OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 3

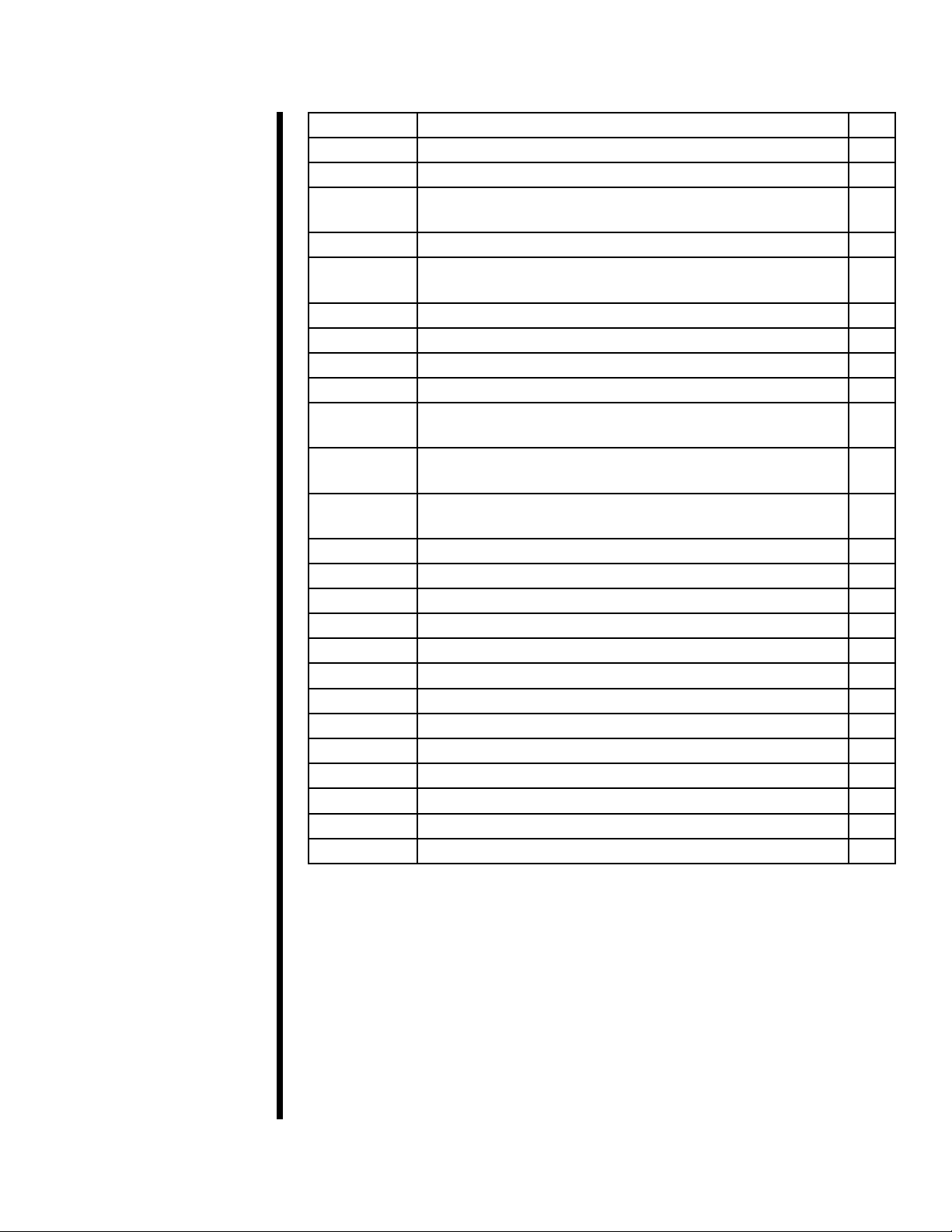

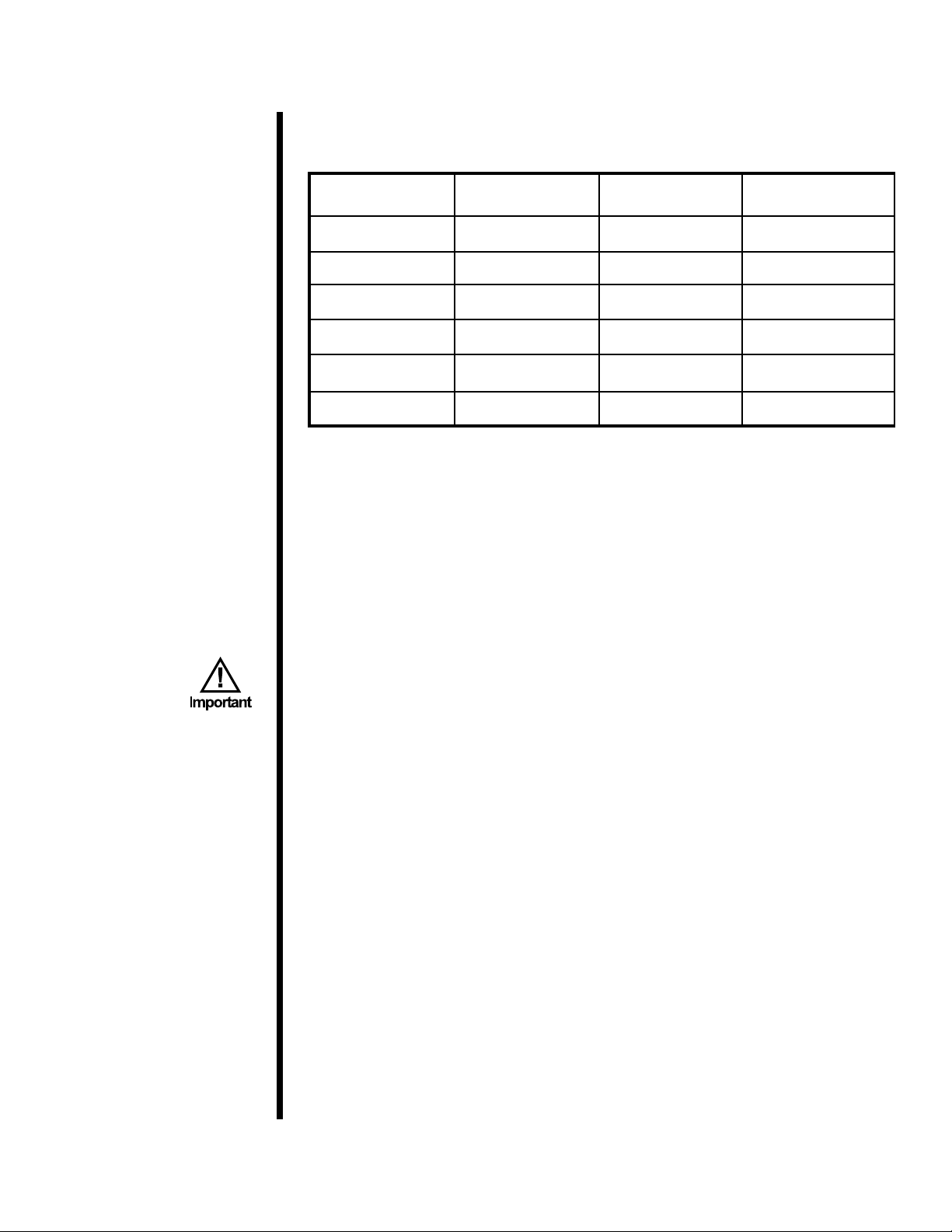

Components #142-58 O-ring for HTHP Coupling

#143-00 Regulator

#143-02-10 CO2 Puncture Head Assembly

#143-02-13 O-ring for Puncture Pin Holder Assembly, CO2Cartridge

#143-02-14 O-ring for Puncture Pin Holder Assembly

#143-03 Barrel for CO2Cartridge

#145-601 Hydrogen Sulde Test Papers, Package of 100

#151-01 Dispersion Tube

#151-02 Dräger Tube, Hydrogen Sulde 100/1, Range: 100 - 2,000 PPM

(Low Range)

#151-03 Dräger Tube, Hydrogen Sulde 0.2%/A, Range: 0.2 - 7% by Vol-

ume (High Range)

#151-04 Dräger Tube, Carbon Dioxide 0.01%/A, Range: 0.01 - 0.3% by

Volume

#151-06 Gas Bag

#151-07 Stopcock

#151-08 API Flow Meter Tube

#151-09 Dräger Hand Pump

#151-10 O-ring for Dräger Pump

