Metso Outotec Nordtrack J127 User manual

For more information and

language versions, see:

mogroup.com/driving

Nordtrack J127

'RF1R'20717-EN5HYLVLRQ

ಘ2ULJLQDOLQVWUXFWLRQV

DRIVING ,16758&7,21S

Copyright © Metso Outotec.

Table of Contents

1. DRIVING INSTRUCTIONS ................................................................................................................... 1

1.1. SAFETY ...................................................................................................................................... 1

1.2. DRIVING DIRECTIONS .............................................................................................................. 2

1.3. EMERGENCY STOP LOCATIONS ............................................................................................ 3

1.4. REMOTE STOP LOCATION ...................................................................................................... 4

1.5. DRIVE CONTROLS .................................................................................................................... 4

1.5.1. Remote control device ................................................................................................. 4

1.6. PREPARING FOR DRIVING ...................................................................................................... 6

1.6.1. Starting the engine ....................................................................................................... 8

1.6.2. Connecting the remote control device (wireless connection) ..................................... 17

1.6.3. Connecting the remote control device (wired connection) ......................................... 18

1.6.4. Unlocking the remote control device .......................................................................... 19

1.7. DRIVING ................................................................................................................................... 20

1.8. STOPPING THE ENGINE ........................................................................................................ 22

1.9. TROUBLESHOOTING .............................................................................................................. 23

1.9.1. Pairing the remote control device and machine ......................................................... 24

DRIVING INSTRUCTIONS

1. DRIVING INSTRUCTIONS

These driving instructions are valid for Nordtrack J127 machines. The purpose of these instructions is to

enable safe moving of the machine during transportation.

NOTICE: Do not use the machine for crushing solely based on these instructions. The

actual instruction manual for the machine is delivered separately.

NOTICE: In these driving instructions, it is assumed that the machine is in the transport

position. If needed, see the actual instruction manual of the machine for

information on how to prepare the machine for transportation.

1.1. SAFETY

Because of the size and weight of the machine, pay special attention when moving the machine. It is highly

recommended that a banksman is used when the machine is moved.

DANGER!

GENERAL HAZARD

Will cause death or serious injury.

Read the safety section before working with the machine. Only competent and

trained personnel are allowed to work with the machine.

WARNING!

PERSONAL INJURY HAZARD

Can cause death or serious injury.

Before starting and during track driving the machine, make sure that there

are no persons in the area whose safety may be endangered. Establish a

buffer zone of at least 4.5 m (15 feet) around the machine. Walk around the

machine and make sure that there is nobody on, by or below the machine.

Warn everybody in the vicinity before starting.

WARNING!

CRUSHING HAZARD

Can cause death or serious injury.

Do not drive the machine in locations where there is a risk of squeezing.

Always drive the machine from a safe distance. If possible, drive the machine

from either end of the machine.

DRIVING INSTRUCTIONS D100020717-EN

490 0 EN 2022-09-27

1

DRIVING INSTRUCTIONS

WARNING!

UNEXPECTED MOVEMENT HAZARD

Can cause death or serious injury.

Be extremely cautious when driving in cold temperatures (below 0°C). The

response time of the controls might be longer than usual due to stiff hydraulic

oil.

WARNING!

COLLISION HAZARD

Can cause death or serious injury.

Pay attention to the machine dimensions to avoid power lines, bridges,

branches, and other obstacles.

1.2. DRIVING DIRECTIONS

4

3

2

1

Callout Description Callout Description

1 Forward 2 Backward

3 Left 4 Right

2 D100020717-EN

490 0 EN 2022-09-27

DRIVING INSTRUCTIONS

DRIVING INSTRUCTIONS

1.3. EMERGENCY STOP LOCATIONS

DANGER!

GENERAL HAZARD

Will cause death or serious injury.

In a dangerous situation, stop the machine with the emergency stop button,

the key switch of the machine, or with the remote stop button (located on

either the drive control device, radio control device). Before starting the

machine, make sure you know the location of the emergency stop buttons.

1

2

Figure 2: Locations of emergency stop buttons

Callout Description

1 On the left side of the machine

2 On the right side of the machine

DRIVING INSTRUCTIONS D100020717-EN

490 0 EN 2022-09-27

3

DRIVING INSTRUCTIONS

1.4. REMOTE STOP LOCATION

DANGER!

