Medite Meditome M 530 User manual

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

Rotary

Microtome

Meditome M 530

© Copyright: Duplication of this manual by any means for any purpose without written consent of

MEDITE GmbH is prohibited.

Subject to change without prior notice. Errors excepted.

Manual

Page 1of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

Konformitätserklärung

Certificate of Conformity

Attestation de Conformité

Type of instrument: Rotary Microtome

Model: Meditome M 530

Serial No.:

We do hereby certify that the above mentioned product meets the requirements set forth in the CE

Guidelines indicated below including all changes and addendums to date thereto. The above

mentioned product has been controlled by an authorized test center and meets the following

standards and guidelines:

Richtlinie 2006/42/EWG Maschinen

Richtlinie 89/336/EWG EMV

Richtlinie 2006/95/EWG Niederspannung

DIN EN ISO 9001

VDE 701

Burgdorf, 20.05.2007 M. Ott – Managing Director

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 2of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

Manual

Page 3of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

Contents

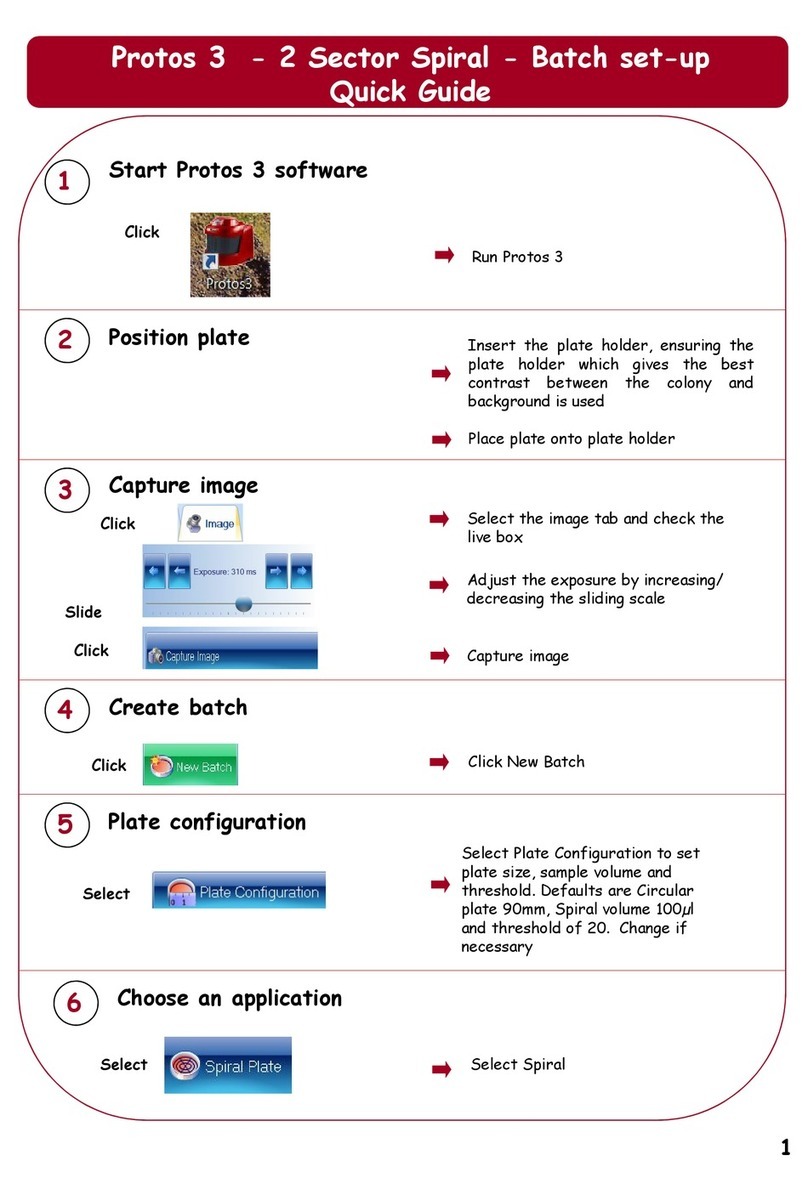

1.Safety ....................................................................................................................................... 5

1.1Introduction ....................................................................................................................5

1.2UsedSymbols .................................................................................................................. 5

1.3IntendedUse................................................................................................................... 5

1.4SourcesOfDanger........................................................................................................... 6

1.5AuthorizedUser/Operator ............................................................................................ 6

1.6SafetyInstructionsOnInstallationSite........................................................................... 7

1.7SafetyEquipment............................................................................................................ 7

1.8CaseOfEmergency ......................................................................................................... 7

2.Transport/Installation............................................................................................................ 8

2.1TechnicalData................................................................................................................. 8

2.2Transport/Storage......................................................................................................... 8

2.3Unpacking........................................................................................................................ 8

2.4SetupAndConnection .................................................................................................... 9

2.5OperatingConditions .................................................................................................... 11

2.6FunctionalComponents ................................................................................................ 11

3.Operation/BeforeOperation ............................................................................................... 12

3.1SwitchingOnTheUnit................................................................................................... 12

3.2CuttingProcessAndHandwheel................................................................................... 12

3.3AdjustmentByOperatorPanel ..................................................................................... 13

