METVISA CFH.300 Series User manual

1

2

CONGRATULATIONS,

You have just purchased a IMG-BRASIL equipment, product of the highest quality, safety

and efficiency.

Founded in 1989, IMG-BRASIL is a respected company as one of the best and most

complete companies in the field of gastronomy equipment manufacturing.

Constant innovation and improvement of its products, using top-of-line raw materials, ensure

superior products consumed in Brazil and in more than 25 countries worldwide.

THE RELIABILITY AND CERTAINTY OF A GOOD PRODUCT ARE IN THE NAME

IMPORTANT:

PRODUCT FOR PROFESSIONAL USE. DO NOT USE BEFORE READING THE MANUAL CAREFULLY.

IN CASEOF QUESTIONS,PLEASECONTACTUS:

:

IMG-BRASIL Gastronomy Machinery Industry Ltda.

CNPJ 11.193.347/0001-14 - CREA 131726-3

Road. Antônio Heil –KM 23 Nº 5825 –Neighborhood: Limoeiro –ZIP CODE 88352-502

Brusque –SC –Brasil

Phone/fax. +55 47 3251-5555 - Site: www.metvisa.com.br

Mail: sac@metvisa.com.br -export@metvisa.com.br

3

INDEX

1. Safety Information......................................................................................................................... 4

1.1 General Warnings...................................................................................................................... 4

1.2 Mechanical Safety ..................................................................................................................... 5

1.3 Electrical Safety......................................................................................................................... 6

2. Technical Characteristics............................................................................................................. 6

2.1 Main Components...................................................................................................................... 6

2.2 Technical Data........................................................................................................................... 7

3. Installation..................................................................................................................................... 8

3.1 Equipment Layout...................................................................................................................... 8

3.2 Electrical Connection................................................................................................................. 9

3.3 Safety Procedures and User Instruction................................................................................... 10

4. Equipment Use............................................................................................................................ 11

4.1 Utility........................................................................................................................................ 11

4.2 Commands.............................................................................................................................. 11

4.3 Operating Procedures.............................................................................................................. 12

5. Cleaning and Maintenance ......................................................................................................... 15

5.1 Cleaning Procedures and Products Used................................................................................ 15

5.2 Breakdown Maintenance and Procedures................................................................................ 17

5.3 Prolonged Interruption in Use of Equipment............................................................................. 19

6. Problem Analysis and Resolution.............................................................................................. 19

6.1 Problems, possible causes and solutions ................................................................................ 19

7. Lifetime of the Equipment and Components............................................................................. 20

8. ANNEXES..................................................................................................................................... 21

Electrical Schematic –Voltage 110 V or 220 V.............................................................................. 21

Exploded View............................................................................................................................... 22

Spare Parts ................................................................................................................................... 24

ATTENTION!

The characteristics, pictures and figures presented in this manual should be considered for

information. IMG BRASIL reserves the right to make such modifications as may be deemed

necessary without prior notice.

4

1. Safety Information

1.1 General Warnings

•Cautions / precautions must be observed when installing, using, maintaining and discontinuing use

of this equipment;

•Before carrying out any operation (assembly, use, maintenance and reuse after prolonged non-use

of the equipment), read the manual carefully;

•The equipment must be used by trained people familiar with the use and safety regulations

described in this manual;

•This equipment is not intended for use by people (including children) with reduced physical, sensory

or mental capacities, or people with lack of experience and knowledge, unless they have received

instructions regarding the use of the equipment or are under the supervision of a person responsible

for their safety.

•It is recommended that children be supervised to ensure that they are not playing with the

equipment;

•In case of rotation of the people that will work with the equipment, the new operator must be

educated about the standards and the operation of the equipment;

•The operator must use the Adequate PPE (personal protective equipment). As for example: use

hair caps, preventing them from locking in the equipment's moving parts

•The operator must always be aware of situations that can cause a risk of accidents and avoid them.

