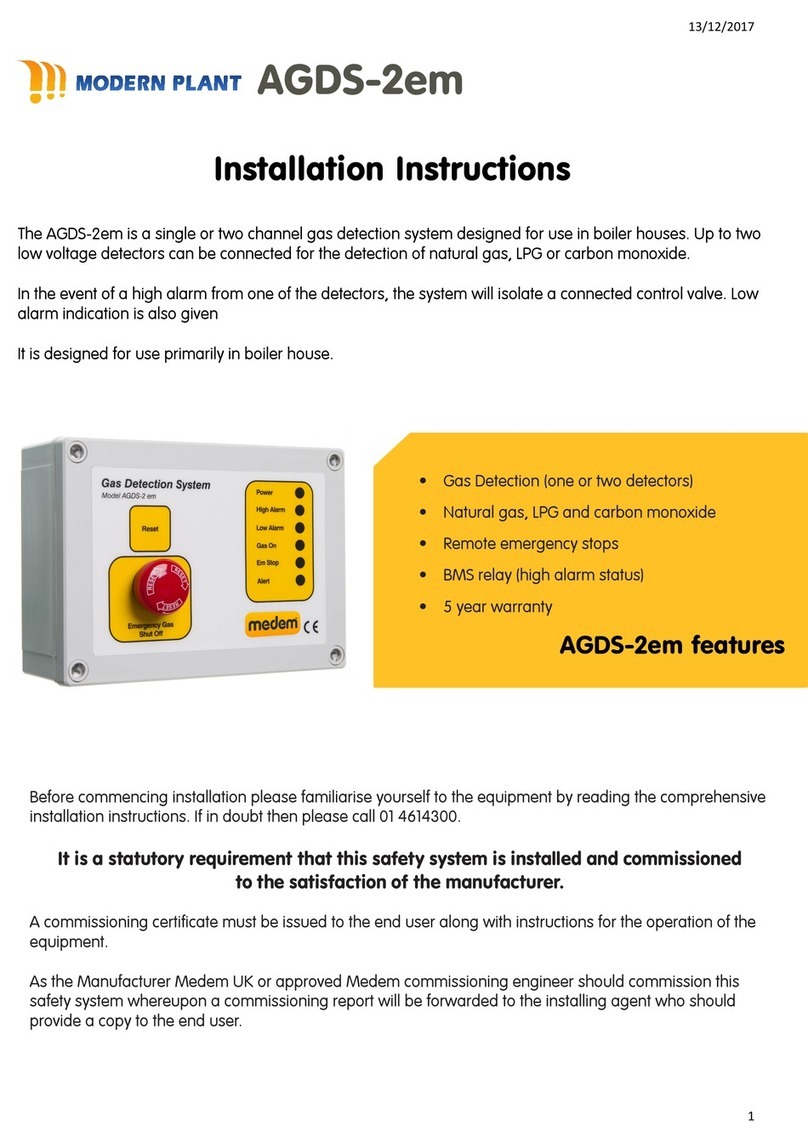

AGDS-MC v2

Detector location will vary dependant on the individual characteristics of the target gas that is being onitored for.

The descriptions below describe the position for each detector after considering these characteristics.

For proper function care ust be taken not to site a detector in a “dead space” or in the flow of any ventilation.

Natural Gas/Methane

Natural gas detectors should be ounted at high level on a wall approxi ately 150 fro the ceiling height and avoiding

corners and potential dead air areas.

Natural gas detectors should not be ounted below the height of the top of a doorway for exa ple. This is because as the gas

is slightly lighter than air it will rise filling the roo fro the ceiling down and will spill through the top of a door opening into the

next roo . If the detectors are ounted below this height then it will take longer the gas to reach the detector.

LPG /Propane

LPG gas is heavier than air so detectors need to be ounted at low level 100 fro the floor, consideration should be given

to any potential opping or wet floor height.

Carbon Monoxide

Carbon Monoxide is si ilarly weighted to air so detectors should be ounted between 1 to 2 eters fro the floor.

Carbon Dioxide

Carbon Dioxide detectors should be installed so they onitor the general level of CO2 within the area. They should be ounted

above standing head height and between 1 and 3 fro the potential source. Care should be taken so they are not located

close to the edge of a canopy or in direct flow of the supply or extract ventilation.

For additional infor ation or guidance on site specific require ents please don’t hesitate to contact us.

Each detector has its own Bi-Colour LED which is used to indicate the status of that detector.

Not Lit: No power/co ’s. These a four wire units and all connections are required, check the polarity of both the

power and the co ’s (MA/MB) ter inals are correct. Check the detector is address to the correct channel

and the detector has been learnt using (21)

Flashing Green: Detector is war ing up, the detectors will flash green on power up for 90 seconds while the sensor

ele ents stabilize. The syste will ignore any detectors while flashing.

Solid Green: Detector is powered and active.

Flashing Red: Low level alar . All detectors have both a low and high level alar , low level alar s serve as a warning

that an unsafe condition aybe building and gives chance to intervene before loss of gas service.

Solid Red High level alar . An unsafe level of the target gas have been reached and the syste will isolate the

gas supply. The cause of the alar will require identifying and resolving before the gas supply can be re-

established.

After installation a si ple bu p test can be perfor ed by using an appropriate level test gas in order to check operation. Full testing and

calibration checking takes place during a Mede co issioning.

Detector Location information

Detector Indications