Meggitt Whittaker C173255-1 User manual

NOTICE: PROPRIETARY INFORMATIONOF WHITTAKER CONTROLS,INC., A BUSINESS UNIT OF MEGGITT PLC.

THE INFORMATION CONTAINED IN THIS DOCUMENT IS DISCLOSED IN CONFIDENCE. IT IS THE PROPERTY OF

WHITTAKER CONTROLS, AND SHALL NOT BE USED, DISCLOSED TO OTHERS, OR REPRODUCED IN WHOLE

OR IN PART WITHOUT THE EXPRESS WRITTEN CONSENT OF WHITTAKER CONTROLS. IF CONSENT IS GIVEN

THIS NOTICE SHALL APPEAR IN ANY SUCH REPRODUCTION.

REVISION 2.1 – 04/01/2004

Maintenance Manual

ABSOLUTE PRESSURE

TRANSDUCER ASSEMBLY

PART NUMBERS:

C173255-1

C173255-2

C173255-3

C173255-4

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page A

LIST OF EFFECTIVE PAGES

On a revised page, the portion of text or illustrations affected by the change is indicated by a vertical line

in the outer margin of thepage. When a revision is issued, the entire document is reissued with the current

revision number and date shown on all pages. For major revisions, the basic number is incremented. For

minor revisions, the number following the decimal is incremented. Dates of issue for original and subse-

quent revisions are as follows:

Original ..............................................05/01/1998

Revision 2.0 ...........................................09/01/2003

Revision 2.1 ...........................................04/01/2004

The total number of pages in this technical document is 17 consisting of the following:

Title, A, 1 – 15

TABLE OF CONTENTS

SUBJECT PAGE

Introduction .......................................................................4

Description and Operation ...........................................................7

Installation ......................................................................10

Fault Isolation ....................................................................11

Repair ..........................................................................13

Maintenance Parts List .............................................................15

LIST OF ILLUSTRATIONS

FIGURE PAGE

1 Absolute Pressure Transducer Assembly .......................................8

2 Interconnection Diagram ...................................................12

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 1

LIST OF TABLES

TABLE PAGE

1 Specifications and Characteristics .............................................6

2 Leading Particulars .........................................................9

3 Recommended Spare Parts .................................................15

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

This manual contains important instructions that should be followed during installation and maintenance

of the Absolute Pressure Transducer Assembly (transducer assembly). The following are general safety

precautions that arenot related to specific procedures andtherefore do not appear elsewhere in this publi-

cation. These are recommended precautions that personnel must understand and apply during many

phases of maintenance.

Safety Alert Symbols

Safetyalert symbolsareused inthismanual toidentifypotential orimmediatepersonalinjury hazards.The

safety alert symbol words are explained below:

DANGERindicatesanimminentlyhazardoussituationwhich,ifnot

avoided, will result in injury or serious injury.

WARNINGindicatesa potentiallyhazardous situationwhich,if not

avoided, could result in injury or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a poten-

tially hazardous situation which, if not avoided, may result in pro-

perty damage.

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 2

WEAR PROTECTIVE CLOTHING

!Wear protective clothing (gloves, apron, etc.) approved for the materials and tools being used.

USE APPROVED SAFETY EQUIPMENT

!When cleaners are being used, approved explosion-proof lights, blowers, and other equipment must

be used. Make sure that fire fighting equipment is readily available and in working order.

GIVE CLEANERS SPECIAL CARE

!Keepcleaners inspecialpolyethylenebottlesorinsafetycansandinminimumquantities. Discardsoil-

ed cleaning rags into safety cans.

Equipment Safety Information

The following safety information briefly discusses hazards peculiar to the equipment, whichare likely to be

encountered during maintenance activity.

GENERAL OPERATING LOCATION PRECAUTIONS

!Use only authorized replacement parts or hardware.

!Observe proper Lock-Out/Tag-Out procedures when working on the transducer assembly and make

sure that personnel protection equipment such as electrical grounds are installed.

