MEFE—Mitchell Engineering Food Equipment Pty Ltd

23 Storie Street Clontarf QLD 4019 Australia

Page 4

+617 3283 4536

Free AU 1800 669 006

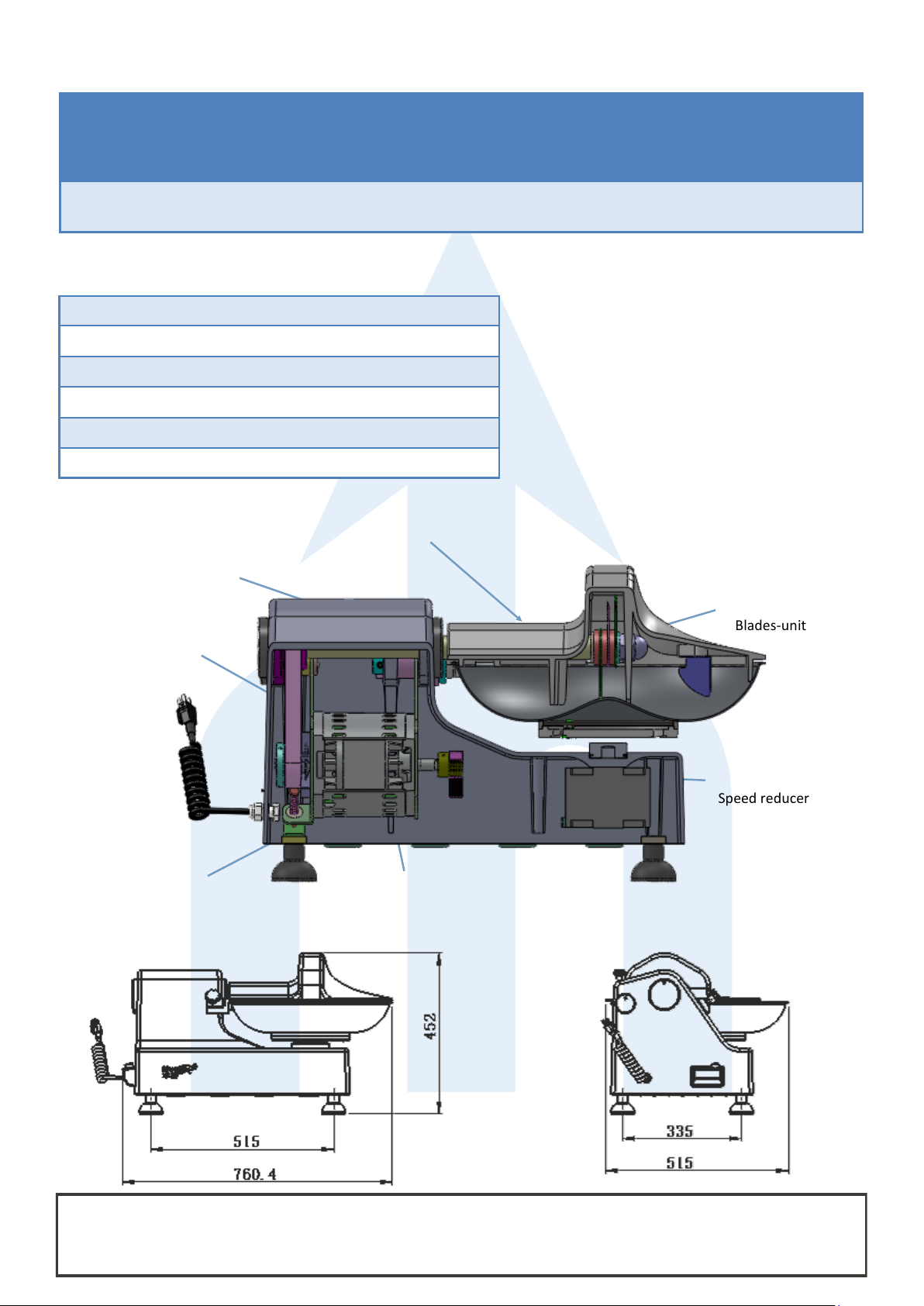

Switch Control

1— ”ON” and “OFF” use cooperavely

2— ”OFF” stop

3— “ON” start

2.1 Instrucons For Use

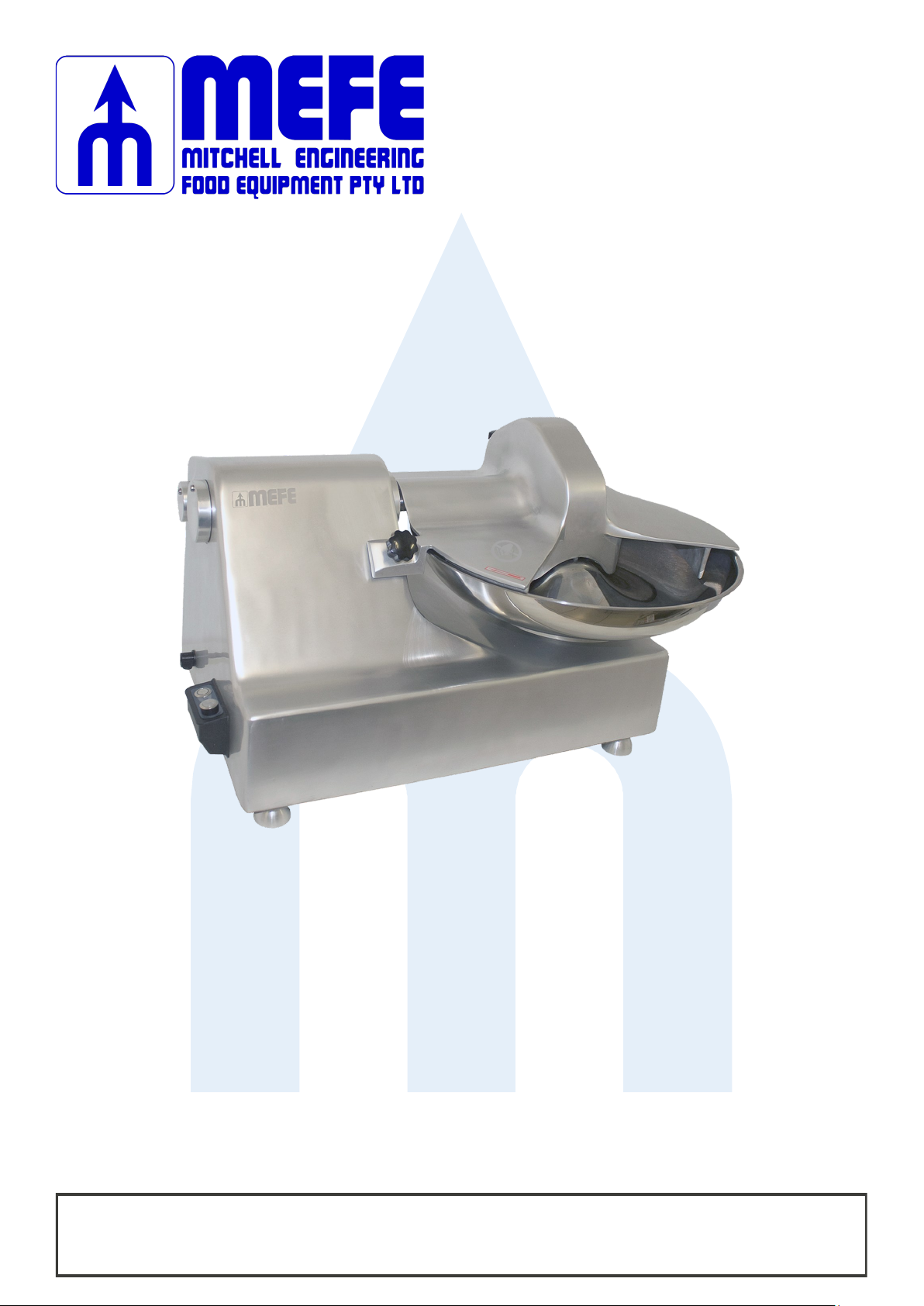

The food rotates an-clockwise with the basin, and will be cut into a paste when coming into contact with the vercally ro-

tang blades (size of the paste is to be controlled by adjusng the cung me).

Note: When the motor stops rotang, the food can be loaded.

1. Plug in the power supply.

2. Open the cover and put in the right amount of ingredients (pay aenon to not over-ll). Large pieces of food should be

cut into smaller pieces and be careful not to add foreign items to the basin as this will damage the cung tool.

3. Close the cover.

4. Press “ON” buon, start up power and check the machine has smooth operaon with no abnormal sounds.

5. Once the cung has nished press “OFF” buon and dish basin and cung blade should stop running.

6. Carefully remove the basin of chopped material.

7. Clean aer every work day or session and keep the machine dry.

8. In machine downme aer use, always disconnect the power supply for safety.

Please note: To prevent overheang the best operang pracce is to run the unit for no more than 15 minutes uninterrupt-

ed, following a 5 minute cool down before further use. The machine should be used with a duty cycle of 75%.

You can run the machine for a maximum of 3-4 hours connuously, however this does run the risk of overheang the motor

and voiding your warranty. The copper wire can undertake 130°C, and the machine body can undertake 75°C.

3. Cleaning and Maintenance

Cleaning

Disconnect the power and pull out the plug before cleaning the machine. Rotate the octago-

nal knob out an-clockwise, take o the scraper from the right side (Figure 1). Rotate the

basin clockwise and take it out.

Machine parts that come into contact with food must be cleaned aer every work day or

session.

Waste residue will damage the machine so it must be cleaned both inside and out.

To clean the machine, please use warm water and a mild detergent.

Do not use harsh detergents, industrial cleaners, iron brushes, or high pressure hoses.

Machine Maintenance and Daily Inspecon

Note: Before maintenance please unplug the power before servicing the machine, make sure the machine is away from power.

Regularly performing maintenance on the machine can eecvely extend the service life.

Periodically performing cleaning on the machine can ensure food quality and safety.

Daily inspecon of key components

1. Cung blade—Should check the cung blade whether installaon is rm or if it is has any damage, before starng the

machine.

2. Belt—Belt should be regularly adjusted, aer 2-3 years belts should be replaced.

3. Cable—Regularly check the cable, replace if necessary.

Figure 1