Metso 7150 Operating and maintenance manual

Other manuals for 7150

1

This manual suits for next models

5

Other Metso Control Unit manuals

Metso

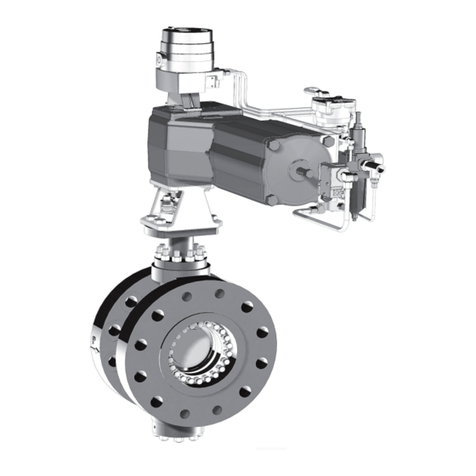

Metso Neles RotaryGlobe ZX Series Operating and maintenance manual

Metso

Metso Top 5 Series Operating and maintenance manual

Metso

Metso Jamesbury Wafer-Sphere Series User manual

Metso

Metso Jamesbury 4000 B Operating and maintenance manual

Metso

Metso 530S Operating and maintenance manual

Metso

Metso PZ Series User manual

Metso

Metso D Series User manual

Metso

Metso Jamesbury 5000 series User manual

Metso

Metso NELDISC LW Series Operating and maintenance manual

Metso

Metso 7150 Operating and maintenance manual

Metso

Metso Neldisc L1 Series User manual

Metso

Metso KH Series User manual

Metso

Metso Neles BW Series Operating and maintenance manual

Metso