GENERAL HAZARD

Will cause death or serious injury.

In a dangerous situation, stop the machine with the emergency stop button,

the key switch of the machine, or with the remote stop button. Before starting

the machine, make that sure you know the location of the emergency stop

buttons.

Figure 3: Location of remote stop button

The remote stop button on the remote control device, if fitted, is not an emergency stop but can be used for

stopping the machine.

1.5. DRIVE CONTROLS

1.5.1. REMOTE CONTROL DEVICE

CAUTION!

GENERAL HAZARD

Will cause death or serious injury.

In a dangerous situation, stop the machine with the emergency stop button,

the key switch of the machine, or with the remote stop button (located on radio

control device). Before starting the machine, make sure you know the location

of the emergency stop buttons.

4 D100020717-EN

490 0 EN 2022-09-27

DRIVING INSTRUCTIONS

DRIVING INSTRUCTIONS

WARNING!

UNEXPECTED MOVEMENT HAZARD

Unexpected movement can cause death or serious injury.

Make sure that the cable (if fitted) of the remote control device does not get

caught in the tracks or in any other moving part of the machine during driving.

The remote control device must be disconnected from the machine

immediately after driving and stored in a safe place when not in use.

Only lift and hold the remote control device by its handles. Do not pull the

device from the cable or drag or move it otherwise.

Callout Description

1 Track left and right track together forward/reverse

2 Right hand track forward/reverse

3 Track driving speed (Slow/Intermediate/Fast)

4 Lock status LED

• Flashing green indicates that the radio control device is locked

• Non flashing green indicates that the radio control device is

unlocked

• Flashing red indicates that the radio control device is charging

5 Lock/unlock

6 Engine stop request

7 RF status LED

• Green when paired with machine and in range

• Red when unpaired with machine or out of range

8 Left hand track forward/reverse

Figure 4: Remote control device

DRIVING INSTRUCTIONS D100020717-EN

490 0 EN 2022-09-27

5

DRIVING INSTRUCTIONS

1.6. PREPARING FOR DRIVING

1. On the left-hand side of the machine, locate the main switch (1) and turn it to ON position.

1

Figure 5: Main switch

2. Visually inspect that there are no loose parts, and everything is secured in place.

3. Locate the control panel. It is located in the power unit on the right-hand side of the machine.

1

Figure 6: Control panel location (1)

6 D100020717-EN

490 0 EN 2022-09-27

DRIVING INSTRUCTIONS

DRIVING INSTRUCTIONS

1

3

4

5

6

7

2

Figure 7: Control panel

Callout Description Callout Description

1 Physical buttons: the functions of the

buttons depend on the menu options

that are displayed on the screen. See

figure below for the physical button

names.

5 Key switch: Crank position

2 Key switch (Ignition switch) 6 Panel lock: when the machine is

oprating, the panel must be locked

(panel lock in horizontal position).

3 Key switch: OFF position 7 LCD screen

4 Key switch: Power ON position

(includes engine pre-heat)

DRIVING INSTRUCTIONS D100020717-EN

490 0 EN 2022-09-27

7

DRIVING INSTRUCTIONS

Figure 8: Control panel physical buttons

4. Make sure that the emergency stop buttons are not pressed, and that the remote stop button is not

pressed down.

5. Proceed to the next section: “Starting the engine”.

1.6.1. STARTING THE ENGINE

WARNING!

EXPLOSION HAZARD

Can cause death or serious injury.

Do not use startup spray or similar to help the engine start, because it might

cause a destructive explosion in the induction manifold.

WARNING!

PERSONAL INJURY HAZARD

Can cause death or serious injury.

Before starting the machine, make sure that there are no persons in the area

whose safety may be endangered. Walk around the machine and make sure

that there is nobody on, by or below the machine. Warn everybody in the

vicinity before starting.

NOTICE: Wear personal protective equipment at all times. Make sure that no personnel

are on the machine.

