Medifa MAT 504220 User manual

Service Manual

Technical Documentation

MAT 504220/ 504225

Operation Table

504220 504225

English

Index

I. Safety Instructions ...................................

II. Normal Use ..............................................

III. Exposing and Removing of the Column

Cover and Control Panel ...........................

IV. Exchange of the Upholstery.....................

V. Replacement of the Motor for the Trend-

elenburg Adjustment as well as the Pull

Spring for Stabilization .............................

VI. Gas Springs for Back Rest Adjustment....

- Dismantling of the Gas Springs .......

- Montage of the New Gas Springs ...

- Replacement of the Release

Handle/Button ..................................

VII. Dismantling of the Upper Frame ..............

- Model 504220 ..................................

- Model 504225 ..................................

VIII. Replacement of the Distribution Panel.....

2

3

4-7

8-9

10-12

13-16

13-14

15

16

17-19

17

18-19

20

IX. Replacement of the Limit Switches (only

504225)..........................................................

X. Dismantling of the Joint Frame incl. Motor for

Lateral Tilt ......................................................

XI. Dismantling of the Lift Column.......................

XII. Dismantling of the Control Panel ...................

XIII. Dismantling of the Movability Function .........

XIV. Dismantling of the Shifting (only 504225)......

XV. Dismantling of the Accumulators...................

XVI. Wiring Diagram..............................................

XVII. Lists of Spare Parts/Drawings .......................

- OP-Table MAT 504220/25 ....................

- Head Plate Art.-No. 61144 ....................

- Small Head Plate Art.-No. 61143..........

- Devided Leg Plate Art.-No. 61615 ........

XVIII. Service and Maintenance Schedule ..............

XIX. Diagnosis (Remote Diagnosis) ......................

21

22-23

24-25

26

27-29

30-31

32

33

34-39

34-35

36

37

38-39

40-44

45-50

Service Manual - MAT 504220/ 504225 Operation Table

The operation table has been manufactured according to the state of the art as well as to the valid safety

specifications and requirements.

Nevertheless, improper handling and/or damages on the operating table can lead to safety hazards for the

user and/or other persons and tangible assets.

Only start running the operating table when in perfect condition. This table has been solely designed for normal

use. Operators should keep in mind to handle the table in compliance with the safety rules and recommendati-

ons as listed in this manual, in order to avoid any hazards which may occur from improper handling. Any de-

faults which may affect the safety have to be repaired immediately!

The table comes with conductive double castors, conductive upholstery and an equipotential bonding.The ope-

ration table can be used in a Zone M - given the area is equipped with a conductive floor.

Always keep this manual close at hand. Please notice as well all legal and further guidelines and regulations

for accident prevention and pollution control.

Do not replace, change or repair any devices of the above mentioned table without the authorization of the ma-

nufacturer. All repairs and maintenance services need to be carried out by the manufacturer or by authorized

personnel.

Spare parts need to be in accordance with the requirements of the manufacturer. Original spare parts always

guarantee the proper running of the operation table.

Keep the mandatory deadlines for recurring controls as stated in this service manual!

Think of an environement friendly disposal of equipment and faulty parts!

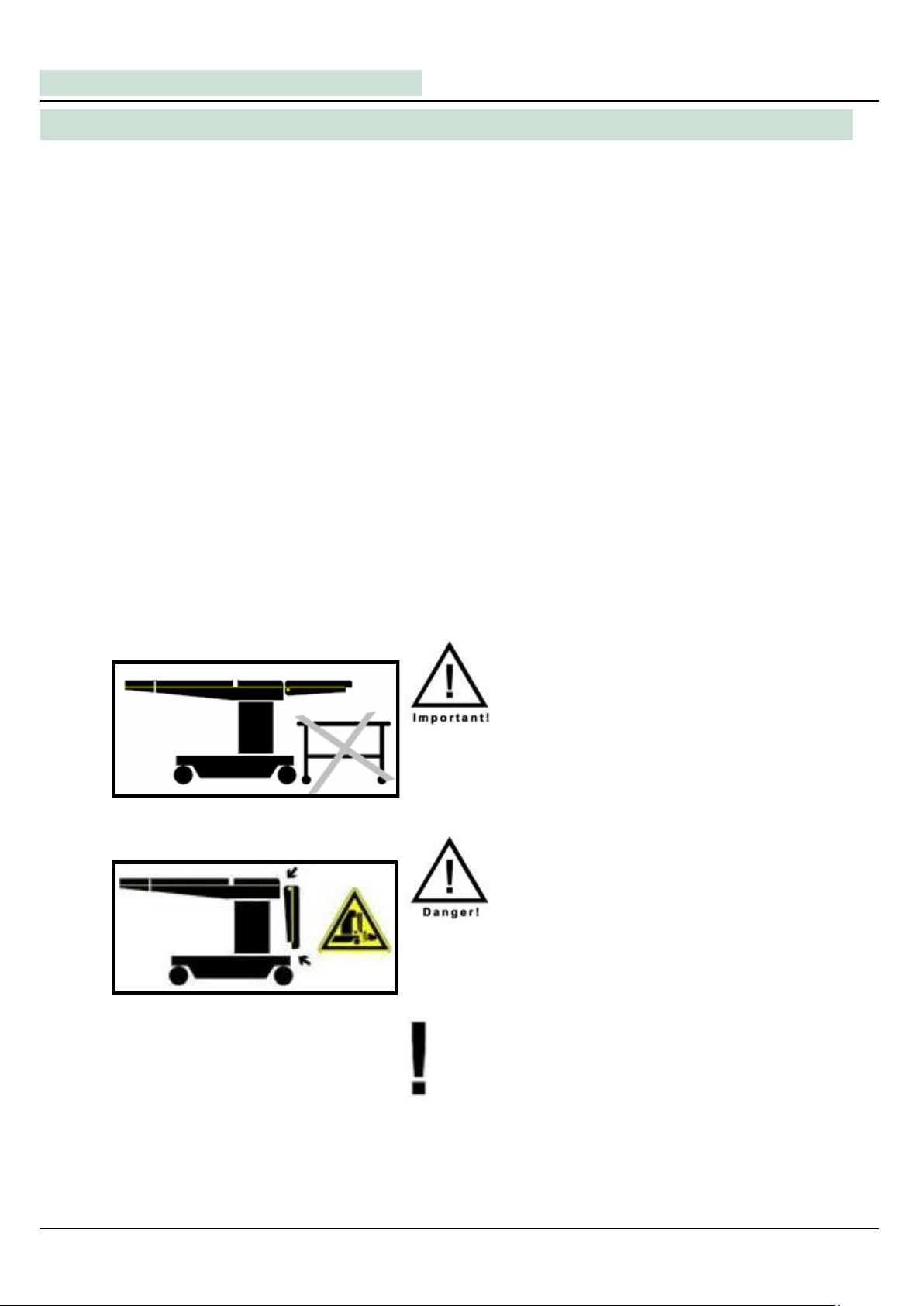

Think of a barrier free surrounding before carrying out a

downward or tilting motion!

DANGER OF TILTING!

Do not touch below or between any surface components or

parts.

DANGER OF SQUEEZING!

