Metso Neles ValvGuard VG9000F Operating and maintenance manual

Other manuals for Neles ValvGuard VG9000F

1

Table of contents

Other Metso Control Unit manuals

Metso

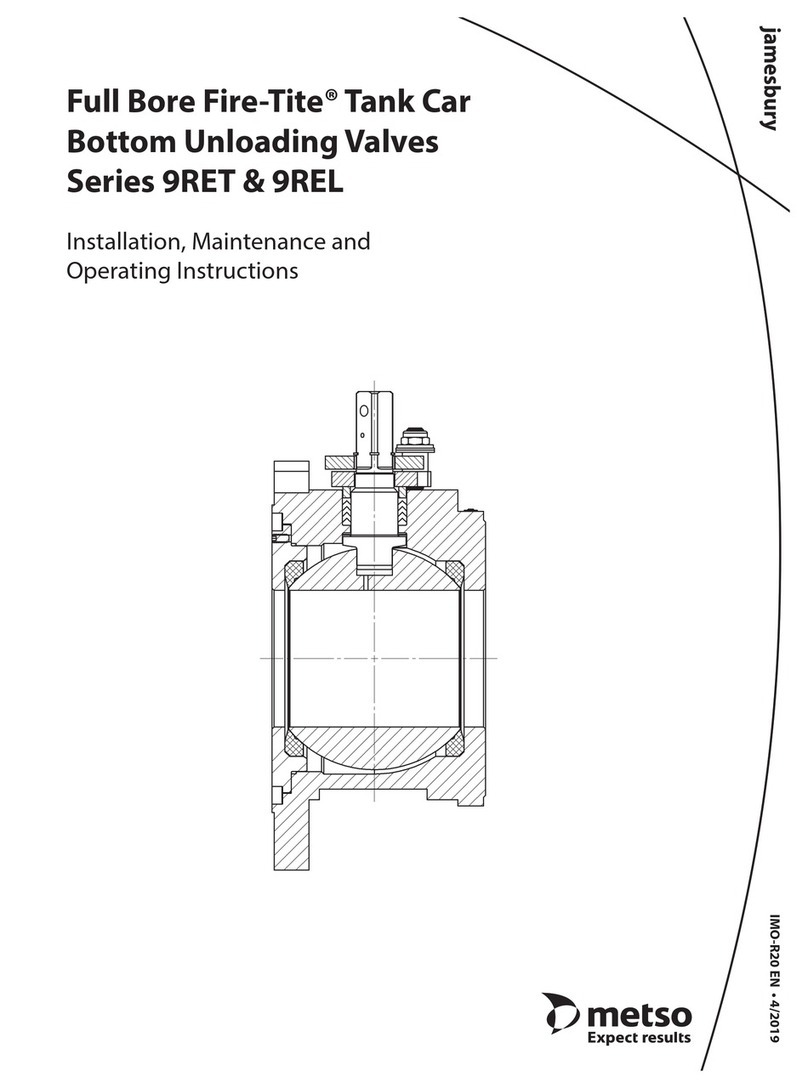

Metso Full Bore Fire-Tite 9REL Series Operating and maintenance manual

Metso

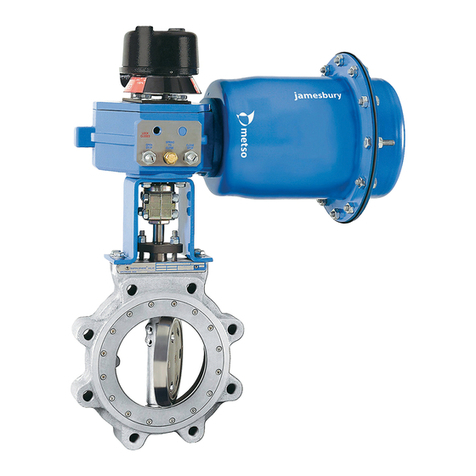

Metso Jamesbury 5000 series Operating and maintenance manual

