Mesa MQC Series User manual

PWM SERVO

CONTROLLERS

SERIES MQC

Operating Manual

Issue September 05

MESA Automation GmbH

RECEIVING AND HANDLING

Upon delivery of the equipment, inspect the shipping containers and contents for

indications of damages in curried in transit. If any of the items specified in the bill of lading

are damaged, or the quantity is incorrect, do not accept them until the freight or express

agent makes an appropriate notation on your freight bill or express receipt.

Claims for loss or damage in shipment must not be deducted from your invoice, nor

should payment be withheld pending adjustment of any such claims.

Store the equipment in a clean , dry area. It is advisable to leave the equipment in its

shipping container until ready fore use. Each amplifier is checked carefully before

shipment. However, upon receipt, the user should make sure that the amplifier

corresponds to or is properly rated in terms of rated voltage and current for the type of

motor which is to be driven. The descriptive label affixed to the amplifier specifies

electrical ratings.

Safety and application information

According to the enclosure the Amplifiers Motors and Power supplies may have live,

uninsulated or rotating parts or hot surfaces during operation.

The inadmissible removing of the required cover, in proper application, wrong installation

or operation may lead to personal or material damages.

For further information please refer to the manual.

Only qualified personal are permitted to install or operate the equipment.

IEC 364, CENELEC HD 384, DIN VDE 0100,0105,0110 and national regulations must be

observed

According to these general safety information a qualified person is someone who is

familiar with installation, assembly, commissioning and operation of the equipment. These

person must have the appropriate qualifications.

Order No.:74.01362

1 TECHNICAL SPECIFICATIONS FOR MQC ..............................................................................................2

1.1 BASIS MODELS .......................................................................................................................................3

1.2 ORDER EXAMPLE....................................................................................................................................3

2 GENERAL CONDITIONS ...........................................................................................................................3

3 BLOCK DIAGRAM......................................................................................................................................4

3.1 SUBPRINT OPT E LIMIT SWITCH ...........................................................................................................5

3.2 SUBPRINT MSM-OPT ............................................................................................................................5

4 POWER SUPPLY .......................................................................................................................................5

4.1 ELECTRONIC SUPPLY ±15 V...................................................................................................................5

4.2 POWER TRANSFORMER...........................................................................................................................5

5 SETTING UP THE AMPLIFIER ..................................................................................................................5

5.1 TACHO ADJUSTMENT: P3........................................................................................................................5

5.2 OFFSET: P1...........................................................................................................................................5

5.3 ADJUSTMENT OF THE SPEED CONTROLLER GAIN ......................................................................................6

5.4 ARMATURE CURRENT MEASUREMENT .....................................................................................................7

5.5 RMS - FUNCTION IARMS ...........................................................................................................................7

5.6 BEMF FEEDBACK SPEED CONTROL WITH I X R-COMPENSATION ..............................................................7

5.7 VARIABLE COMPONENTS .........................................................................................................................8

5.8 SPEED CONTROLLER COMPONENTS, BLOCK DIAGRAM ..............................................................................8

5.9 CURRENT CONTROL................................................................................................................................9

6 PROTECTION AND FAULT SIGNALLING ................................................................................................9

7 WIRING SUGGESTIONS............................................................................................................................9

8 FAULTFINDING AND REMEDY...............................................................................................................10

9 COMMISSIONING AND TERMINAL DESCRIPTION ..............................................................................10

9.1 FRONT CONNECTOR X 1 .......................................................................................................................10

9.2 SOLDER JUMPER ..................................................................................................................................11

9.3 TEST POINTS CONNECTOR X2...............................................................................................................11

9.4 TOP- SCREW TERMINAL – POWER INPUT ...............................................................................................11

