MANOMETER DPC 20

Page 2 INTRODUCTION

CONTENTS

1. INTRODUCTION .....................................................................................................3

1.1 Presentation of the product ................................................................................3

1.2 Precautions ........................................................................................................3

1.3 Features.............................................................................................................4

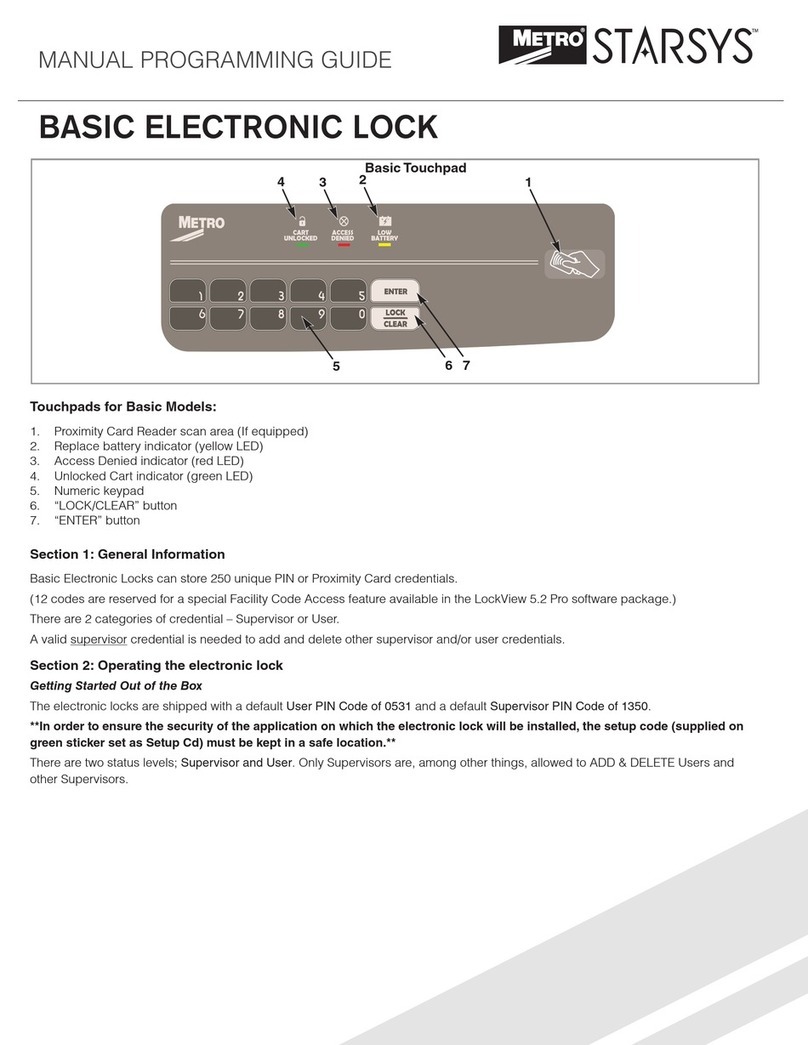

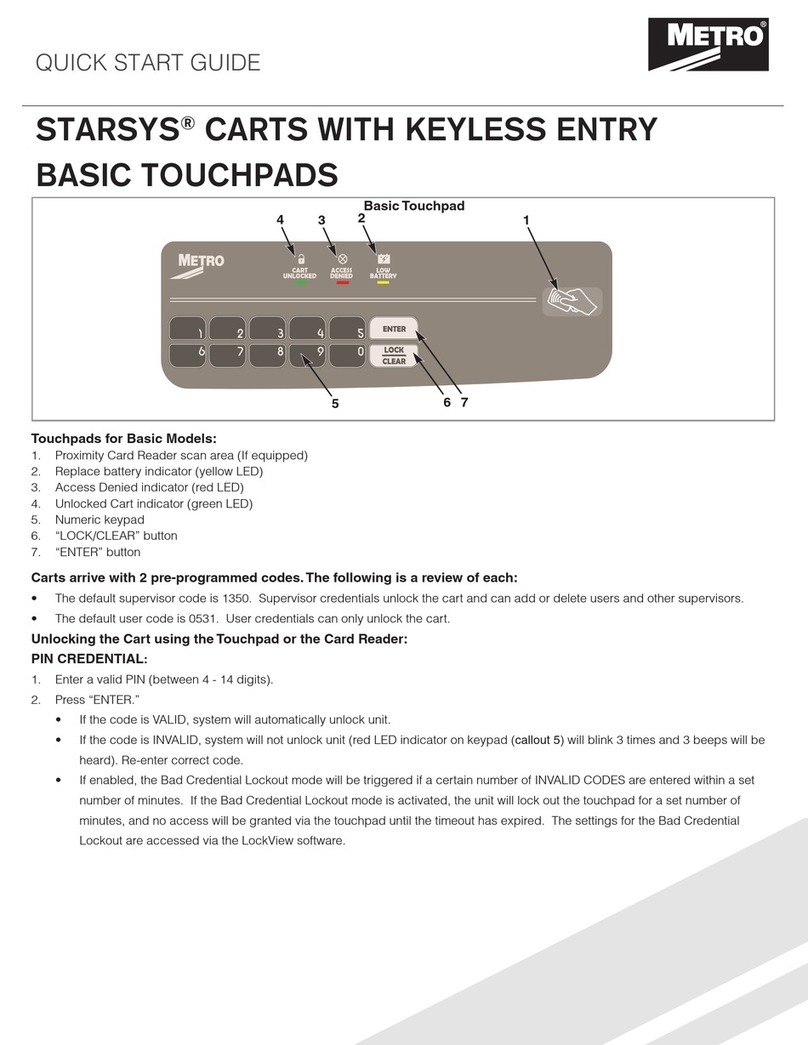

1.4 Front panel.........................................................................................................5

1.5 Battery charge....................................................................................................5

2. CONFIGURATION OF PARAMETERS ...................................................................6

2.1 Unit of measure..................................................................................................6

2.2 Displayed value..................................................................................................7

2.3 Limits of tolerance..............................................................................................7

2.4 Sample size .......................................................................................................7

2.5 Mastering ...........................................................................................................8

2.6 Measurement of differential pressure.................................................................9

2.6 Overview of setting options for parameters........................................................9

3. HOW TO MEASURE .............................................................................................10

3.1 Measuring without recording of values.............................................................10

3.2 Measuring with recording of values (SPC application) .....................................10

3.3 Measurement of differential pressure...............................................................11

4. USING THE DPC 20 WITH THE SPC 400 AEROSOL..........................................11

4.1 Using the manometer permanently connected.................................................11

4.2 Walking around measurements with data download ........................................11

5. HOW TO USE THE SERIAL LINK (RS-232) .........................................................12

5.1 The RS-232 connector .....................................................................................12

5.2 Commands.......................................................................................................12

5.2.1 Transfer of the measurement made on part number n..................................12

5.2.2 Transfer of all memorized measurements and reset of memory ...................13

5.2.3 Transfer of all memorized measurements.....................................................14

5.2.4 Transfer and erasure of memorized measurements one by one...................14

5.2.5 Reset of all memorized measurements.........................................................14

5.2.6 Imposed stand-by..........................................................................................15

6. MAINTENANCE OF THE MANOMETER ..............................................................15