For example: avoid working with loose uniform sleeves, where they can lock in moving parts, causing

accidents;

•After reading and clarifying all doubts, this manual should be carefully stored in an easily accessible

location, known to all people who will operate the equipment and make it available to those who will

carry out maintenance for any inquiries. Whenever any questions arise, be sure to check the manual.

Do not operate the equipment in any way with doubts;

•In the installation, it is essential to make this manual available to the professionals who will do the

work.

•Before starting cleaning and any type of maintenance, it is essential to disconnect the equipment

from the power supply;

•Periodically check the condition of cables and electrical parts;

•Never put your hands, fingers or objects on the cutting disc, on moving parts or in any opening with

the equipment on, as this may cause an accident;

•Do not use frozen products such as meat, chicken or fish on the bone and non-food products to cut

in the equipment;

•Do not leave the equipment turned on unattended.

ATTENTION!

Do not perform repairs on your own. Go to a service center authorized by the manufacturer.

Use only original parts in your equipment.

5

1.2 Mechanical Safety

•Never put your hands, fingers or objects on the cutting disc, on moving parts or in any opening with

the equipment on, as this may cause an accident;

•When cleaning the cutting disc, be extremely careful. The disc is very sharp and can easily cause

accidents (cuts, for example) if not handled carefully. Just clean the disk with the equipment

disconnected from the mains;

•Before turning on the equipment, make sure that the movable table has the rails perfectly fitted into

the grooves and that the bearing has been mounted in the transverse groove (see more details in

item 4.3 of this manual).

The equipment described in this manual complies with the regulation against mechanical

risk. Security is achieved with:

1. Mechanical design that makes it impossible to reach electrical parts and sharp rotating parts by

hand;

2. Structure, that protects the entire engine and electrical parts, preventing operator access and

contact with water, dust and other materials;