8 D100020717-EN

490 0 EN 2022-09-27

DRIVING INSTRUCTIONS

DRIVING INSTRUCTIONS

1. Observe all safety warnings.

2. Check that all control levers are in neutral (OFF) position, and all emergency stops are released.

CAUTION!

PROPERTY DAMAGE HAZARD

Can cause moderate injury or property damage.

Make sure that all control levers are in the neutral (OFF) position.

1

Figure 9: Control levers (1) in neutral (OFF) position

3. Insert the key into the ignition switch of main control panel.

4. Turn the key clockwise to the Power ON position (2). The display will start its boot sequence followed

by entry into the main menu view.

DRIVING INSTRUCTIONS D100020717-EN

490 0 EN 2022-09-27

9

DRIVING INSTRUCTIONS

1

2

3

Callout Description

1 OFF

2 Power ON

3 Crank

Figure 10: Ignition key positions

5. Wait until the engine is pre-heated and the engine pre-heat indicator (see figure below) in the status/

warning bar at the top of the screen disappears before continuing.

Figure 11: Engine pre-heat indicator

6. Turn the key clockwise further to the Crank position (3) and hold it in this position for at least 10

seconds until the engine starts. During the 10 seconds, you will hear an audible start alarm signal to

indicate that the machine is about to start and a “Pre-crank” countdown (in seconds) is shown on the

screen. The engine cranking indicator is also show in the status bar at the top of the screen.

Figure 12: Pre-crank countdown (left) and engine cranking indicator (right)

7. Release the key immediately after the engine starts.

8. Wait for the clutch to engage and the Clutch Engagement indicator to disappear from the status bar at

the top of the screen:

Figure 13: Clutch engagement indicator

9. Before operating the machine, allow the engine to run at idle for 5 minutes to allow the running

temperature to be reached.

10. Check around the engine compartment area for engine oil, fuel, coolant, or hydraulic fluid leaks.

10 D100020717-EN

490 0 EN 2022-09-27

DRIVING INSTRUCTIONS

DRIVING INSTRUCTIONS

1.6.1.1. Adjusting the engine speed

The machine may be fitted with a variable-speed or fixed-speed engine, where a fixed-speed engine has two

speed set-points: idle and 1800 rpm.

NOTICE: For a fixed-speed engine, access to the higher speed of 1800 rpm is restricted

in that it can only be reached once during every engine session. Therefore, if

the engine is run at 1800 rpm and then its speed is reduced, the speed cannot

be increased again to 1800 rpm without first stopping and restarting the engine.

1. From the main view, press the Engine button L2 to enter the Engine Control menu. In the menu, you

can see the buttons for controlling the engine speed (see figure below).

DRIVING INSTRUCTIONS D100020717-EN

490 0 EN 2022-09-27

11

DRIVING INSTRUCTIONS

NOTICE: Buttons (2) and (3) only change the engine speed while they are

pressed down. Hold down the relevant button to continuously

change the speed. The longer you hold down the button, the

higher the rate at which the speed changes. This allows the

desired speed to be reached quickly.

NOTICE: For a fixed-speed engine, buttons (2) and (3) will not allow

continuous change but will change the engine speed between the

two set-points (idle and 1800rpm). Buttons (1) and (4) will also

change the engine speed between idle (minimum) and 1800rpm

(maximum).

1

2

3

4

Figure 14: Engine speed adjustment buttons

Callout Description

1 Press to ramp up the engine speed to its maximum

2 Press to increase the engine speed continuously

3 Press to decrease the engine speed continuously

4 Press to ramp down the engine speed to its minimum

1.6.1.2. Monitoring engine information

You can monitor the engine from the Engine screen.

1. Press button L8 repeatedly until the adjacent Engine symbol is highlighted in green (see figure

below).

12 D100020717-EN

490 0 EN 2022-09-27

DRIVING INSTRUCTIONS

DRIVING INSTRUCTIONS

Figure 15: Engine screen chosen

2. The Engine screen is shown on the display. The status and warning indicator bar (1) shows all engine

warnings.

1

Figure 16: Engine screen

3. In the Engine screen, you can view and monitor following information:

DRIVING INSTRUCTIONS D100020717-EN

490 0 EN 2022-09-27

13

DRIVING INSTRUCTIONS

1

2

3

4

5

67

8

14 13

12

11

10

9

16

15

Figure 17: Engine status, engine levels and hours of use

Callout Description Callout Description

1 Engine status indicators 9 Coolant Temperature: shown in °C or

°F.

