Meriam M2000 User manual

A trusted leader in measurement

and calibration solutions.

10920 Madison Ave.

Cleveland | Ohio | 44102 | USA

+ 1 216 281 1100

Meriam.com

(800) 817-7849

Copyright © 2018 Meriam®

User Manual

M Smart Manometer

Smart Manometers and Sensors

Meriam Tethered Sensors

meriSuite CG Application

9R715-IR October 2018

User Manual for M2000 Smart Manometer 2 of 68

Contents

M Smart Manometer ....................................................................................................................1

General Information...................................................................................................................................4

Notification Statements...................................................................................................4

Glossary......................................................................................................................................5

General warnings and cautions.......................................................................................................7

Preventing injury ..................................................................................................................7

Safety symbols.......................................................................................................................7

Sample label for General Purpose Smart Manometers ...........................8

Fire or explosion hazard..................................................................................................8

For General Purpose Series .........................................................................................8

Do not exceed pressure limits....................................................................................9

Sensors..............................................................................................................................................................10

Meriam Tethered Sensors (MTS)...........................................................................12

How to zero Absolute Sensors................................................................................12

How to zero DN, DI, or CI sensors........................................................................14

Smart Manometer.....................................................................................................................................15

Battery and USB power................................................................................................15

Batteries...................................................................................................................................15

The display.............................................................................................................................17

Keypad: Description of the keys............................................................................18

The backlight........................................................................................................................20

Measurement units..........................................................................................................21

Damping..................................................................................................................................22

Data Logging........................................................................................................................23

Leak Test .................................................................................................................................24

Relief Valve Test .................................................................................................................27

Dierential displays.........................................................................................................28

Auto O (Automatic shut o)...................................................................................28

What does the Zero (ø) key do?.............................................................................29

meriSuite CG application...................................................................................................................30

How does meriSuite CG benefit you?................................................................30

meriSuite CG and USB Drivers required..........................................................30

Tips for using meriSuite CG ......................................................................................31

Connection status.............................................................................................................34

Configuration button ......................................................................................................36

User Calibration button ................................................................................................40

Data Log button.................................................................................................................42

TSV file format.....................................................................................................................44

Application button............................................................................................................55

Update button......................................................................................................................56

9R715-IR October 2018

User Manual for M2000 Smart Manometer 3 of 68

Specifications ..............................................................................................................................................57

Internal sensors: type and range...........................................................................57

Internal sensors: type and range - continued..............................................58

Meriam Tethered Sensors: type and range....................................................59

Overrange limit...................................................................................................................61

Temperature..........................................................................................................................61

Relative Humidity..............................................................................................................61

Vibration ..................................................................................................................................61

Ingress specifications....................................................................................................61

Altitude specifications...................................................................................................61

Keypad......................................................................................................................................61

Media Compatibility........................................................................................................62

Battery Type..........................................................................................................................62

Dimensional specifications........................................................................................63

Weight.......................................................................................................................................64

Enclosure ................................................................................................................................64

Maintenance and cleaning................................................................................................................65

Cleaning...................................................................................................................................65

Prepare the Smart Manometer for storage....................................................65

Help.......................................................................................................................................................................66

Register your product....................................................................................................66

Find downloads and documents ...........................................................................66

Returning for repair or calibration ........................................................................67

Meriam Contact Information...........................................................................................................68

9R715-IR October 2018

User Manual for M2000 Smart Manometer 4 of 68

General Information

Notification Statements

Disclaimer

Every precaution has been taken in the preparation of this

manual. Nevertheless, Meriam assumes no responsibility for

errors or omissions or any damages resulting from the use of

the information contained in this publication, including, without

limitation, incidental, special, direct or consequential damages.

MERIAM MAKES NO REPRESENTATIONS OR WARRANTIES

WITH RESPECT TO THE ACCURACY OR COMPLETENESS OF

THE CONTENTS HEREOF AND SPECIFICALLY DISCLAIMS ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. Meriam reserves the right to

revise this publication and to make changes from time to time in

the content hereof without obligation to notify any person of such

revision or changes.