Avoid collisions between parts of the table top and the co-

lumn, when carrying out the following adjustments:

Height adjustment (downwards)

Tilt adjustment

Legplate Adjustment (downwards)

I. Safety Instructions

2

In compliance with the fullfilled regulations and rules of the international standard IEC 60601-1 and

IEC 60601-2-46 this table is a Class I device, following the classification of the law for medical products

(Medizinproduktegesetz)(MPG).

It has to be listed in a respective index. All maintenance works, new installations, adjustments and mountings

should be reported in that index.

Alway keep in mind, that all of the above mentioned works should be solely carried out by Medifa Service

Technicians to guarantee a long, safe and proper function of the product.

This is an important requirement for all kind of warranty claims!

Operation tables, manufactured by Medifa, have been exclusively designed for human medicine and

should only be operated by authorized personnel in areas equipped according to the known standards.

Authorized personnel by definition are persons who took part in a training for the correct use of the device

by specially skilled staff.

This training will be documented and confirmed in a respective report.

Only use tables in a perfect condition and maintenanced according to the given schedule!

II. Normal Use

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 3

Attention:

This manual is based on the knowledge and contents of a training for skilled staff.

This manuel cannot replace the absolutely necessary training for the operation and

maintenance of our products!

Service Manual - MAT 504220/ 504225 Operation Table

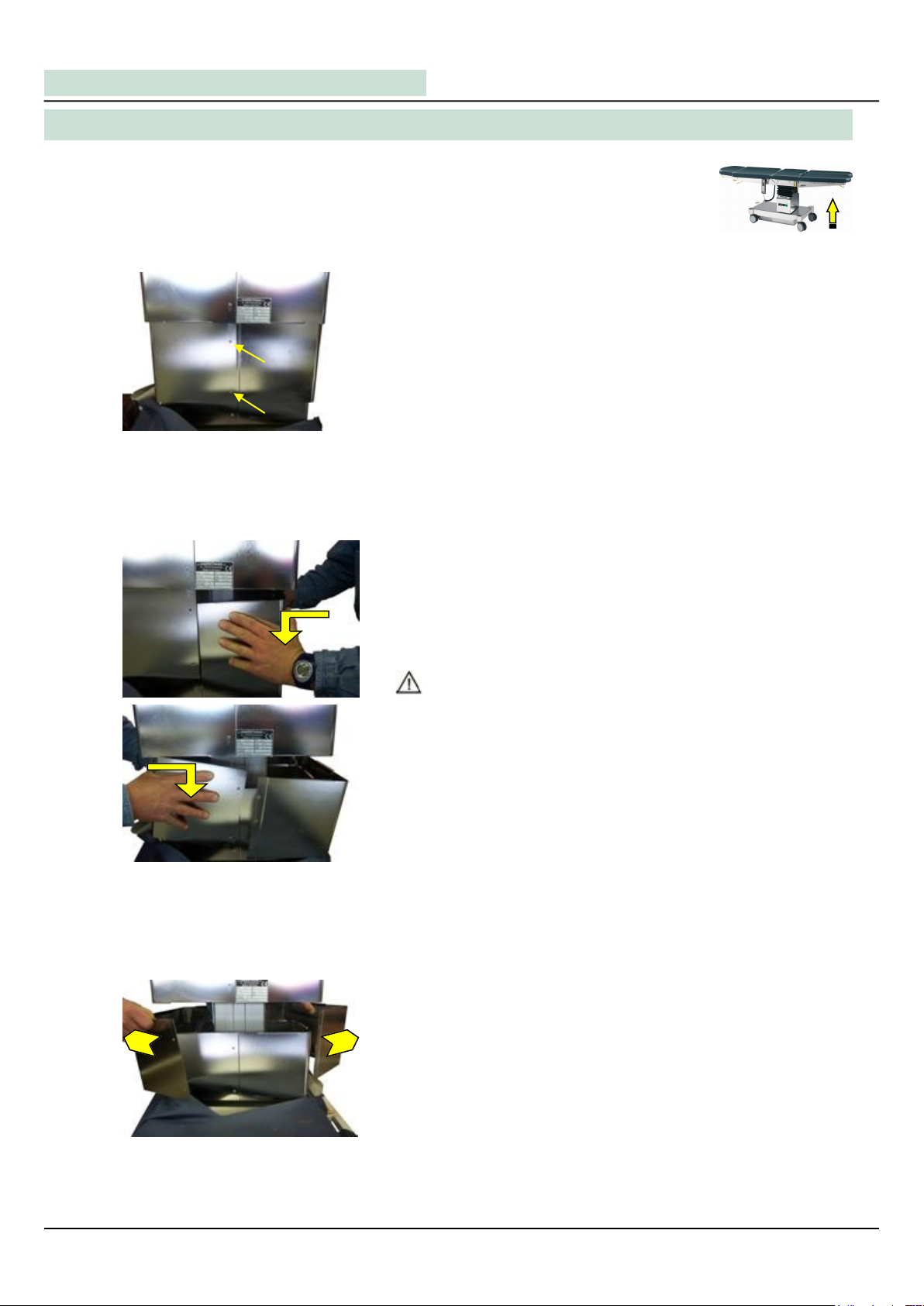

For various repairs the column cover needs to be removed.

Do as follows:

Use the hand switch or the control panel and put the table into the top position.

Remove the supply cable, if necessary. Turn off the table at the base.

III. Exposing and Removing of the Column Cover and Control Panel

4

Loosen the screws on the back of the middle part of the

cover.

When unhooked, the cover can be bend up around the lower

cover and can be dismantled.

fig. 1: open the middle part of the column

fig. 4: dismantle middle part of the co-

lumn

fig. 2+3: unhook the middle part of the

column

After removing both screws, the cover can be unhooked from

the upper cover by pushing it to the inside and pulling it down

at the same time. Repeat this procedure on the other side

and you will be able to completely uncover the middle part.

Attention:

Be careful to prevent the cover from falling down!