Metso Jamesbury VAQ214NC Series Operating and maintenance manual

Metso

Metso BO Series Operating and maintenance manual

Metso

Metso MAPAG Butterfly valve Type A Operating and maintenance manual

Metso

Metso Jamesbury Installation instructions

Metso

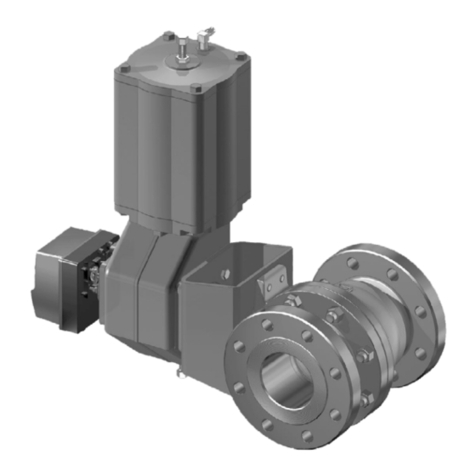

Metso R Series Operating and maintenance manual

Metso

Metso Jamesbury Wafer-Sphere Series Operating and maintenance manual

Metso

Metso Neles XT Series Operating and maintenance manual

Popular Control Unit manuals by other brands

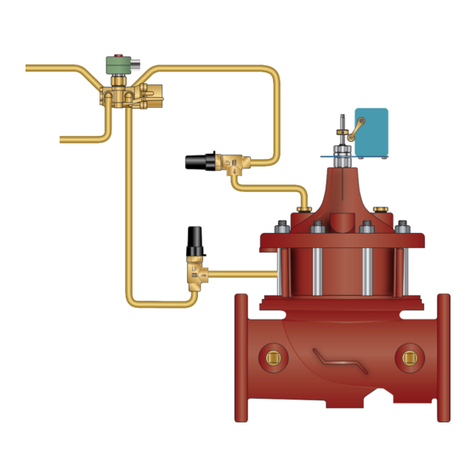

CLA-VAL

CLA-VAL 750B-4KG1 Installation operation & maintenance

ITRON

ITRON OpenWay Riva 500G ERT installation guide

Silicon Laboratories

Silicon Laboratories EFR32 G1 Series Reference manual

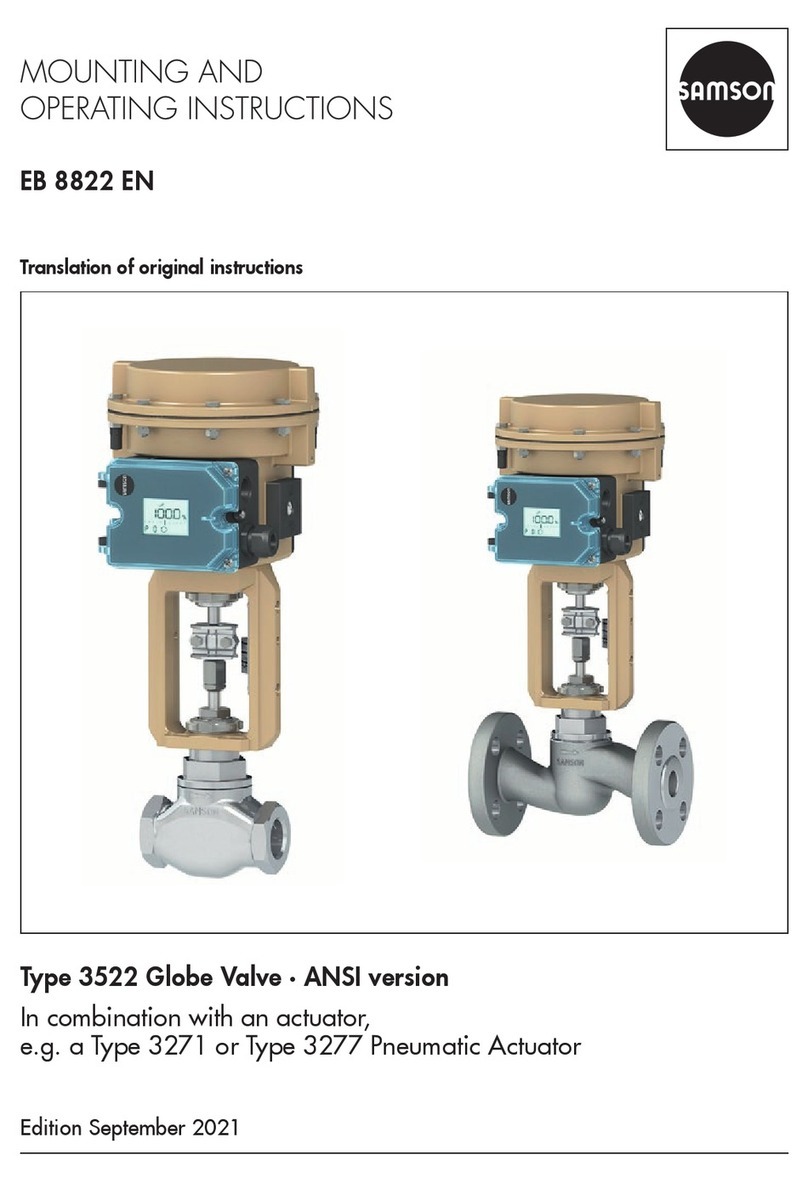

Samson

Samson 3522 Mounting and operating instructions

Brainlab

Brainlab Buzz 2.0 System and Technical User Guide

Enviro

