1 T5 71 en 5

2 TRANSPORTATION, RECEPTION

AND STORAGE

Check the valve and the accompanying devices for any

damage that may have occurred during transport.

Store the valve carefully before installation, preferably

indoors in a dry place. Do not take the valve to the

intended location and do not remove the flow port pro-

tectors until the valve is installed. The valve is delivered

in the open position, with the exception of valve pack-

ages where the actuator spring closes the valve.

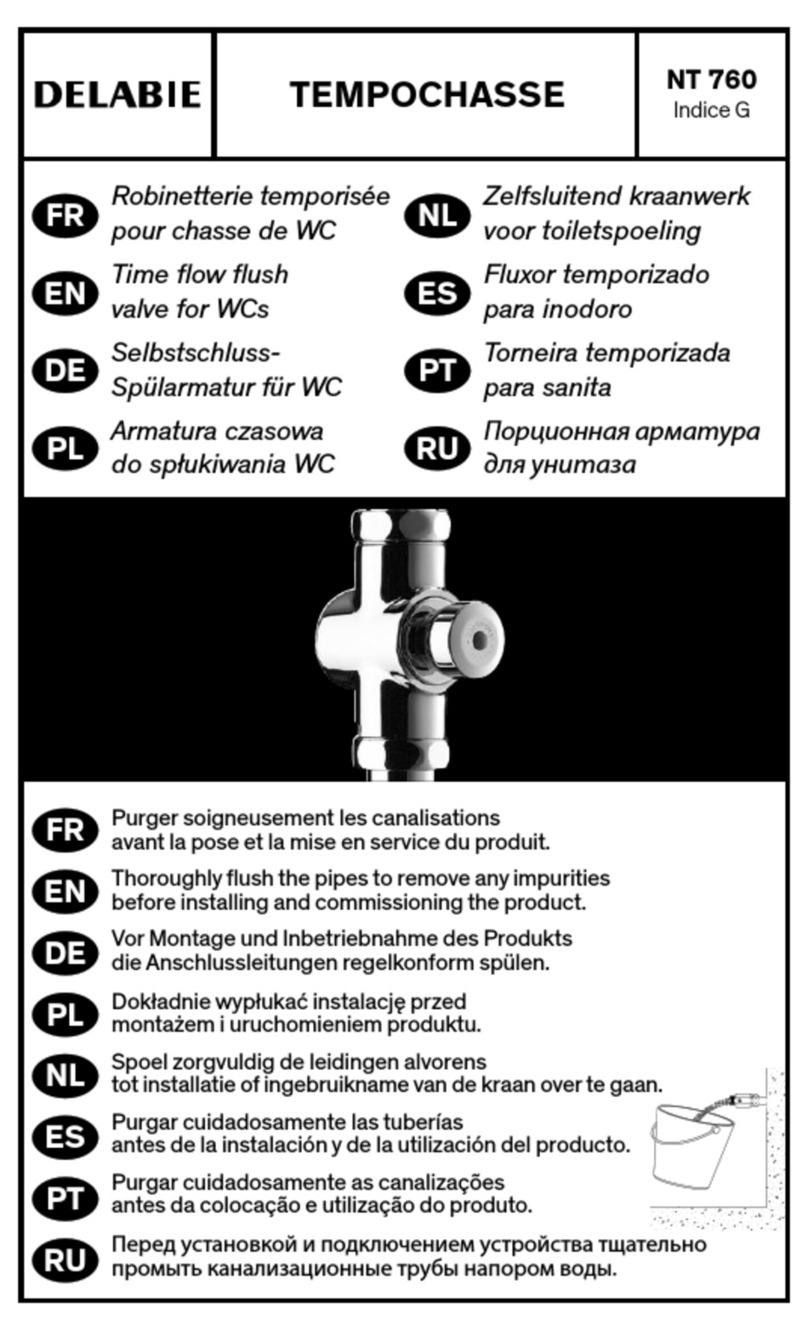

3 INSTALLATION IN THE PIPELINE

Remove the protecting plates around the valve and

check that the valve is clean. Flush and blow the pipe-

line carefully before installing the valve. Foreign parti-

cles, such as sand or pieces of welding electrode, will

damage the valve.

Check that the pipeline is supported properly. Do not

attempt to correct any pipeline misalignment by means

of the flange bolting or welding of the valve. Do not sup-

port the pipeline using the valve as help.