Metso

Metso NelesAce User manual

Metso

Metso BO Series Operating and maintenance manual

Metso

Metso Top 5 Series Operating and maintenance manual

Metso

Metso M12 Operating and maintenance manual

Metso

Metso neles ND7000H User manual

Metso

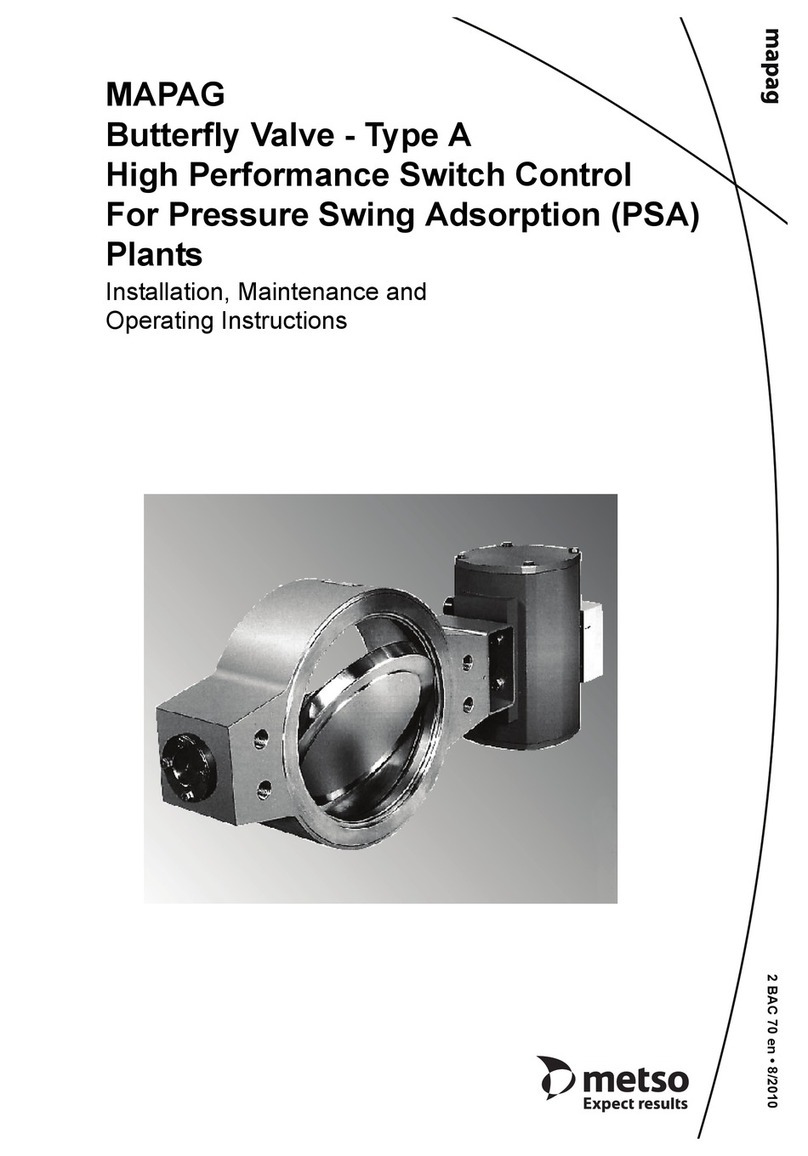

Metso MAPAG Butterfly valve Type A Operating and maintenance manual

Metso