3.3.1SectionCounterAndObjectFeedPosition................................................................... 13

3.3.2ObjectFeed‐TrimAndFineMode............................................................................... 14

3.3.3AutomaticRetraction.................................................................................................... 15

3.3.4PositionMemory........................................................................................................... 15

3.4ObjectClamp................................................................................................................. 16

3.4.1UniversalCassetteClamp.............................................................................................. 16

3.4.2ObjectOrientation ........................................................................................................ 17

3.4.3FixingObjectClamps..................................................................................................... 18

3.4.4Re‐AdjustingTheSpecimenClamp ............................................................................... 18

3.5KnifeCarrier .................................................................................................................. 19

3.5.1InsertingTheKnife ........................................................................................................ 19

3.5.2Forward/BackwardAdjustmentOfTheKnifeCarrier................................................. 20

3.5.3AdjustingTheKnifeCarrierAngles ............................................................................... 21

4.RegularCleaningAndMaintenance ...................................................................................... 22

4.1CleaningInstructions..................................................................................................... 22

4.2TimingOfCleaningAndMaintenance .......................................................................... 23

5.Troubleshooting..................................................................................................................... 24

5.1ChangingTheFuses....................................................................................................... 24

5.2Troubleshooting ............................................................................................................ 25

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 4of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

6.Abandonment/Recycling ..................................................................................................... 25

7.Greasing ................................................................................................................................. 25

8.Equipment ............................................................................................................................. 25

Manual

Page 5of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

1. Safety

1.1 Introduction

By purchasing this Meditome, you decided for a quality product of MEDITE GmbH, Germany.

Intention of this manual is to help you working with your unit. Please read it carefully and completely

and follow its advices.

1.2 Used Symbols

This symbol warns you of risks for the life or health of persons. Pay attention!

This symbol warns you of risks for machine, material or environment. Pay

attention!

This symbol stands for areas of information. Pay attention!

1.3 Intended Use

The Meditome is a highly efficient multi-purpose microtome which can be used for any tasks in

paraffin, hard- and thin-sectioning techniques in biology, medicine, industry and research.

A use in food industries and similar facilities is strictly prohibited.

Arbitrary rebuilding or changing of this laboratory instrument is strictly prohibited due to safety

reasons. Use only original MEDITE spare parts in case of replacement issues.

Operation, maintenance or service conditions mentioned in this manual have to be strictly observed.

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 6of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

1.4 Sources Of Danger

RISK OF INJURY

When adjusting the specimen and the knife, the finger protection should be used to decrease the risk

of injury at the blade.

If possible, the specimen should be inserted before the knife is clamped into the knife carrier. Always

remove the knife or the blade when changing the knife carrier.

A knife not being used should always be kept in the knife case!

Never try to catch a dropping knife!

Never check the sharpness of the Meditome knife with your fingers!

The blade is extremely sharp! Be careful with cutting and removing sections!

1.5 Authorized User / Operator

Users working with the Meditome may only be those, who have been instructed by the operator. The

operator is responsible to third persons on the operating site. The operator has to make this

instruction manual available to the users and to make sure, the users have read and understood it.

Manual

Page 7of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

1.6 Safety Instructions On Installation Site

The Meditome M530 has to be installed only on a stable, even and solid basis to be sure, it stands

and works safely. A falling instrument means a big accident risk!

Violation of the technical regulations of use of the Meditome or improper substitution means

exclusion from any warranty for defects!

1.7 Safety Equipment

The Meditome M530 offers a protective bar, which can be flapped up to secure the area of the knife.

The handwheel brake – if activated – keeps the handwheel in its position.

You should always activate these two safety precautions, when the Meditome is not in use.

1.8 Case Of Emergency

In case of injuries due to a cut by the knife, directly start first aid actions and inform your local

medical emergency service! Follow your local first aid regulations for such situations!

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 8of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

2. Transport / Installation

2.1 Technical Data

Meditome M530:

Power supply:

Section thickness:

Section resolution:

Trimming thickness:

Trimming resolution:

Width:

Depth:

Hight:

Weight:

Storage temperature:

Operating conditions:

110…240 VAC / 50…60 Hz

1 - 99 µm

1 µm

5 - 500 µm

5 µm

377 mm

530 mm

281 mm

26 Kg

-20°C up to +50°C

+5°C up to +40°C

2.2 Transport / Storage

The Meditome is delivered in a protection box. Please move it only upright and avoid shocks.

Remove the section waste tray when transporting or lifting the Meditome

because it will get loose during carriage!

It can be removed from the unit by pulling it to the front.

Read 2.4 carefully!

2.3 Unpacking

Put the machine on a flat and stable surface and remove the packing. You should keep the material

for safety in cases of later transports, if possible.

Check the integrity of the delivery.

