4 KH 70 en 3

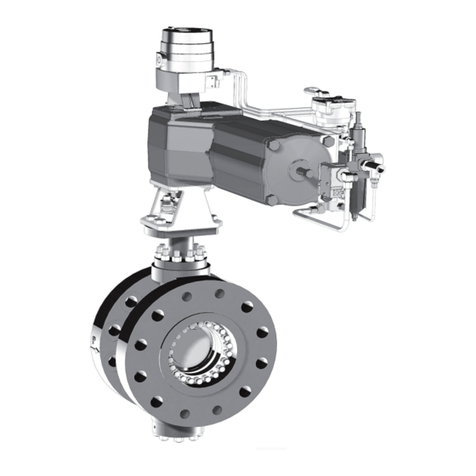

1 PRODUCT DESCRIPTION

Knife gate valves from Metso are designed and

manufactured to meet strict quality and safety standards.

This manual is intended to provide advice and instructions

to the installation engineers and qualified service

personnel so that they can safely undertake the necessary

procedures to correctly install the product and carry out the

future service and maintence work.

Our certified quality management system is an assurance

for you as our customers. You can rely on our products and

service always fulfilling the most demanding quality and

environmental standards in place today. Metso® quality

assurance system fulfils demands and instructions specified

in ISO 9001 and ISO 14001.

IMPORTANT! This installation- and service instruction must

be read carefully and understood prior to the installation,

use and servicing of this product.

1.1 Liability for defects

The Supplier warrants that the product will be free from

defects in materials and workmanship when used properly

and in accordance with the directions of the product. The

Supplier´s obligations shall not apply to nor include any

products, which have been subjected to accidents,

alterations, abuse or misuse.

1.2 Important information

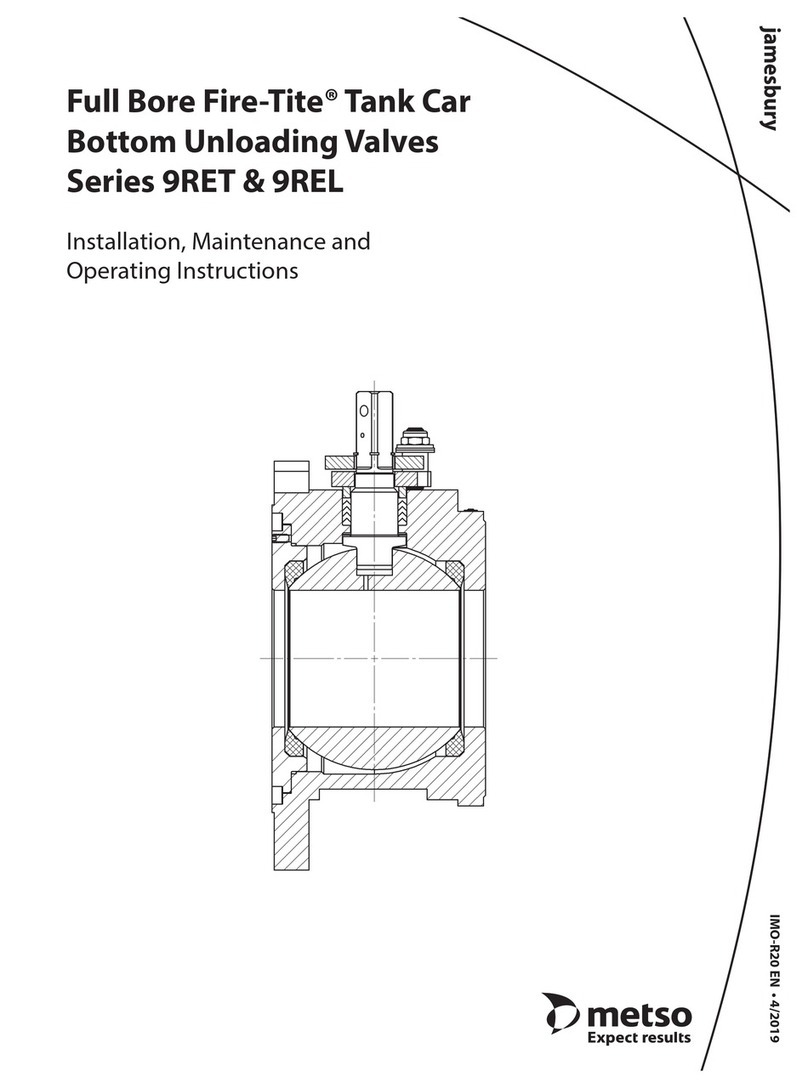

Pictures shown in this manual are illustrative only and do

not necessarily show the design of the products on the

market at any given point in time. For detailed illustrations,

please refer to specific assembly drawings and parts list.

Specifications of the products and equipment presented

herein are subject to change without notice.

1.3 General application

Knife gate valves from Metso are recommended for many

industries such as:

Mining

Chemical plants

Fertilizer plants

Sewag Waste Water applications

Pulp & Paper

Power Generation

2 SAFETY AND RECYCLING

The product must be used in conformity with applicable

practice and safety regulations and only for the type of

operation that it is intended for. Use only spare parts and

accessories that are recommended by the manufacturer.

Every country (state) has its own safety and recycling

regulations. It is the work management’s and installation

engineer’s responsibility to know and follow these. If the

recommendations in this manual diverge from those of

your country’s, then the local regulations shall prevail.

2.1 Safety Precautions

The product must be used in conformity with appl icable

practice and safety regulations and only for the type of

operation that it is intended for. Use only spare parts and

accessories that are recommended by the manufacturer.

Every country (state) has its own safety regulations. It is the

work management’s and installation engineer’s

responsibility

to know and follow these. If the recommendations in this

manual diverge from those of your country’s, then the local

safety regulations shall prevail.

It is of great importance that the installation engineer is

aware of the product’s functions and characteristics. It is

also the installation engineer’s responsibility to know and

follow general regulations as well as national legal

requirements and provisions. It is the installation engineer’s

responsibility to know and follow the information given on

labels, in instructions and safety regulations for the

product.

Always use approved personal safety equipment.

Installation engineers and other personnel who are in the

working area should use at least the following safety

equipment: Protective clothing, protective gloves,

protective helmets, protective goggles, protective shoes,

hearing protection..

2.2 Recycling and disposal

Most valve parts can be recycled if sorted according to

material. Most parts have material marking. A material list is

supplied with the valve. In addition, separate recycling and

disposal instructions are available from the manufacturer. A

valve can also be returned to the manufacturer for recycling

and disposal against a fee.

CAUTION:

Beware of extreme temperatures!

The valve body may be very hot or very cold during

use.

Protect people against cold injuries or burns.

CAUTION:

When handling the valve or the valve package, bear in

mind its weight!

Never lift the valve or valve package by the actuator,

positioner, limit switch or their piping. Place the lifting

ropes securely around the valve body. Damage or

personal injury may result from falling parts.

CAUTION:

Do not exceed the valve performance limitations!

The valve may produce noise in the pipeline. The noise

level depends on the application. Observe the relevant

work environment regulations on noise emission.

CAUTION:

Beware of the cutting movement!

Keep hands, other parts of the body, tools and other

objects out of the open flow port. Leave no foreign

objects inside the pipeline. Close and detach the actuator

pressure supply pipeline for valve maintenance.

Failure to do this may result in damage or personal injury.

CAUTION:

Do not exceed the valve performance limitations!

Exceeding the limitations recommended by the supplier

may cause damage and lead to uncontrolled pressure

release.