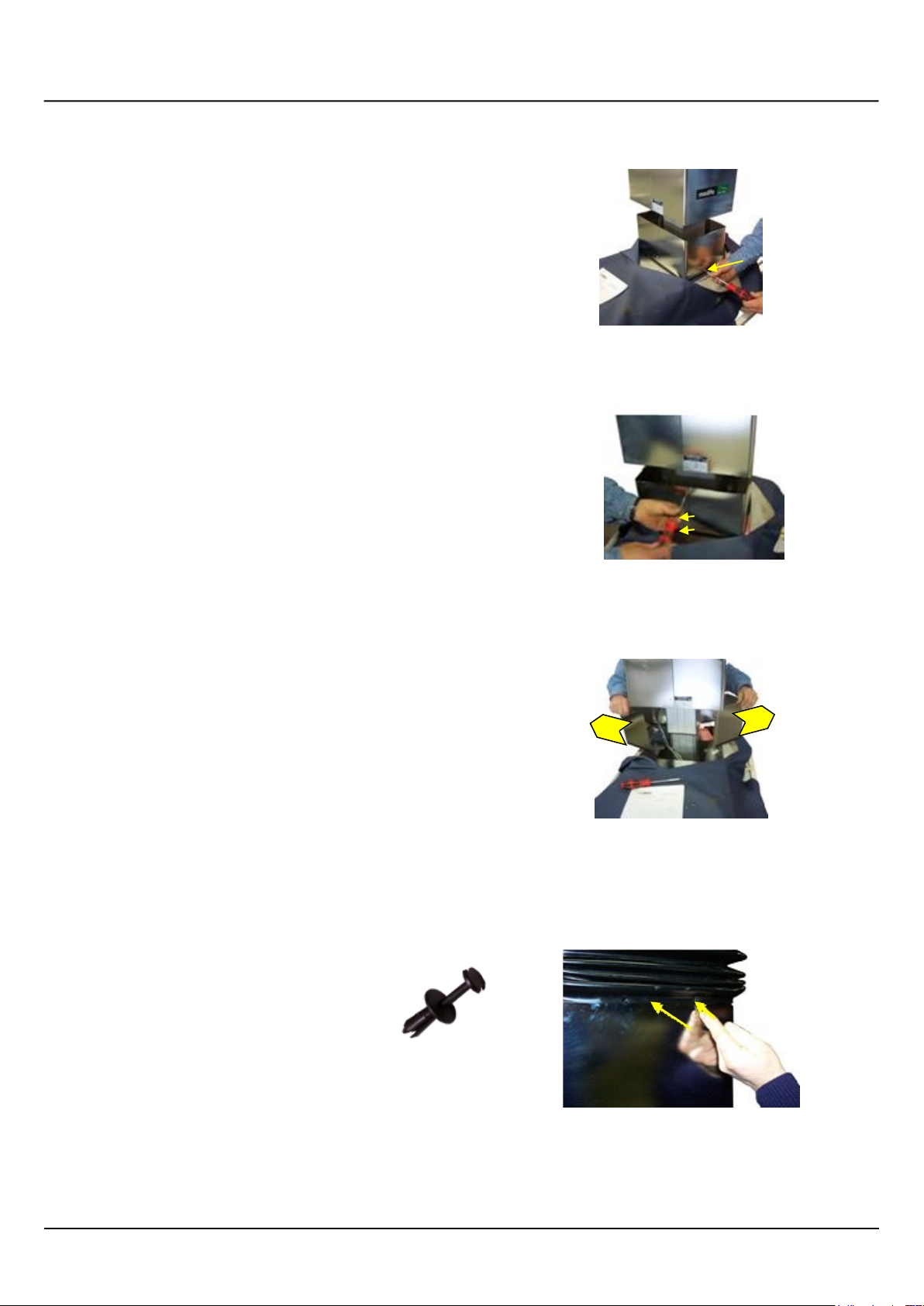

Remove the screws on the left and on the right to dismantle

the lower cover.

fig. 5: dismantle the lower cover

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 5

fig. 6: dismantle the lower cover

Now, loosen the screws in the back.

Dismantle the cover by bending it up around the column.

fig. 7: dismantle the lower cover

fig. 8: loosening expansion bellow

To dismantle the upper cover, the expansion

bellow need to be detached.

Remove all four expanding rivets to dismant-

le the expansion bellow from the upper co-

ver. Use a small slot screw driver or flat

pliers.

Now the expansion bellow can be put over its holders.

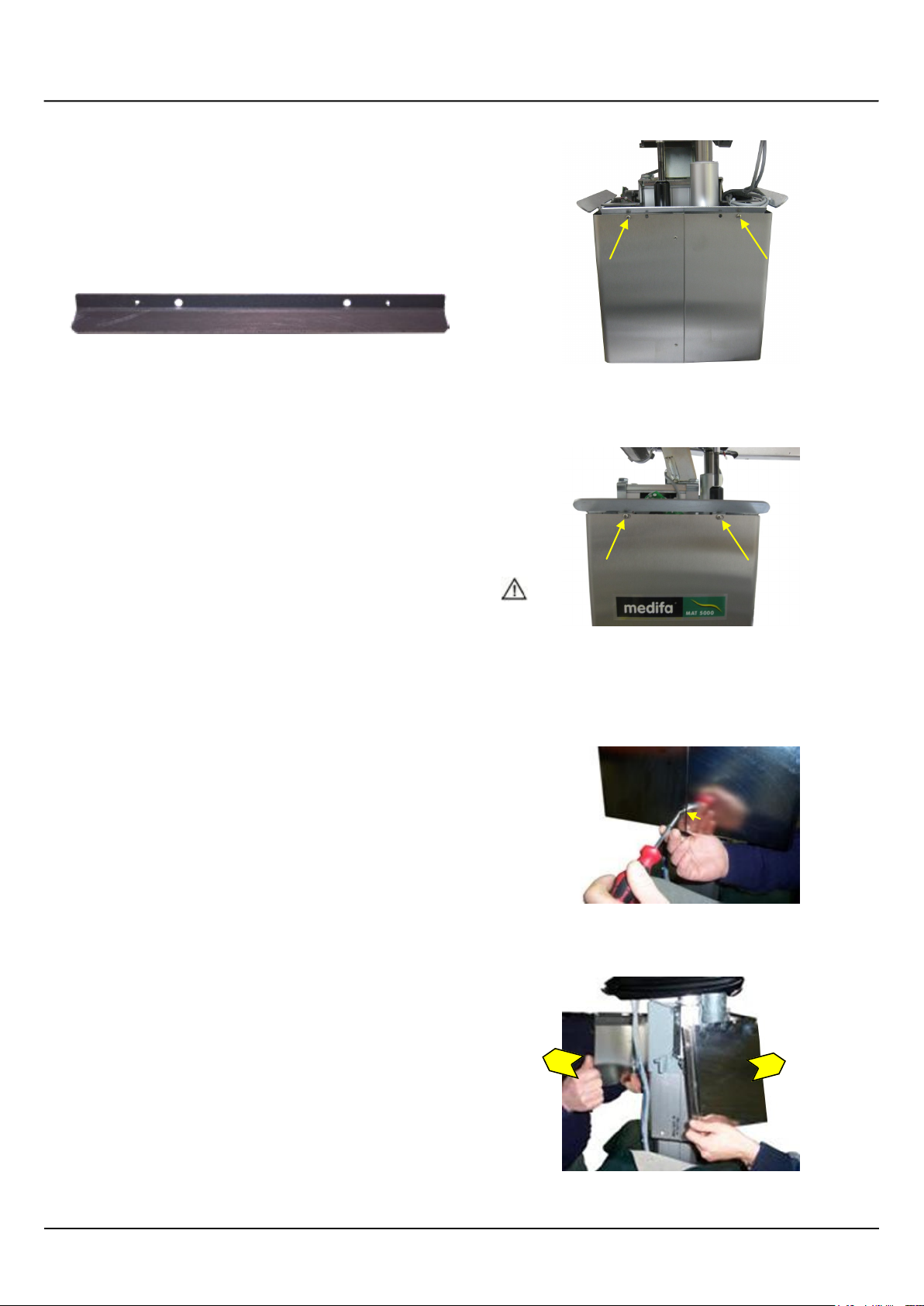

Remove the two screws to dismantle the upper cover.

Service Manual - MAT 504220/ 504225 Operation Table

6

fig. 9: loosening expansion bellow

fig. 11: removing control panel data cable

fig. 10: dismantling control panel

Remove the two screws at the back of the holder, pull of the

data cable from the control panel and pull it through the

notch, to dismantle the control panel from the holder.

