8DO NOT leave the sharpener running unattended.

8DO NOT operate the sharpener when you are tired or under the influence of alcohol, drugs or intoxicating medication.

9 When not in use switch grinder off, remove plug from power supply.

2. INTRODUCTION

Wet stone sharpening system with aluminium oxide particle stone and detachable water trough, suitable for HSS tools. Supplied with leather honing

wheel, grinding jig and angle guide.

3. SPECIFICATION

Model No:.............................................................. SMS2101

Motor Power:.................................................................180W

Electrical Supply .................................................. 230V-50Hz

Wheel Diameter ...............................................Ø200 x 40mm

Axle Diameter ........................................................... Ø12mm

No load Speed .............................................................95rpm

Grinding Stone .................................................Ø200 x 40mm

Leather Honing Wheel .....................................Ø200 x 30mm

Sharpening Wheel............................................SMS2101.SW

Leather Honing Wheel .....................................SMS2101.HW

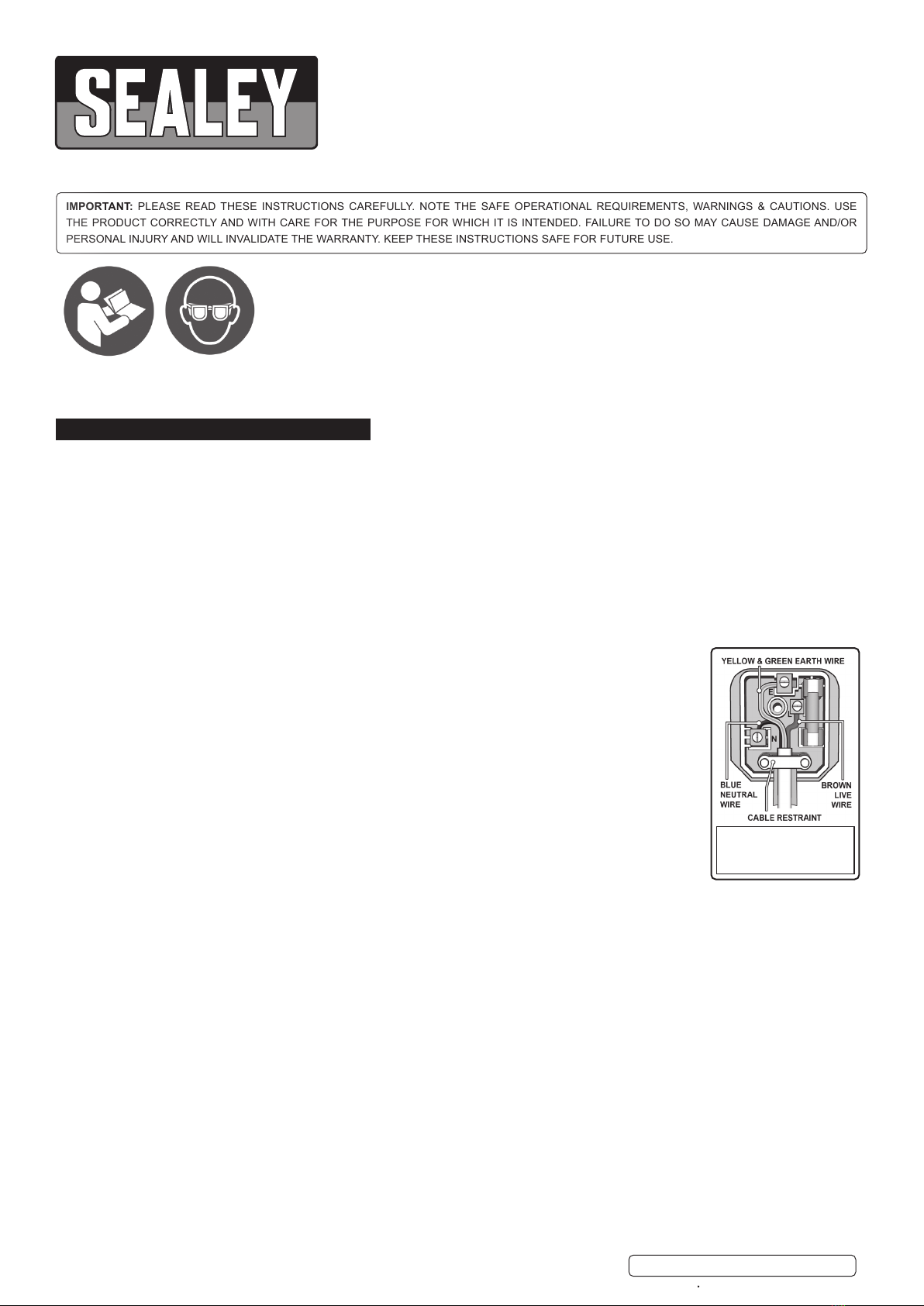

SEE FIG.1

A.........................................................................Power Cable

B...................................................................... On/Off Switch

C....................................................Detachable Water Trough

D........................................................................... Wet Stone

E..................................................... Cow Hide Honing Wheel

F...................................................................Tool Rest/Clamp

G..............................Adjustable Support for Tool Rest/Clamp

H...................................................................... Lifting Handle

4. ASSEMBLY

WARNING! Before assembly check to ensure grinder is unplugged from mains. Position on a at surface with sufcient

illumination.

4.1. TOOL REST