2 Engine coolant level low: Lamp

illuminates in red when the engine

coolant level is low.

10 Inlet Pressure: shown in Bar or PSI.

3 Engine Pre-heat: Lamp illuminates

in green when the engine pre-heat is

active.

11 Engine Speed: shown in rpm.

4 Engine Stop: Lamp illuminates in red

when an engine shutdown has been

initiated due to a serious issue.

12 Engine Load: shown as a percentage.

5 Engine Protect: Lamp illuminates in

green when an engine derate has

been initiated due to a serious issue.

13 Engine Oil Temperature: shown in

°C or °F (not available for all engine

types).

6 Engine Cold: Lamp illuminates

in green when the engine is cool

(engine speed is limited and machine

functions are disabled until the engine

coolant temperature is greater than

30°C).

14 Engine Oil Pressure: shown in Bar

or PSI (not available for all engine

types).

7 Engine Warning: Lamp illuminates in

green when an engine fault has been

detected.

15 Engine Hours: Total number of hours

that the engine has run (since new).

8 Engine Service Required: Lamp

illuminates in green when an engine

service is required.

16 Crushing Hours: Total number of

hours that the crusher has run (since

new).

14 D100020717-EN

490 0 EN 2022-09-27

DRIVING INSTRUCTIONS

DRIVING INSTRUCTIONS

8

9

10

1

2

3

7

6

5 4

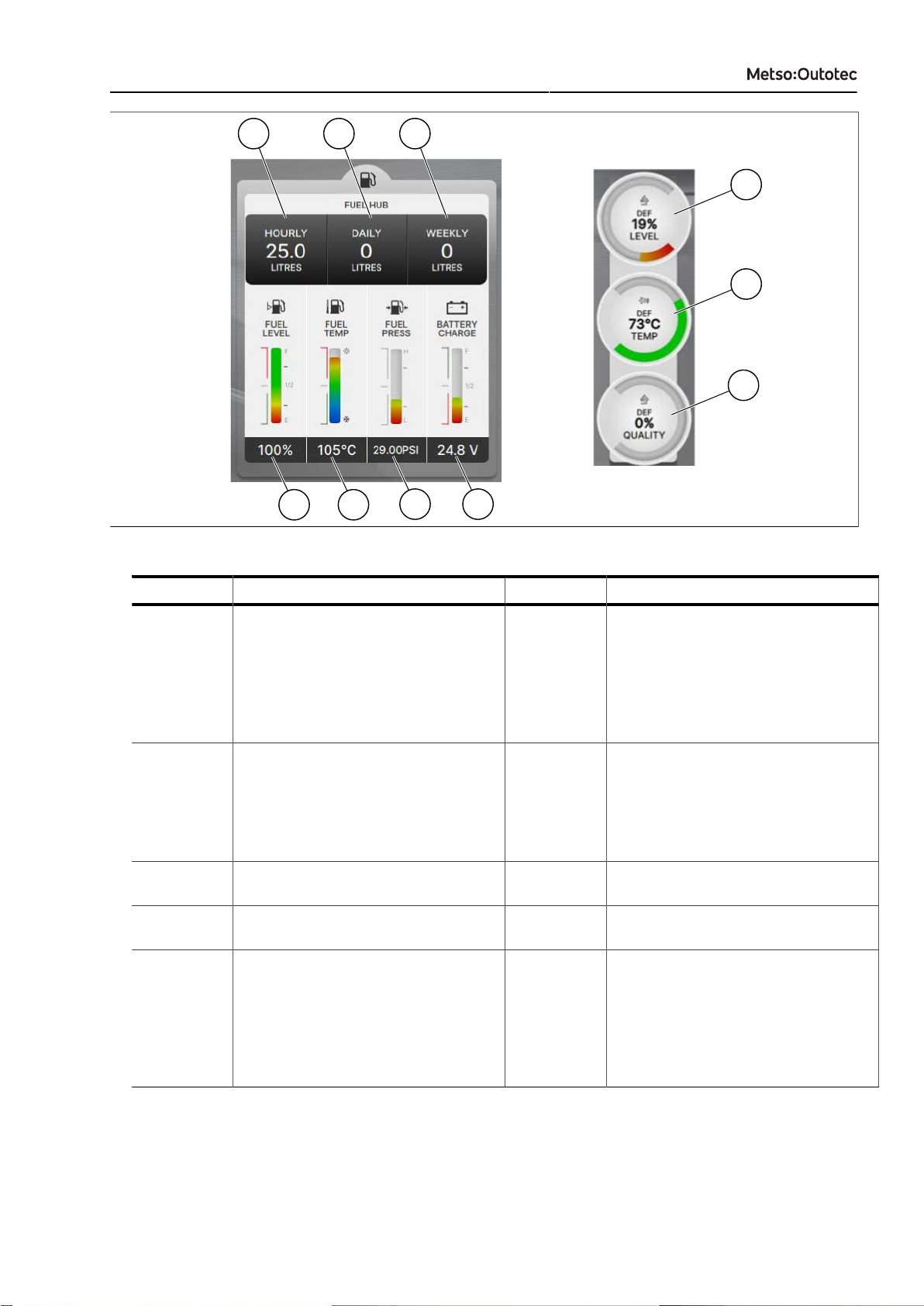

Figure 18: Fuel information, battery voltage and DEF (diesel exhaust fluid) information

Callout Description Callout Description

1 DEF level: shown as percentage. 6 Fuel Temperature: shown in figures in

°C or °F.

The bar-chart is colour-coded from

bright blue through green to bright

red, where green means acceptable,

blue means too low and red means

too high.

2 DEF temperature: shown in °C or °F. 7 Fuel Level: shown in figures as a

percentage of full capacity.

The bar-chart is colour-coded from

bright red to green, where green

means acceptable and red means too

low.

3 DEF quality: shown as percentage. 8 Hourly fuel usage: Average fuel