!Make sure that all of the electrical wiring is properly terminated. Make sure that all of the wire terminals

are securely connected.

!Avoid hazardous voltage situations that can result from unsafe conditions such as, but not limited to

the following:

CImproper grounding

CHandling electrical leads or devices with wet hands or on wet ground

CDamaged electrical wire insulation

CImproper connection or re-connection of the power terminals.

CShort circuits to ground

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 3

OPERATION AND MAINTENANCE NEAR HIGH PRESSURE COMPRESSED GAS SYSTEMS

!Protect all gas lines from damage or puncture. Do not operate the equipment if a gas leak is detected

– this could indicate a loose or damaged high pressure fitting.

!Do not use flammable solvents for cleaning parts.

!Check for tools, rags, or loose parts left in the area before resuming operation.

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 4

INTRODUCTION

1. Purpose of Manual

A. This technical manual contains instructions for operation and maintenance of the Absolute

PressureTransducerAssembly(transducerassembly).Thismanualisintendedtoprovideinfor-

mation in sufficient detail to permit proper fault isolation, maintenance, and repair of the equip-

ment.

B. The transducer assembly is a component of a fuel metering system used in conjunction with

the General Electric Engine Control System to control delivery of natural gas to individual com-

bustor manifolds of a Gas Turbine Engine. Refer to Table 1 for specifications and characteris-

tics.

2. Revision Service

This manual will be revised as necessary to show the current information.

3. Weights and Measurements

Weights and measurements in this manual are expressed in both English (U.S. customary) and

Metric (SI) units.

4. Scope of Manual

The technical manual is divided as follows:

Introduction – Describes the purpose and scope of this manual.

DescriptionandOperation–Containsaphysicaldescriptionoftheequipmenttogetherwithexplan-

ations of its operation and component functions and characteristics.

Installation – Provides information for installing, connecting, and preparing the equipment for use.

Fault Isolation – Contains procedures for finding the cause of a malfunction.

Repair – Provides instructions for replacement of defective components.

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 5

Maintenance Parts List – Contains a list of spare parts recommended for on-site support of the

equipment.

5. Symbols and Abbreviations

Symbols and abbreviations used in this technical manual are as follows:

AWG American Wire Gage

C Centigrade (Celsius)

DC Direct current

F Fahrenheit

Hz Hertz

kg Kilogram

kg/s Kilograms/second

kPa KiloPascal

kPad KiloPascal, differential

kPag KiloPascal, gage

LVDT Linear variable differential transformer

mm Millimeter

Nm Newton-meter

NPT National Pipe Thread

P/N Part Number

psi Pounds per square inch

psia Pounds per square inch, absolute

psid Pounds per square inch, differential

psig Pounds per square inch, gage

SPDT Single-pole, double-throw

VDC Volts direct current

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 6

Table 1. Specifications and Characteristics

Applications ................................. General Electric LM1600, LM2500, LM2500+

and LM6000 Gas Turbine Engines

Service Fluid .......................................... Natural Gas (per MID-TD-0000-1)

Electrical Power ................................................ 12VDC (9 to 16 VDC)

Temperatures

Normal Ambient ....................................... –54 to 104°C (–65 to 220°F)

High Ambient (one hour) ........................................... 177°C (350°F)

Natural Gas ............................................. 0to149°C (32 to 300°F)

DESCRIPTION WHITTAKER

PART NUMBER HAZARDOUS AREA RATING

Absolute Pressure

Transducer Assembly C173255-1

C173255-2 Explosion Proof Design, CSA/UL, certified for NEC, Class

I, Division 1, Groups C and D, Temp Code T4 (maximim

ambient 120°C); CENELEC EEx d IIB, T4, Tamb = 120°C

C173255-3

C173255-4 Explosion Proof Design, CSA/UL, certified for NEC, Class

I, Division 1, Groups C and D, Temp Code T4 (maximum

ambient 120°C); CENELEC EEx d IIB, T4, Tamb = 120°C;

Group II, Category 2, Zone 1 (II 2 G) for ATEX

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 7

DESCRIPTION AND OPERATION

1. System Operation

A. The fuel metering system is designed to provide the controlled flow of natural gas fuel to the

engine.