In no event shall Meriam be liable for any indirect, special,

incidental, consequential, or punitive damages or for any lost

profits arising out of or relating to any services provided by

Meriam or its ailiates.

It is not possible for Meriam to identify all foreseeable uses or

misuses, therefore all persons involved in commissioning, using,

or maintaining this product must satisfy their self that each

intended application is acceptable.

Copyright

This publication is proprietary to Meriam and no ownership

rights are transferred. Neither this manual, nor any of the material

contained herein, may be reproduced without the prior written

consent of Meriam.

Trademark information

Design Patent D769,141 for the Smart Manometer’s LCD display.

All other trademarks are the property of their respective owners.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 5 of 68

Glossary

Words and phrases with their definitions or explanations.

Words &

phrases

Definitions or explanations

Blinking • It indicates the active edit field on an edit

screen.

• It indicates the displayed value is not actively

changing (like Hold or stopped Test).

FS • FS is the abbreviation of Full Scale.

Home • Home is the first screen that displays after

turning on the Smart Manometer. It’s the

screen with measurements and units on it.

• After you press the Home key in many other

screens, the Smart Manometer returns you to

Home.

Key and

button

• A key refers to hardware push-buttons on the

keypad that you can press.

• A button refers to an area in meriSuite CG that

you can tap or click to select functions.

Isolated • The word isolated refers to the sensing

element being separated from the media. It

is commonly used in the phrases Absolute

Isolated (AI) pressure and Compound Isolated

(CI) pressure.

Customer

Calibration

• Customer calibration refers to any calibration

done outside of Meriam with non-Meriam

traceability.

• Customer calibration includes: Multipoint

calibration or adjustment.

Meriam

Tethered

Sensor (MTS)

• A Meriam Tethered Sensor (MTS) always

refers to an external pressure sensor P2 or to

an external temperature sensor T2.

-- P1 -- • P1 on the display always refers to the internal

sensor.

-- P2 --

or

--t2--

• P2 on the display always refers to the external

pressure sensor.

• T2 on the Smart Manometer display always

refers to the MTS RTD temperature sensor.

p1.P2 • Data from the internal and external pressure

sensors display in two lines on the Smart

Manometer at the same time.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 6 of 68

Words &

phrases

Definitions or explanations

P1.T2 • Data from the internal pressure sensor and

MTS temperature RTD sensor display on the

Smart Manometer at the same time.

DIFF P1-P2 • The displayed result of the external pressure

measurement subtracted from the internal

pressure measurement.

Diff p2-p1 • The displayed result of the internal pressure

measurement subtracted from the external

pressure measurement.

--out- • --out- displays on the process readout

when the information readout is providing

information about exiting tests.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 7 of 68

General warnings and cautions

Preventing injury

Failure to follow all instructions could result in injury:

▪Read the entire manual before using the Smart Manometer.

▪Understand the contents before using the Smart Manometer.

▪Follow all safety warnings and instructions provided with this

product.

Safety symbols

The following table defines the safety symbols, signal words,

and corresponding safety messages used in the manual. These

symbols:

▪Identify potential hazards.

▪Warn you about hazards that could result in personal injury or

equipment damage.

Safety symbols Explaining the symbols

Read directions

before using

This is the Read directions before using

symbol. This symbol indicates that you

must read the instruction manual.

DANGER

!

Indicates a potentially hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING

!

Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION

!

Indicates a potentially hazardous situation

which, if not avoided, could result in minor

or moderate injury.

NOTICE

Indicates information essential for

proper product installation, operation or

maintenance.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 8 of 68

Sample label for General Purpose Smart

Manometers

All M2000 Series models are available for general-purpose use.