#151-11 O-ring for Flow Meter Tube

#151-12 O-ring for 2nd and 3rd Chambers

#151-13 O-ring for 1st Chamber

#151-14 Rubber Hose, ¼" OD × " ID, 1' Length

#151-14-1 Nylon Tube, 3" Length

#151-16 Rubber Septum, Qty: 2

#151-17 Octyl Alcohol (Defoamer), 2 oz.

#151-53 Carrying Case

#153-34 Glass Pipet, 1 mL × mL

#153-40 Glass Pipet, 10 mL × mL

#153-63 10 cc Disposable Syringe with Needle

#230-15 *Sulfuric Acid, 5 N, 2 oz., (UN #2796)

Optional:

#153-53-9 Magnetic Stirrer, 1,500 RPM, 115 Barnant (for oil-mud analysis)

#151-20 Kit for Determining Active Suldes in Oil-Based Fluids:

#151-17 Octyl Alcohol Defoamer, 2 oz.

#151-20-1 *Citric Acid, 2M, Demulsier, IPA Solution, UN #1219, 16 oz

#151-20-2 Sample Injection Needle

#153-29 Glass-Tip Syringe, 2 CC

#153-29-1 Glass-Tip Syringe, 5 CC

#153-29-2 Glass-Tip Syringe, 10 CC

#153-66 Disposable Syringe, 20CC