B. Afterthenatural gasinletsupplylineandthefuelmeteringvalveoutlet linesareconnected, and

the electrical connections are made, natural gas is applied to the fuel metering valve gas inlet

from the facility gas supply system. Fuel flow through the fuel metering system is initiated by

electrically commanding the fuel metering valve to open.

C. The fuel metering valve is opened as necessary to control the flow of natural gas fuel to the

individual engine combustor manifolds by modulating in response to position commands re-

ceived through the motor controller from the GE engine control system.

D. The position commands fromthe GE engine control system arederived from many parameters

suchasengineoperating conditions, gasproperties, gaspressuresandgastemperatures.The

use of an extensive valve characteristics map and accurate position feedback, accurately pro-

vides the desired mass flow rates of the natural gas into the individual combustor manifolds.

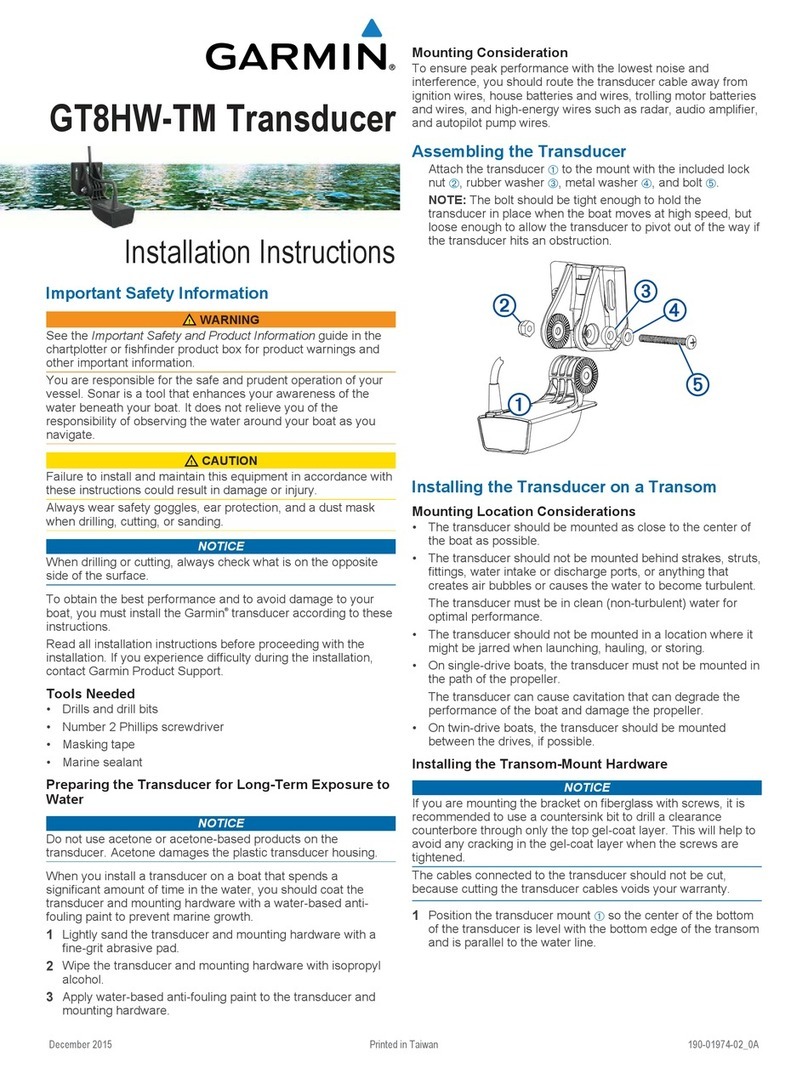

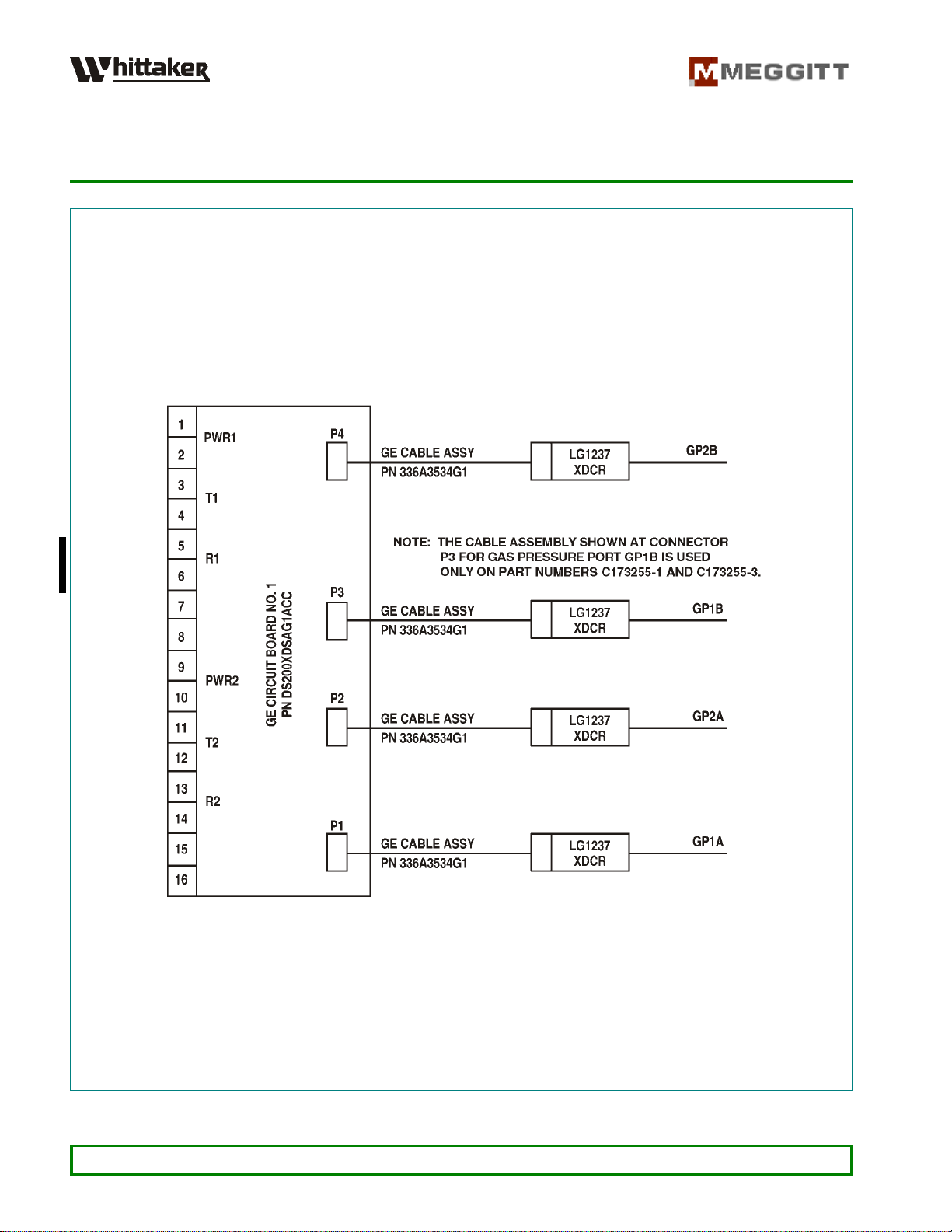

2. Absolute Pressure Transducer Assembly (See Figure 1)

A. When operating the engine, gas pressure at the inlet and outlet of each fuel metering valve is

monitoredbytheanabsolutepressuretransducer.Eachfuelmeteringvalvehasitsowndedica-

ted pressure transducer assembly, each of which includes three or four “smart” temperature

compensateddigitalabsolutepressuretransducersandtheircorrespondingelectronicinterface

circuit cards in one explosion proof enclosure.