The standard equipment of the Meditome contains:

1 power cable

1 instruction manual

1 section waste tray

1 dust cover

1 tool kit (allen key)

Manual

Page 9of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

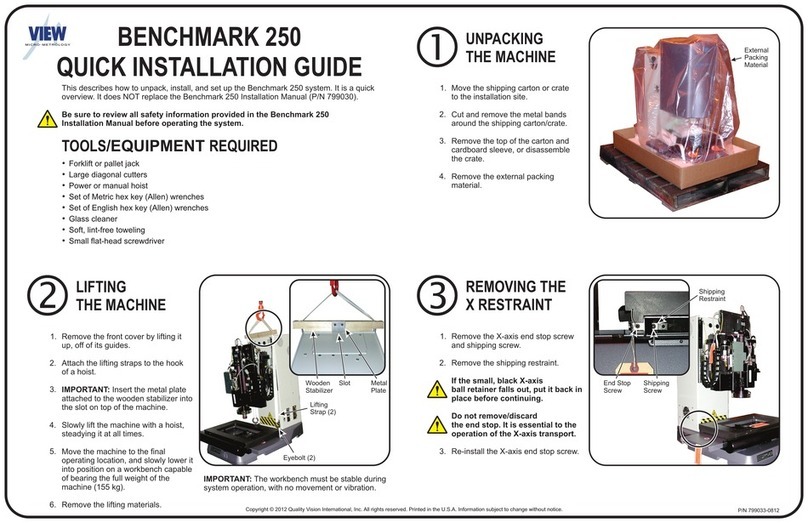

2.4 Setup And Connection

When unpacking, carrying or moving the Meditome use the recessed

handles, which are positioned at the front and at the back

underneath the unit.

- Do never use the object holder or the handwheel as handle for

carrying!

- Do never use the knife holder or the section waste tray as handle

for carrying!

- Remove the knife holder and the section waste tray!

Remove the section waste tray by pulling it to the front and the knife

holder by unlocking it and also pulling it away to the front. (3.5.2)

Carry handles

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 10of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

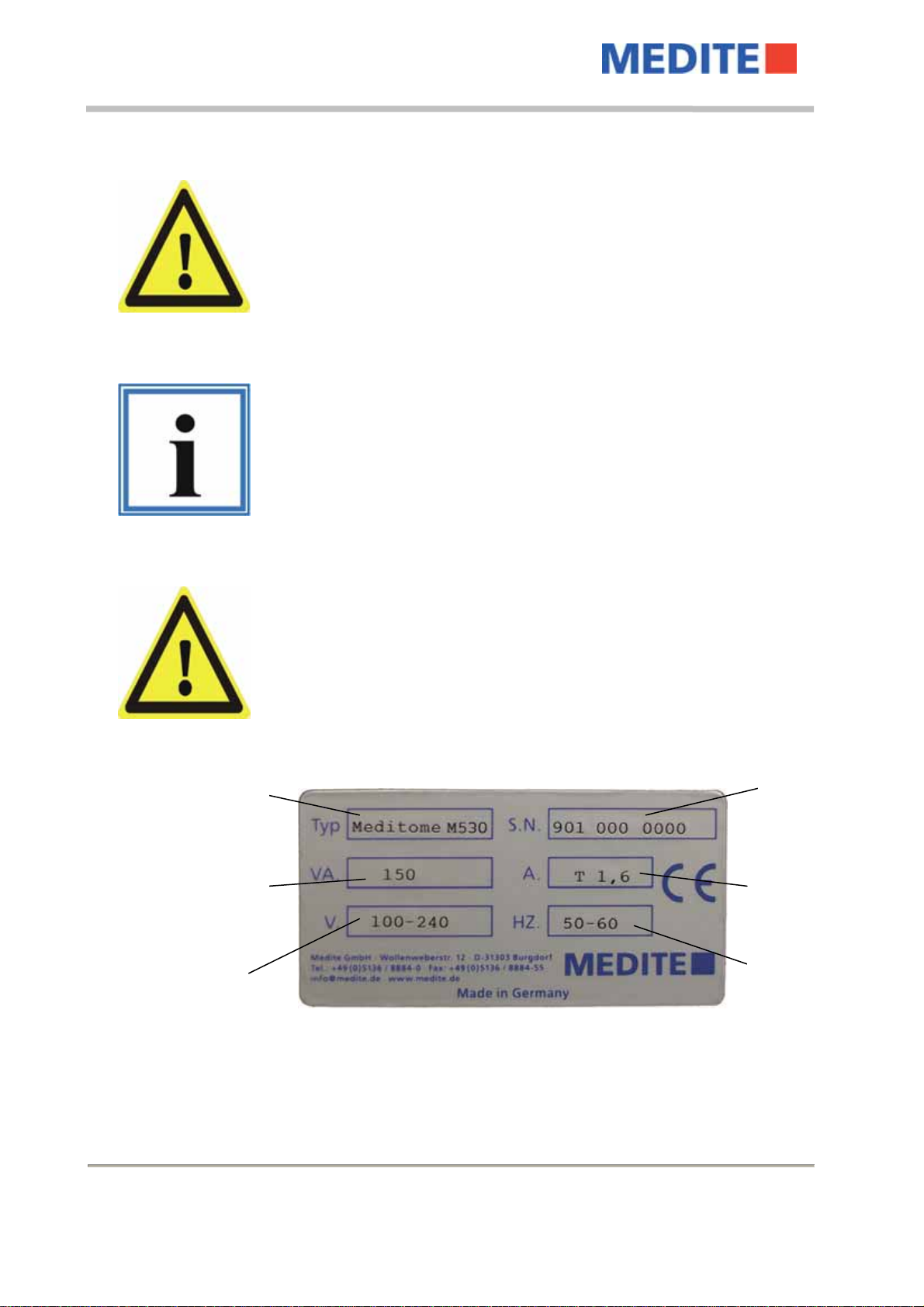

Before initially switching on the Meditome M530, leave the unit on the

designated workspace for at least 2 hours or more, to adjust to room

temperature.

