6

safety:

The machine is designed for the manufacture

of products that do not trigger any reactions or

release substances that may be harmful to the

user when in use.

Usersmustbe over 14yearsofageand trained

in the use of the machine according to these

instructions.

User safety is assured as follows:

• Tools can only rotate when the safety guard is in place

and the bowl is lifted.

• The safety guard is made of plastic. It is not possible

to attach the guard incorrectly.

• No access to rotating tools.

• Thespreadofourdustisinhibited

• Equipped with emergency stop - The tool stops rotat-

ing in less than 4 seconds (also for normal shut-down

and stop via safety guard).

• Clearancebetweenguard/standandliftinghandleat

least 50 mm.

• Noise level under 70 dB.

• Machine remains stable on a slope of up to 10o

The machine is protected against overvoltage.

The machine should be positioned to allow space for nor-

mal use and maintenance.

Non-ionisingradiationisnot produced intentionally,butrather

technically conditioned by electrical equipment (e.g. electric

motors, live power lines or solenoids). The machine is not

equipped with strong permanent magnets. By maintaining

asafedistance(betweentheeldsourceandimplant)of

30 cm, any impact on active implants (e.g. pacemakers,

debrillators)canlikelybeprevented.

The following recommendations apply to work with

powdery ingredients:

• Powdery ingredients should not be poured into the

bowl from a great height.

• Bagsofe.g.ourshouldbeopenedatthebottom,

down in the bowl.

• Do not run up to the maximum speed too quickly.

There is a risk of injury if the machine is not

earthed.

It must be ensured that the cable used to

connect the machine to the mains meets the

standard for the country in which the machine

isinstalled. Seealso ‘Electrical Connection’.

Placing your hands in the bowl while the ma-

chine is running may cause physical injury.