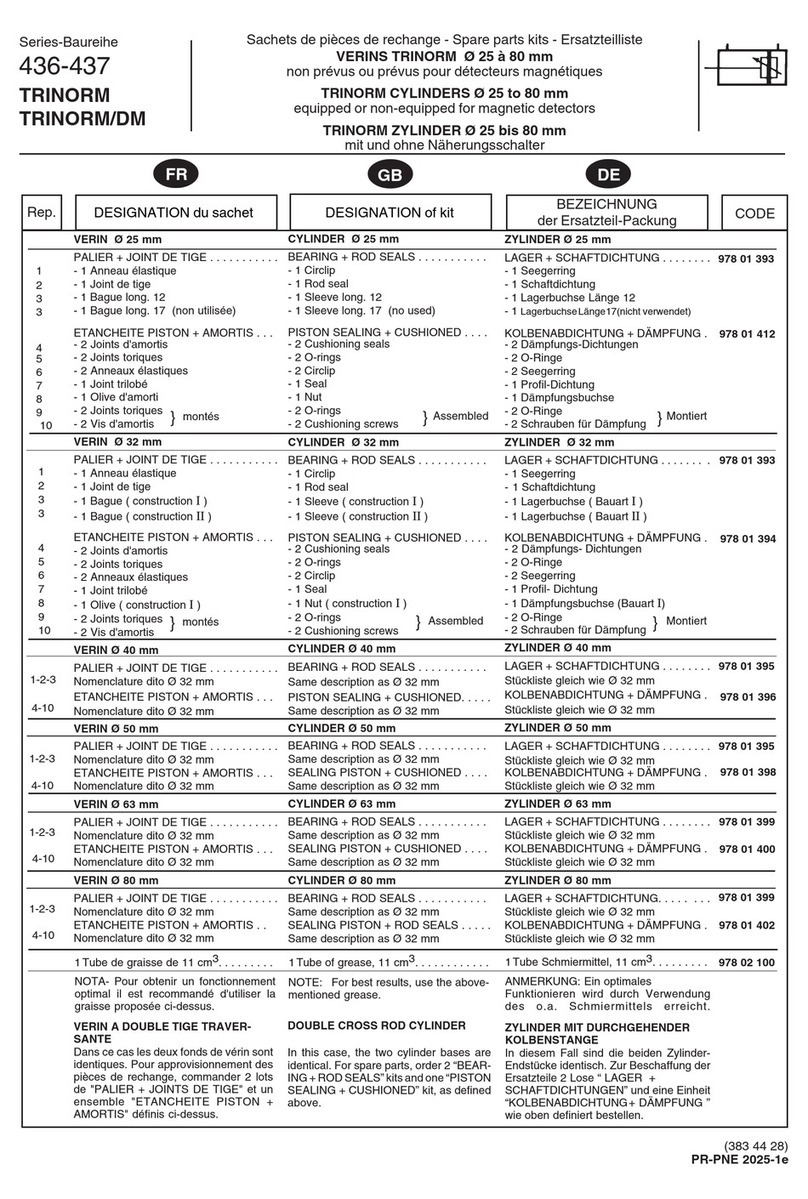

9.5 TECHNICAL DATES - DRIVE BRAKING MODULE .......................................................................................12

9.6 ADDITIONAL DATES ..............................................................................................................................12

10 DRAWINGS ...........................................................................................................................................13

10.1 AMPLIFIER INPUT ..................................................................................................................................13

10.2 DC-POWER SUPPLY .............................................................................................................................13

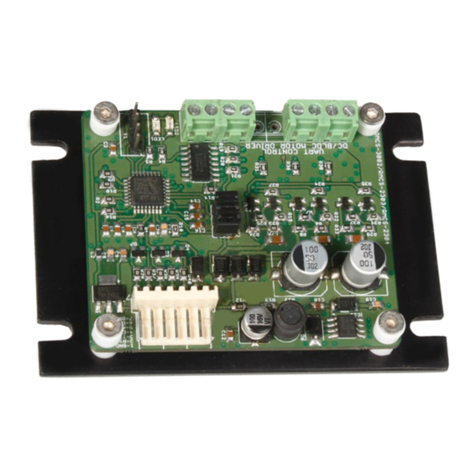

10.3 COMPONENTS LOCATION ......................................................................................................................14

10.4 MECHANICAL STYLE..............................................................................................................................15

MESA Automation GmbH

MQC 05 V 3 EM2

1 Technical specifications for MQC

Power stage

Input voltage Chapter 1.1 Basis models

Over voltage protection 85 VDC (UA=60 V)

160 VDC (UA=120 V), 190 VDC (UA=150 V)

Chopper frequency 8 kHz (to GND)

Form factor at nominal ratings 1.01 (Rated current)