Metso JAMESBURY EASYFLOW SC Series Operating and maintenance manual

Metso

Metso XT/XA Series Operating and maintenance manual

Metso

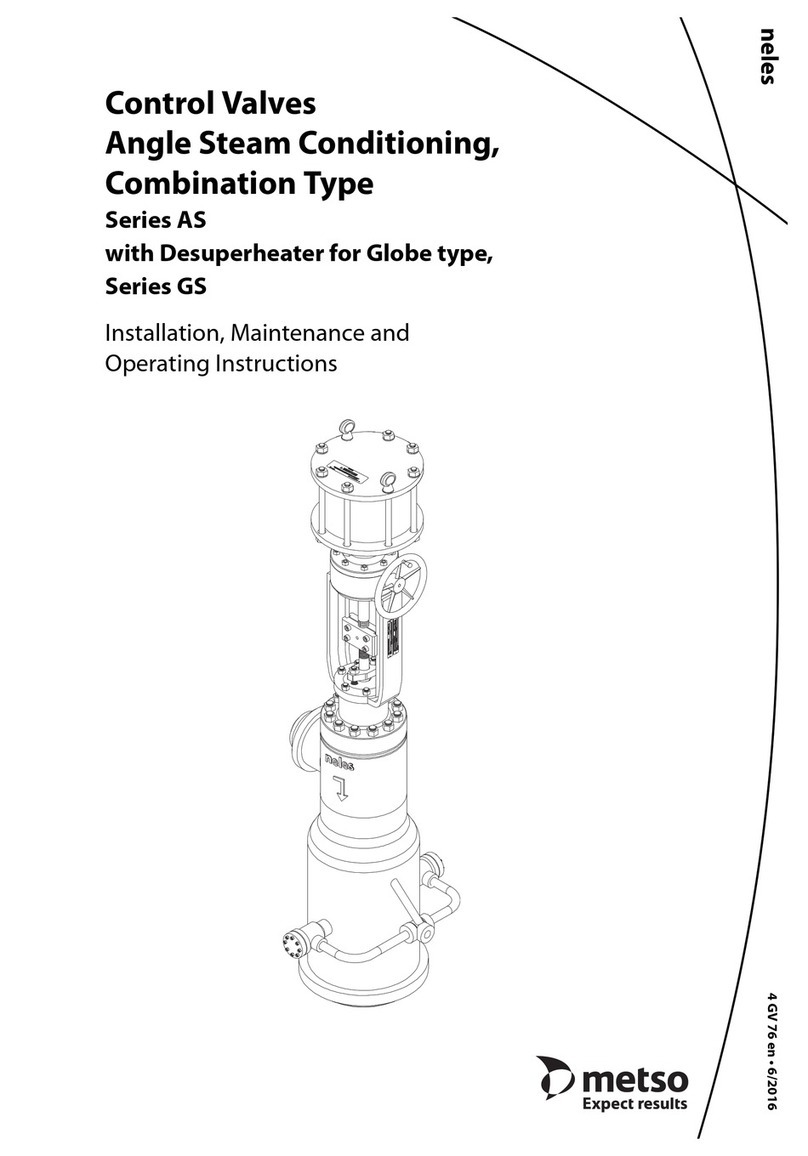

Metso AS series User manual

Metso

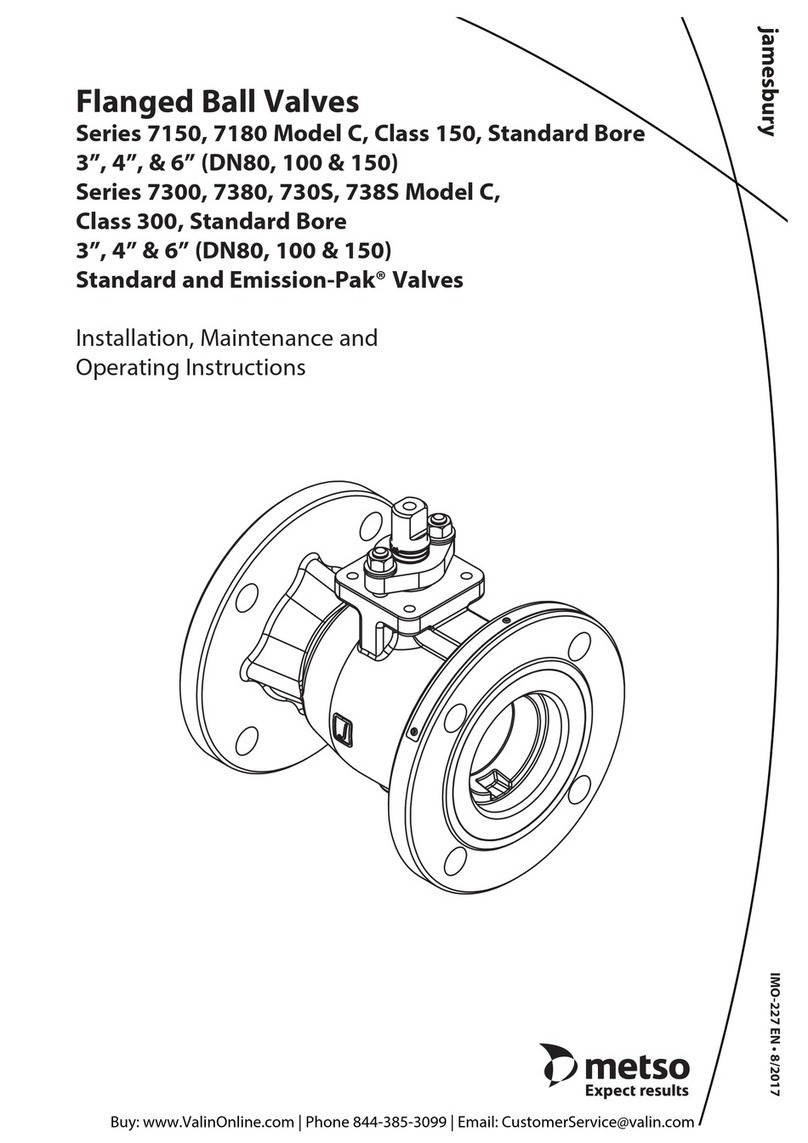

Metso Jamesbury 7000 Series Operating and maintenance manual

Metso

Metso 7000 Series: 7150RR Series Operating and maintenance manual

