Metasys B110LP User manual

Fire Initiating Devices and Notification Appliances Technical Manual 408

Conventional Products Section

Technical Bulletin

Issue Date 1095

© 1995 Johnson Controls, Inc. 1

Code No. LIT-408110

Introduction Page 3

●

General Description 4

Installation Procedures 5

●

General Information 5

●

Mounting 5

●

Wiring Installation Guidelines 7

●

Tamper-Proof Feature 10

●

Limitations 11

B110LP Plug-In Conventional Low Profile Detector Base

2 Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base

Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base 3

Introduction

This document contains important information about installing and

operating B110LP plug-in detector bases. These conventional detectors

are manufactured by System Sensor for use with Johnson Controls

systems. If you install this base for someone else to use, you must leave a

copy of this document with the user.

These instructions provide information regarding mounting, wiring, and

installation. Follow only those instructions that apply to the model you

are installing.

Before you install any B110LP plug-in detector bases, read and be familiar

with:

●the system’s control panel installation manual

●the requirements of the authority having jurisdiction

●National Fire Protection Association (NFPA) Standards 72-National

Fire Alarm Code

●System Sensor Guide for Proper Use of System Smoke Detectors

Technical Bulletin in the Fire Initiating Devices and Notification

Appliances Technical Manual (FAN 408) that provides detailed

information on detector spacing, placement, zoning, wiring, and

special applications

●or, for non-United States installations, applicable codes and standards

specific to the country and locality of installation

Failure to follow these directions may result in failure of this device to

report an alarm or trouble condition or respond properly to an alarm

condition. Johnson Controls is not responsible for devices that have been

improperly installed, tested, or maintained by others.

4 Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base

The B110LP 2-wire base is equipped with screw terminals for the

connection of power, ground, and an optional remote annunciator.

Table 1: Detector Head Models and Accessories Used with the

B110LP Detector Base

Model Description

1151 Ionization detector head

2151 Photoelectronic detector head

RA400Z Remote annunciator for 2- or 4- wire systems, 3-32V.

Fits standard, single gang box.

XR2 Detector removal tool

XP4 Extension pole for XR2. Three 5 foot sections.

Table 2: Specifications Summary

Base Diameter 6.2 in. (157 mm)

Base Height

Front of Backbox to Front of Detector 0.95 in. (24 mm)

Weight 0.3 lb (136 g)

Mounting

4 in. Square Box with or without Plaster Ring

3-1/2 inch Octagon Box Minimum depth is 1.5 in.

Minimum depth is 1.5 in.

Operating Temperature Range 32 to 120°F (0 to 49°C)

Operating Humidity Range 10 to 93% Relative Humidity

Non-condensing

General

Description

Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base 5

Installation Procedures

This section contains installation information for the B110LP plug-in

detector base. Instructions are given for mounting the base, and basic

installation information is provided.

!

CAUTION: Equipment hazard. Do not use in potentially

explosive atmospheres. Do not leave unused wires

exposed.

The detector base mounts directly to 3-1/2 inch (88.9 mm) and 4 inch

(101.6 mm) octagon boxes and 4 inch square boxes, with or without

plaster rings.

To mount the base:

1. Remove the decorative ring by rotating it in either direction to unhook

the snaps before separating the ring from the base.

2. Use the screws supplied with the junction box to attach the base to the

box through the appropriate slots in the base (Figure 1).

3. Position the decorative ring around the base and rotate it in either

direction until the ring snaps into place.

General

Information

Mounting

6 Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base

Snap-on

Decorative Rin

g

Screws

(

Not Supplied

)

Detector Base

Box

(

Not Supplied

)

mntbase3

Shortin

g

Jumper

Figure 1: Mounting Detector to Box

Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base 7

All wiring must be installed in compliance with the National Electrical

Code (NEC), all applicable local codes, and any special requirements of

the authority having jurisdiction, using the proper wire size. The

conductors used to connect smoke detectors to control panels and

accessory devices should be color-coded to reduce the likelihood of wiring

errors. Improper connections can prevent a system from responding

properly in the event of a fire.

For Initiating Device Circuit (IDC) wiring (the wiring between

interconnected detectors and the fire alarm control panel), it is

recommended that the wire be no smaller than No. 18 American Wire

Gauge (AWG) (1.0 square mm). Wire sizes up to No. 14 AWG

(2.1 square mm) for Terminals 8-14 and No. 12 AWG (3.3 square mm)

for Terminals 1-5 may be used with the base. For best system

performance, the IDC wires should be a twisted pair and installed in a

separate grounded conduit to protect the IDC from other types of circuits

in the system.