To ensure a faultless function, the microtome has to be placed on a stable

and vibration-free table.

For detailed information ask your local MEDITE sales representative.

Before connecting the instrument to the power supply, make sure the unit

is adequate to your local electrical power line. The unit is delivered “ready

to start”. For the connection to your laboratory power supply use the

supplied power cord and a socket with an intact ground wire.

Do not put or store inflammable things nearby the Meditome.

Serial‐No.

FuseRating

Frequency

TypeofInstrument

Power

Voltage

Manual

Page 11of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

2.5 Operating Conditions

- Operating of the Meditome M530 is only intended within closed premises

- Field temperatures may differ from + 5°C to + 40°C (no big oscillations)

- Max. allowed height over sea: 2000 m (EN 61010-1:2001)

- Vibration free and weight-adequate work ground assumed

- Relative air humidity max. 80%, not condensing for temperatures up to 31°C, Linearly decreasing

to 50% relative humidity at 40°C

- No variations of electrical power supply more than to 10%

2.6 Functional Components

Handwheel

Handwheel

brake

Section waste tray

Specimen

clamping system

Display

Operator panel

Knife carrier

Turn and

push button

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 12of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

3. Operation / Before Operation

3.1 Switching On The Unit

Press the power switch on the back panel of the

unit.

When switching the unit on the specimen clamp

moves to the reference position. This is

repeated every time the unit is switched on so

that a high accuracy of positioning is

guaranteed. As soon as the reference position

is found, the display shows the data and setting

parameter required for operation.

3.2 Cutting Process And Handwheel

The handwheel is integrated in the casing. The position of the handwheel handle corresponds to the

respective vertical position of the specimen.

The cutting stroke of the microtome is produced by turning the handwheel. The section is done by the

downward movement of the specimen which is positioned in the object clamp. Continuing to turn the

wheel results in the upward and return movement of the object. During this return movement the

specimen is retracted to protect the knife and the specimen.

During retraction the display shows the symbol “!” .

If required, the retraction (3.3.3) can be switched off.

It is possible to block the handwheel by using the brake,

so that it cannot be turned any longer.

To lock the wheel the brake lever has to be turned up,

and turned down to loosen it.

RISK OF INJURY

For safety reasons the handwheel always has to be locked during transport or

change of objects.