4.1.1. Fit adjustable support for tool rest fig.1G by unscrewing knobs and sliding rods into guides clamp in required position.

4.1.2. Side tool rest clamp fig.1F onto support.

4.2. WATER RESERVOIR

4.2.1. Position water reservoir fig.1C by hooking on to main body of sharpener.

4.2.2. Ensure water reservoir is clear of rotating wheel.

4.2.3. It is recommended to install the sharpener by mounting on a fireproof bench. Use the mounting holes to secure to work surface.

NOTE:- the machine has no front or rear side so you can grind with or against the direction of wheel rotation. When positioning

please consider access to On/Off switch fig.1B. G

5. GRINDING WHEELS

5.1. MANDATORY SAFETY INSTRUCTIONS. (The following instructions must be observed together with those in Section 1).

▲DANGER! Use of a damaged wheel (stone) is dangerous and may cause damage and/or personal injury.

5.1.1. WARNING! Ensure grinder is unplugged from mains supply before attempting to change grinding wheel (stone). Only persons

qualified under the “Abrasive Wheels Regulations” and holding a current grinding wheel certificate are authorised to change and dress

grinding wheels (stones).

5.1.2. Grinding wheels used with this machine must be of an adequate speed rating and suitable for the material to be ground.

5.1.3. Ensure the maximum speed specification of the wheel is higher than that indicated on the machine data plate.

5.1.4. Check that grinding wheels are secure and that wheels are not worn or damaged, that there are no fissures or cracks. If damaged

replace immediately.

5.1.5. Ensure replacement wheel is not damaged in any way such as cracks, deformations or splinters etc. Also check the mounting flanges

for deformation, burrs or chips. Damaged flanges must not be used as they may produce high stresses in the wheel causing it to

break. DO NOT over tighten a wheel. Never tamper with a wheel in order to adapt it to a different size shaft.

5.1.6. Install a new wheel as in 5.2. Once mounted on the grinder test the wheel before use by facing the grinder in a safe direction (point it

away from yourself, others and vulnerable items) and run for a short time. Dress the wheel if necessary.