An arrow pointing at the tight direction of a seat that is

tight in one direction (the most commonly used version)

is cast on both sides of the valve. This is usually the

flow direction. If the flow direction and the tight direc-

tion can be opposite to each other, the piping plan must

be checked for the correct position.

Check that the unbroken side of the ball faces the seat

when the valve is in the CLOSED position.

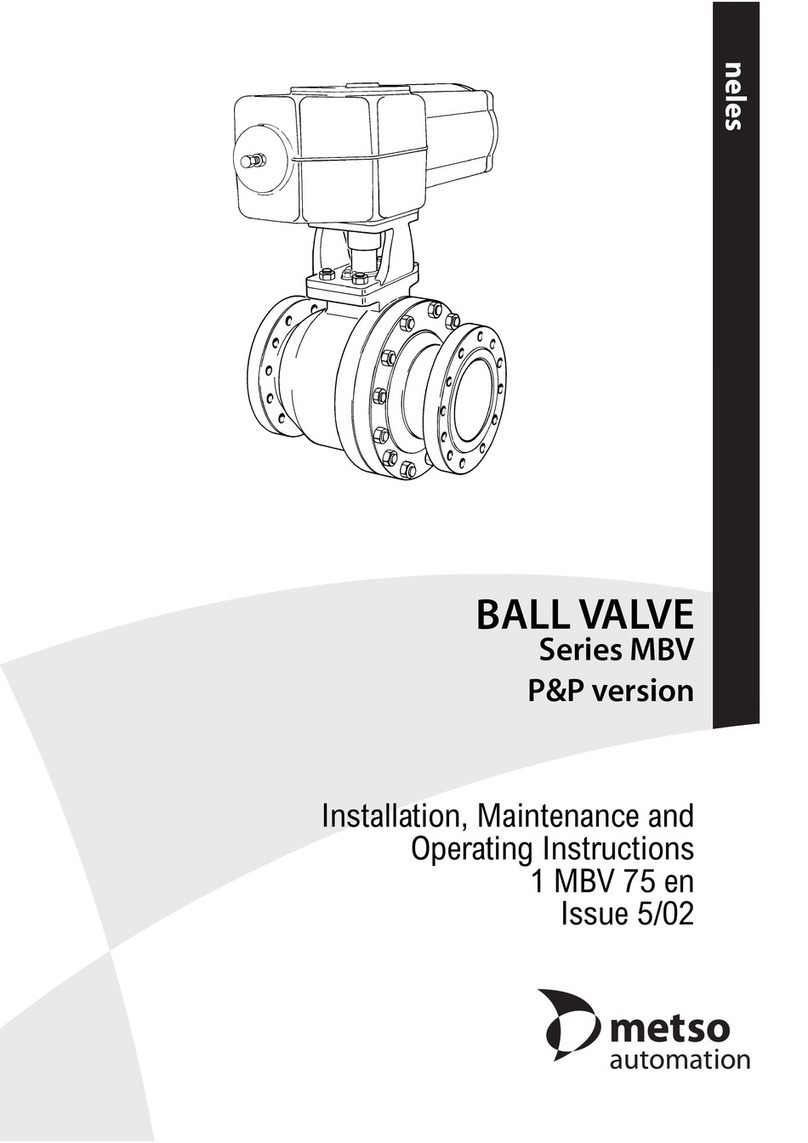

Install the valve in the position shown in the piping

installation drawing. The position code shows the instal-

lation position that should be used when the actuator

has been installed at the factory. The position code has

been given either on the specification sheet or in the

dimensional drawing of the valve.

There should be enough free space around the valve

so that the actuator can be removed and the valve dis-

mantled without detaching the valve from the pipeline.

Check that the indicator arrow on the actuator is paral-

lel to the ball flow opening.

The actuator must not touch the pipeline or any perma-

nent structures, because pipeline vibration may dam-

age it or interfere with its operation. If the pipeline

drawings show a support for the actuator, the support

must be installed.

Make sure that the valve is in the OPEN position when

welding a weld end valve into the pipeline.

Note! A valve equipped with a BJ actuator is in the

CLOSED position when it is not pressurized. Direct

compressed air into the cylinder to turn the valve open.

When welding a valve into a pipeline, protect the valve

from welding spatter, see Fig. 5. Always ground the

welding apparatus on the side of the pipeline.

