ENGLISH

CHAPTER

........................................................

1

Chapter for the technician and operator

1.1

GENERAL WARNINGS

.......................................Page GB-3

1.2

REFERENCE NORMATIVE

.................................Page GB-4

1.3

DESCRIPTION OF THE SYMBOLS

.....................Page GB-4

1.4

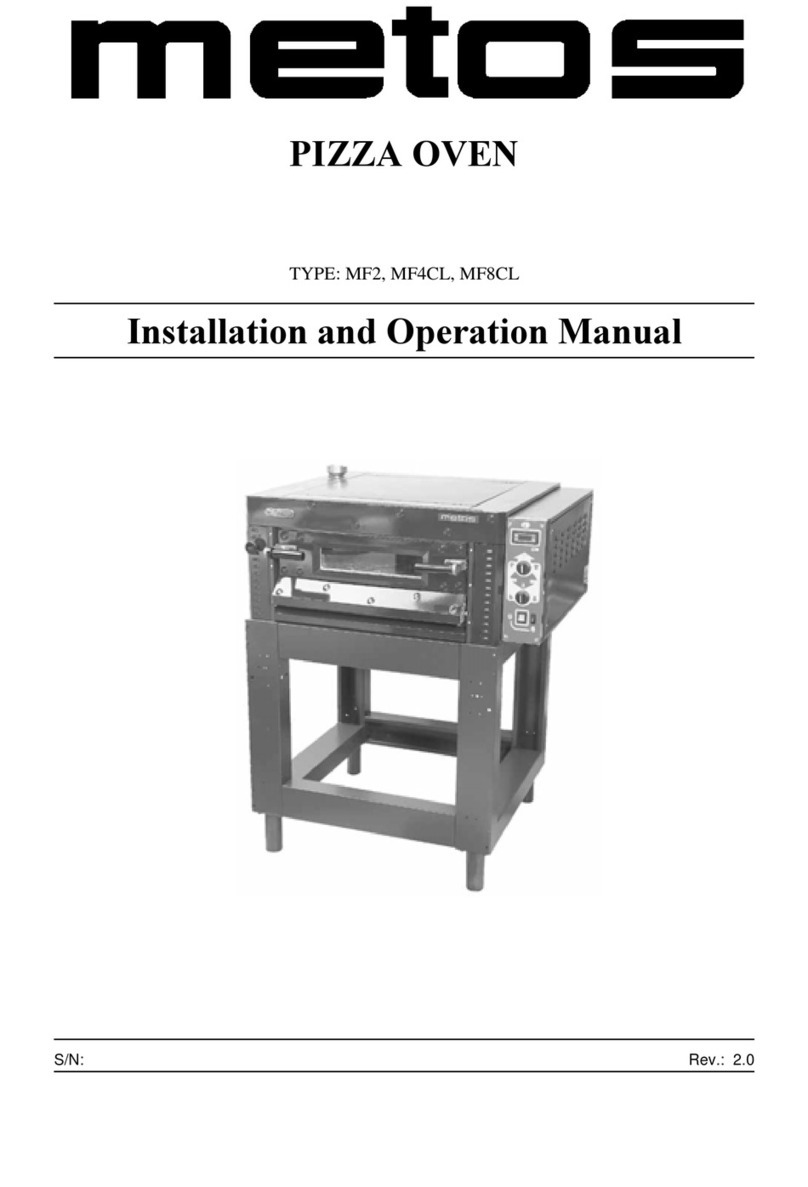

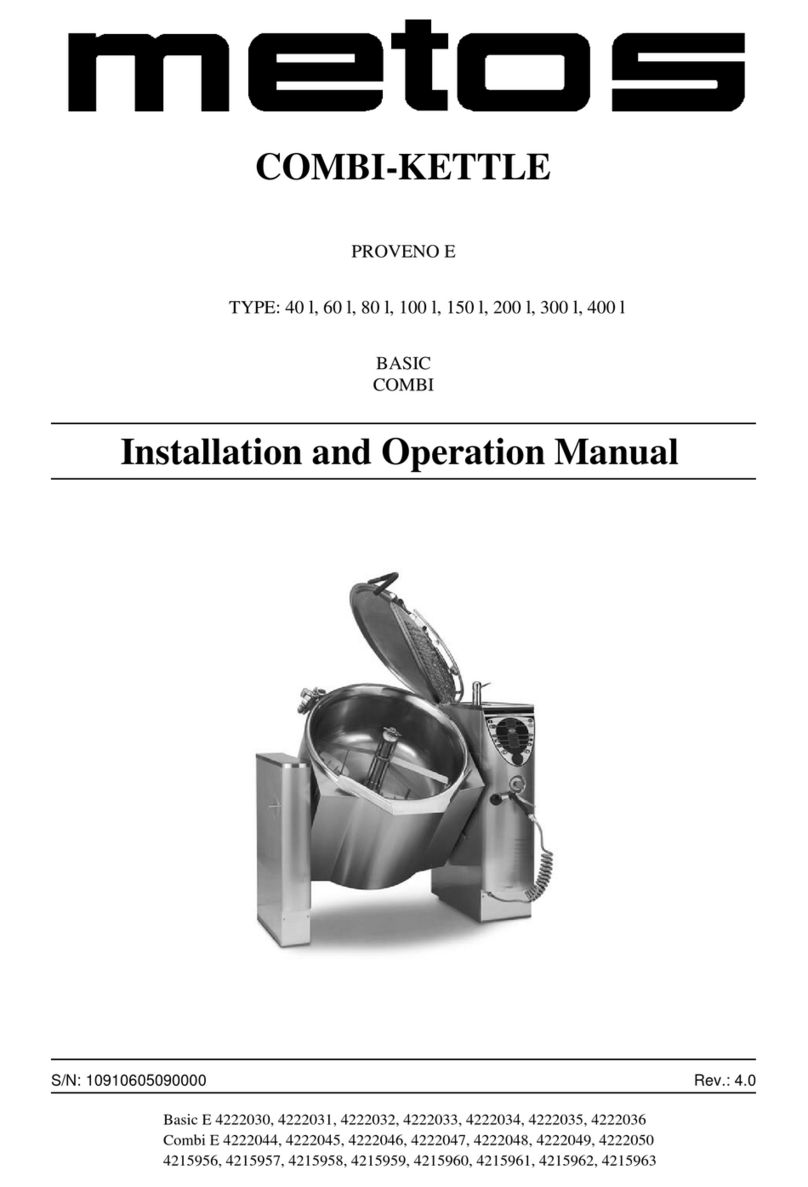

OVEN COMPOSITION

.........................................Page GB-4

1.5

PREARRANGEMENTS AT PURCHASER’S

CHARGE

.............................................................Page GB-5

1.6

EMERGENCY OPERATIONS

IN CASE OF FIRE

..............................................Page GB-5

1.7

EXPLOSION RISK

...............................................Page GB-5

1.8

ACOUSTIC PRESSURE LEVEL

.........................Page GB-5

CHAPTER

........................................................

2

Chapter for the technician

-

OVERALL DIMENSIONS

..........................................Page GB-6

2.1

TECHNICAL FEATURES

...................................Page GB-7

2.2

TRANSPORT

......................................................Page GB-9

2.2.a

Shipment

....................................................Page GB-9

2.2.b

Lifting of the packing

...................................Page GB-9

2.2.c

Storage

......................................................Page GB-9

2.3

RECEPTION OF THE MACHINE

.......................Page GB-10

2.4

UNPACKING

.....................................................Page GB-10

2.5

IDENTIFICATION OF THE COMPONENTS

........ Page GB-11

2.6

OVEN IDENTIFICATION

.................................... Page GB-11

CHAPTER

........................................................