The control panel is now dismantled and can be put aside.

fig. 12: control panel loose

To remove the upper cover, loosen the screws on the back.

fig. 16: loosen upper column cover

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 7

fig. 17: loosen upper column cover

Bend the cover around the column, like you did with the

middle and lower covers in order to remove it.

Abb. 13: dismantle holders of expansion

bellow

Now dismantle the two holders of the expansion bellow from

the upper cover. For that, loosen the two screws on the front

and in the back.

fig. 15: loosen upper column cover

fig. 14: holder expansion bellow loose

Now the fastening screws on both sides can be removed as

well. If the holder hasn´t been removed yet, loosen the two

screws as well.

Attention:

Before removing the fastening screws on both sides, a

second person should secure the upper cover to prevent

it from falling down and causing secondary failures!

Service Manual - MAT 504220/ 504225 Operation Table

The upholstery of this operation table is just loosely fitted, to make cleaning and desinfection easy. Dismantle

the upholstery as follows:

To loosen the upholstery of the pelvis plate pull it upwards.

To remount the new upholstery put the notches on the back

onto the respective fixtures. Now push the upholstery against

the upper frame until it snaps in.

Repeat this procedure for mounting the back plate upholstery.

IV. Exchange of the Upholstery (Model 504220)

8

fig. 18: dismantle upholstery

Owing to the sliding table top, the upholsteries of this operation table model are screwed.

This leads to greater stability of the table top.

Dismantle the upholstery as follows:

Take off the upholstery of the pelvis plate by loosen the

fastening screws (4 screws) below the pelvis plate rods.

Now the upholstery can be taken off.

To loosen the upholstery of the back plate pull it upwards.

To remount the new upholstery put the notches on the back

onto the respective fixtures.

Now push the upholstery against the upper frame until it snaps in.

IV. Exchange of the Upholstery (Model 504225)

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 9

fig. 19: dismantle upholstery

fig. 20: dismantle upholstery

As soon as all screws are loosened, the expansion bellow is

supported by the remaining holders.

Service Manual - MAT 504220/ 504225 Operation Table

V. Replacement of the Motor for the Trendelenburg Adjustment

10

fig. 21+22: dismantle expansion bellow

To open up the motor for Trendelenburg adjustment, the

expansion bellow has to be dismantled from the upper cover.

For that, loosen the screws on the front and in the back as

well as in the back of the linkage box.

After that, remove both srews between pelvis plate rod and

linkage box.

This procedure has to be carried out both on the left and on

the right of the table!

Model 504225

To be able to loosen the screws of the expansion bellow, the

table top of the model 504225 (incl. sliding table top ) has to

be moved towards the foot plate. In addition, the back plate

has to be adjusted upwards.

The rear screw can be pulled out, because it is only hooked

in the linkage box.

fig. 24: Expansion bellow loosened

fig. 25: Expansion bellow loosened

The expansion bellow can now be pulled over the remaining

holders and put down on the base.

This is the easiest method for future repair works.