consumption (litres/gallons) per hour.

4 Battery voltage: shown in voltage (V). 9 Daily fuel usage: Average fuel

consumption (litres/gallons) per day

5 Fuel Pressure: shown in figures in Bar

or PSI.

The bar-chart is colour-coded from

bright red through green and back

to bright red, where green means

acceptable and red means too high or

too low.

10 Weekly fuel usage: Average fuel

consumption (litres/gallons) per week.

DRIVING INSTRUCTIONS D100020717-EN

490 0 EN 2022-09-27

15

DRIVING INSTRUCTIONS

2 3 4

5 6

7

8

10

11

12

1

9

Figure 19: Aftertreatment status (Tier4 only) and DPF (Diesel Particulate Filter) information

Callout Description Callout Description

1 Aftertreatment status (Tier4 only) 7 DEF Level Low: Lamp illuminates in

yellow when the DEF level is low and

needs replenishing.

2 DPF Outlet Gas Over-temperature:

Lamp illuminates in yellow when the

temperature of the outlet gas from the

DPF is too high.

8 Emissions System Failure:

• Lamp illuminates in yellow when

the DEF level is very low

• Lamp flashes in yellow when the

DEF level is extremely low or

another emissions system fault

occurs.

3 DPF Regeneration Needed: Lamp

illuminates in yellow when a DPF

regeneration is required.

9 DPF (Diesel Particulate Filter)

information

4 DPF Regeneration Inhibited: Lamp

illuminates in yellow when automatic

DPF regeneration is inhibited/

disabled.

10 DPF soot level: shown as a

percentage.

Depending on engine type, can

alternate with DPF ash level (%).

5 Manual DPF Regeneration Active:

Lamp illuminates in yellow when a

manual DPF regeneration has been

initiated.

11 DPF temperature: shown in °C or °F.

6 DPF Regeneration with High Exhaust

Temperature: Lamp illuminates in

yellow when a DPF regeneration is in

progress and exhaust temperature is

elevated.

12 Time elapsed since the last DPF

regeneration: shown in hours.

16 D100020717-EN

490 0 EN 2022-09-27

DRIVING INSTRUCTIONS

Table of contents

Other Metso Outotec Industrial Equipment manuals