Power stage protection short circuit

Fault signalling red LED ϑmax , - Îmax ;- Umax

Braking module page 12/10.4

Speed controller

Input command Differential ± 10 V Ri = 20 kΩ

Tacho reference signal Differential ± 5V ... ± 60 V Ri = 54 kΩ

Compensation network PI (D)

correction with potentiometer or components

Speed control range 1:20000

static Error 30...3000 rpm ± 0,1 %

1...30 rpm ± 2,0 %

< 1 rpm ± 5,0 %

Current controller

Band width 1 kHz

Compensation network Pl

Current limitation 1 IArms

Current limitation 2 max. output current IAmax

Enable X1/PIN5 connect to 0 V, (optional + 24 V)

signals

Drive healthy (relay contact) X1/PIN6 connect to X1/PIN7

Contact ratings 160 VDC/20 mA

"OK“ LED green on

"error" LED red on

„Braking“ LED red + green on

other Data

Operating temperature ϑu0...45 °C derating 2 %/ K from 45 °C to 60 °C

Storage temperature -10...+70°C,

Cooling by air convection, or fan

rel. humidity 65 %, without condensation

Protection class IP 20

Isolation group C /VDE 0110

Size Chapter 9.5

MESA Automation GmbH

MQC 05 V 3 EM 3

1.1 Basis models

TYPE UAImax INRMS UCCN UNUmin 1) Umax 1)

(V) (A) (A) (V DC) (V AC) (V AC) (V AC)

MQC 0506 48 12 6 55 24 -48 V DC 16 V DC 65 V DC

MQC 0510 48 20 10 55 24 -48 V DC 16 V DC 65 V DC

MQC 0606 60 12 6 65 46 20 51

MQC 0608 60 16 8 65 46 30 51

MQC 0610 60 20 10 65 46 30 51

MQC 1206 120 12 6 125 90 30 98

MQC 1208 120 16 8 125 90 30 98

MQC 1210 120 20 10 125 90 30 98

MQC 1510 150 20 10 155 113 30 125

MQC 1515 150 30 15 155 113 30 125

UA: Output voltage UCCN ; Imax : max. Output current ; INrms : rated current 1) max. rating!

1.2 Order example

A) Standard without option MQC 1208 (M 99)

Mesanor Compact-DC-Drive Modification

Rated current INrms 8A

Output voltage UA= 120 V

B) Limit switch OPT.E and 0 V Logic (Enable and Opt.)

MQC 0606 OPT. E (-)

2 General conditions

The MQC servo modules are extremely compact PWM servo amplifiers that provide 4 quadrant speed

control of any DC servo motors with Tacho or with BEMF feedback. MQC amplifiers are conceived for

regulation of brush DC motors. The MQC is equipped with an internal power supply. From dc voltage the

amplifier is producing the current for the motor. Output current is PWM controlled and due to high chopper

frequency a large bandwidth and dynamic are granted.

Relations for the operation of the motor:

•torque is proportional to output current

•speed is proportional to output voltage

•direction of rotation corresponds to sense of the output voltage

For limit values, please look the specifications. Inadmissible working conditions or wrong application of the

amplifiers should be avoided.

Never plug in or unplug any connectors on the amplifier when power is applied. A time of discharge

of 3 minutes must be considered

The Mesanor-Amplifiers series MQC are designed for stand alone application :

Mounting: Front connector upright

Cooling: natural cooling or forced cooling (Chap.1.1)

ambient temperature less then 45°C .

Electronic supply: Internal DC/DC converter ± 15 V, max external charge with 20 mA

Supply from net: Isolation transformer required

Attention !

The MQC 05 XX Version are for 24 /48 V DC Battery supply . The input terminals L1’,L2’L3’ are used for DC

input with or without Reverse-diode.

MESA Automation GmbH

MQC 05 V 3 EM4

3 Block diagram

MESA Automation GmbH

MQC 05 V 3 EM 5

3.1 Subprint OPT E Limit switch

By connection of GND (OPT E -) or 24 V signal (OPT E +) to the terminals for negative and positive direction

the limit switch can be deactivated. If the limit switch is active, the motor will stop in these direction. The limit

switch logic level (OPT E += positive, OPT E (-)= negative logic) is set by factory. R 111 must be removed,

otherwise option B;C and E will not work.

3.2 Subprint MSM-OPT

Other Options are available by using MSM-OPT Subprint- please ask for more information.

- external current limiting, positive and negative Output current separate (Opt.A)

- Speed controlled current limiting (Opt. L) - programmable Limit-Switch (Opt. KE)

- Ramp generator (Opt. B ) - Limit switch (Opt. C) only available with negative logic

4 POWER SUPPLY

4.1 Electronic supply

±

±±

±

15 V

Electronic (+/-15V) of the amplifier is supplied from power voltage.

