MEFE—Mitchell Engineering Food Equipment Pty Ltd

23 Storie Street Clontarf QLD 4019 Australia

www.mefe.com.au | info@mefe.com.au

Page 5

+617 3283 4536

Free AU 1800 669 006

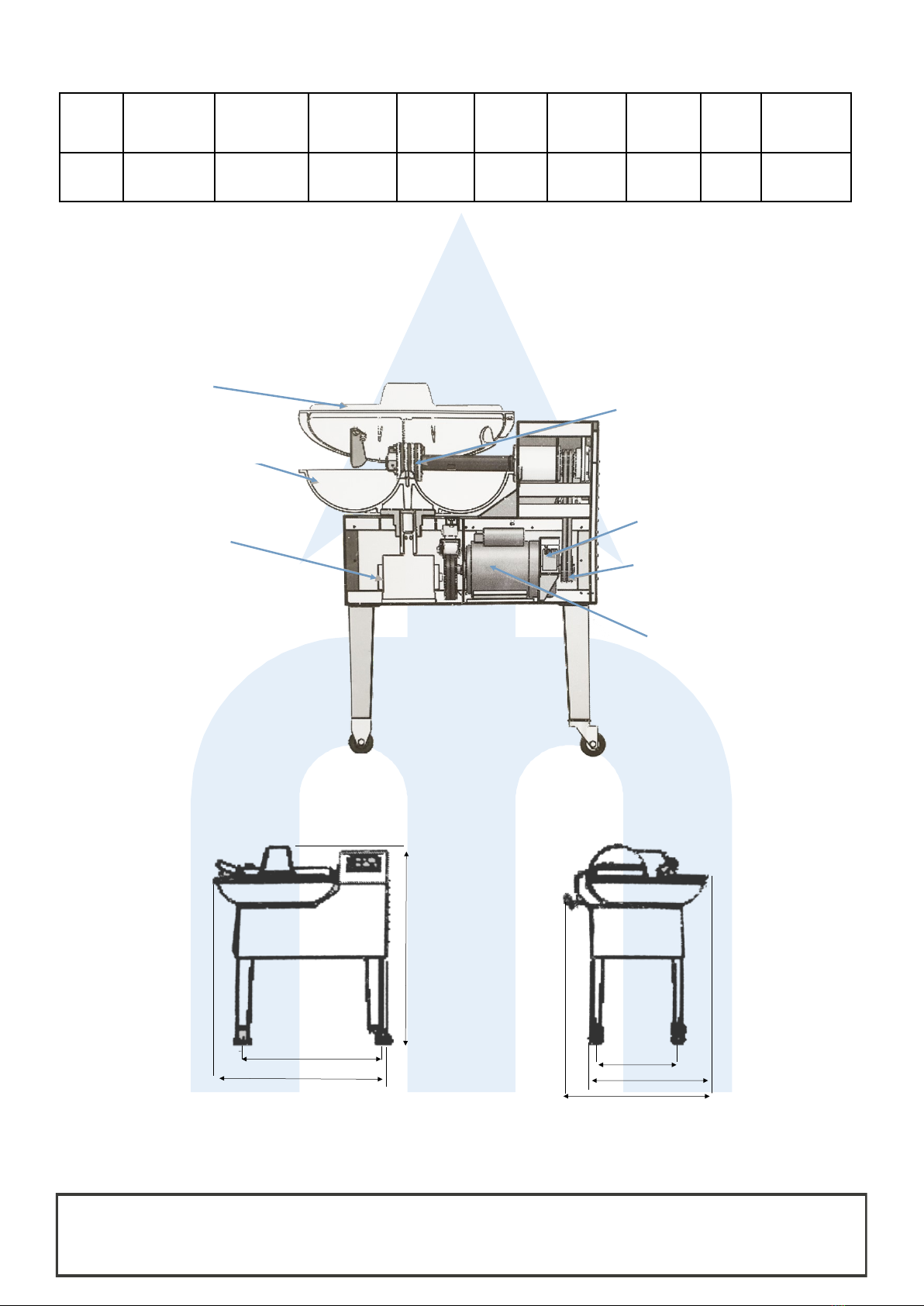

1. Product Descripon

The 24L table top bowl cuer is a high performance bowl cuer mainly used for food processing elds, such as processing

dierent kinds of roots, stems, leaves and vegetables into pastes speedily and eecvely, emulsifying meat, fat and ingrediets.

It is the perfect machine for processing food material which needs to be cut, mixed and homogenised.

In order to use the machine eecvely, we provide this manual with specicaons, operaon procedures and instrucons.

This manual should be submied to the qualied operators to help them get familiar with the operaon and maintenance of

the machine.

1.1 Features

• Polished Stainless Steel and high-speed sharp rotang blades.

• Simple operaon and easy maintenance.

• Streamline appearance and fully enclosed box type body.

• Safely and securely bolt lid in place.

• Good cung eciency, slight temperature liing and short cung me.

• On-and-o switch has good waterproof properes, reliability, long service life, low noise and simple operaon.

1.2 Safety

Do not remove any components from this machine.

Do not immerse in water.

Do not place hands in the cung bowl.

Machine must used in accordance with these instrucons and only by persons competent to do so.