3

Chapter for the technician

3.1

OVEN LIFTING

..................................................Page GB-12

3.2

ASSEMBLING OF THE COMPONENTS

..........Page GB-12

3.3

ELECTRICAL CONNECTION

............................Page GB-14

3.3.a

Electric oven connection

...........................Page GB-14

3.3.b

Electric hood connection

...........................Page GB-15

3.3.c

Unipotential connection

.............................Page GB-15

3.4

OVEN POSITIONING

........................................Page GB-15

3.4.a Chimney connection................................Page GB-15

3.5

FIRST STARTING

..............................................Page GB-15

CHAPTER

........................................................

4

Chapter for the technician and operator

4.1

TYPE OF USE AND

CONTRAINDICATIONS

.....................................Page GB-16

4.2

SAFETY PLATES

.............................................Page GB-16

4.3

SAFETY DEVICES

............................................Page GB-17

4.4

USER’S AREAS

.................................................Page GB-17

4.5

RESIDUAL DANGER AREAS

.............................Page GB-17

CHAPTER

........................................................

5

Chapter for the technician and operator

5.1

OVEN CONTROL BOARD

.................................Page GB-18

5.2

OVEN PREPARATION

.......................................Page GB-19

5.2.a

Oven starting

............................................Page GB-19

5.3

PIZZA BAKING

..................................................Page GB-20

5.4

SELF-CLEANING CYCLE

..................................Page GB-20

5.5

CUTTING OFF

..................................................Page GB-20

5.6

MALFUCTIONING,CAUSE AND CURE

..............Page GB-21

5.7

SAFETY THERMOSTAT RECHARGE

...............Page GB-21

CHAPTER

........................................................

6

Chapter for the technician and operator

6.1

ROUTINE AND PLANNED MAINTENANCE

.....Page GB-22

6.1.a

In general

...............................................Page GB-22

6.1.b

Ordinary maintenance

.............................Page GB-22

6.1.b - a

Outer cleaning

(to be carried out every day).................

Page GB-22

6.1.b - b

Fireproof surface cleaning

(to be carried out every day)

..............Page GB-22

6.1.c

Planned maintenance

.............................Page GB-23

6.1.c - a

Every 600 hours a careful

chamber cleaning

..............................Page GB-23

6.1.c - b

Every 2 years

...................................Page GB-23

6.1.d

Maintenance in case of need

....................Page GB-23

6.1.d - a

Lamp holder replacement

..................Page GB-23

6.1.d - b

lamp replacement

...............................Page GB-24

6.1.d - c

Ceiling or bedplate resistance

replacement

.....................................Page GB-24

6.1.d - d

Door spring replacement

..................Page GB-25

6.1.d - e

Door pane replacement

....................Page GB-26

CHAPTER

........................................................

7

Chapter for the technician

7.1

OVEN DISASSEMBLY

.......................................Page GB-27

7.2

OVEN SCRAPPING

...........................................Page GB-27

7.3

DISPOSING OF HARMFUL SUBSTANCES

........Page GB-27

WIRING DIAGRAM

DM 430-435

V400 Trifase

.............................................................Page GB-28

WIRING DIAGRAM DM 430-435

V230 Single-phase

....................................................Page GB-29

WIRING DIAGRAM DM 430-435

V230 Trifase .................................................................

Page GB-30

WIRING DIAGRAM DM 630-635

V400 Trifase .................................................................

Page GB-31

WIRING DIAGRAM DM 630-635-930-935

V230 Trifase .................................................................

Page GB-32

WIRING DIAGRAM DB 830-835

V400 Trifase .................................................................

Page GB-33

WIRING DIAGRAM DB 830-835

V230 Trifase .................................................................

Page GB-34

WIRING DIAGRAM DB 1230-1235

V230 Trifase .................................................................

Page GB-35

WIRING DIAGRAM DB 1230-1235

V400 Trifase .................................................................

Page GB-36

OVEN CAPTION 430-435 V400/230

..........................Page GB-37

OVEN CAPTION 630-635-930-935 V400/230

............Page GB-37

OVEN CAPTION 830-835 V400/230

..........................Page GB-38

OVEN CAPTION 1230-1235 V400/230

......................Page GB-39

COLOURS

................................................................Page GB-39