4.2 Power transformer

Transformers with galvanic separated primary an secondary winding are used for adjustment of supply

voltage to the existing net. The Transformers have to correspond to VDE 0550. One and three phase

transformers can be used.

If the transformer used has a star point in its secondary winding then this should be isolated and NOT

connected to earth.

A three phase transformer is recommended for current higher than 10 A continuos overall.

The factory or your dealer should be consulted to specify the proper size and secondary voltage.

5 Setting up the amplifier

The adjustment of Tacho, output current, Irms is made by factory. An adjustment of an amplifier for another

motor is possible

In order to achieve best performance for the system motor/amplifier, optimisation of speed circuit is

necessary. The following components are used:

•P 2 /R21: P- Gain

•C2: I - Gain

•P3/R31: tachometer signal

•

5.1 Tacho adjustment: P3

As a general rule, amplifiers driving servo motors are designed such that the continuously rated speed of the

motor corresponds to an input command to the amplifier of 10 V.

•apply a 10 V signal to the command input and measure the motor speed. The Tacho pot. P3 can now be

adjusted until the correct maximum speed is reached. If unable to obtain the speed over range of P3, then

consult factory for modifications.

Standard-range:

Left side: 5 V Tacho input voltage correspond to 10 V Set value

Right side: 60 V Tacho input voltage correspond to 10 V Set value

adjustment of the standard range with R31

Components can be adjusted in factory or by service.

5.2 Offset: P1

If an input of exactly 0 V is applied to the command input then the motor shaft should be stationary. Any

creep may be eliminated with P 1.

MESA Automation GmbH

MQC 05 V 3 EM6

5.3 Adjustment of the speed controller gain

Amplifiers are equipped with a standard optimisation and can be adapted by P2. Is this adjustment not

possible, PI on the Personality card must be checked.

P-Gain: P2

Standard range: Right side: 160

Left side: 8

adjustment of the standard range with R21

A) Response when correctly adjusted

Demand Signal

t1; t3 acceleration

IDC

IAMotor current t2; t4 deceleration

UTSpeed OPTIMAL

(Tacho)

Incorrect Response

IDC Motor current Attention!

IAmismatched

Motor current oscillates

UTSpeed P-Gain too high

(Tacho) adjust with P2

t1 t2 t3 t4

MESA Automation GmbH

MQC 05 V 3 EM 7

5.4 Armature Current Measurement

Armature current is measured by means of a shunt placed in series with the armature circuit. The voltage

produced can be measured at the „I Monitor“ test point. 10 Volts output corresponds to the maximum current

of the amplifier.

Max. Output current IAmax: P4

The amplifier is capable of supplying twice is rated current for 1.5-5 seconds. Peak current will be adjusted by

P4.

Standard-Range: Right side: IAmax = 1 x Imax = Type-max. current

Left side: IAmax = 0,03 x I max

Current balance: P7

Adjustment of the internal Current measurement! Set by factory, do not change !

5.5 RMS - Function IArms

Momentary current is processed into an I rms. Value by a squarer network and is negatively feed back to the

armature current control point via a threshold value switch. The I rms. Current is adjusted with P5 and is

maintained irrespective of the curve shape of the armature current actual value.

I

IAmax t1= acceleration pick-up

IArms t2= limitation

τ= t2-t1(without pre charge)

t1t2t

RMS output current IArms: P5

Follow the procedure given above for adjustment of IAmax. The IArms pot P 5 can be adjusted and is value read

from the monitor after about 5 seconds.

Standard-

Range Right side: IArms = 1 x INrms = Type rated current

Left side: IArms = 0,1 x INrms

5.6 BEMF feedback Speed control with I x R-compensation

Application without Tacho feedback are possible with lower accuracy of the speed controller

the use of an compensation resistor R12 gives an increase of accuracy.

Attention:

Solder jumper Br1, Br2 close for BEMF operation, in this case BR 3 must be open !

For amplifiers with more then 60 V output voltage never close direct BR1 + Br2 use two additional resistors

RV (R211/212)

MESA Automation GmbH

MQC 05 V 3 EM8

5.7 Variable components

Set value adjustment: R111 Standard: 10 k Ω

Tacho adjustment: R31 Standard: 1,8 kΩ

IxR compensation: R12 Standard: not used

5.8 Speed controller components, Block diagram

lntegral part C2 Standard: C2 = 0,1 µF Proportional part P2 / R 21 Standard: R21 = 82 kΩ

TN = R21 x C2

KNS = R21/R111 x K (command gain)

KN = R21/(P3 + R31) x K (error gain)

K factor is the result of P2 adjustment : Right side: K = 20

Left side: K = 1

Block diagram Speed control

MESA Automation GmbH

MQC 05 V 3 EM 9

5.9 Current control

The controller is optimised by factory, do not change !