Metso

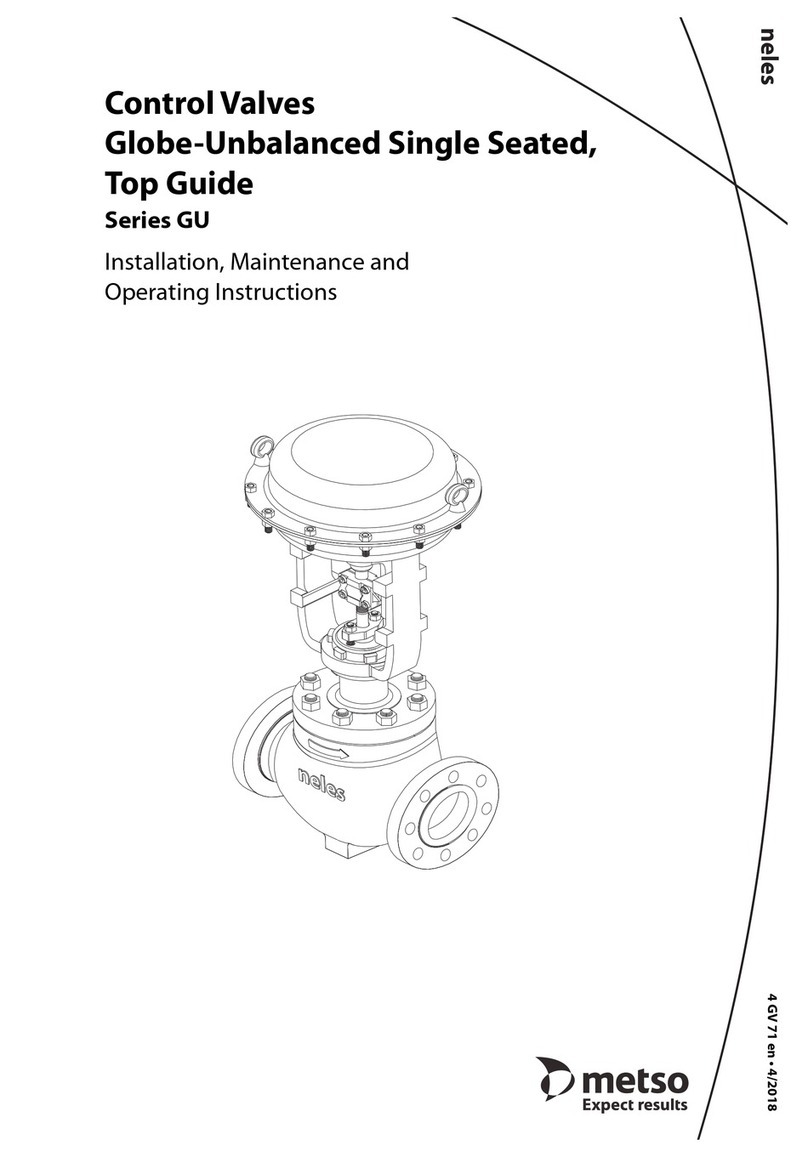

Metso GW Series Operating and maintenance manual

Metso

Metso 7150 Operating and maintenance manual

Metso

Metso Mapag BAR Series Operating and maintenance manual

Metso

Metso Neles PZ Series Operating and maintenance manual

Metso

Metso Jamesbury Wafer-Sphere K815W Operating and maintenance manual

Metso