B. Depending on system upstream piping geometry, one or two transducers are provided in each

assembly for upstream pressure measurement (GP1) and two transducers are provided for re-

dundant downstream pressures (GP2). For systems requiring two upstream pressure trans-

ducers, Whittaker Controls P/N C173255-1 is used; or P/N C173255-3 for European CE com-

pliance.Forsystemsrequiringasingleupstreamtransducer,WhittakerControlsP/NC173255-2

is used; or P/N C173255-4 for European CE compliance. .

C. For pressure transducer characteristics and specifications, refer to Table 2.

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 8

Figure 1. Absolute Pressure Transducer Assembly

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 9

3. Leading Particulars (Refer to Table 2)

Table 2

Leading Particulars

Type .......................................Digital pressure transducers and interface

electronics in explosion proof enclosure

Service Fluid ....................................... Natural Gas (per MIL-TD-0000-1)

Pressure Ports ............................. 3/8-inch tube, 3 places (compression fitting)

Pressures

Calibrated .......................................... 0to5170 kPa (0 to 750 psia)

Over-Pressure ........................................... 13800 kPa (2000 psia)

Accuracy ..................................................... ±0.02% of full scale

Temperatures

Fluid .............................................. –54 to +121/C (–65 to 250°F)

Ambient (maximum) ............................................... 82

/C (180°F)

Electrical Data

Voltage (normal) .......................................................12VDC

Voltage Range .................................................... 9to16VDC

Current ....................................................... 10milliamperes

Electrical Connections ........................ Terminal Block (¾-inch NPT conduit entry)

Dry Weight ................................................. 17.5 kg (38.5 pounds)

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 10

INSTALLATION

1. General

This section contains information on installation and interfacing of the transducer assembly with the

engine and the GE engine control system.

2. Installation

A. Pressure Ports

The gas pressure ports are standard ¾-inch compression tube fittings in accordance the appli-

cable ANSI standards.

B. Pressure Ports

The gas pressure ports are standard ¾-inch compression tube fittings in accordance the appli-

cable ANSI standards.

C. Electrical Interfaces

Hard wiring to terminal strips, conduit, conduit connectors.

D. Shielding

The shields on all of the cabling must be open at the device end and tied to the shield bar at the

GE engine control system interface, or tied to a common ground at the motor controller.

E. Cable Entries

Allofthecable entries intotheenclosure mustbedoneusingmethodsapproved by local certifi-

cation agencies (i.e., CENELEC, CSA, FM, etc.).

F. Cable Wire Sizing

All customer cabling conductors must be 18 AWG.

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 11

FAULT ISOLATION

1. General

Thissectioncontainsspecificchecksrequiredtofaultisolatethetransducerassemblyduringservice.

The first step in fault isolation is to verify the electrical connections. Make sure that all of the con-

nections are secure and that there are no damaged conductors. Refer to Figure 2 for the electrical

interconnectiondiagram.Iftheconnectionsareallintact,performcomponentfaultisolationinaccord-

ance with the following paragraphs.

2. Pressure Transducers (GP1/GP2)

If the outputs of the redundant GP2A and GP2B transducers, or the GP1A and GP1B (where appli-

cable) inlet pressure transducers from any of the three input branches vary from each other by an

amount that exceeds the allowed limits, a fault will be registered by the GE engine control system.

Since these pressure transducers are not adjustable, the fault can only be isolated to the transducer

or printed circuit board. To isolate a defective pressure transducer or printer circuit board, the follow-

ing procedure should be performed.