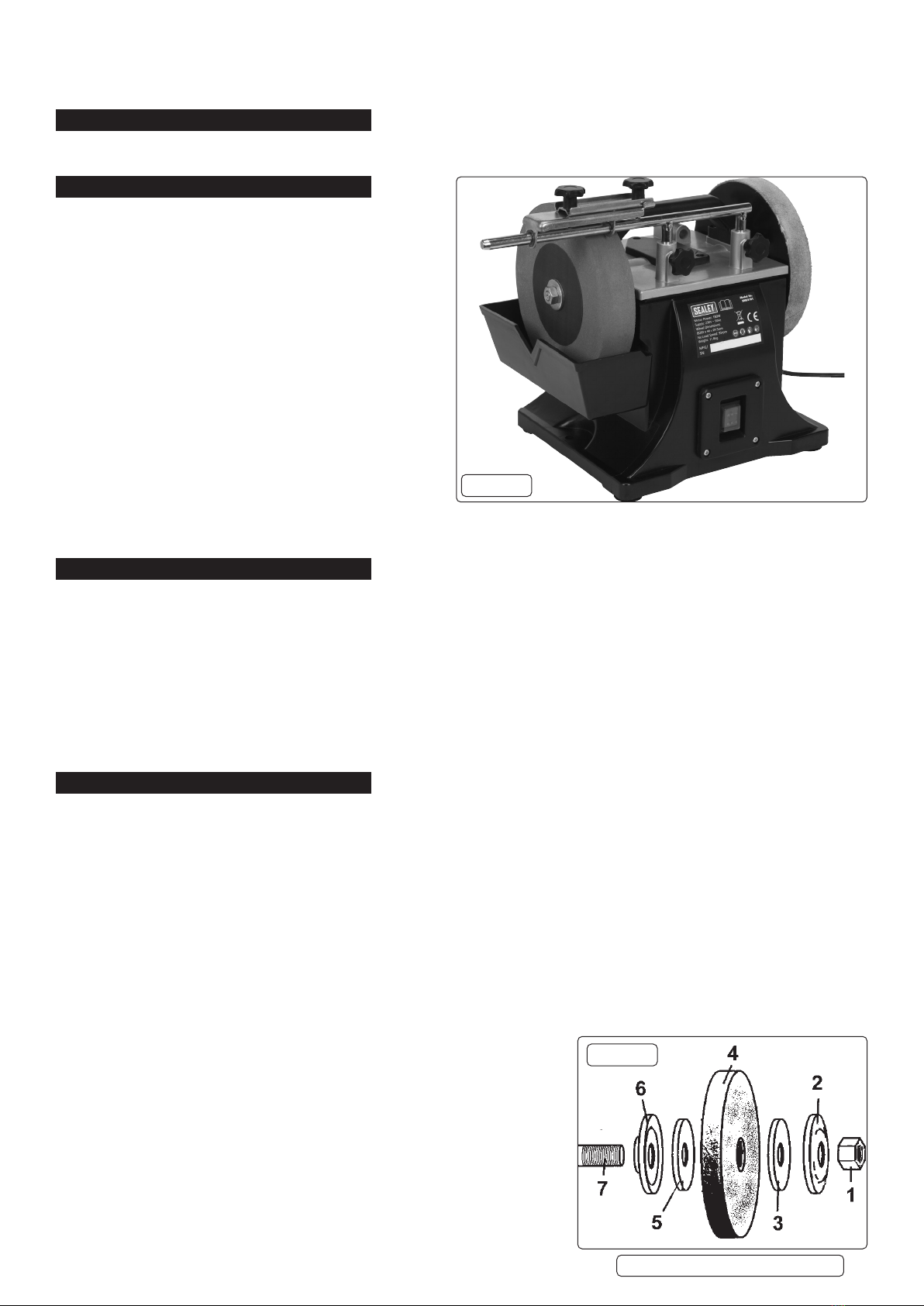

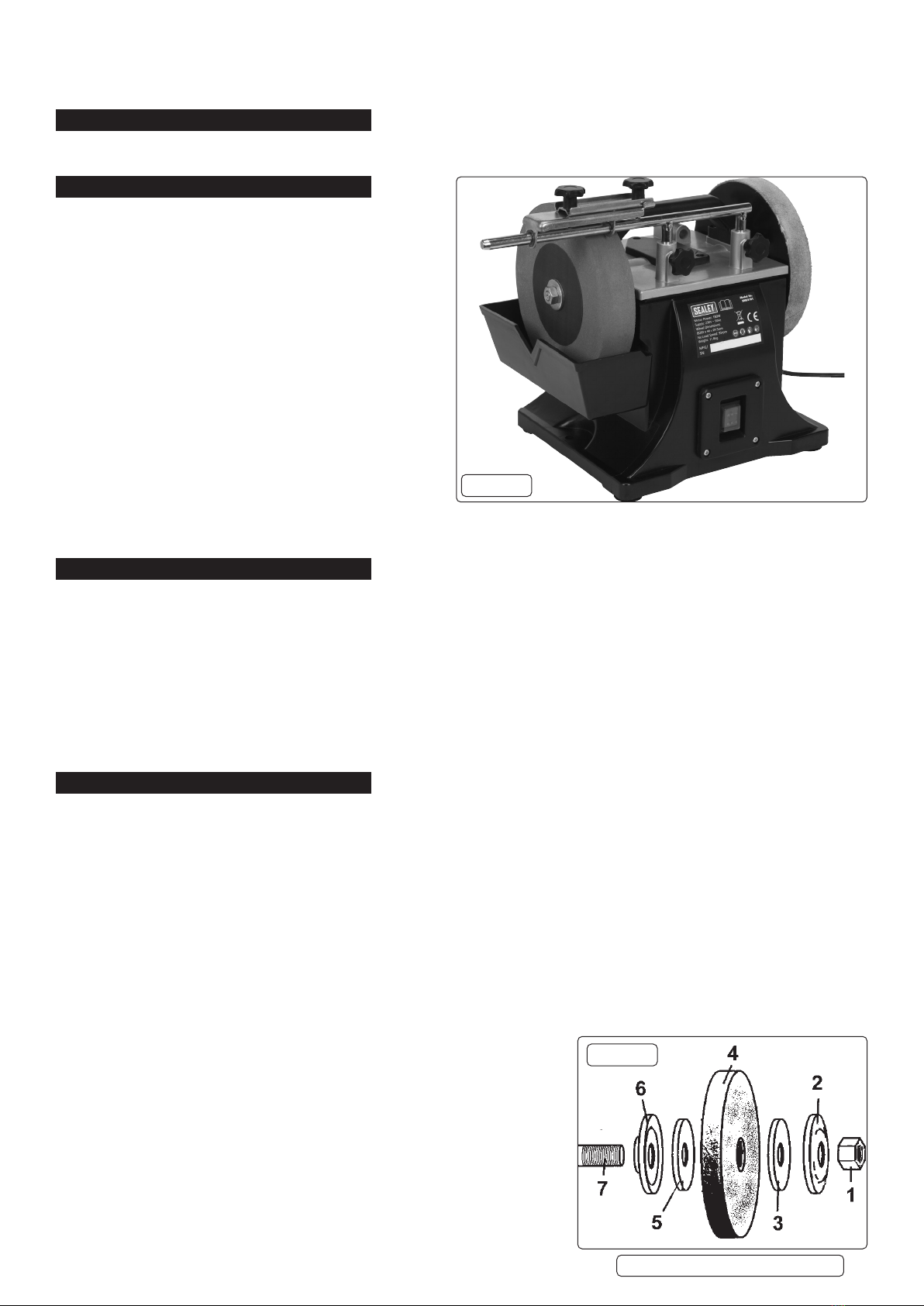

5.2. WHEEL CHANGING PROCEDURE

WARNING! Unplug sharpener from the mains power supply before changing

wheel.

5.2.1. Hold grinding wheel firmly - protect your hands with a cloth, or wear gloves.

5.2.2. Unscrew retaining nut fig.2.1.

Note: The nut has standard right-hand thread (undo anti-clockwise).and must be

loosened by turning anticlockwise. It may be necessary to strike the wrench sharply

in the loosening direction, with a soft-faced hammer, to loosen the nut.

5.2.3. Remove grinding wheel washer in order shown in fig.2 Carefully inspect the new

wheel before installing to ensure there are no fissures, chips, or cracks.

WARNING! DO NOT USE A DAMAGED WHEEL.

5.2.4. Inspect the blotters - if they are damaged, replace them. The grinder must never be

used without genuine wheel blotters.

5.2.5. Install the new wheel by reversing steps above.

Original Language Version

© Jack Sealey Limited

Fig.1

A

B

C

DE

F

G

H

SMS2101 Issue 3 (2,3,F) 11/05/21

Fig.2