locked

unlocked

Manual

Page 13of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

3.3 Adjustment By Operator Panel

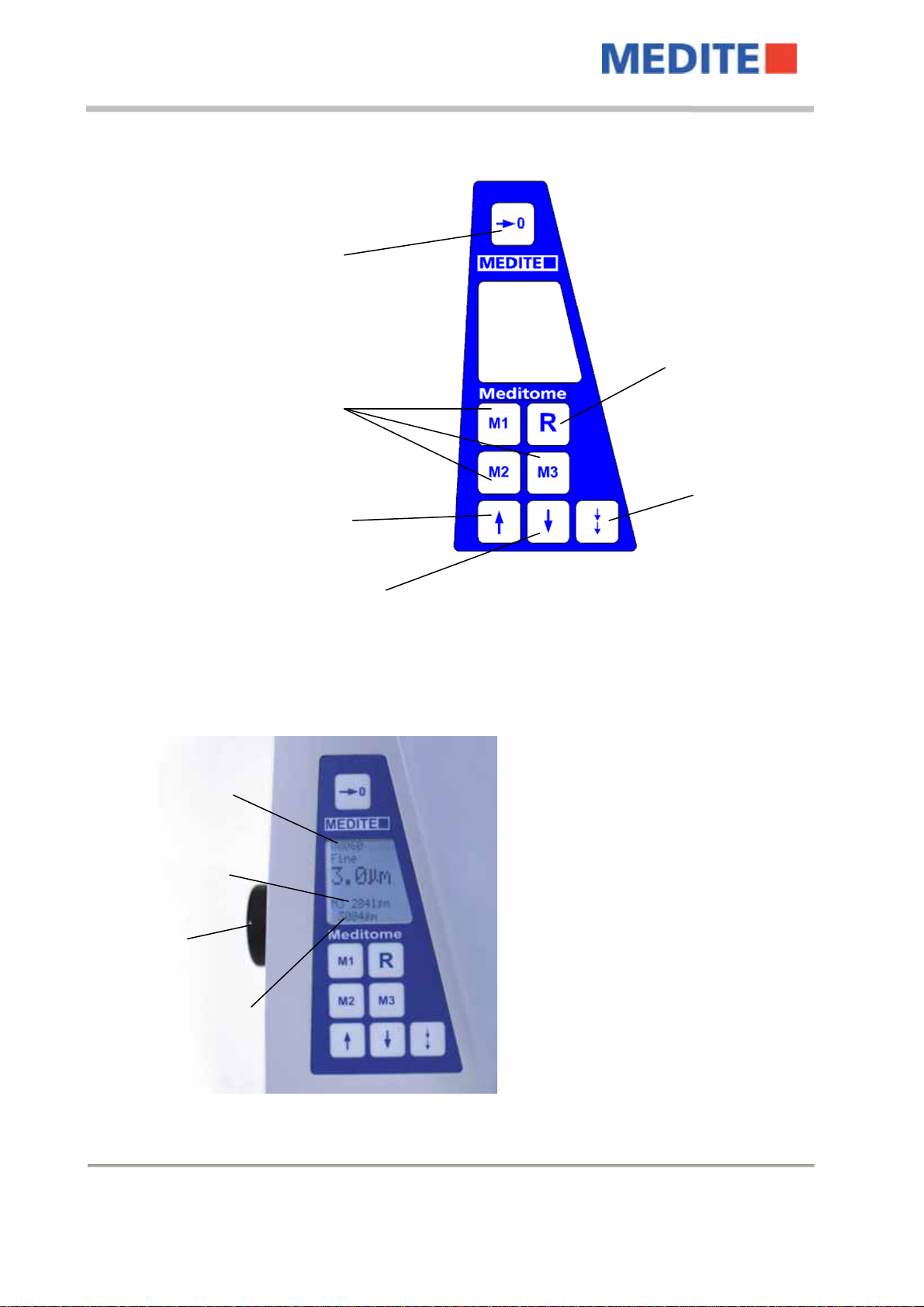

3.3.1 Section Counter And Object Feed Position

The following information is shown on the

Meditome display:

With every cut movement of the object

clamp one step is added on the section

counter.

By pushing the “Reset counter” key above

the display, the counter is set to “0” again.

The value of the section counter is shown

in the first line of the display.

Another indication shows the current

position of the object clamp. (“0” is

completely back, the value counts up when

the feed starts moving towards the knife)

The actual value can be found at the

bottom of the display.

Object feed forward

Object feed backward Trim

Automatic

Retraction

Reset counter

Memory keys for

object feed values

Section

counte

r

Position of

object feed

Memory

values

Turn and

p

ush button

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 14of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

