M2 Series Instruction Manual 9R68-A

Mar, 2008

page 2 of 6

Table of Contents

User Interface ................................................................................

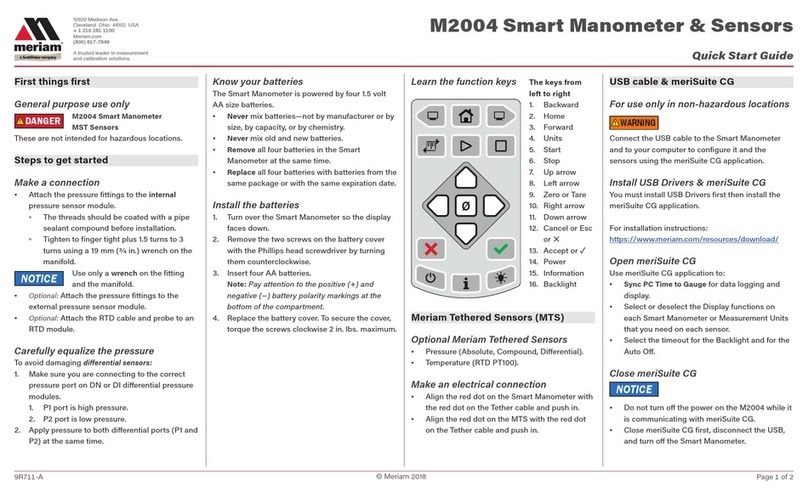

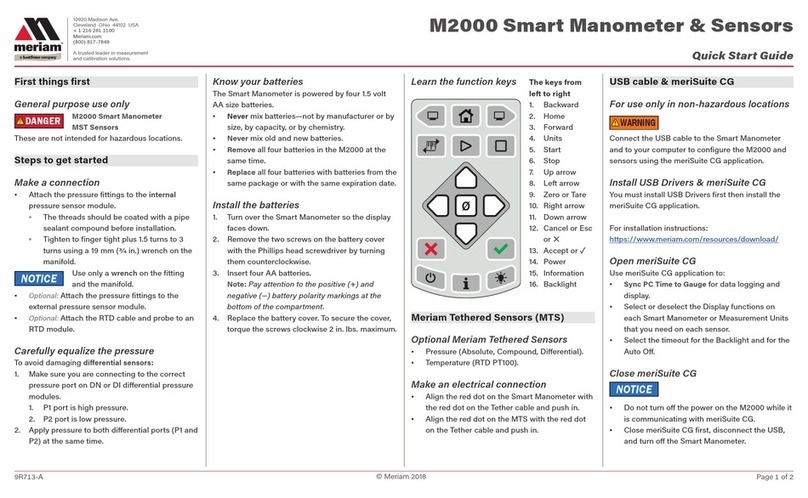

1. Keypad Functions ...............................................................

ON/OFF & BACK KEY......................................................

MIN/MAX & UP KEY .......................................................

TARE & DOWN KEY........................................................

PRGM & ENTER KEY....................................................... 4

BACKLIGHT KEY ................................................................. 4

2. Zeroing the Manometer....................................................... 5

. Program Mode .................................................................. 10

Units Select ............................................................................ 11

Displaying Altitude (US Standard Atmosphere 1962)............ 12

Display User Defined Altitude ............................................... 12

Pressure Corrected to Sea Level............................................. 15

Damp Rate Select................................................................... 17

User Info Select...................................................................... 18

Auto Shut-Off ........................................................................ 19

Lockout Select........................................................................ 20

Header Name.......................................................................... 21

Contrast Select ....................................................................... 22

Data Logging.......................................................................... 2

Leak Test................................................................................ 24

Re-Calibration ............................................................................. 25

RE-CALIBRATION – 1 Point EDIT and START ................. 27

RE-CALIBRATION – 5 Point EDIT ..................................... 28

RE-CALIBRATION – 5 Point START.................................. 29

RE-CALIBRATION – Restore Factory Defaults ................... 0

Specifications .............................................................................. 1

Certification/Safety/Warnings .....................................................

Changing the Batteries................................................................. 4

Contact Information..................................................................... 6