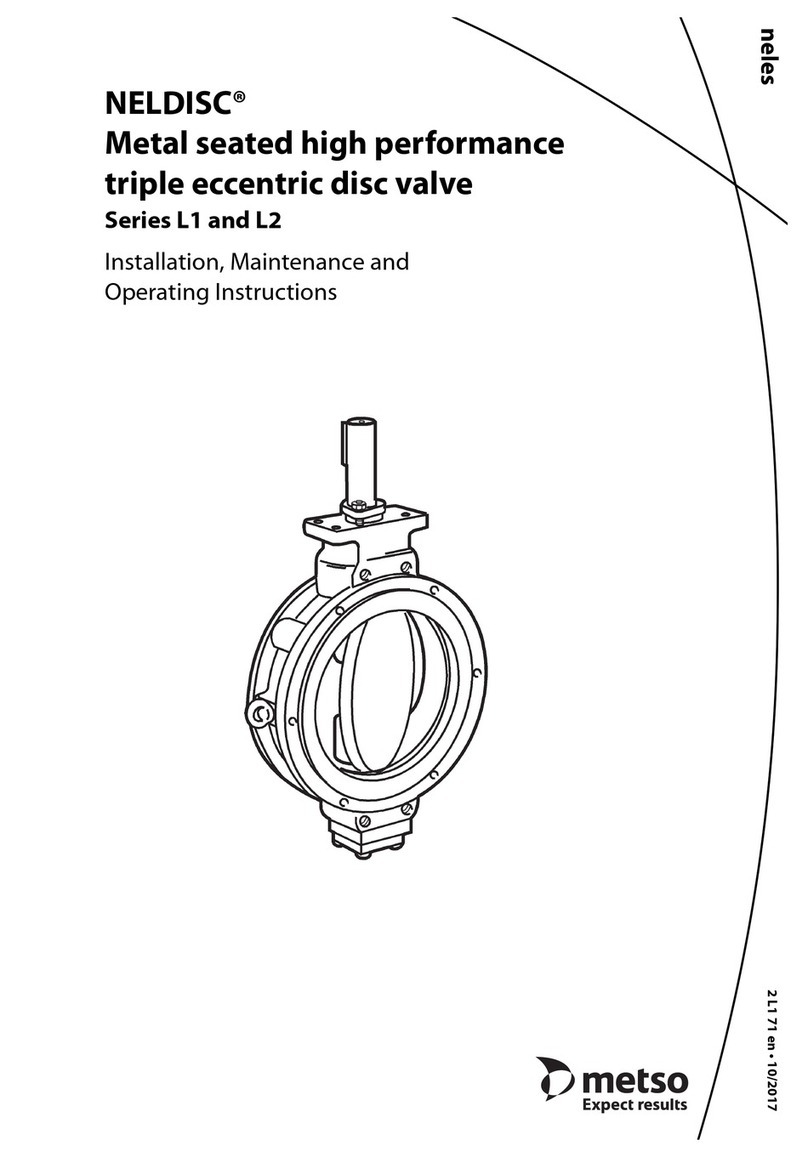

Metso Neles L4 Series Operating and maintenance manual

Metso

Metso NELES XH Series Operating and maintenance manual

Popular Control Unit manuals by other brands

Embest

Embest CAM8100-D user manual

Graco

Graco 24W870 Kit instructions

TJERNLUND

TJERNLUND UC1 UNIVERSAL CONTROL (VERSION X.02 OR EARLIER) 8504107 REV... installation instructions

