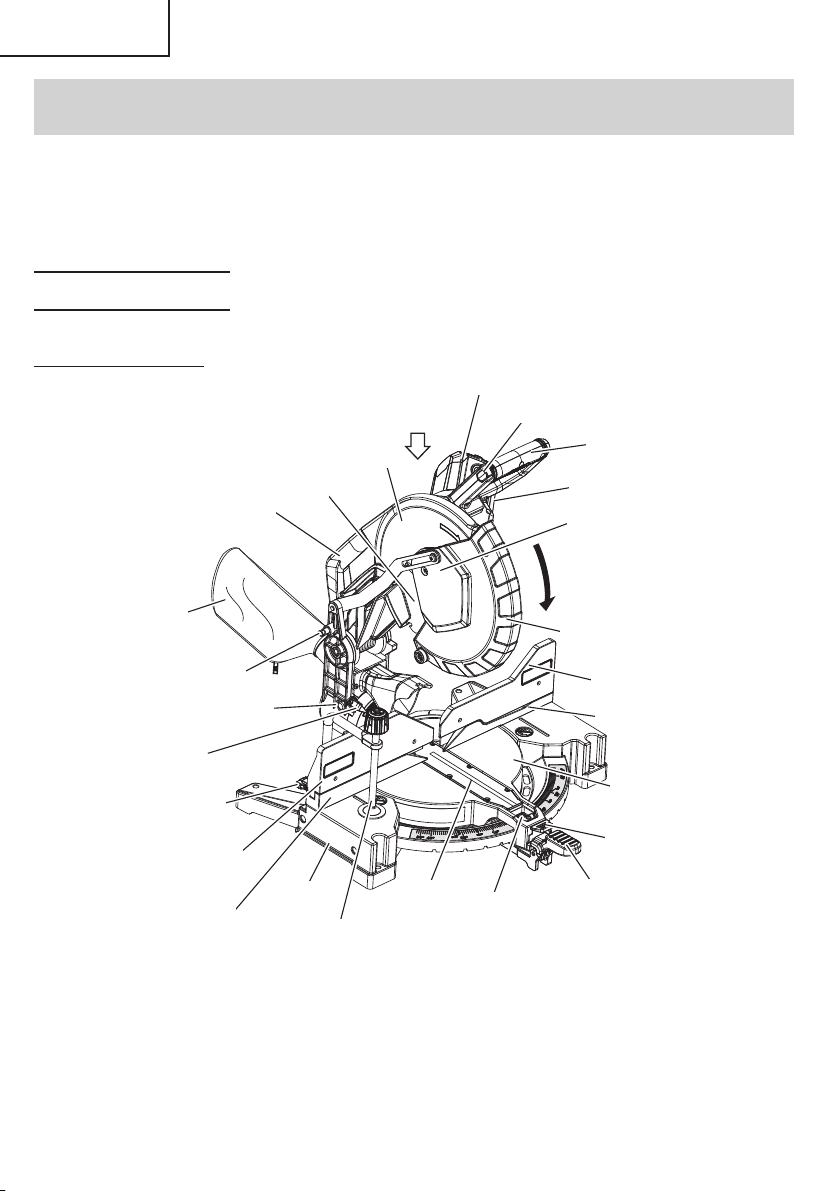

6

English

18. Always confirm that the proper lengths and types of

extension cords are being utilized, if necessary, before

starting the tool.

19. Always confirm that the motor air vents are fully open

before using the tool.

20. Always wait until the motor has reached full speed

before starting a cut.

21. Always keep the handles dry, clean and free of oil and

grease. Hold the tool firmly when in use.

22. Always use outboard stands to provide support for long

workpieces that overhang the table of the compound

miter saw.

23. Always operate the tool after ensuring the workpiece

is fixed properly with a vise assembly.

24. The operating instructions provided with the tool shall

direct the user to secure the tool to supporting structure

if, during normal operation, there is a tendency for the

tool to tip over, slide, or walk on the supporting surface.

25. Ensure before each cut that the machine is stable.

26. If the saw blade should become jammed, switch the

machine offand hold the workpiece until the saw blade

comes to a complete stop. To prevent kickback, the

workpiece may not be moved until after the machine

has come to a complete stop.

Correct the cause for the jamming of the saw blade

before restarting the machine.

27. Use only saw blades that are marked with a maximum

permitted speed equal or higher than the no-load speed

marked on the POWER TOOL.

28. Use only a saw blade diameter in accordance with the

markings on the POWER TOOL.

29. Replace the table insert when worn.

DON’Ts

NEVER VIOLATE THE FOLLOWING RULES TO ASSURE

SAFE USE OF THIS TOOL:

1. Never operate the POWER TOOL unless you fully

understand the operating instructions contained in this

Manual.

2. Never leave the POWER TOOL unattended without

first unplugging the power cord.

3. Never operate the POWER TOOL when you are

tired, after you have taken any medications, or have

consumed any alcoholic beverages.

4. Never use the POWER TOOL for applications not

specified in the instruction manual.

5. Never operate the tool while wearing loose clothing, a

necktie or jewelry, or while your hair is uncovered, to

protect against getting caught in the moving machinery.

6. Never reach around the saw blade.

7. Never touch any moving parts, including the blade,

while the saw is in use.

8. Never remove any safety devices or blade guards; use

of the tool without them would be hazardous.

9. Never lock the lower guard; always confirm that it slides

smoothly before using the tool.

10. Never damage the power cord of the tool.

11. Never attempt to move a plugged-in POWER TOOL

while your finger is on the starting switch.

12. Never use the POWER TOOL if the starting switch does

not turn on and offproperly.

13. Never use the POWER TOOL if the plastic housing or

the handle is cracked or deformed.

14. Never use the POWER TOOL near flammable liquids

or gases because sparking can cause an explosion.

15. Never clean plastic components with solvents because

the plastic may dissolve.

16. Never operate the saw unless all the blade guards are

in place.

17. Never raise the saw blade from the workpiece until it

has first come to a complete stop.

18. Never place your limbs inside of the line next to warning

sign “ ” while the tool is being operated. This may

cause hazardous conditions.

19. Never use abrasive type blades on this saw.

20. Never expose to rain or use in damp locations.

21. Never cut ferrous metals or masonry.

22. Do not replace the LED light with a different type.

23. Do not stand in a line with the saw blade In front of the

machine. Always stand aside of the saw blade. This

protects your body against possible kickback. Keep

hands, fingers and arms away from the rotating saw

blade.

24. Do not cross your arms when operating the tool arm.

WARNING

FOR YOUR OWN SAFETY READ THIS INSTRUCTION

MANUAL BEFORE OPERATING THE COMPOUND

MITER SAW

1. Always wear eye protection when using the compound

miter saw.

2. Always keep hands out of the path of the saw blade.

3. Never operate the saw without the guards in place.

4. Never perform any freehand operation with the

compound miter saw.

5. Never reach around the saw blade.

6. Always turn offtool and wait for saw blade to stop before

moving workpiece or changing settings.

7. Always disconnect power before changing blade or

servicing.

8. Saw blade diameter is 12" (305 mm).

9. No load speed is 4,300 /min.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

Repairs should be conducted only by a metabo HPT

authorized service center.

00BookC12FDHBNANA.indb600BookC12FDHBNANA.indb6 2021/01/2910:32:112021/01/2910:32:11