General Purpose (GP) versions are identified by the name plate

located on the rear of the unit under the protective rubber boot. A

sample of the General Purpose name plate is shown below:

USA

|designed|engineered|assembled

+ 1 2162811100

(800)817-7849

Meriam | 10920 Madison Avenue

Cleveland |Ohio | USA | 44102

Meriam.com

For repair or calibration |

General Purpose

Four 1.5 V alkaline AA batteries

Operating Temperature:

–10 ºC < Ta < 50 ºC

Refer to manual for use and

safety precautions.

For use only

in non-hazardous

locations.

WARNING

!

Fire or explosion hazard

DANGER

!

▪Do not use General Purpose versions in hazardous areas.

▪Do not use General Purpose versions in areas that may

contain flammable gas or vapors, combustible dusts or

ignitable fibers where an unintended spark can cause a fire or

explosion.

For General Purpose Series

CAUTION

!

Substitution of components may impair operation and safety.

▪Disconnect power before servicing.

▪Do not power the Smart Manometer with a combination of

new and old batteries.

▪Do not power the Smart Manometer with a combination of

batteries from dierent manufacturers.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 9 of 68

Do not exceed pressure limits

WARNING

!

▪Do not exceed the Pressure Limits listed in the Specifications

section of this manual.

▪Failure to operate within the specified pressure limit could

result in minor or moderate injury.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 10 of 68

Sensors

Overview of Sensors

The Smart Manometer can display two measurements: one from

the internal sensor and one from the optional tether sensor.

NOTICE

▪P1 on this Smart Manometer always refers to the internal

sensor.

▪P2 or T2 on this Smart Manometer always refers to the

external sensor.

Use two wrenches to install or remove pressure

connections

Connection: 1/8” female NPT, 316L SS.

▪Always use a 3/4 in. wrench on the pressure manifold when

you install or remove the 1/8 in. NPT fitting.

▪Applying torque to the manifold can damage the plastic

enclosure and voids the warranty.

▪Do not over tighten.

Carefully equalize the pressure

Avoid these two issues with dierential sensors:

1. Connecting pressure to the incorrect pressure port on DN or

DI dierential pressure modules may cause damage to the

pressure sensor.

2. Applying pressure to either port before both connections are

made.

NOTICE

Apply pressure to both dierential ports at the same time.

Note: See Overrange limit in the section called Specifications

concerning overrange pressure limits. If over pressure damage

occurs, you must return the Smart Manometer to the factory for

sensor replacement.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 11 of 68

Sensor manifold types

ZMTS-CNXXXX

ZM2000-CNXXXX

ZMTS-CIXXXX

ZM2000-CIXXXX

ZMTS-DNXXXX

ZM2000-DNXXXX

ZMTS-DIXXXX

ZM2000-DIXXXX

ZMTS-ANXXXX

ZM2000-ANXXXX

ZMTS-AIXXXX

ZM2000-AIXXXX

ZMTS-RTD

9R715-IR October 2018

User Manual for M2000 Smart Manometer 12 of 68

Meriam Tethered Sensors (MTS)

Overview of the temperature and pressure sensors

1. The P2 sensor and the T2 sensor can be displayed with the P1

sensor.

2. When two sensors are displayed, no Units are displayed and

the Units key is disabled.

3. The Zero key is also disabled.

4. When a single sensor is selected it displays the measurement

units that were selected in meriSuite CG.

Make an electrical connection

▪Align the red dot on the Smart Manometer with the red dot on

the Tether cable and push in.

▪Align the red dot on the MTS with the red dot on the Tether

cable and push in.

How to zero Absolute Sensors

Overview of the zeroing Absolute Sensors

The Smart Manometer is a stable and precise instrument.

However, on occasion the Smart Manometer should have a new

zero taken. The new zero removes a zero drift that can occur after

the Smart Manometer was last zeroed. The Smart Manometer can

be zeroed only if the new applied zero is within ± 1 % FS of the

original factory calibration zero. This prevents accidental zeroing

at atmospheric pressure or other relatively high pressures. If the

Smart Manometer is outside this limit, the Smart Manometer

cannot zero.