M-system

M-system R7C-YS2 instruction manual

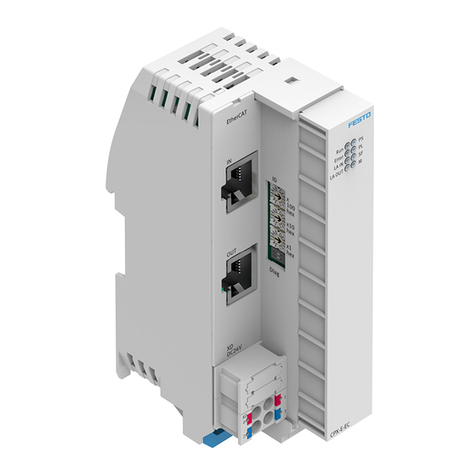

Festo

Festo CPX-E-PN Translation of the original instructions

MFZ

MFZ CS 300 operating instructions

Paradox

Paradox MG-RCV3 Reference and installation manual

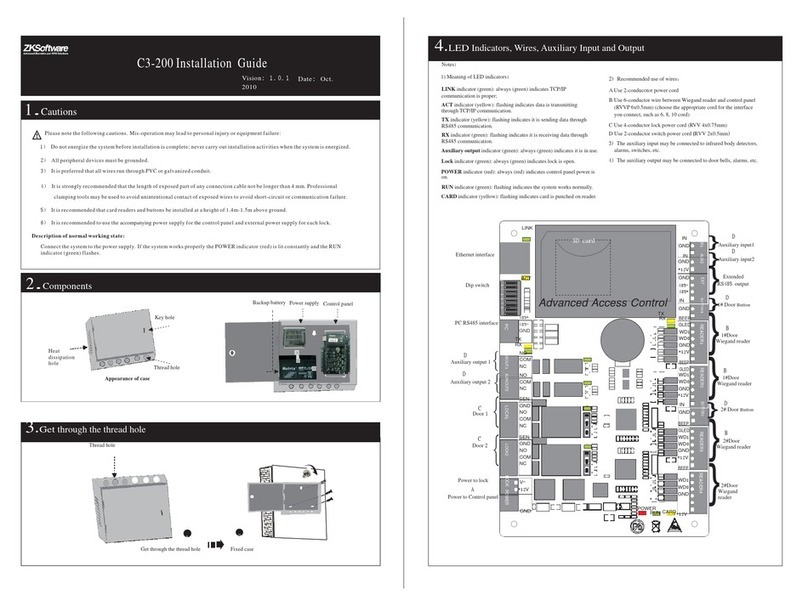

Zksoftware