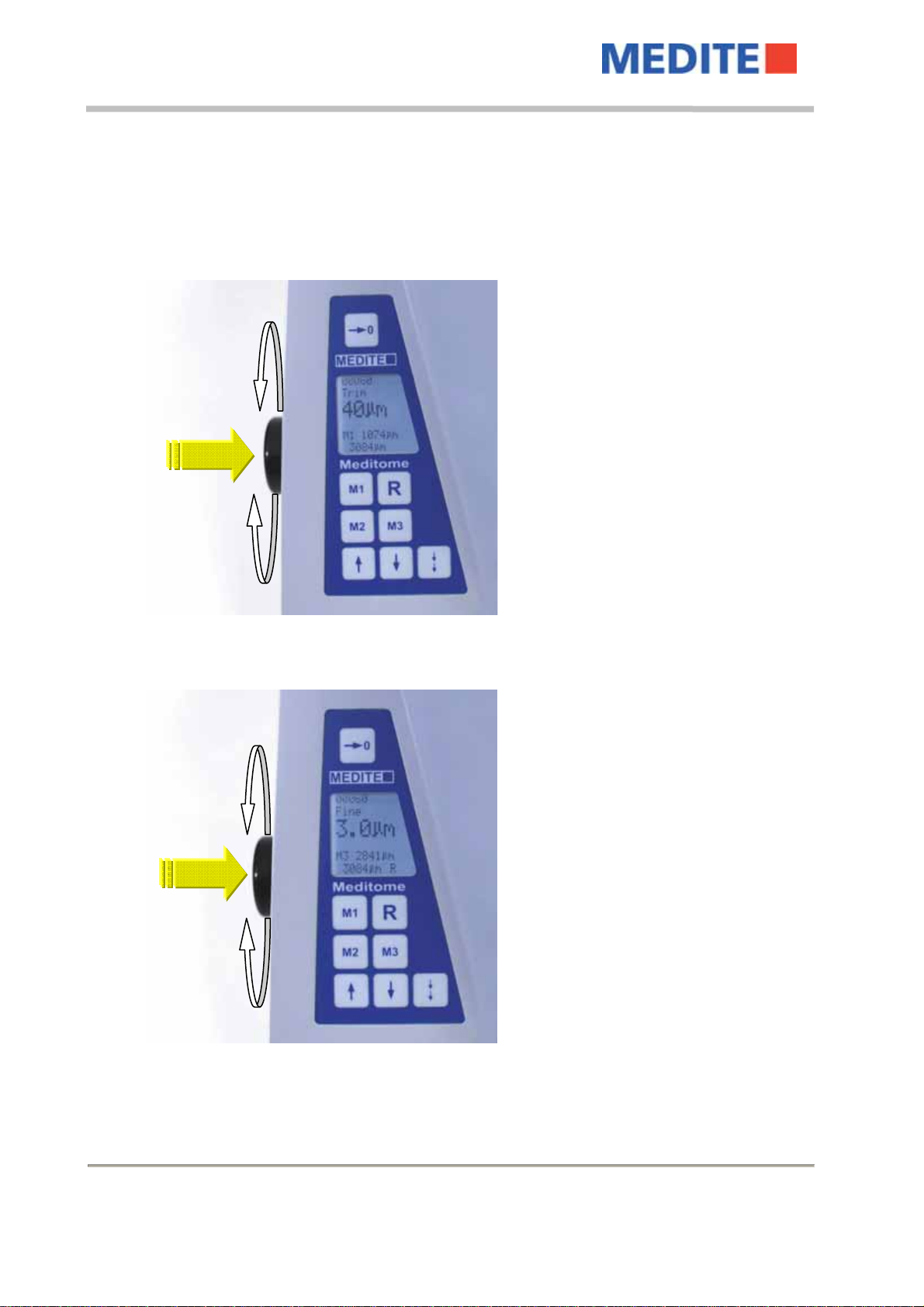

3.3.2 Object Feed - Trim And Fine Mode

To achieve a fast change of the distance between specimen and knife edge, the Meditome offers

a motorized object feed with a “Trim” (coarse) and a “Fine” movement, offering also 3 memory

keys for storing regular used values.

To set your desired “Trim” or “Fine” values

just use the “turn and push” button on the

left side of the Meditome. Push the button

to switch between trim and fine (shown in

the display) and turn it left or right to

change the values.

The left picture shows the “Trim” mode (set

to 40µm).

Also the memory value for “M1” is shown

(1074µm).

(Read 3.3.4 for further information)

The actual value here is “3084”.

In the next picture “Fine” mode for object feed is activated and set to 3µm (shown in the display).

As soon as the key “object feed forward” is

pressed, the specimen is moving towards

the knife. When the key is released the

feed stops.

By tapping on the key „Trim“, one feed with

the value saved in “Trim”, is accomplished.

If the key is held for longer while the

handwheel is turned, one feed with the

value saved in “Trim” is carried out each

cut.

When the key “Trim” is released, the value

seen in the display is active again.

In the picture on the left “Retraction”

function is activated, which is signed by an

“R” at the lower border of the display.

(Read 3.3.3 for further information)

To move the specimen in the object clamp away from the knife the key „object feed backward“

can be used. If the key is held for longer, an acoustic beep confirms an automatic movement of

the object clamp to its reference position. By pressing the key “object feed forward” the

movement is interrupted and stopped.

Manual

Page 15of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

ATTENTION!

The very fast approach of object feed and blade has to be observed

thoroughly to prevent damages at the microtome knife and the

specimen.

3.3.3 Automatic Retraction

To prevent the knife and the specimen from damage when the object clamp is moving up again,

the specimen can be pulled back during upward movement by activating the automatic

“Retraction”.

The “Retraction” can be switched on and off by pressing the “R” key.

If the function is activated there is an “R” appearing in the display.

3.3.4 Position Memory

The Meditome offers the possibility to store 3 values for trimming positions. These values can be

used to recover certain positions within a short time.

A position can be stored by pushing one of the memory keys (M1, M2 or M3) for more than one

second until a signal appears. The value of the actual positioning then is stored in your chosen

memory and can be approached any time later on by just pushing the memory key again.

Occupied memory numbers are shown “M1 … M3” including their values in the display to avoid

an overwriting of your positions.

Of course you can overwrite your values just by proceeding the same way again.

After each restart of the Meditome these values are deleted for safety.

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 16of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