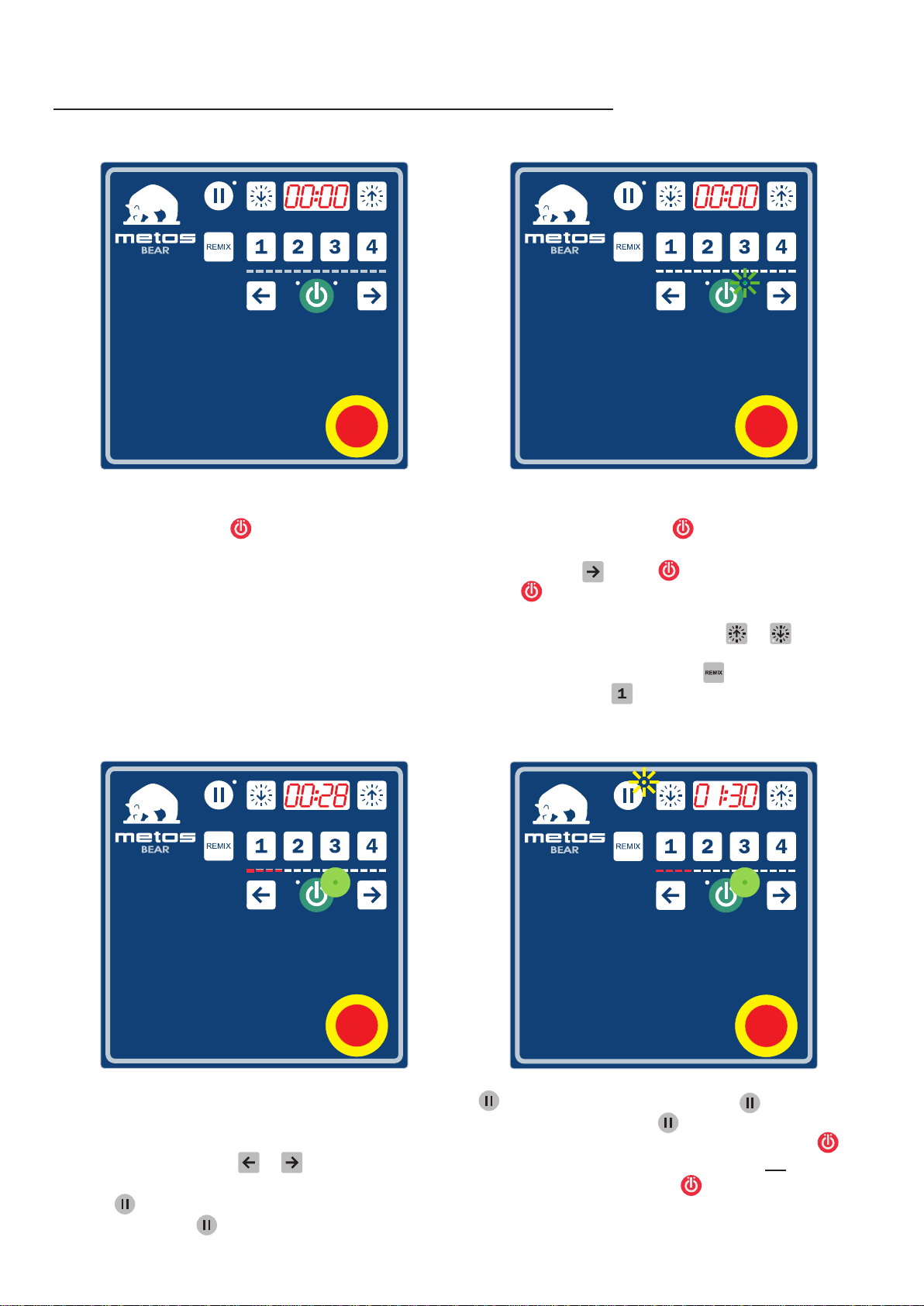

CorreCt Use of tools:

Recommended uses of tool:

The whip should not be struck against hard

objects such as the edge of the bowl. This will

shorten the life of the tool because of increasing

deformation.

Tomake mashedpotato,use thebeaterand then

the standard whip.

CleaninG:

The machine may only be cleaned by trained

staff over 14 years of age.

The machine should be cleaned daily after use. It should be

wipedwitha soft brush and clean water.Sulphonatedsoaps

should be used with care, as they destroy the lubricants in

the machine.

The machine should never be rinsed with a hose.

Aluminium parts should not be used for strongly

acidic,alkaline orsaline foodproducts, which may

attack non-coated aluminium.

Aluminium mixer tools must not be washed in

stronglyalkalineagents(pH between 5.0 and8.0).

Please note that the plastic safety guard may be

damaged if it is exposed to high temperatures for

a prolonged period. (Max. temperature 60ºC)

The soap suppliers may be able to help by recommending

the right type of soap.