Zksoftware C3-200 installation guide

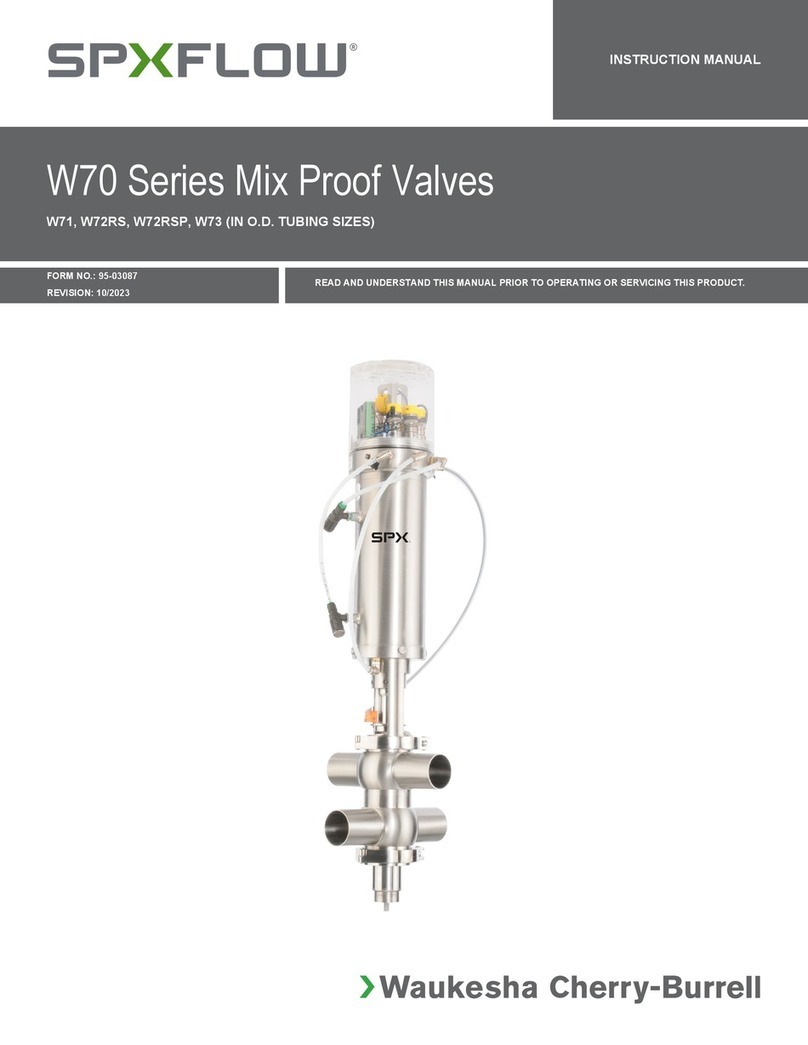

SPX FLOW

SPX FLOW W70 Series instruction manual

SIGMA TEK

SIGMA TEK ST 011 instruction manual

red lion

red lion Graphite Crimson GMCC installation guide

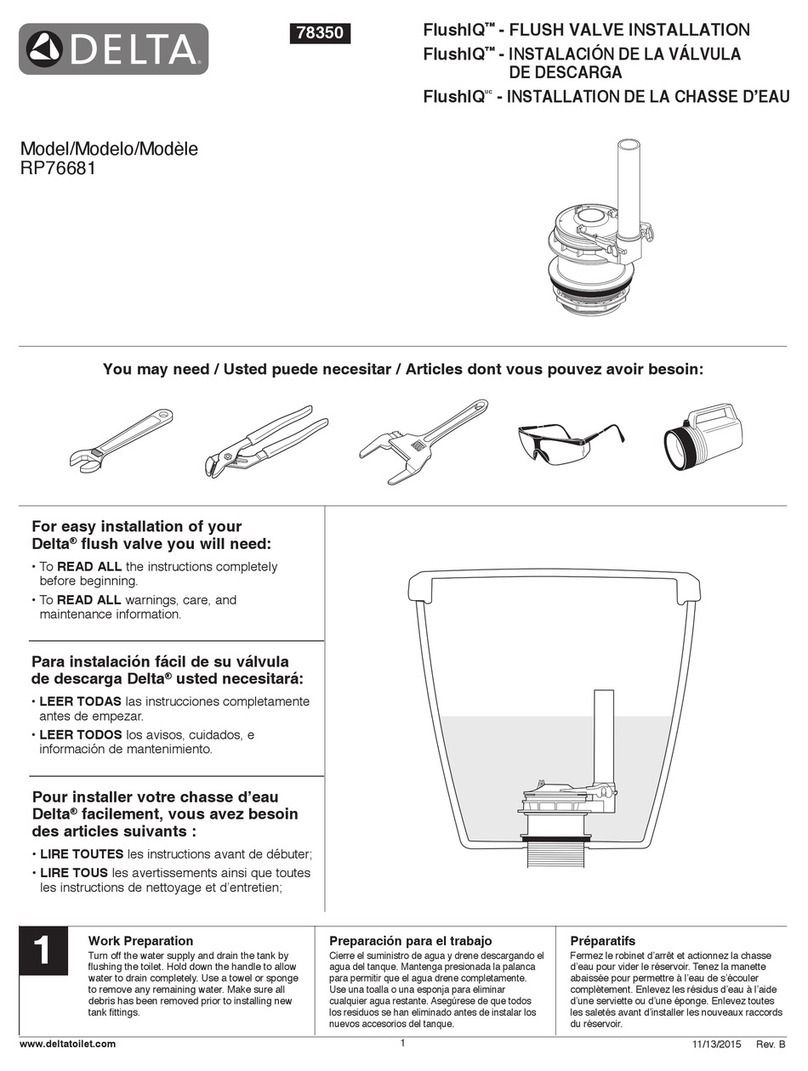

Delta

Delta FlushIQ RP76681 installation instructions