4 COMMISSIONING

The gland packing may leak after long storage. If the

packing leaks, tighten it steadily until the leaking stops.

Do not tighten the packing unnecessarily as this will

increase the required torque and impair the control

properties. (More information about the gland packing

in section 5.1.).

Check that the valve has been installed correctly in

relation to the flow direction.

5 SERVICING

The valve can be serviced without removing it from the

pipeline. Servicing in a workshop is, however, recom-

mended whenever possible.

If the valve is removed from the pipeline, the body must

be supported for servicing with the stem standing

upright.

The numbers in parentheses refer to the exploded view

and the parts list on pages 12 and 13, unless otherwise

NOTE:

Valves with a carbon steel body may become badly

corroded on the inside if the inside is left damp during

storing.

CAUTION:

Never lift the valve or valve package by the actua-

tor, positioner, limit switch or their piping. Place

the lifting ropes securely around the valve body.

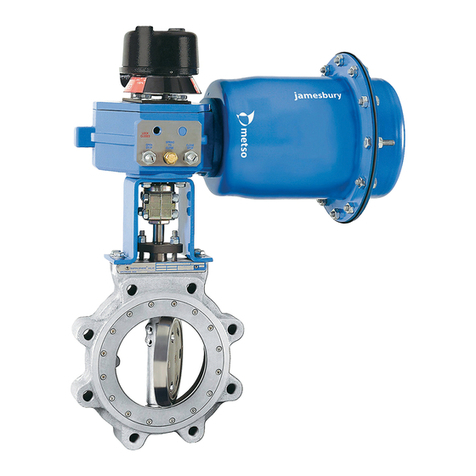

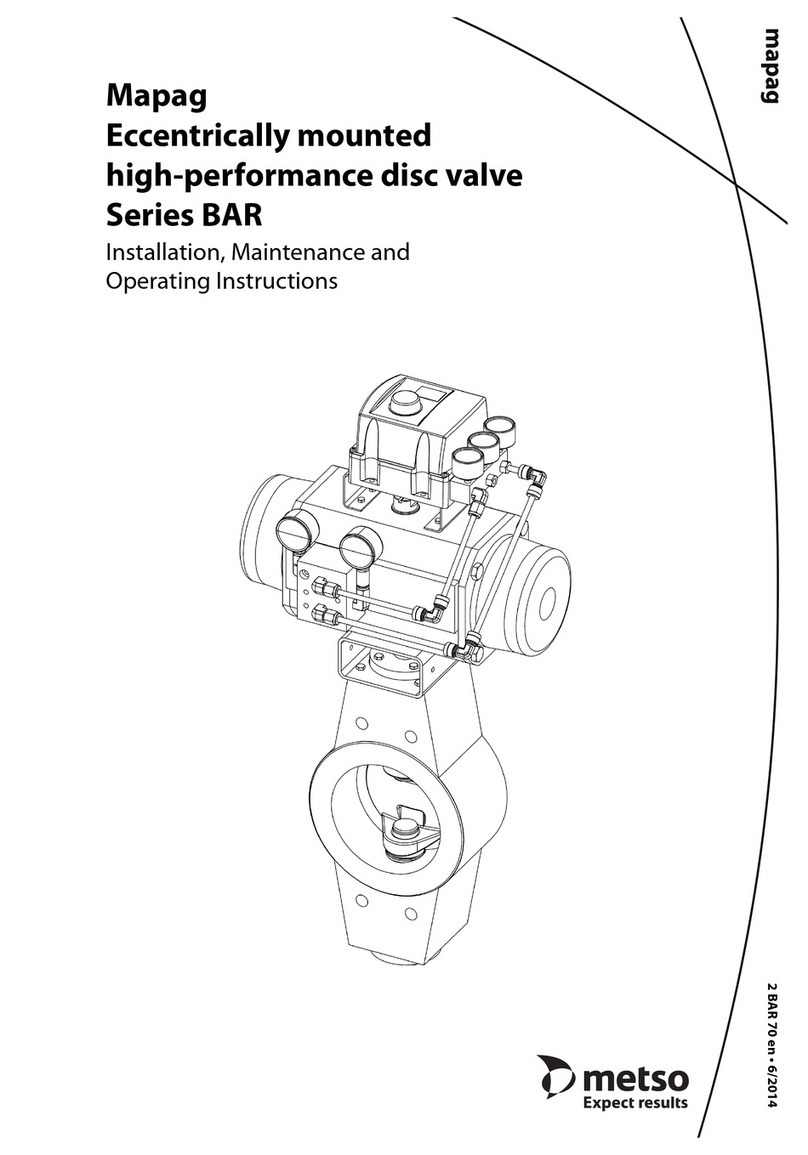