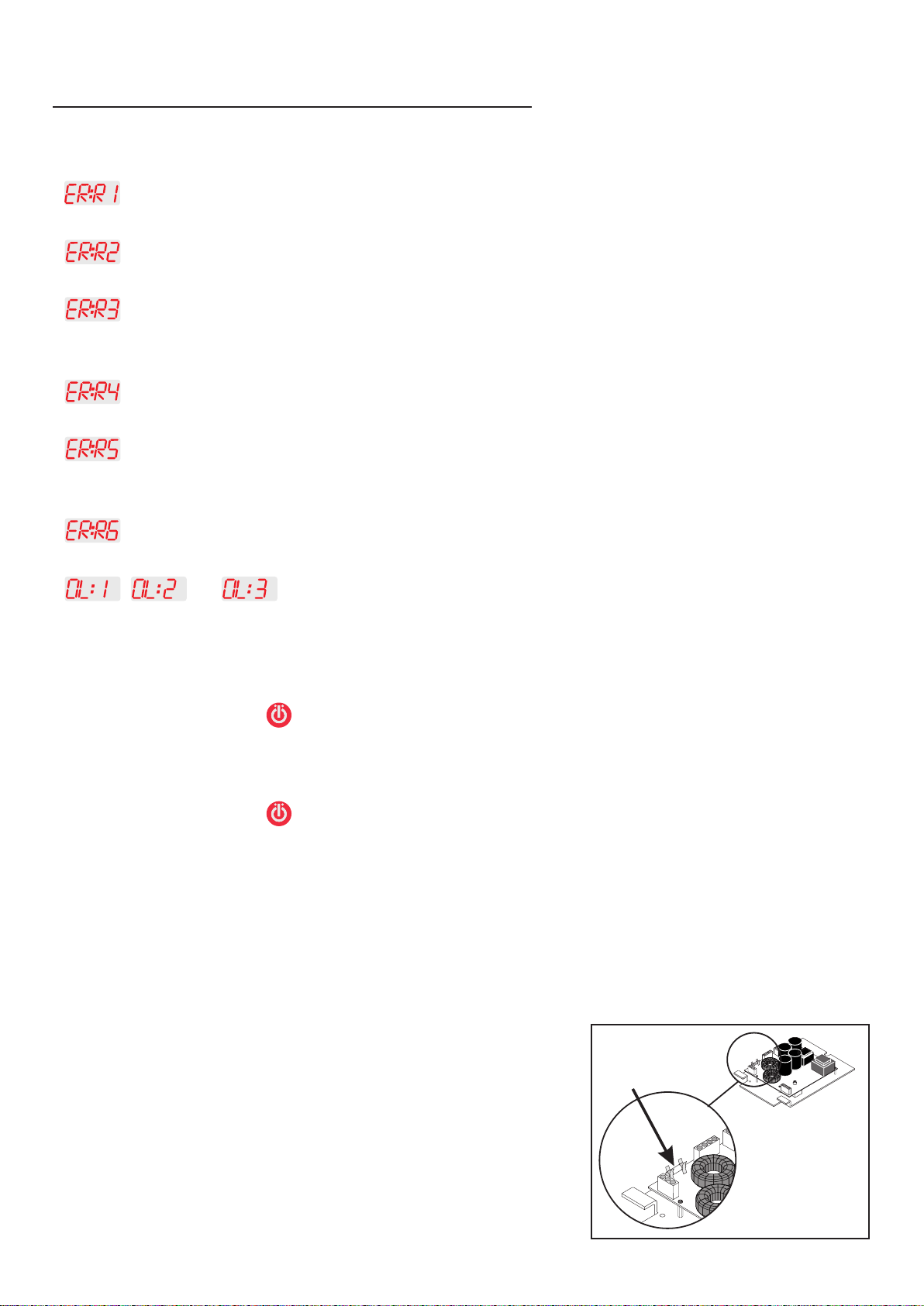

lUbriCation and Grease types:

Lubrication and other servicing may only be car-

ried out by trained staff over 14 years of age.

The lid of the mixer may only be removed when

thecable tothe mainssupply hasbeen removed.

Whenrepairs are madetothemixerhead, thegearwheeland

internal gear should be lubricated with Molub Alloy 936SF

Heavy or Castrol Grippa 355,but the needle bearingsinthe

mixerheadshould not be lubricated with thistype ofgrease.

Ifthemachine is supplied with an attachmentdrive, thegear

for the attachment drive should be lubricated with TOTAL

Ceran CA.

Donotuseanyothergreasetypesthanthosespeciedabove.