fig. 23: dismantle expansion bellow

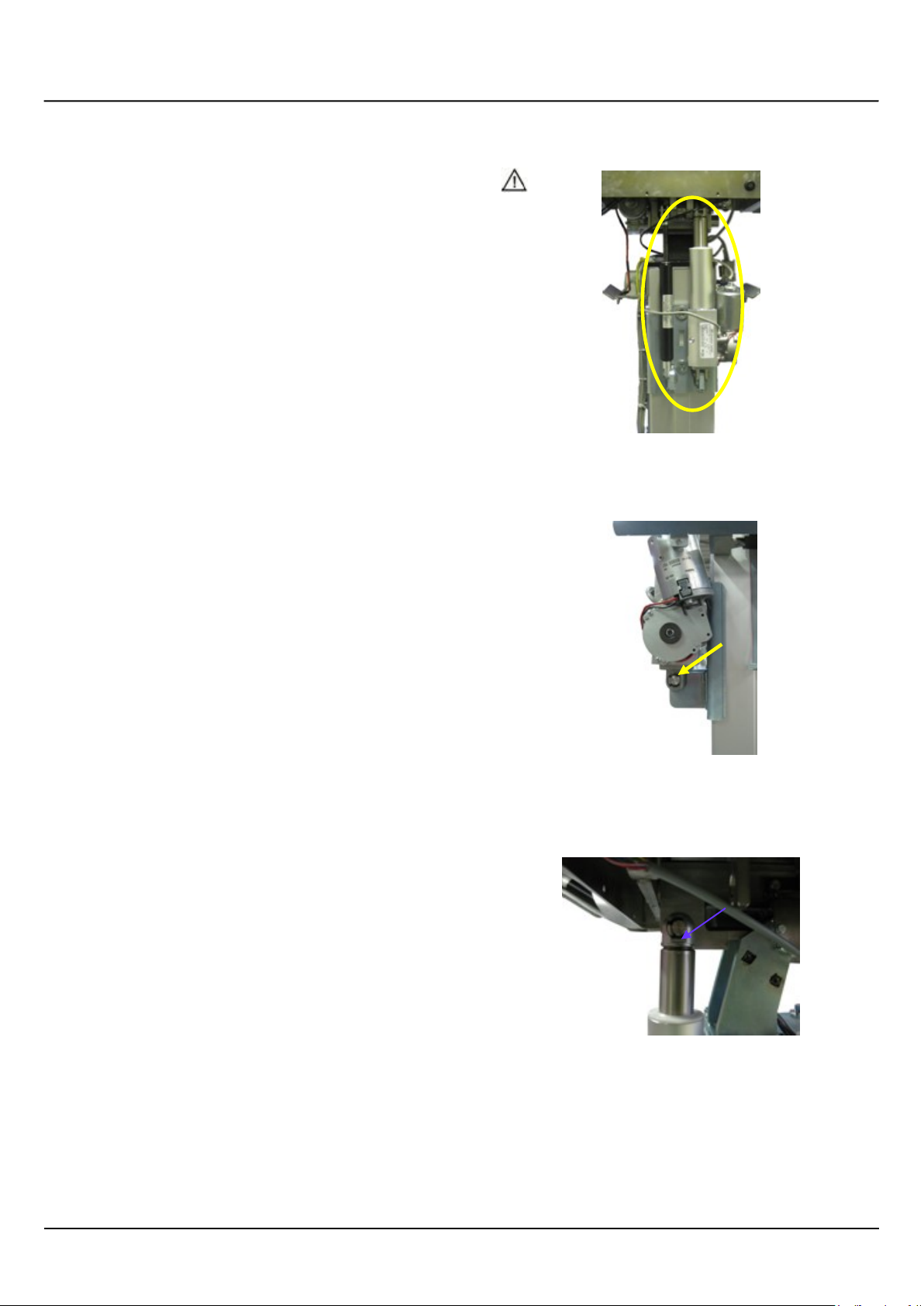

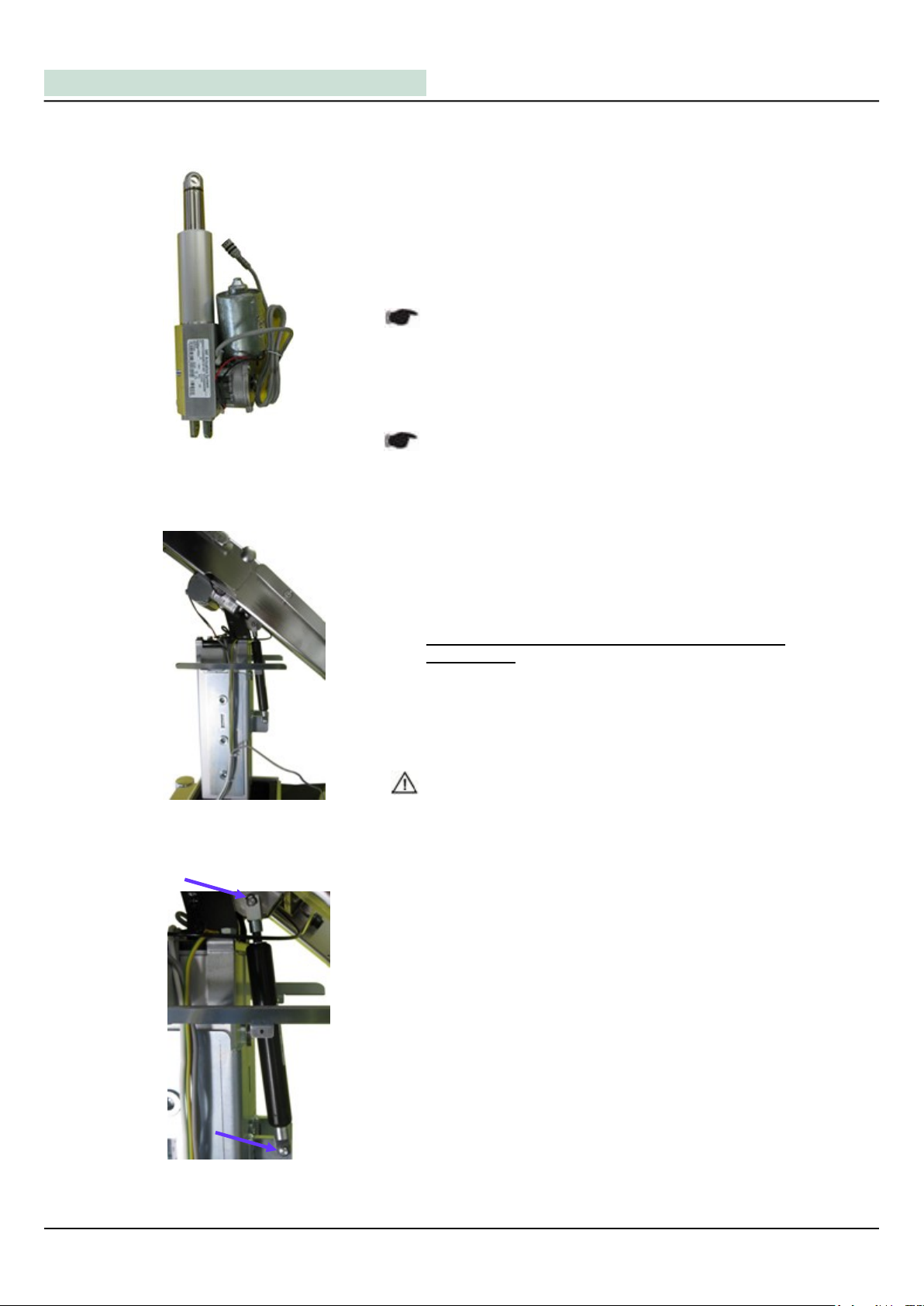

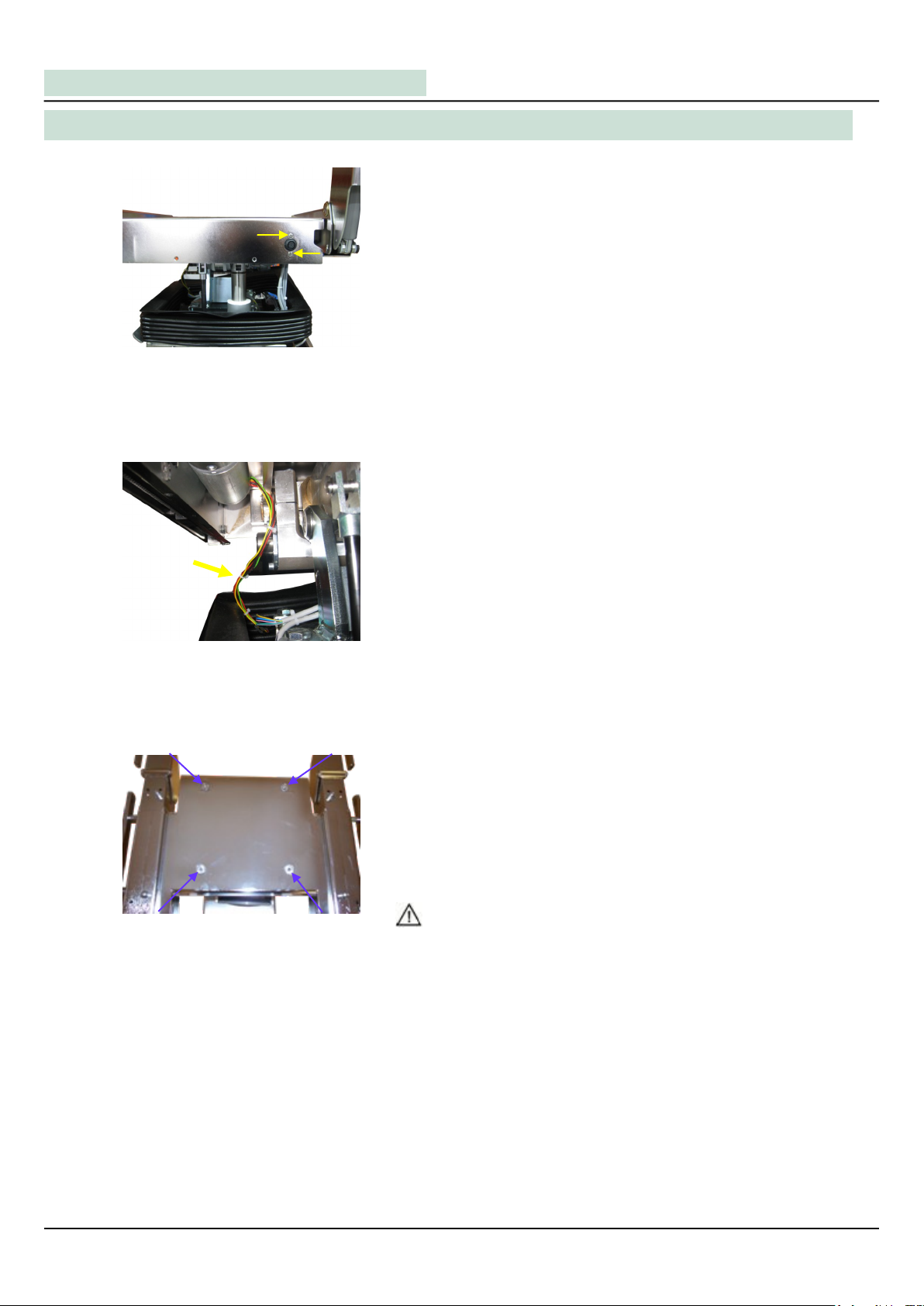

fig. 26: Motor for Trendelenburg

adjustment uncovered

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 11

To remove the motor, pull the locking ring of the bolt. You will

find it on the lower suspension.