3.4 Object Clamp

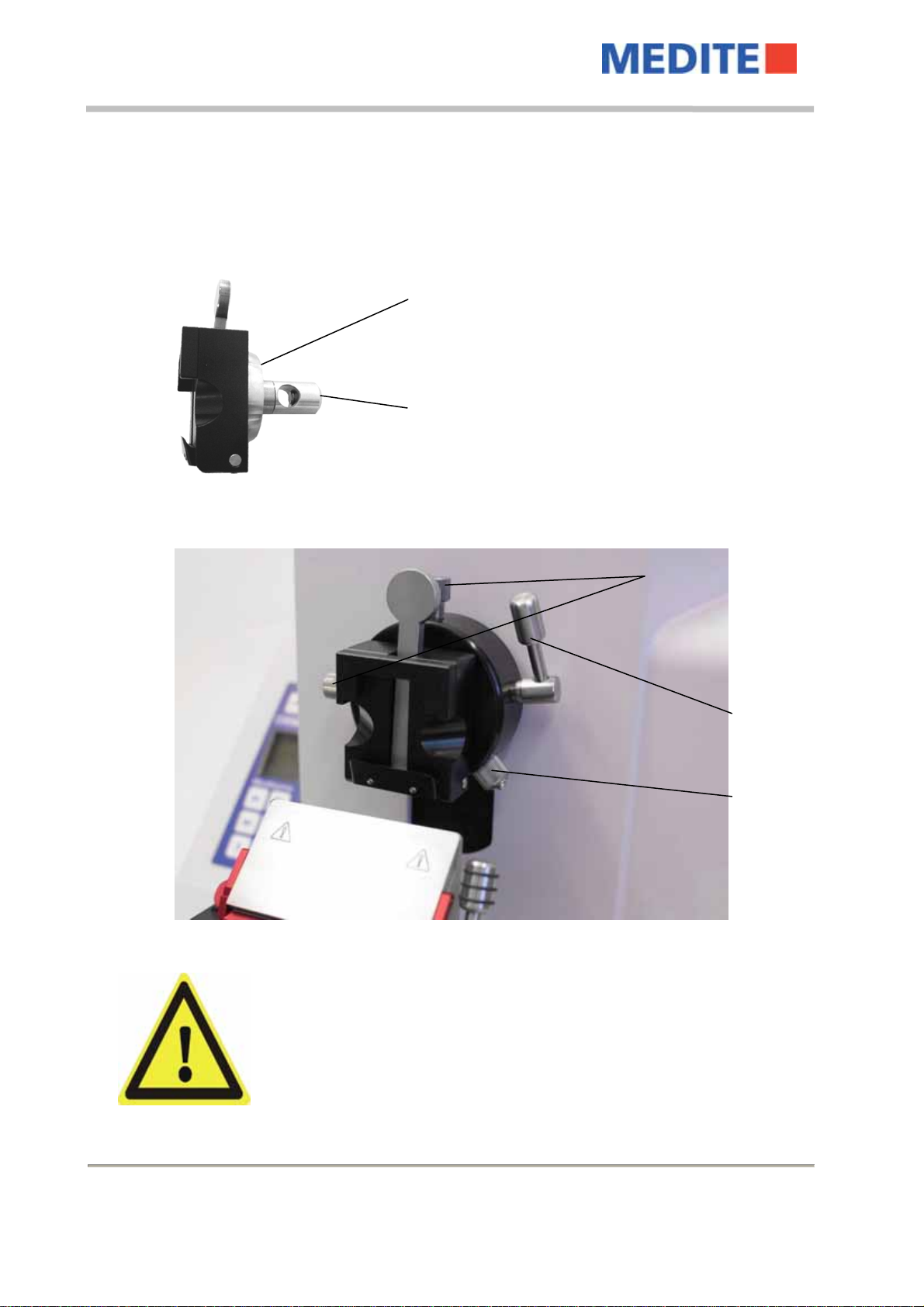

3.4.1 Universal Cassette Clamp

The universal cassette clamp is a quick change system. By pulling the lever (fig. 1, no. 1) to the

front, the cassette can be inserted or removed between the fixed (fig. 1, no. 2) and the movable

(fig. 1, no. 3) jaw.

figure 1

Make sure the contact surfaces of the cassette are free from paraffin to

achieve an optimal clamping.

1

2

3

Manual

Page 17of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

3.4.2 Object Orientation

By the adjustable adaptor (fig. 2, no. 1) at the cassette clamp, which is fixing the object clamps at

the cylinder head, the specimen can be oriented.

figure 2

To adjust the specimen in the desired position, the

clamping lever (fig. 3, no. 2) has to be turned to the

front. Thereby the object clamp is released and can

be turned 360° to find your desired position.

In addition the object clamp can be adjusted by 8°

in each direction (left/right and up/down) by using

the two adjusting screws (fig. 3, no. 1).

When the adjustments are done the clamping lever

(fig. 3, no. 2) has to be pushed back up, so that the

adjusted orientation of the specimen is fixed.

Note: To facilitate the orientation of the specimen,

the clamping lever (fig. 3, no. 2) may be pushed up

slightly. The slight fixing prevents undesired

movements of the clamp during adjustments.

figure 3

To keep the adjusting screws under constant tension, the spring bolt

(fig. 3, no. 3) always has to be tightened.

1

3

2

1

2

Manual

Rev.02(2010‐05‐06)Manual_M530_Rev02.doc Page 18of26

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

3.4.3 Fixing Object Clamps

A specimen clamp is exchanged by turning the eccentric lever (fig. 3, no. 2) down and pulling it

out to the side. In addition the two adjusting screws (fig. 3, no. 1) and the spring bolt (fig. 3, no. 3)

have to be unscrewed a little, so that the specimen clamp can be pulled out to the front and be

exchanged with another one.

When inserting a specimen clamp into the cylinder head the clamping lever has to fit all the way

through the hole of the adapter from the right side. After pushing it in, the spring bolt (fig. 3, no. 3)

has to be tightened and by using the adjusting screws (fig. 3, no. 1), the specimen clamp can be

oriented. At the end the clamping lever (fig. 3, no. 2) has to be pushed back up to fix the

adjustment.

3.4.4 Re-Adjusting The Specimen Clamp

After frequent use the clamping lever might lose its adjustment, so that an optimal clamping of the

specimen clamp is not possible any longer. If there are no re-adjustments done, the clamping

might not work at all anymore after a while.

To achieve an optimal clamping, the locked clamping lever (fig. 3, no. 2) should be in an almost

upright position. The clamping position of the lever can be readjusted by turning the inner screw

on the back side of the orienting adapter (fig. 2, no. 2) with the help of an Allen key (size 3 mm). If

there is no clamping at all or the clamping position of the lever is too high, the Allen key has to be

turned in a clockwise direction. Consequently, it has to be turned counter-clockwise if the

clamping position of the lever is too low.

After the adjustment the specimen clamp can be inserted and the clamping position has to be

checked. If necessary, the correction can be repeated once more in the same way.

To decrease the risk of injury, the clamping plate is equipped with a

bracket (fig.8, no.2 or fig.7, no.3). It has to be turned up over the cutting

edge during any adjustments at the knife or the specimen. Even better is,

to take out the blade before doing any adjustment work.