Machine is Equipped with an Emergency Stop buon. . To be tested.

Posion on a at, stable surface. This mobile unit can easily be moved anywhere. And must be stable before use

Always switch o and disconnect power supply to the appliance when not in use.

Regularly check the screws xing the blades to the cung discs and ghten as necessary.

If power cord is damaged, it must be replaced by a qualied electrician to avoid hazard.

Keep all packaging away from children and dispose of in accordance with the local regulaons and guides.

The machine parts that come directly into contact with food are made of material strictly in accordance with the requests of

food safety and health standards, which means no rust or corrosion, ensuring it remains non-toxic and harmless to human

health even aer using for a long me.

Before usage always check machine is clean and free of any residue from past use.

2. Install and Operaon

Before the rst operaon follow these steps:

1. Carefully unwrap the package and read the instrucon manual.

2. Inspect each component: conrm that the fasteners have not come loose in transit, switch or power cord damaged due

to transport, and that the power supply voltage and exisng product voltage match.

3. Check whether there is a foreign item inside the dish basin, if so clean up in me to avoid external impuries or dam-

age of cung tools and other machine parts.

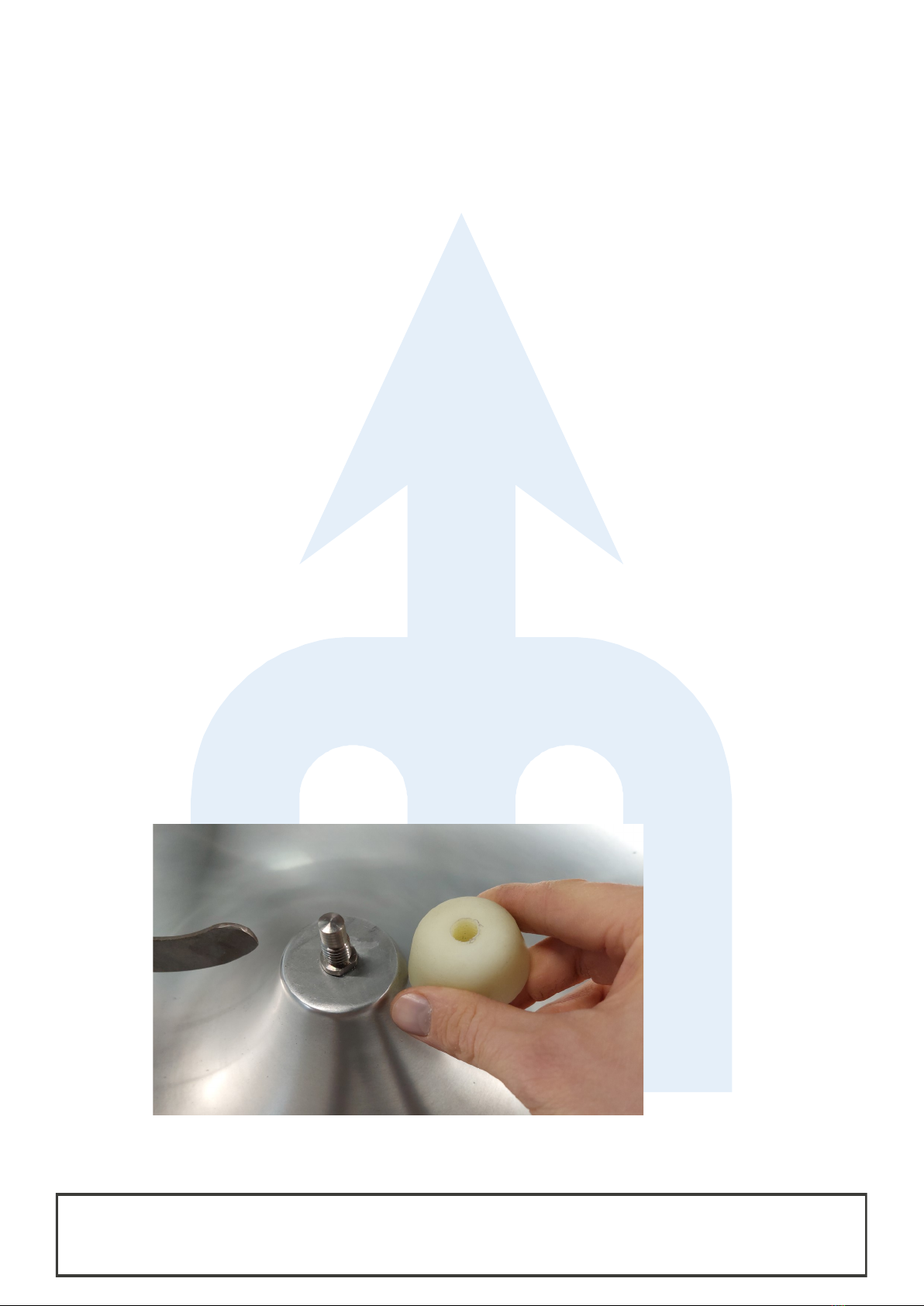

4. Gently spin blades ( turning the drivesha by hand ) to ensure they DO NOT make contact with the bowl, see locang

blades on page 4.

Place the machine in a dry and venlated level surface to ensure the machine works smoothly and safely.