6 Protection and fault signalling

The green LED indicates the proper function of the unit. In case of a fault, a signal is given by the front red

LED (H1), power stage will be disable and the „ready/drive healthy" relay contact will be open.

Reset the amplifier: supply voltage off-/-on

Monitoring ground fault

Over currents due to ground fault causes the safety switching circuit to respond the same way as an over

current fault.

Monitoring over voltage

If over voltage occurs in the DC Bus voltage, a fault is signalled.

Monitoring under voltage

The +/- 15 V will drop to 0V DC and disables the amplifier.

Monitoring over temperature of the power stage

Monitoring of the heat sink temperature up to 90 °C or 190 °F

7 Wiring suggestions

•It is important that the amplifier (Rack or stand-alone) is properly earthed. If the amplifier is not earthed

then if an earth fault occurs in the motor circuit the output of the amplifier will be destroyed.

•Each motor must be wired separately (cable should be shielded)

•Motor cable may be shielded if there is a requirement for reduced electrical noise.

•Speed demand and tacho circuits should be individually shielded (twisted) pairs.

•Speed demand inputs are differential inputs consequently either polarity can be used. It is Important that if

a single ended input is used then one of the amplifier inputs must be connected to ground. The controller

and the amplifier must operate with the same GND reference potential.

•All control inputs (for example: limit switch, speed demand) have to be twisted and shielded pairs.

•If cables with two outside shields (better EMV security) are used, the outside shield must be connected to

earth on both sides, the inside shield must be connected to the rack. GND contacts of amplifiers are not

suited to be connected with the shield circuit.

MESA Automation GmbH

MQC 05 V 3 EM10

8 Faultfinding and remedy

Fault Cause Remedy

The motor will not start supply voltage missing check all fuses are good and supply voltage are

present

there is no current drive not enable Terminal X1/Pin5 should be connected to 0VDC

(optional +24V) for power stage enable

Motor wiring open check the wiring for the armature circuit

The motor runs at an uncontrollably high

speed after switching on.

The control circuit is polarised Change the polarity of the tachometer or the

motor.

The motor will not start although current

is present

The motor is blocked (mechanically)

Shorted motor circuit

Release the brake, if there is one; if necessary

dismantle the motor and run no-load test.

Check the wiring of the armature circuit

The motor runs unevenly P-portion too high

I-portion too small

Turn P2 counter clockwise

Increase C8

Wiring fault at control leads or tachometer

leads

Check the shielding and check wiring

After enable the amplifier Choke are not wired in the armature check wiring

the red fault LED is lit choke and/or motor inductance too low the value must amount to, at least, the value for

the corresponding amplifier

short circuit in the motor, wiring or chokes check wiring, motor and chokes

After turn on amplifier the red LED is lit

without enable amplifier

power stage is defective exchange amplifier

the red LED is on after a long running

time

power stage overheat let the module cool down

Red LED goes on when the motor is

decelerating

over voltage caused by high system inertia A braking regulator board needs to be added to

insure proper amplifier use

Red LED goes on immediately after

power up

Over voltage caused by high bus voltage check transformer and net

9 Commissioning and terminal description

9.1 Front connector X 1

PIN Signal direction Function Remark

1

2

- IN

+ IN

Set value differential , Ri = 20 KΩ, max. input voltage

20 V ,max. input Voltage to GND +/- 30 V

3

4

+ IN

- IN

Tacho input differential, Ri = 54 KΩ, max. input voltage

65 V , max. input voltage to GND +/- 70 V

Att. BEMF control for output voltage higher then 60V

5 IN Enable negative Logic: open Drive disable

0V (GND) Drive enable

Attention! do not connect to source

positive Logic: open or 0V(GND) Drive disable

+ 24 V Drive enable

6

7

OUT

OUT

drive healthy

signal

relay contact

closed if Drive OK

8OUT

(IN)

+ 15 V

(Limit switch)

Auxiliary Voltage max. load with 20 mA, not available if using OPT E

input for OPT E Limit switch Logic level set by factory

90V

E(GND) Electronic ground

10 OUT

(IN)