Now the motor only hangs on the upper suspension.

fig. 27: Motor for Trendelenburg adjustment

-remove lower suspension

To remove the motor from the upper suspension, remove the

locking ring of the suspension.

Now the motor can be pulled off to the side where the locking

ring has been removed.

Should the motor be stucked on the suspension, a second

person has to lift up the upper frame in the region of the head

plate. Now the suspension can be pushed aside.

Attention:

Before removing the motor for Trendelenburg ad-

justment, a second person should secure the upper co-

ver, because the built-in pull spring next to the motor will

tilt the upper frame into the Trendelenburg position.

fig. 2: Motor for Trendelenburg adjustment

-remove upper suspension

Service Manual - MAT 504220/ 504225 Operation Table

12

After removing the motor from the fixing points, the motor has

to be disconnected from the control.

Trace back the connection cable and remove the plug from

the control box.

Advice:

The right plugs can be looked up in the wiring diagram.

The control can be better achieved through the base plate

front cover. See also chapter „ Dismantling of the control pa-

nel“.

Advice:

To reintegrate the motor, the complete upper frame (table

top) has to be moved, with help of another person, into hori-

zontal position.

Now it is possible to fit the motor into the suspensions.

Dismantling & Replacement of the gas spring for

stabilization

To replace the pull spring (pull spring for stabilization) next to

the motor for Trendelenburg adjustment, the motor for Trend-

elenburg adjustment has to be dismantled first.

After that proceed as follows:

Attention:

During the work on the pull spring, a second person

shpuld secure the entire upper frame, because it is freely

pivoted on the Trendelenburg axis.

Pull the two locking rings (snap ring) on the upper and lower

end of the pull spring off the fastening bolt.

Now the pull spring can be pulled off the bolts!

fig. 29: Motor for Trendelenburg

adjustment dismantled

fig. 30: dismantle pull spring for

stabilization

fig. 31: dismantle pull spring for

stabilization

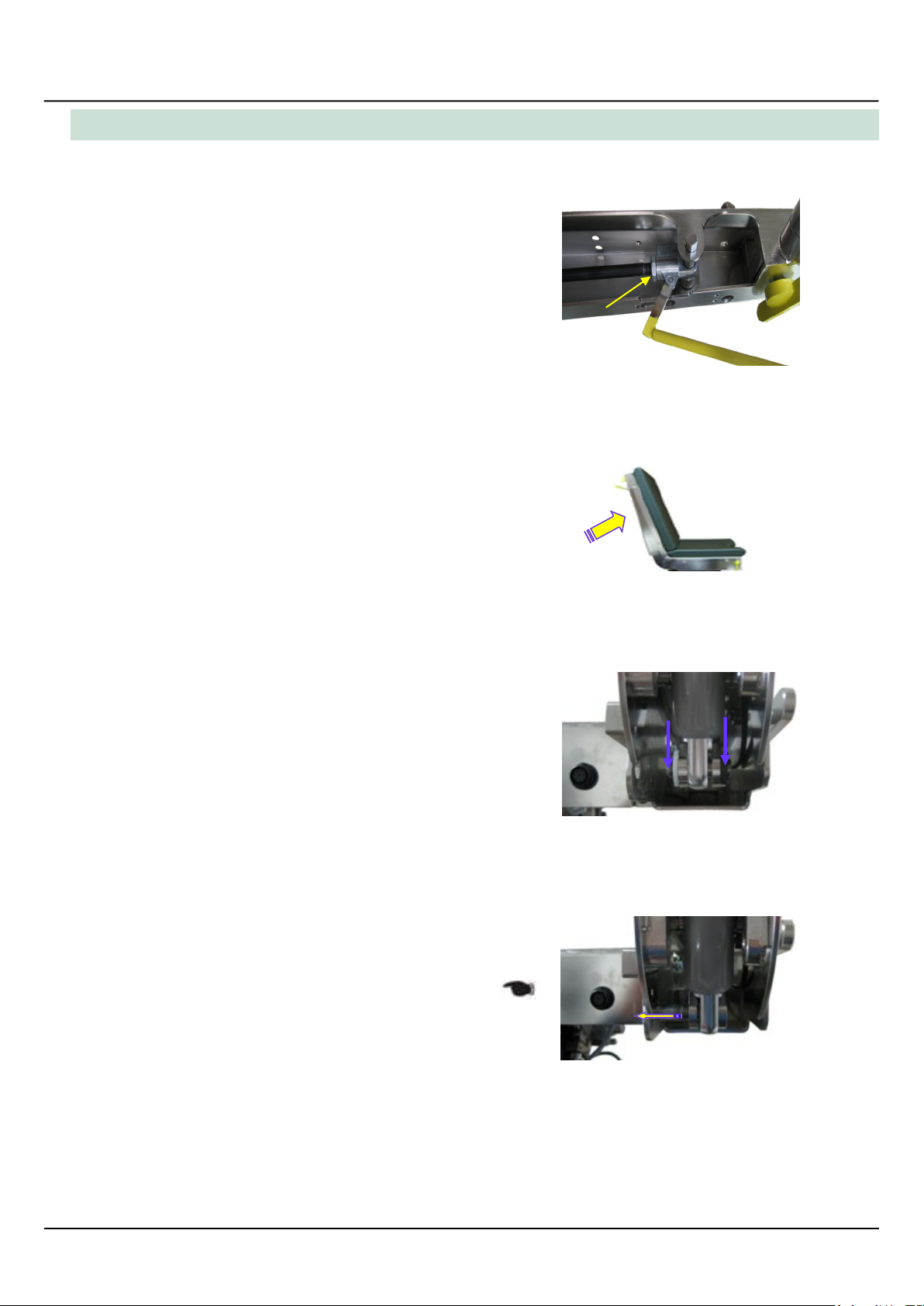

Replace the gas springs for back rest adjustment as follows:

At first, loosen the lock nuts on the upper end (top) of the gas

spring. With that, they can be unscrewed easily from the re-

lease button later.

Prick up the back rest as steep as possible.

Pull the two locking rings (snap rings) on both sides off the

fastening bolt of the gas spring on the lower suspension.

Now remove the bolt to be able to unscrew the gas spring

from the rod.

Advice:

This process should only even be carried out on one side.

Therefore, one gas spring should always be installed

correctly to avoid that the back rest falls down.

VI. Gas Springs for Back Rest Adjustment (Dismantling)

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 13

fig. 33:

dismantle gas spring for back

rest adjustment

fig. 34:

dismantle lower suspension

gas spring for back rest adjustment

fig. 35:

dismantle lower suspension

gas spring for back rest adjustment

fig. 32:

dismantle gas spring for back

rest adjustment

Advice:

Please note the montage advices of the gas springs in the

following chapter.

fig. 36: unscrew gas springs for back

rest adjustment

Service Manual - MAT 504220/ 504225 Operation Table

14

fig. 37: gas spring for back rest adjustment 750N LOOSE

Now the gas spring can be unscrewed from the release

button.

Please note that the new gas spring only should be screwed

in as far as the first resistance.

After that, the spring should be turned back by one turn

again, to provide a certain leeway of the release handle.