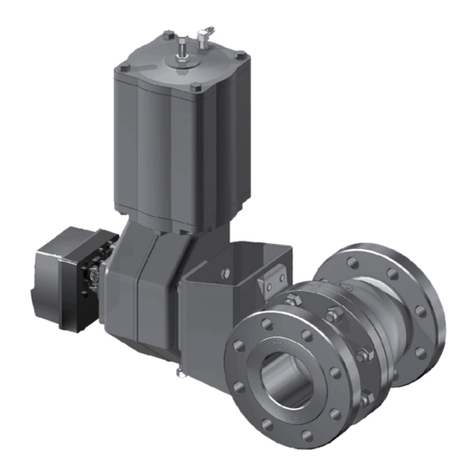

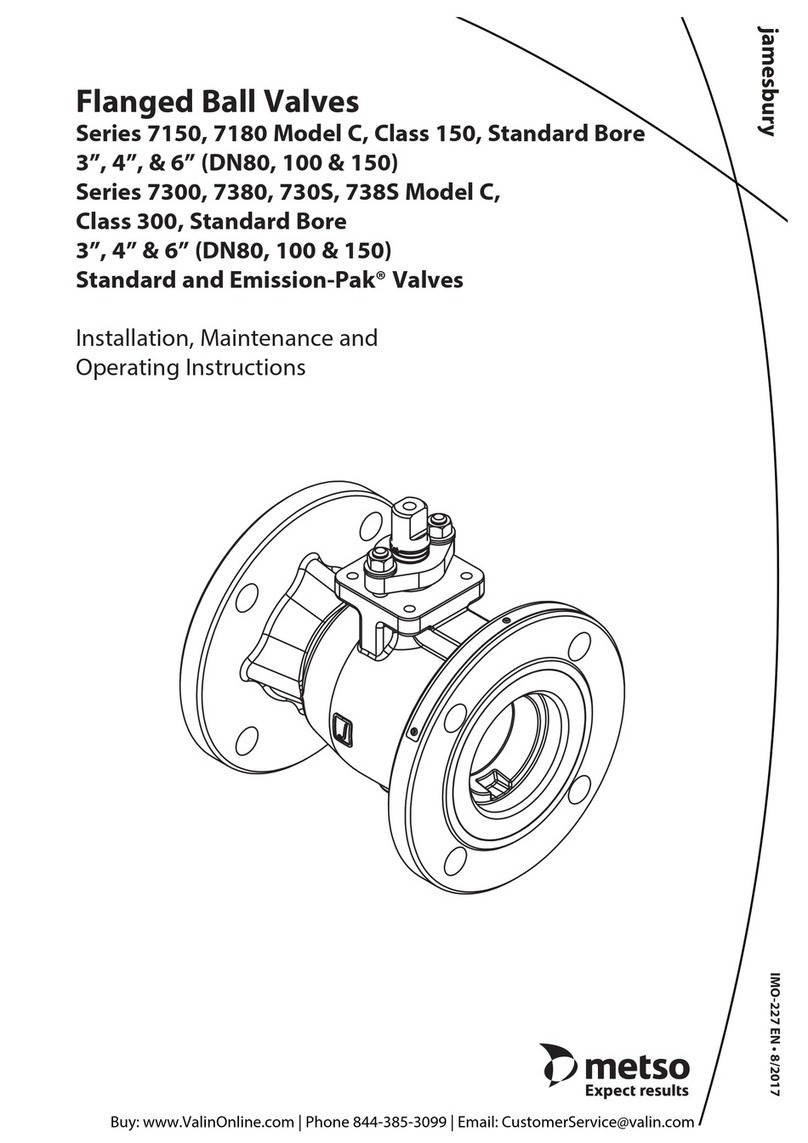

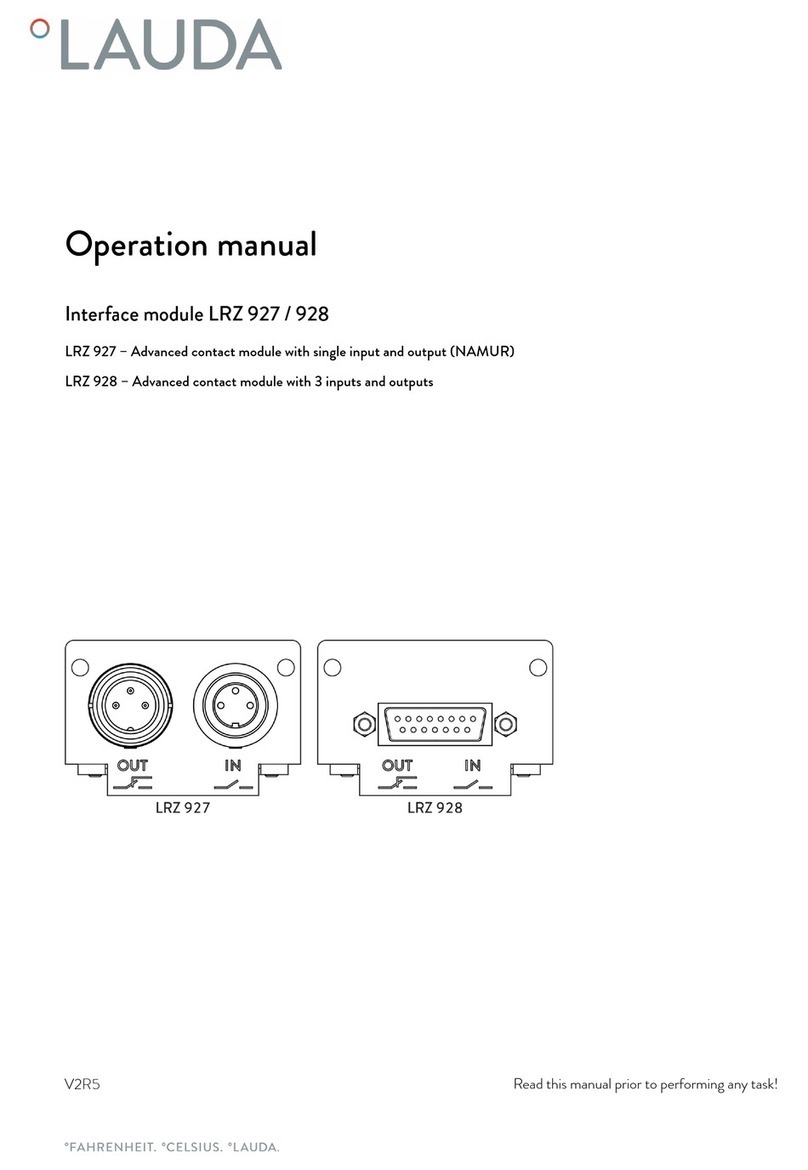

Fig. 4 Installation of the valve into the pipeline

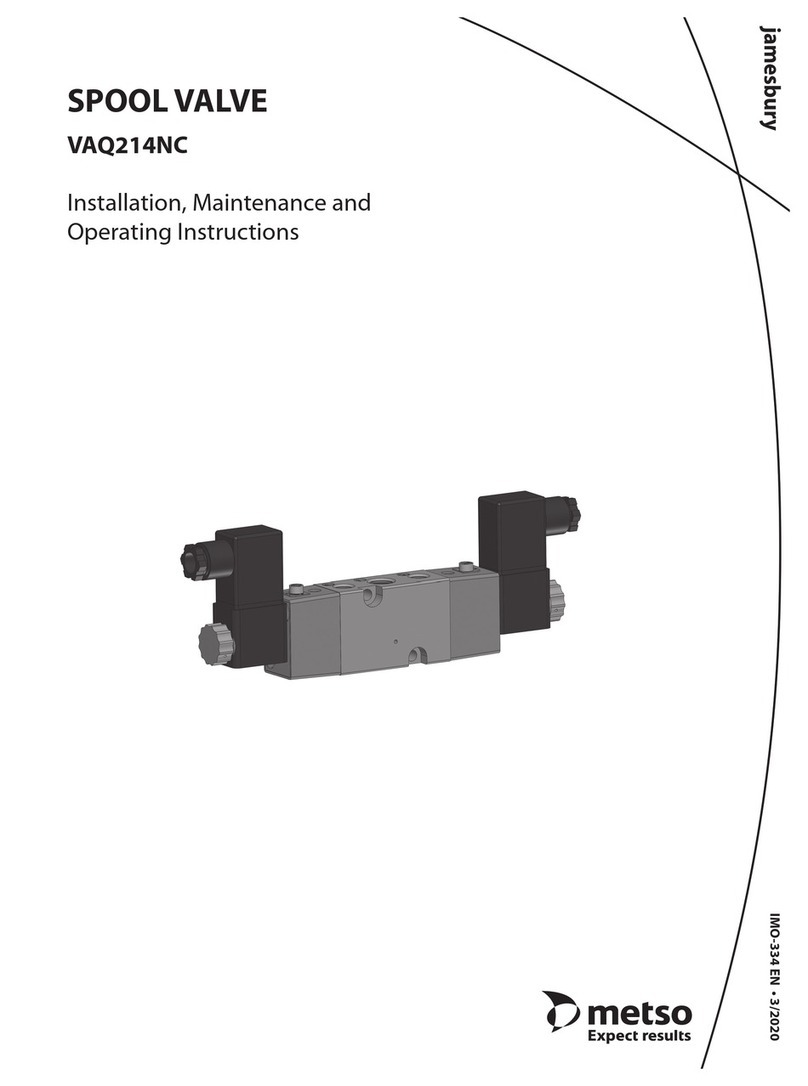

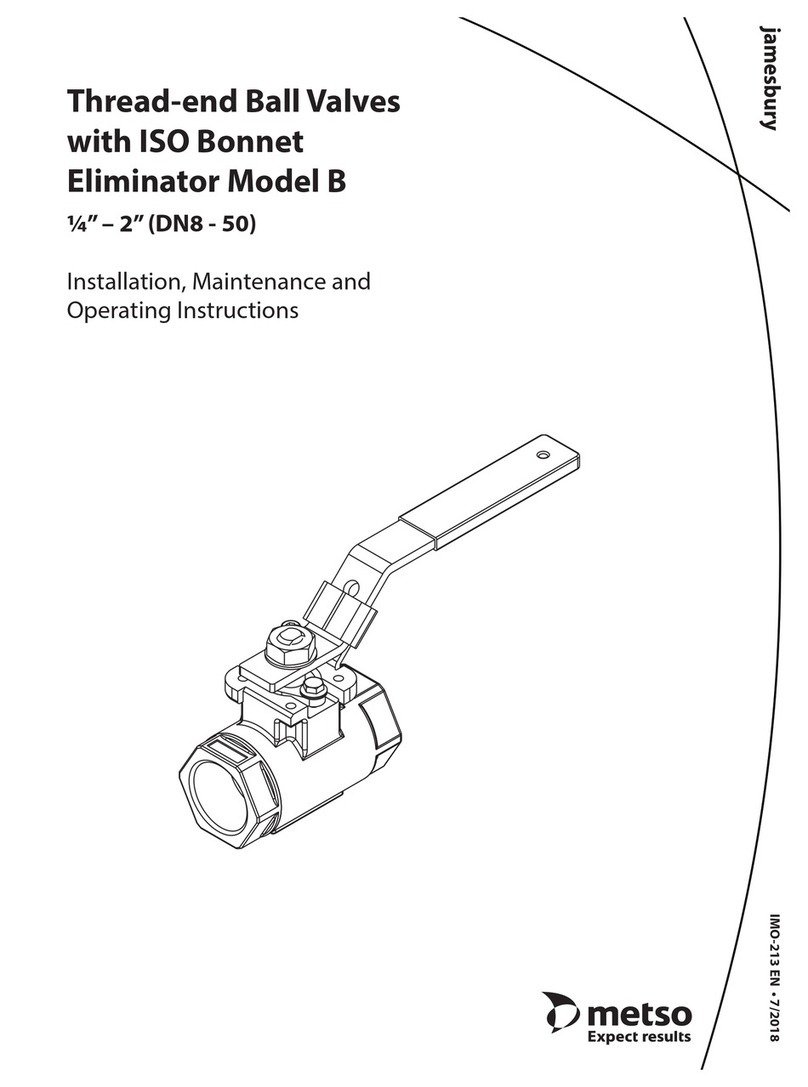

Fig. 5 Protecting the valve during welding

CAUTION:

Observe the safety precautions listed in section

1.8 before starting work.