- 15 V

(Limit switch)

see PIN 8

11

12

+ OUT

- OUT

Motor A1

Motor A2

notice diameter , never short to ground or A2 or power input

ATTENTION ! Apply no Voltage

13

14

IN

IN

+ Ucc

- Ucc/

MESA Automation GmbH

MQC 05 V 3 EM 11

9.2 Solder jumper

Solder jumper Function (closed) Remark

BR 1 Drive output to Tacho input BEMF control

BR 2 Drive output to Tacho input BEMF control

BR 3 Tacho input to GND disturbance reduction

BR 4 P-connector R= 1,8 KΩ

BR 5 Enable logic level + 24 V set by factory

9.3 Test points connector X2

Test point X2 /PIN Remark

2 Speed controller output/ current command

3 Tacho signal

4 current monitor +/- 10V = Imax

6 current command (Pot. P4)

10 Speed control junction

12 -15 V

14 0VE (GND)

18 Speed command

19 +15 V

20 Enable CMOS level 15 V

21 Error over voltage 0 = Error

22 Error over current 1 = OK

23 Error over temperature

24 Error input from Option subprint

Attention ! All test points refer to 0VE/GND power and logic ground direct connected

9.4 Top- Screw terminal – power input

Type PIN 1 PIN 2 PIN 3 PIN 4 Supply

MQC 0506 Housing / GND -Ucc + Ucc direct + Ucc via reverse diode DC

MQC 0510 Housing / GND -Ucc + Ucc direct + Ucc via reverse diode DC

MQC 0606 Housing / GND L'3 (AC) L'2 (AC) L'1 (AC) AC

MQC 0610 Housing / GND L'3 (AC) L'2 (AC) L'1 (AC) AC

MQC 1206 Housing / GND L'3 (AC) L'2 (AC) L'1 (AC) AC

MQC 1208 Housing / GND L'3 (AC) L'2 (AC) L'1 (AC) AC

MQC 1210 Housing / GND L'3 (AC) L'2 (AC) L'1 (AC) AC

MQC 1510 Housing / GND L'3 (AC) L'2 (AC) L'1 (AC) AC

MQC 1515 Housing / GND L'3 (AC) L'2 (AC) L'1 (AC) AC

MESA Automation GmbH

MQC 05 V 3 EM12

9.5 Technical Dates - Drive Braking module

Type UBR ON (V DC) UBR OFF (V DC) PMAX (W) Pcont. (W)

MQC 0506 77 74 530 10

MQC 0510 77 74 530 10

MQC 0606 77 74 530 10

MQC 0610 77 74 530 10

MQC 1206 140 137 1800 10

MQC 1208 140 137 1800 10

MQC 1210 140 137 1800 10

MQC 1510 180 175 2200 10

MQC 1515 180 175 2200 10

Attention : Never overload the braking system, calculate before the max. power.

9.6 Additional Dates

Type Fuse F2

(A)

internal choke

(mH)

Lmin FAN Size

(mm)

Min. distance

(mm)

Wight

(Kg)

RVin KΩ

ΩΩ

Ω

0,25 W/1% (R211/212)

MQC 0506 6,3 1,1 50 80/30 1,3 .........

MQC 0510 10 0,5 50 80/30 1,3 .........

MQC 0606 6,3 1,1 1 50 30 1,3 -

MQC 0608 8 0,5 0,5 50 30 1,3 -

MQC 0610 10 0,5 0,5 50 30 1,3 -

MQC 1206 6,3 1,1 1 50 30 1,3 64,9

MQC 1208 8 1,1 1 50 30 1,3 64,9

MQC 1210 10 0,5 0,5 75 30 1,7 64,9

MQC 1510 10 0,5 0,5 75 50 1,7 100

MQC 1515 16 no 0,5 yes 75 50 1,9 100

Lmin : minimum Inductance

Please note all necessary information and drive adjustments for service and order.

MESA Automation GmbH

MQC 05 V 3 EM 13

10 Drawings

10.1 Amplifier input

10.2 DC-Power supply

Attention ! Do not ground the secondary winding !

MQC 05 XX L1’;L2’;L2’ DC Input !

MESA Automation GmbH

MQC 05 V 3 EM14

10.3 Components location

MESA Automation GmbH

MQC 05 V 3 EM 15

10.4 Mechanical style

MESA Automation GmbH

MQC 05 V 3 EM16

The manual is subject to modifications or misprint.

Please call our service for further technical questions.

MESA Automation GmbH

MQC 05 V 3 EM 17

This manual suits for next models

10

Table of contents