As soon as the gas springs are in the right position, fasten

the gas spring with the lock nut on the piston, to exclude an

inadvertent adjustment!

fig. 38: screw in gas springs for back

rest adjustment

fig. 39: adjust release handle for back

rest adjustment

fig. 40+41: fasten gas spring for back rest

adjustment

VI. Gas Springs for Back Rest Adjustment (Montage)

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 15

Service Manual - MAT 504220/ 504225 Operation Table

VI. Gas Springs for Back Rest Adjustment (Release Handle / Button)

16

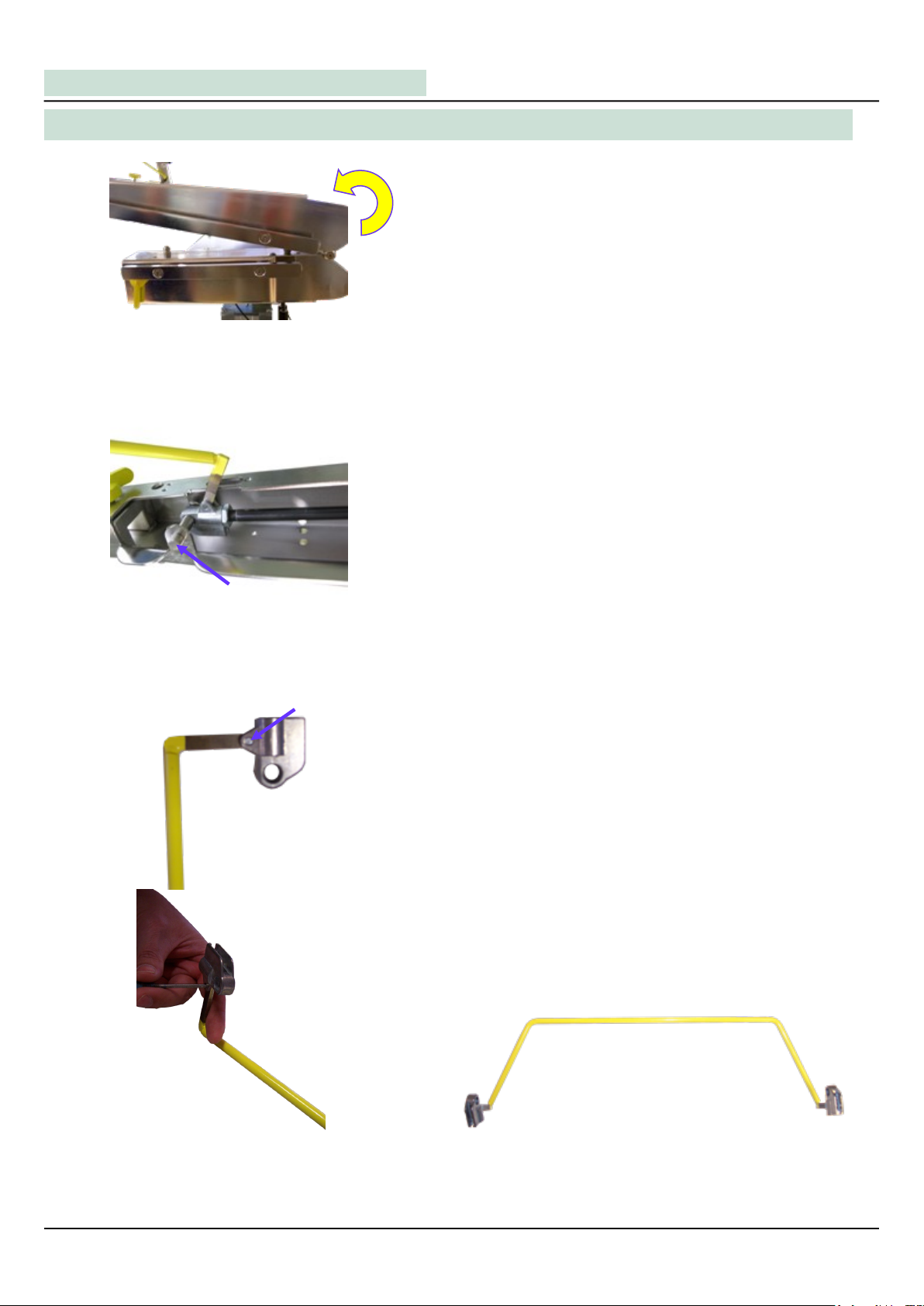

fig. 42: Dismantling release handle back

rest

fig. 44+45: Dismantling release handle/

buttons back rest

fig. 43: adjust release handle of the

back rest

Remove the small fastening bolt with a punch from the inside

of the handle, to loosen the release buttons from the handle.

Please note that the bolt is manufactured conically, by instal-

ling a new handle!

Please proceed in the opposite order to that described for

dismantling, to install a new handle.

Defective release handles or buttons can be replaced as

follows:

Dismantle the gas springs as described before.

Now fold both back plate rods over the pelvis plate to obtain

a better accessibility.

Now the complete handle incl. both release buttons can be

dismantled. For that, loosen both fastening screws on the

end of both back plate rods.

fig. 46: Dismantling release handle back rest

VII. Dismantling of the complete Upper Frame (Model 504220)

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 17

fig. 50: Dismantling upper frame

fig. 48+49: Dismantling upper frame

After removing all 4 screws from the linkage box, the

entire upper frame can be taken off and put aside!

Attention:

Do not touch the release handle of the back plate.

This may lead to dangerous injuries!

