disc cools, clean the welds with a wire brush. CAUTION:

Use care to keep contamination out of the valve.

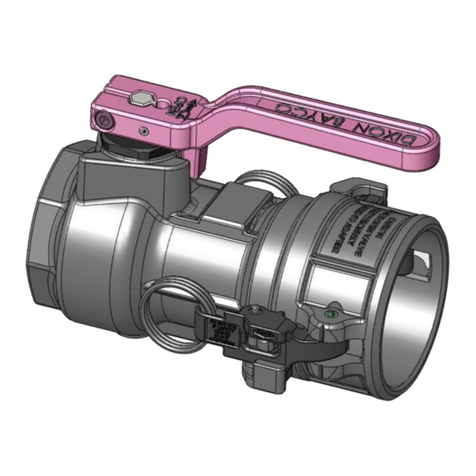

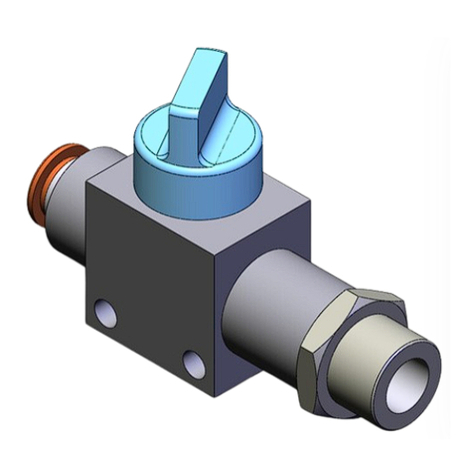

9. Install the spacer (7), the packing (8), the compression

ring (9) (30”– 48”(DN 350-1200) Type K815, 14”– 36”(DN

350-900) Type K830, 14”– 24”(DN 360-600) Type K860

only). If the packing is of the PTFE chevron type, be

certain that it is installed in the orientation shown in

Figure 9.

10. If the studs (14) have been removed from the valve,

reinstall them in the holes shown in Figure 8 or 9.

11. Place the compression plate (10) over the shaft (4) and

studs (14). Orient the plate so that the indicator pointer

will be over the indicator plate. Install the lockwashers

(16) and nuts (15), but do not tighten. Install the

indicator pointer in the shaft.

12. On valves with cover plates, install bottom bearing

spacer (43) in 14”– 16”(DN 350-400) 830W and 830L

valves only. Assemble the cover plate (53) and gasket

(54) to the cap screws (55) and lockwashers (56).

Torque the cap screws per Table 3. Place the plug seal

in the recess at the bottom of the valve and install the

plug. Torque the plug until it is ush with the body.

A small (1/16”) tack weld on the corner of the plug is

recommended. CAUTION: A larger tack weld is apt to

have enough heat to damage the seal.

13. Cycle the valve fully closed. If the seat is to be re-placed

as recommended, do so at this point. For details see

seat replacement sections 3.3 and 3.4, as applicable.

14. Install the seat (5), insert (2), and insert screws (21) as

shown in Figure 8 or 9. Torque values are given in Table 1.

15. With the valve still closed, tighten the nuts (15) on

the compression plate evenly until the packing is

adequately compressed to prevent leakage. This

should require tightening the nuts approximately 1-1/2

to 2 full turns past the “nger-tight” position.

4. VALVE TESTING PROCEDURE

Should it become necessary to perform a leak test of the

valve prior to its installation in the pipeline, follow the

procedure outlined below.

NOTE: This valve is intended for cryogenic service. It is

important that you take every precaution to keep moisture

out of the valve. DO NOT test the valve with water. It is

recommended that an inert gas such as nitrogen or helium

be used to perform leak testing of cryogenic valves.

1. In the following test, suitable gaskets or seals are required

between the faces of the valve and the test hardware.

2. Before pressurizing the valve be sure all actuator

linkage fasteners are tight, and that the power or

pressure is applied to the actuator to maintain the

valve in the closed position. The oset design of the

valve can cause it to rotate when pressure is applied to

one side of the disc.

3. The valve should be installed between anges or in a

testing apparatus using suitable gaskets. If using anges,

refer to Section 2 step 6. If a testing device other than

anges is used, the clamping force of the device must be

comparable with ange bolt loads on the valve.

4. Cycle the valve slightly open. Verify that you do not

have a seal between the seat and disc. Exercise caution

when cycling a valve in the test apparatus to avoid

possible disc damage from striking the test xture.

5. Cap the downstream vent and apply 100 psig (6.9 bar)

to the valve. Check the shaft seals, pressure plug or

cover plate, and ange gaskets for leakage. This can be

done by applying a liquid mixture of soap and water at

all seal joints and watching for bubbles.

IMPORTANT: If leakage is detected between the valve and

anges STOP IMMEDIATELY. Mark the area of leak-age.

Vent the valve and, when it has returned to 0 psig,

retighten the ange bolts in that area. Repressurize the

valve, checking the whole gasket again. If leakage persists,

disassemble and inspect for damage.

6. If leakage is detected at the shaft seals, tighten only

enough to stop the leak.

7. Vent the valve and, when it has returned to 0 psig, cycle

the valve closed.

8. Attach a small tube or hose to the downstream ange

(shaft side of valve).

9. Be sure power/pressure is still applied to the actuator.

Pressurize the upstream ange (insert side of valve) to

100 psig (6.9 bar). Check for leakage passing through

the free end of the tube/hose.

10. If leakage is detected, vent the valve and make an

actuator close-stop adjustment as described in the

appropriate IMO listed on page 8.

11. Repressurize the valve and check the leakage. If the

valve still leaks, repeat step 10. If leakage cannot be

stopped, adjust the actuator stop so that leakage is

minimized.

12. Rebuilt valves may have some minor leakage due to

damage to the disc. With the valve still pressurized,

insert the free end of the tube/hose into a beaker of

water and check for bubbles. In the absence of other

test standards, observe leakage after it has reached a

stable condition. Because of the volume of air that must

be exhausted from a cycled valve, it may be necessary

to wait several minutes for the leakage to stabilize or

stop. One bubble per inch of valve diameter per minute

may be considered acceptable for re-built valves.

IMO 1/18

IMO-319 EN 7