Smoke detectors and alarm system control panels have specifications for

the maximum allowable IDC resistance and supervision current. Consult

the control panel manufacturer’s specifications for the total IDC resistance

and supervisory current allowed.

The IDC zone wiring of the detector base should be checked before the

detector heads are installed in them. To make this possible, this base

contains a special spring-type shorting jumper. After a detector base is

properly wired and mounted on an electrical box, make sure that the

jumper spring is in contact with the base of Terminal 3. This temporary

connection shorts the negative-in and negative-out leads and permits the

wiring of the IDC to be checked for continuity.

Once all the detector bases have been wired and mounted and the IDC,

power, and optional releasing device control wiring has been checked, the

detector heads may be installed in the bases. The shorting spring in the

base will disengage when the detector head is turned into place.

Wiring

Installation

Guidelines

8 Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base

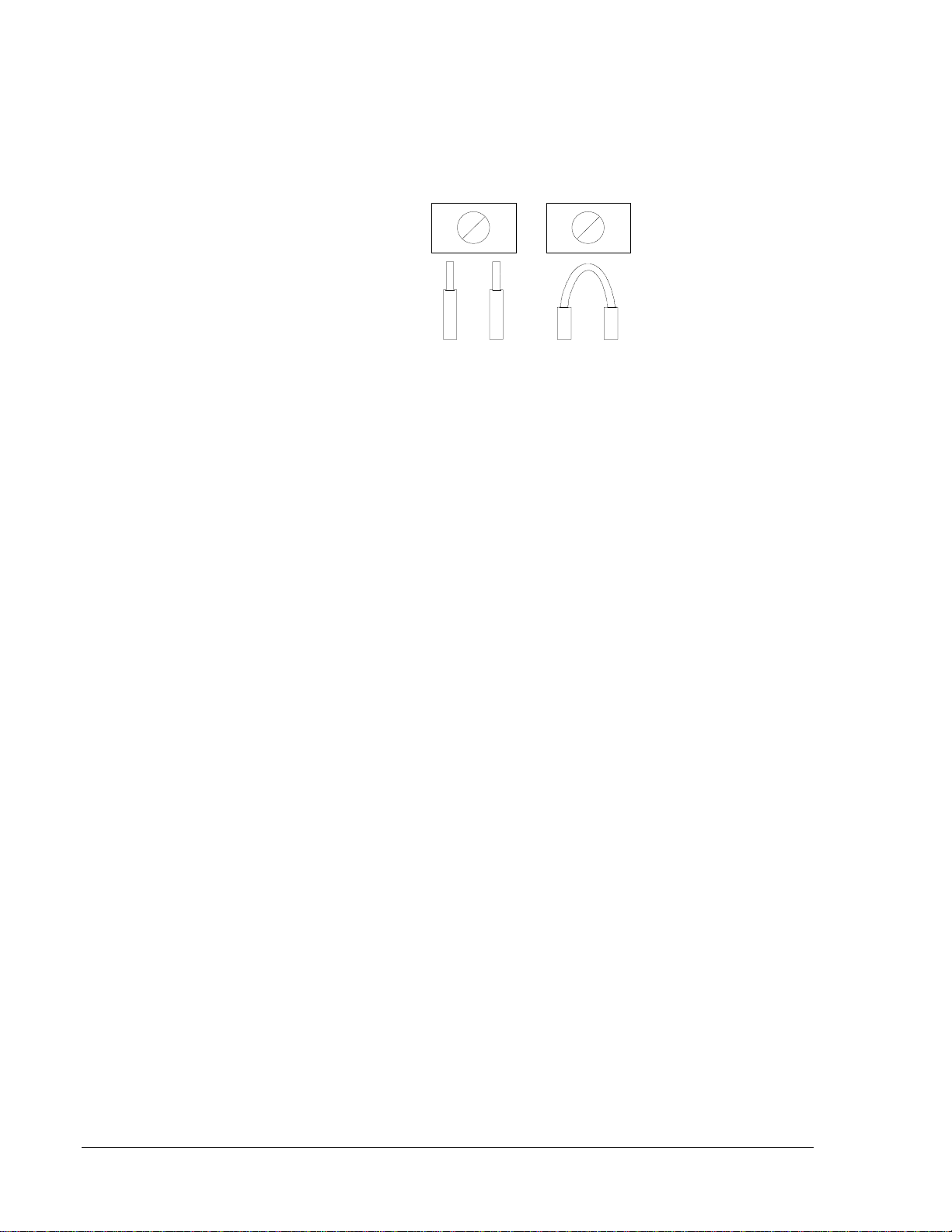

Note: Terminals 2, 3, and 5 do not use looped wire under terminals.

Break wire run to provide system supervision of connections.