1. Referenced to Absolute Zero - This traditional and preferred

method takes a snapshot of the measured pressure when a

vacuum of less than 100 microns Absolute is applied to the

sensor.

2. Restore Factory Zero - This method restores the calibration

curve to the original zero taken at the factory.

Note: This feature is intended for comparison purposes, and

should not be used for real pressure measurement. This feature

does not compensate for any zero drift.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 13 of 68

3. User Defined Oset (Zero) - With this method, you can enter

any pressure value when a known reference is applied (for

example, the local barometer). The Smart Manometer will

compare its actual measured value with the entered value, and

calculate a new zero reference based on the oset.

Steps for zeroing Absolute Sensors

You can zero the Smart Manometer in one of three ways. The

following may appear in a dierent order depending on which

arrow key you press. When an absolute sensor displays on-screen

as P1 or P2, press the Zero key to see one of the three sets of

characters below and the following three messages

On-screen

message Explanations

TAP TO

CHOOSE REF

• Tapping the Accept key selects the displayed

reference.

ARROWS TO

CHANGE REF

• Tapping an Arrow key changes the displayed

reference.

X Cancels

• Tapping the Cancel key cancels the zero

request.

ab5 0 • This is the on-screen abbreviation for

Absolute Zero.

dflt • This is the on-screen abbreviation for Default.

• If you want to restore the Factory Zero on a

sensor, press the Accept key when you see

these characters appear.

u5Er 0 • This refers to User Defined Oset (Zero). You

can set an absolute reference point other than

zero.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 14 of 68

How to zero DN, DI, or CI sensors

1. Disconnect from a pressure source and vent the pressure port

to atmosphere.

1. Do not remove the factory installed P2 plug if it is present.

2. The display should read close to zero.

2. Press the Zero key.

The top line displays dashes ------.

3. The process is complete when the Smart Manometer returns

to the Home (Measurement Units) screen.

4. If someone has turned on the Password Required For Future

Access feature in meriSuiteCG, the password feature does

not prevent you from zeroing the Smart Manometer.

Note: You can only zero the Smart Manometer if the new zero

value is within ± 5 % (of FS) of the original factory calibrated

zero. If the zero procedure generates a new zero reference

outside this limit, the procedure fails. Factory service may be

required.

5. You can turn o the Zero function in meriSuite CG by

deselecting Allow zero adjust (Ø) in the Display Functions list.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 15 of 68

Smart Manometer

Battery and USB power

When you turn on the Smart Manometer, it draws power from the

batteries and the battery icon displays in the bottom row. When

you press the information button, it displays Batt %.

When you turn on the Smart Manometer and plug in the USB

cable to the computer, the Smart Manometer switches to the

power supplied by the USB cable. The battery icon disappears

from the bottom row. When you press the information button, it

displays USB POWER.

DANGER

!

Do not use the USB in hazardous locations.

Batteries

DANGER

!

Remove and replace batteries in non-hazardous (safe) areas only.

Turn o the backlight

▪Turn o the backlight when you need to conserve battery

power.

▪The backlight is dimmed when the Smart Manometer is in low

battery mode.

Suggested brands of batteries

The following is a suggested list of batteries.