A. Therearethreeorfourtransducerchannelsineachpressuretransducer assembly.Ifthesignal

ofonechannelissuspect,openthetransducerenclosureandinterchangetheconnector onthe

printed circuit card of the suspect channel with the adjacent channel printed circuit card (i.e.,

if channel GP2B is suspect, disconnect its cable from terminal P4 and reconnect it to terminal

P2).

B. If the suspect signal follows to the adjacent channel, the problem has been isolated to the

pressure transducer and the pressure transducer must be replaced.

C. Ifthesuspectsignalremainsonthesamechannel,theproblemhasbeenisolated totheprinted

circuit board and the printed circuit board must be replaced.

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 12

Figure 2. Interconnection Diagram

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 13

REPAIR

1. General

A. This section outlines specific repair tasks which may be required, as determined by the results

of performing fault isolation procedures. Prior to any repair action, perform the fault isolation

procedures (refer to FAULT ISOLATION).

B. Refer to Figure 2 for the system electrical wiring interconnection diagram.

2. Repair Tasks

A. Pressure Transducer Replacement

1) Removal

a. Disconnect the cable assembly from the pressure transducer by loosening the two

connector screws.

b. Remove the screws and washers securing the pressure transducer to the mounting

block.

c. Remove and discard the packing between the pressure transducer and the mounting

block.

2) Installation

a. Install a new packing on the pressure port of the new pressure transducer, between

the pressure transducer and the mounting block.

b. Secure the pressure transducer to the mounting block with the screws and washers.

c. Connect the cable assembly to the pressure transducer and tighten the two attaching

screws.

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 14

B. Circuit Board Replacement

1) Removal

a. Disconnect all (three or four) transducer cable assemblies from the circuit board.

b. Disconnectthecables connected tothe 32-pinconnector.Makesurethattheconnec-

tor terminations are marked on the cable, so that they can be easily reconnected

during installation.

c. Removethemountingscrewssecuring thecircuitboard,andremovethecircuitboard

from the enclosure.

2) Installation

a. Install circuit board in the enclosure and secure it with the screws and washers.

b. Connect the cables to their assigned pins of the 32 pin connector.

c. Connect the transducer cables to their assigned connectors of the circuit board.

WHITTAKER CONTROLS, INC.

A MEGGITT PLC COMPANY

MAINTENANCE MANUAL

ABSOLUTE PRESSURE TRANSDUCER ASSEMBLY

C173255

INDUSTRIAL PRODUCTS GROUP Revision 2.1 04/01/2004 Page 15

MAINTENANCE PARTS LIST

1. General

Thissection identifiespartsrecommended foron-site maintenanceoftransducer assembly. Allofthe

recommended items may be ordered from Whittaker Controls.

2. Maintenance Parts

Table 3 comprises a listing of spare parts recommended for on-site maintenance support of the

transducer assembly. Table 3. Recommended Spare Parts

ITEM

NUMBER PART NUMBER DESCRIPTION RECOMMENDED

QUANTITY

1 C325937-2 Transducer, Pressure 1

2 C326270-1 Circuit Board 1

3 C327371 Cable Assembly 2

4 M83248-1-010 Packing (transducer to manifold) 4

5 NAS1352C04-12 Screw (#4-40 x 0.75 inch long) (manifold attaching) 4

6 MS35338-135 Washer, Lock (#4) (manifold attaching) 4

7 C326462 Screw (circuit board attaching) 6

8 C326469 Washer, Lock (circuit board attaching) 6

This manual suits for next models

3

Table of contents

Other Meggitt Transducer manuals

Popular Transducer manuals by other brands

MG

MG 17CE instruction manual

Gossen MetraWatt

Gossen MetraWatt SINEAX DME 4 Series operating instructions

WIKA

WIKA F2301 operating instructions

Desoutter

Desoutter DLT Series Product instructions

Lumel

Lumel P300 User Manual & Quick Start

S+S Regeltechnik

S+S Regeltechnik AERASGARD RCO2 Operating and mounting instructions