This Not This

wirguide

Figure 2: Electrical Connections

To make wire connections:

1. Strip insulation from the end of the wire.

2. Slide the bare end of the wire under the clamping plate.

3. Tighten the clamping plate screw.

4. Use the strip gauge molded into the base for ease of wiring

to terminals.

The smoke detectors and mounting bases are marked with a compatibility

identifier located as the last digit of a five digit code stamped on the back

of the product. Connect detectors/mounting bases only to compatible

control units as indicated in the Device Compatibility Technical Bulletin in

the Fire Management Accessories Manual (FAN 445).

Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base 9

The IDC zone wiring of the detector base should be checked before the

detector heads are installed in them. To make this possible, this base

contains a special spring-type shorting jumper. After a detector base is

properly wired and mounted on an electrical box, make sure that the

jumper spring is in contact with the base of Terminal 3. This temporary

connection shorts the negative-in and negative-out leads and permits the

wiring of the IDC to be checked for continuity.

Once all the detector bases have been wired and mounted and the IDC

wiring has been checked, the detector heads may be installed in the bases.

The shorting spring in the base will disengage when the detector head is

turned into place.

Class A Optional Wirin

g

Remote

Annunciator

2base-a

3

2

1

4

5

2-wire

Control

Panel

Remote

Annunciator

3

2

1

4

5

E

O

L

Figure 3: Wiring Diagram for a Typical 2-Wire Detector System

10 Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base

Note: Do not use the tamper-proof capability if the XR2 removal tool

will be used to remove detectors from the base.

This detector base can be made tamper-proof so that the detector cannot be

detached without the use of a tool.

To make the base tamper-proof before installing the detector:

1. Break off the smaller tab at the scribed line on the tamper-proof tab on

the detector mounting bracket (Figure 4).

tmprprf

Plastic Lever

Break tab at

dotted line by

twisting toward

center of base.

Figure 4: Enabling the Tamper-Proof Feature

To remove the detector from the base after it has been made tamper-proof:

1. Remove the decorative ring by rotating it in either direction and

pulling it away from the base.

2. Insert a small screwdriver into the notch (Figure 5).

3. Press the plastic lever toward the mounting surface before rotating the

detector counterclockwise for removal.

remdetct

Use small-bladed

screwdriver to

push plastic lever

in direction of arrow.

Figure 5: Removing the Detector Head from the Base

The tamper-proof feature may be defeated by breaking and removing

the plastic lever from the base. However, this prevents using the

feature again.

Tamper-Proof

Feature

Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base 11

This smoke detector used with this base is designed to activate and initiate

emergency action, but will do so only when used in conjunction with other

equipment. This detector is designed for installation in accordance with

National Fire Protection Association (NFPA) Standards 71 and 72.

●Smoke detectors cannot work without power. Alternating Current

(AC) or Direct Current (DC) powered smoke detectors will not work

if the power supply is cut off for any reason.

●Smoke detectors will not sense fires which start where smoke does

not reach the detectors. Smoke from fires in chimneys, in walls, on

roofs, or on the other side of closed doors may not reach the smoke

detector and alarm it.

●A detector may not detect a fire developing on another level of a

building. For this reason, detectors should be located on every level

of a building.

●Smoke detectors have sensing limitations. Ionization detectors offer a

broad range fire-sensing capability, but they are better at detecting

fast, flaming fires than slow, smoldering fires. Photoelectronic

detectors sense smoldering fires better than flaming fires. Because

fires develop in different ways, and are often unpredictable in their

growth, neither type of detector is always best, and a given detector

may not always provide warning of a fire. In general, detectors

cannot be expected to provide warnings for fires resulting from

inadequate fire protection practices, violent explosions, escaping gas,

improper storage of flammable liquids like cleaning solvents, other

safety hazards, or arson.

Smoke detectors compatible with this base are UL Listed to operate in

specific maximum air velocities. Air velocity, along with other

factors, may affect detector sensitivity. To find out the air velocities

of specific detectors, see the appropriate technical bulletin. For more

information, see the 1993 NFPA-72-National Fire Alarm Code,

Appendix B.

●Test your smoke detector system per NFPA 72-National Fire Alarm

Code or codes and standards specific to the country of installation, at

least semiannually. Clean and take care of your smoke detectors

regularly. Taking care of the fire detection system you have installed

will measurably reduce your product liability risks.

Limitations

12 Conventional Products—B110LP Plug-In Conventional Low Profile Detector Base

Notes

Controls Group FAN 408

507 E. Michigan Street Fire Initiating Devices and Notification Appliances Technical Manual

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201

Table of contents

Other Metasys Safety Equipment manuals