• Duracell MN1500

• Duracell PC1500

• Energizer EN91

• Panasonic LR6XWA

• Rayovac 815

• Varta 4906

Note: The Smart Manometer is powered by four 1.5 volt AA size

batteries.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 16 of 68

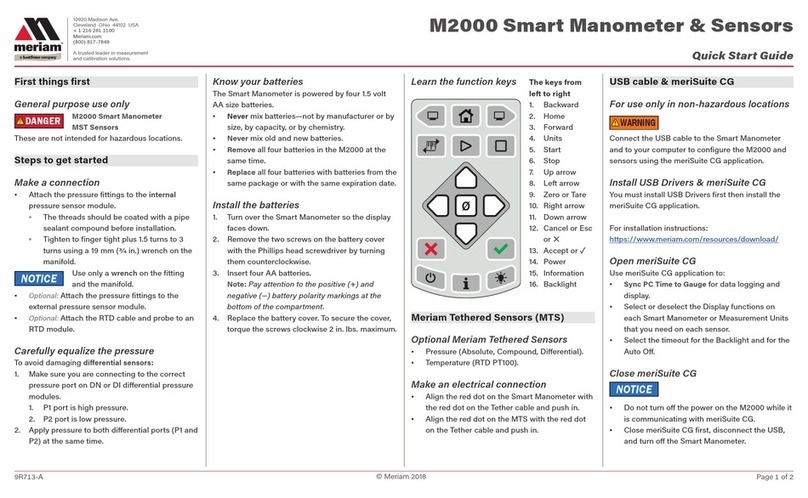

Know your batteries

▪Never mix batteries—not by manufacturer or by size, by

capacity, or by chemistry.

▪Never mix old and new batteries.

▪Remove all four batteries in the Smart Manometer at the same

time.

▪Replace all four batteries with batteries from the same

package or with the same expiration date.

Install the batteries

1. Turn over the Smart Manometer so the display faces down.

2. Remove the two screws on the battery cover with the Phillips-

head screwdriver by turning them counterclockwise.

3. Insert the four AA batteries.

Note: Pay attention to the positive (+) and negative (−) battery

polarity markings at the bottom of the compartment.

4. Replace the battery cover.

5. To secure the cover, torque the screws clockwise 2 in. lbs.

maximum.

6. Do not over tighten.

NOTICE

To prevent internal damage to circuitry, do not substitute screws

with lengths that are dierent from the screws Meriam provided to

you.

Watch for the low battery indicator

The battery indicator on the display shows the current charge.

Note: Be prepared to change batteries when you see the outline

of the battery icon and the outline of the battery icon flashes.

You have approximately 2 hours of run time following a low

battery warning.

Refer to battery manufacturers’ instructions

Visit the website of the battery manufacturer to learn more about

the care, storage, shipping, use, disposal, and recycling of your

batteries.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 17 of 68

The display

Information Readout

Process Variable Readout

Bar Graph

The bar graph

The bar graph displays a live indication of the current pressure or

temperature applied to a sensor as a percent of FS.

Note: When you press the Information key, the bar graph

displays the remaining state of the charge for the batteries.

Display functions

The Smart Manometer has twelve display functions. It ships with

five display functions active (they appear in bold below). You can

change which displays are active with meriSuite CG.

Press the Forward (or Backward in reverse order) key to view

these modes.

1. Home is the default view

with measurement units

7. AVG (Average)

2. MIN (Minimum) 8. RATE

3. MAX (Maximum) 9. DATA LOG

4. RELIEF VALVE TEST 10. Temperature & Time

5. + / - (Accuracy) 11. LEAK TEST

6. T.OFF, T.ON ( Tare) 12. LEAK TEST DURATION

Display function NOT appearing on the MTS

The following display function do not appear on an MTS when you

attach it to the Smart Manometer.

▪Temperature & Time.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 18 of 68

Keypad: Description of the keys

Name Key Description

Backward • It cycles backward through menu

options.

Home • Home key returns you to the

Measurement and Units screen.

• Home key is disabled during tests

and edits

Forward • It cycles forward through menu

options.

Units • Select a measurement unit.

Start • Start key begins a test or data log.

Stop • Stop or Hold (Freeze) key.

Up arrow • It increases digits by one.

• It switches between the P1 and P2

sensors displays.

Left arrow • It moves the blinking cursor one

space at a time to the left.

Zero & Tare • Zero key resets pressure values to

zero.

• It resets min max values.