Manual

Page 19of26Rev.02(2010‐05‐06)Manual_M530_Rev02.doc

Medite GmbH . Wollenweberstr. 12 . D-31303 Burgdorf/Germany

Tel. +49 (0) 51 36/88 84-0 . Fax +49 (0) 51 36/88 84-55 .info@medite.de .www.medite.de

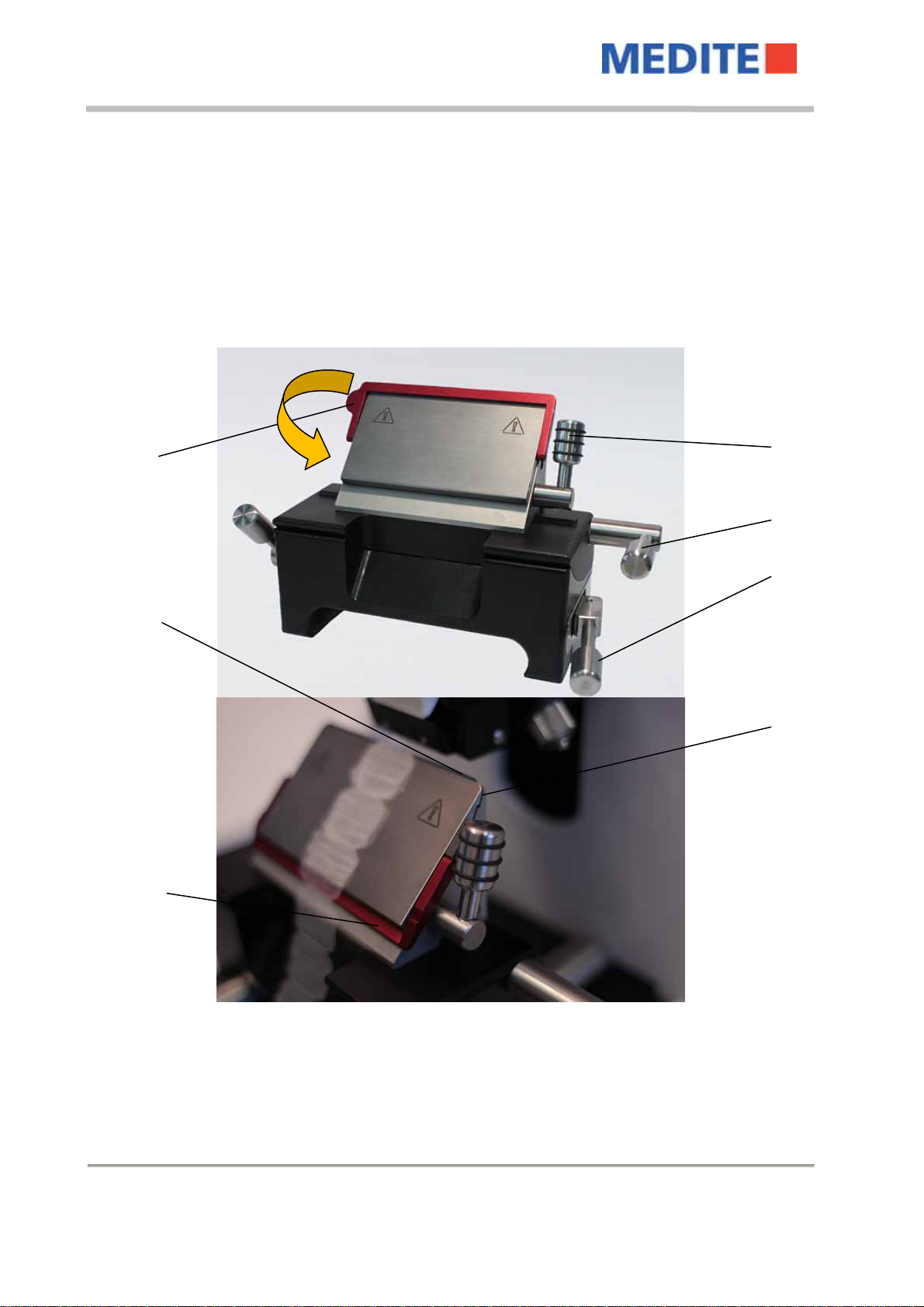

3.5 Knife Carrier

3.5.1 Inserting The Knife

The disposable blade carrier can be used for commercially available low profile blades.

For inserting a blade, the clamping lever (fig. 4, no. 4) and the finger protection (fig. 4, no. 1) have

to be turned to the front. This opens a gap (fig. 4, no. 2) between the rail and the clamping plate

in which the disposable blade (fig. 4, no. 6) can be pushed from the side to the middle. After the

insertion the clamping lever can be turned back, so that the blade is fixed.

figure 4

If the clamping lever (fig. 4, no. 3) is released and the bracket (fig. 4, no. 1) is turned up, the

blade and the clamping plate can be moved together to the left or to the right. Thereby the whole

cutting length of the blade can be used. At the end of any adjustments the clamping levers have

to be fastened again!

1

2

3

4

5

1

6

Table of contents

Other Medite Laboratory Equipment manuals