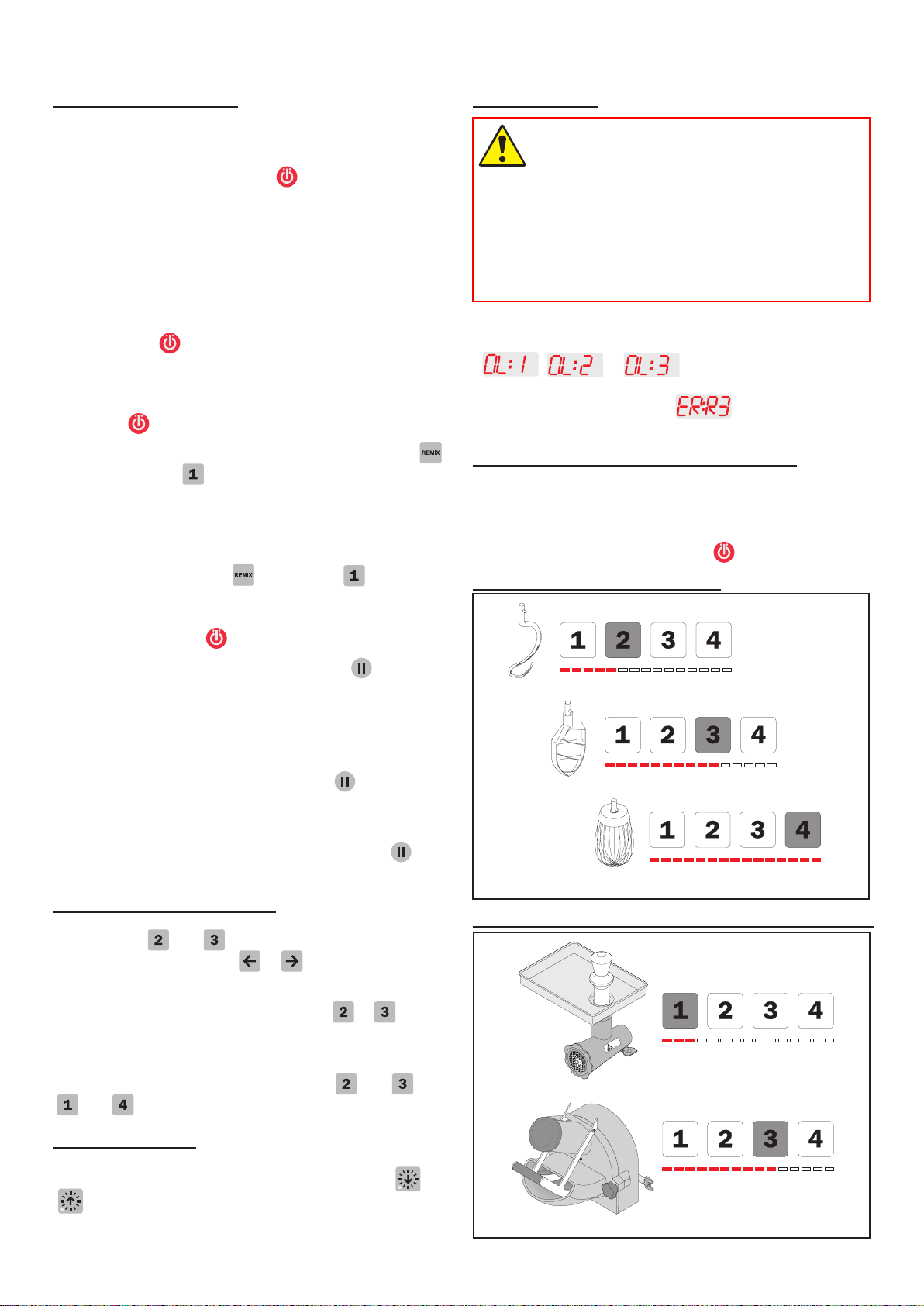

attaChment drive:

Themachinemaybettedwithanattachmentdriveinto

which optional accessories, such as meat mincers and

vegetable cutters, can be attached.

For further information on the assembly and use of optio-

nal accessories, please refer to the manual that comes

with the accessory.

The machine must be shut down when the ac-

cessoryisttedtotheattachmentdrive.

Whip Beater Hook

Cream Cake mix Bread dough

Egg whites Buttercream Rye bread

Mayonnaise Wafemix etc.

etc. Forcemeat

etc.