• It sets edit values to zero.

• It resets relief valve test.

• As a Tare key, it turns o or turns on

the Tare function.

Right arrow • It moves the blinking cursor one

space at a time to the right.

Down Arrow • It decreases digits by one.

• It switches between the P1 and P2

sensors displays.

Cancel or Esc • Cancel any editing or changes

without saving.

• It also stops tests.

Accept • Accept applies all editing and

changes, and then saves them.

• It also stops tests.

Power • Turns the Smart Manometer on or o.

Information • Displays information about the Smart

Manometer, internal sensor, attached

MTS sensor, and the firmware.

Backlight • It provides three levels of brightness

and o.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 19 of 68

The Information key and the Home screen

The Information menu provides you with details about the Smart

Manometer and sensors.

Depending on what is attached to the Smart Manometer and

depending on what is selected in the bottom row in the LCD

display, determines what data appears.

1. Batt % displays the percentage on the bar graph and in digits

or it displays the words USB POWER.

2.

-- P1 -- or -- P2 -- or --t2--

Note: the bottom row indicates sensor (or measurement type):

compound, absolute, or dierential, or RTD temperature. All the

following sensor information describes the sensor indicated by

P1 or P2.

3. CAL DATE

4. USL is an abbreviation for upper sensor limit.

5. LSL is an abbreviation for lower sensor limit.

6. LT MAX % displays the Life-Time Maximum that has been

reached on the sensor.

7. SENSOR F/W VERS F/W is an abbreviation for firmware (this

message scrolls to display the information).

8. SENSOR S/N S/N is an abbreviation for serial number

(this message scrolls to display the information).

9. SNSR NAME [this message scrolls to display the information].

10. DEV F/W VER DEV is an abbreviation for device; it refers to

the M2000 (this message scrolls to display the information).

11. DEV S/N (this message scrolls to display the information).

12. DEV NAME refers to the Smart Manometer (this message

scrolls to display the information).

Up and Down Arrows

In the edit mode, the Up Arrow increases the digit each time you

press it. The Down Arrow decreases the digit

and

1. Up Arrow: 0 to 1 to 2 to 3 to 4 to 5 to 6 to 7 to 8 to 9.

9R715-IR October 2018

User Manual for M2000 Smart Manometer 20 of 68

2. Down Arrow: –0 to –1 to –2 to –3 to –4 to –5 to –6 to –7 to –8

to –9.

3. The negative symbol in the display appears in front of the first

digit when it is required.

The backlight

White backlight

The white backlight has an automatic time out. If you do not press

any keys while the backlight is on, it automatically turns o after 1

minute.

Note: You can configure the backlight timeout using meriSuite

CG.

Levels of backlight intensity

Press the Backlight key to cycle through these choices:

▪Low.

▪Medium.

▪High.

▪O.

Flashing red backlight

The flashing red backlight indicates an error condition. Possible

error conditions are:

▪Pressure has exceeded the calibrated accuracy of the Smart

Manometer.

▪Pressure has fallen below the stated accuracy of the M2000.

Note: The red backlight overrides the white backlight.

Overrange condition

During an error or overrange condition, the red backlight

overrides the white backlight.

However, once the error or overrange condition is corrected, the

white backlight is restored to its previous state (if the backlight

Auto O timeout did not expire).

Other manuals for M2000

1

This manual suits for next models

1

Table of contents

Other Meriam Measuring Instrument manuals

Meriam

Meriam M2000 User manual

Meriam

Meriam MGF16BN-30V15PSIG User manual

Meriam

Meriam M2 Series User manual

Meriam

Meriam M1 series User manual

Meriam

Meriam M2110P User manual

Meriam

Meriam meriGauge Plus User manual

Meriam

Meriam M4 Series User manual

Meriam

Meriam meriGauge Plus User manual

Meriam

Meriam M2001 User manual

Meriam

Meriam MGF16BN User manual