Enviro MMG1 quick start guide

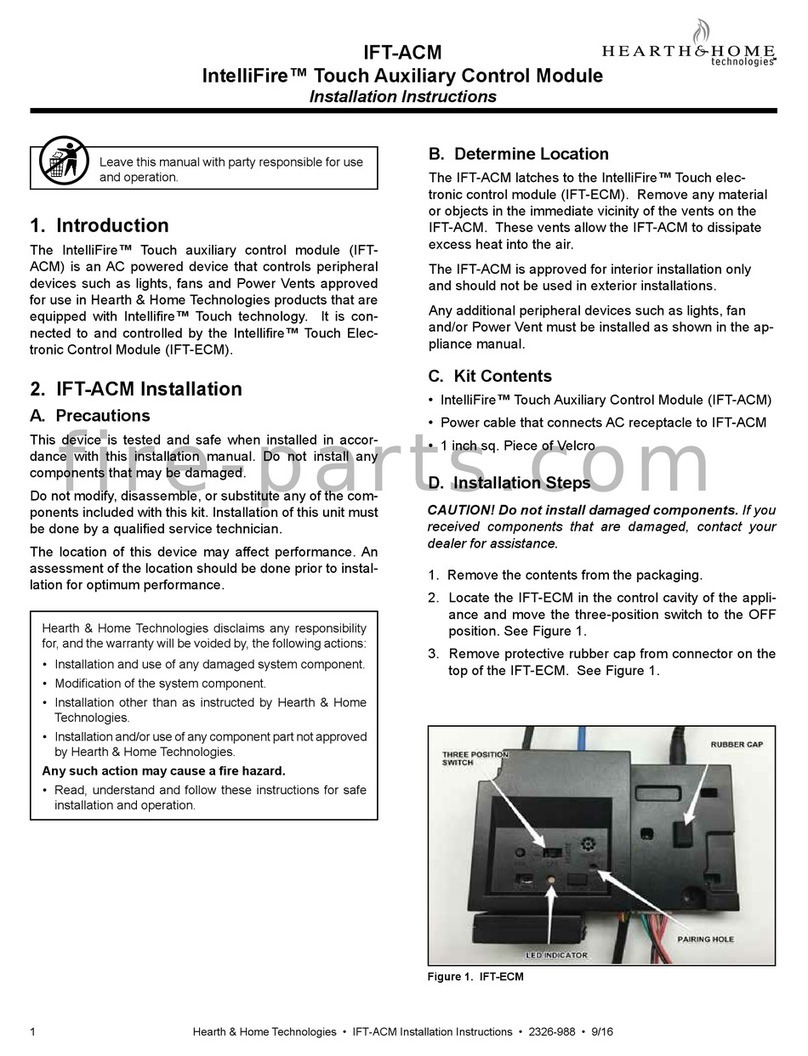

Hearth & Home

Hearth & Home IntelliFire IFT-ACM installation instructions

SPX

SPX APV DELTA DET3 operating manual

Midland

Midland A-7200 Installation, operation & maintenance manual

Mini-Circuits

Mini-Circuits RUDAT Series user guide

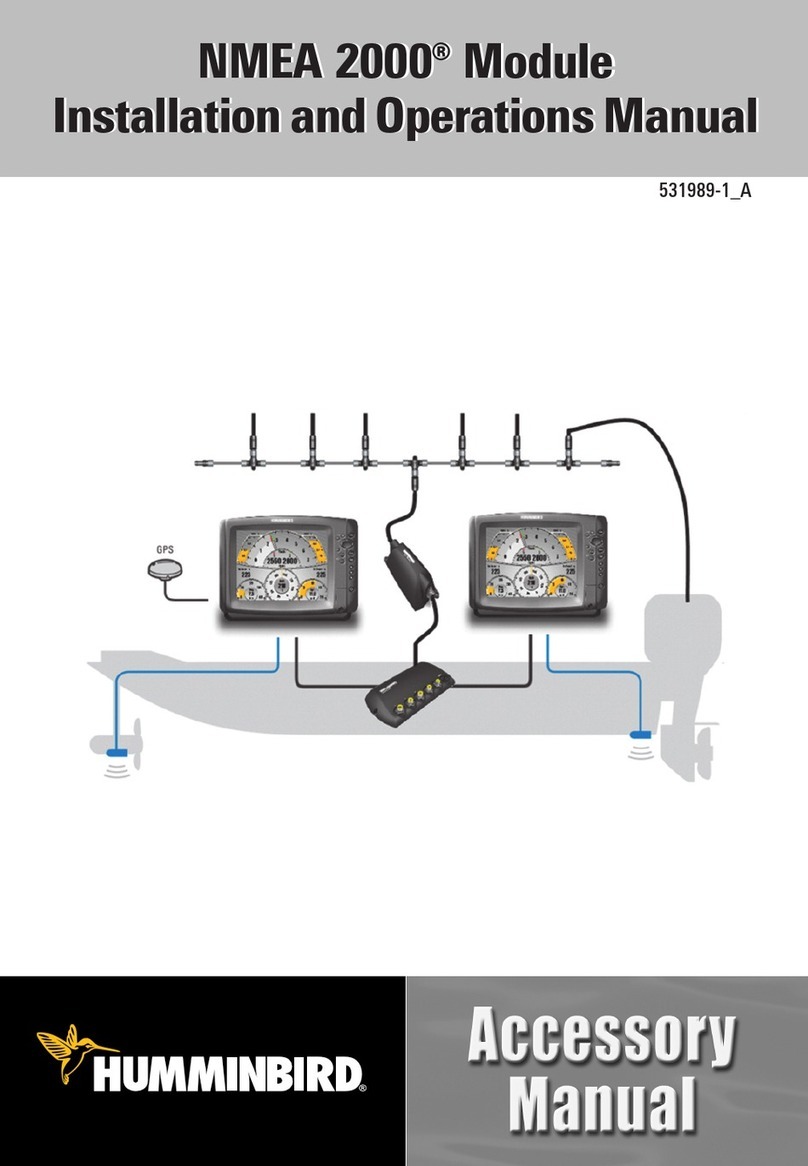

Humminbird

Humminbird NMEA 2000 module Installation and operation manual

Keystone

Keystone EPI2-MAN-652NA-OM1 user manual

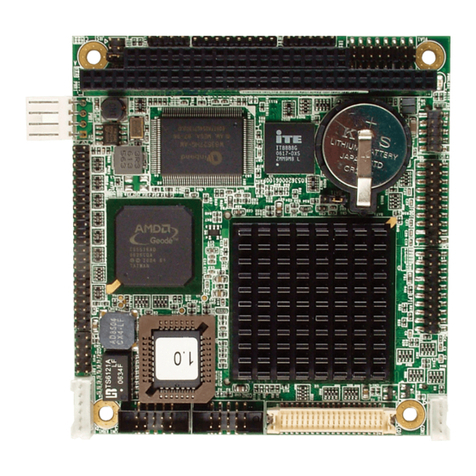

Arbor Technology

Arbor Technology Em104-a5362 Quick installation guide

Dometic

Dometic AH-Passport I/O Compact Operation manual

Watts

Watts AMES LF985GD Series Installation, operation and maintenance manual

Taco

Taco Comfort Solutions 5000-3 Series instruction sheet

Sentiotec

Sentiotec wave.com4 touch Instructions for installation and use

Niko

Niko 350-70980 quick start guide