fig. 51: Upper frame loose

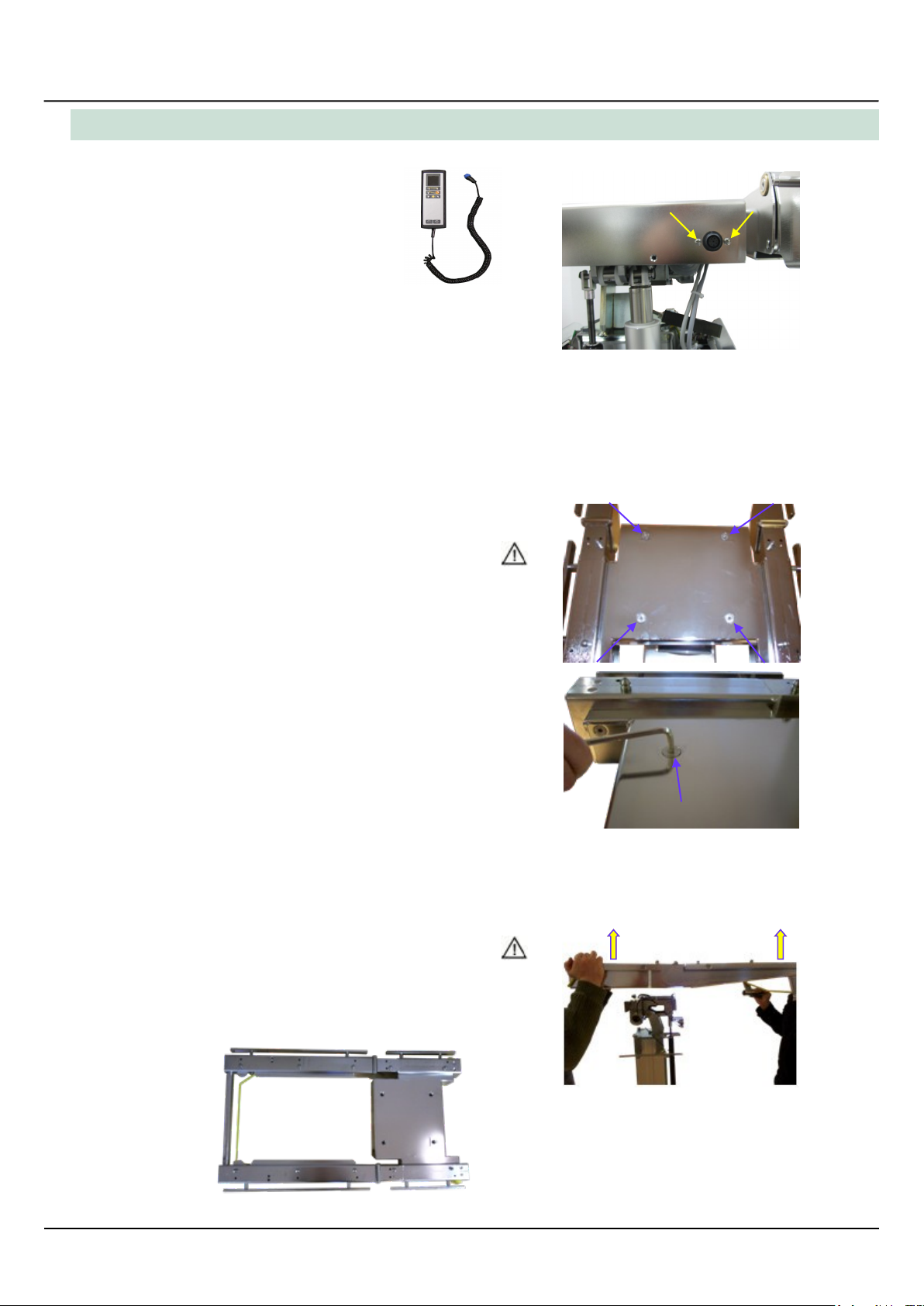

To dismantle the upper frame, remove the co-

ver of the table. Also dismantle the expansion

bellow so that it lies on the base. Now dismant-

le the hand switch. The plug can simply be

unscrewed from the linkage box. Besides, the

plug of the hand switch connector has to be

removed, too.

For that, remove the both srews of the linkage box on both

sides of the plug.

After that, remove the upholstery of the pelvis plate.

In this way the linkage box will be uncovered.

The linkage box incl. rest of the upper frame is fixed on the

table base, by the now visible 4 screws.

Attention:

Before removing the last screws, a second person

should secure the upper frame to prevent it from falling

down!

fig. 47: Dismantling upper frame

Service Manual - MAT 504220/ 504225 Operation Table

VII. Dismantling of the complete Upper Frame (Model 504225)

18

To dismantle the upper frame, remove the cover of the

table. Also dismantle the expansion bellow so that it lies

on the base and dismantle the pelvis plate

upholstery (as described before). Now dismantle the

hand switch. The plug can simply be unscrewed from

the linkage box. Besides, the plug of the hand switch

connector has to be removed, too.

For that, remove the two srews of the linkage box above an

below the plug.

The linkage box incl. rest of the upper frame is fixed on the

table base, by the 4 screws visible above the linkage box.

Before loosing the screws and removing the upper frame

from the table base, the cable of the shifiting engine has to

be disconnected from the control. Retrace the cables to the

control or look it up in the wiring diagram.

fig. 53: Shifting engine

fig. 54: Dismantling upper frame

fig. 52: Plug hand switch connector

Now loosen the 4 screws on the top of the linkage box, which

fix the upper frame on the table base.

Attention:

Before removing the screws, a second person should

secure the upper frame to prevent it from falling down!

medifa

®

medifa-hesse GmbH & Co. KG –Industriestraße 5 –D-57413 Finnentrop, Tel.: +49 (0) 2721-7177-0 –Fax: +49 (0) 2721-7177-77 19

After removing all 4 screws from the linkage box, the

entire upper frame can be taken off and put aside!

Attention:

Do not touch the release handle of the back plate

This may lead to dangerous injuries!

fig. 56: Dismantling upper frame

fig. 57: Upper frame loose

fig. 55: Dismantling upper frame

Service Manual - MAT 504220/ 504225 Operation Table

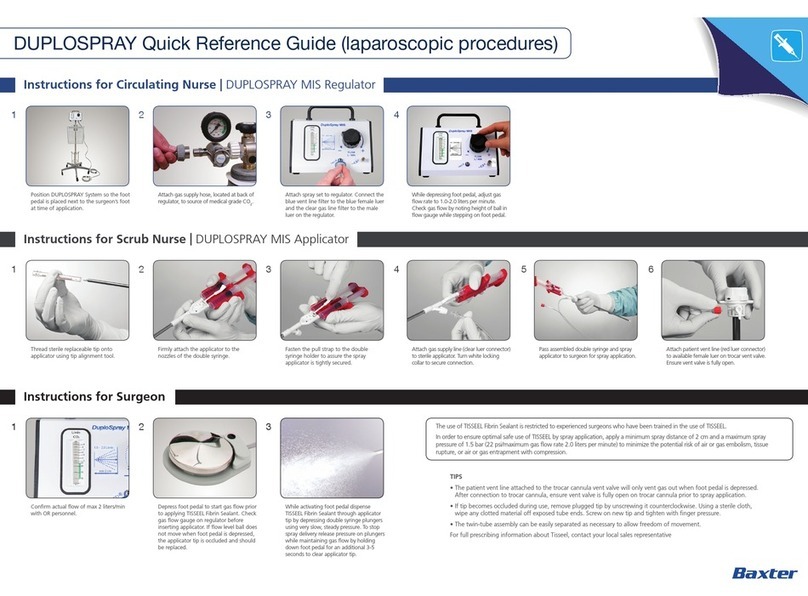

VIII. Replacement of the Distribution Panel

fig. 58+59: Replacement of the

distribution panel

To replace the distribution panel, the expansion bellow has to

be loosen (as described in chapter III of this manual).

When loosen, the inside of the table is visible and both faste-

ning screws have to be removed from the distribution panel.

In case of model 504225 with shifting function, the Sub-D

plug and the cable tie on the top of the distribution panel

have to be removed.

fig. 60: Opening of the distribution panel

After dismantling, the distribution panel has to be opened.

For that, remove the 4 screws on the back of the panel.

fig. 61: Replacement of the distribution

panel.

Advice:

Take care of the connections of the cables by replacing the

distribution panel. Remember the order or have a look in the

wiring diagram.

Now loosen the 4 plugs in the panel, to uncover them

completely.

Please proceed in the opposite order to that described for

dismantling, to install a new distribution panel.

20

This manual suits for next models

1

Table of contents

Other Medifa Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Invacare

Invacare Birdie EVO Series user manual

baxter

baxter DUPLOSPRAY Quick reference manual

CardiAid

CardiAid CT0207RS User Manual and Introduction to the Device

Nonin

Nonin Sensmart H500 Operator's manual

Integra

Integra MAYFIELD Head Clamp A2079 Instructions for use

Storz

Storz VITOM 3D Instructions for use