3. Base with protection, preventing access to moving parts, such as gear transmission sets;

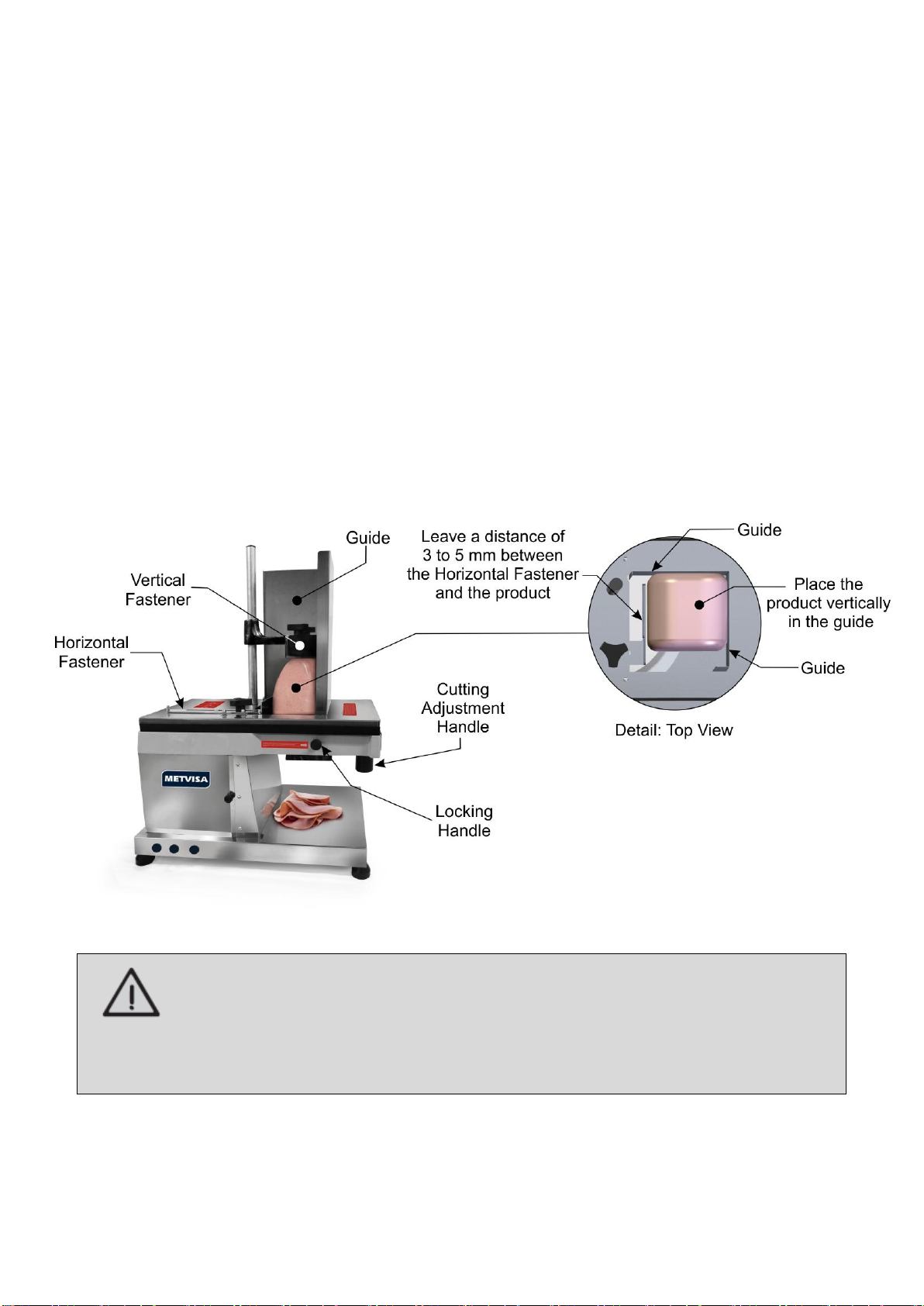

4. Groove, used to guide the product to be sliced without the need for the operator to use his

hands;

5. Horizontal fastener that holds the food against the guide preventing it from moving

Vertical fastener, pushes the product against the cutting disc. Both fasteners work so that the

operator does not use his hands during the food cutting process;

6. Mobile Table, makes the cutting movement of the product automatically;

7. Non-slip Feet;

8. Sharpener and Deburring, they work so that it is not necessary to disassemble the mobile table

and the cutting disc from the equipment, making the sharpening process safer;

9. Protection of the sharpener and deburring, prevents access to the sharpening and deburring

wheels and the cutting disc when the moving table is in motion.

To view the parts described above, see the image in item 2.1 (Main Components –page 7) of this

manual.

6

ATTENTION!

Whenever any item related to the safety of the equipment is removed (such as when

cleaning or maintenance), put it back in its proper place and confirm that it is performing its

function correctly.

1.3 Electrical Safety

•Periodically check the condition of cables and electrical parts;

•If the power cord is damaged, it must be replaced with a new one. The exchange must be carried

out by the manufacturer, an authorized agent or a qualified person in order to avoid risks;

•Do not use water jets, as it may cause electric shock. To clean your equipment, follow the

instructions in item 5 of this manual;

•Do not work with the equipment in damp places, or with wet clothes and shoes. Put on proper

footwear, this will avoid electric shocks and even death;

•Place the equipment on a firm, dry and well-leveled surface;

•Never carry out any maintenance, adjustment or disassembly operations on the device while it is on.

For such procedures, make sure that it is turned off, removing the plug from the electrical outlet;

•Do not use extension cords or adapters with various other appliances connected to them. This may

cause fire or overload;

The components used for safety against electrical hazards have been selected in accordance with

applicable safety standards. Given the perfect insulation of all electrical parts and the excellent

resistance of all the materials used, this equipment is capable of carrying out the tasks it is intended

to do.

ATTENTION!

Whenever any item related to the safety of the equipment is removed (such as when

cleaning or maintenance), put it back in its proper place and confirm that it is performing its

function correctly.

2. Technical Characteristics

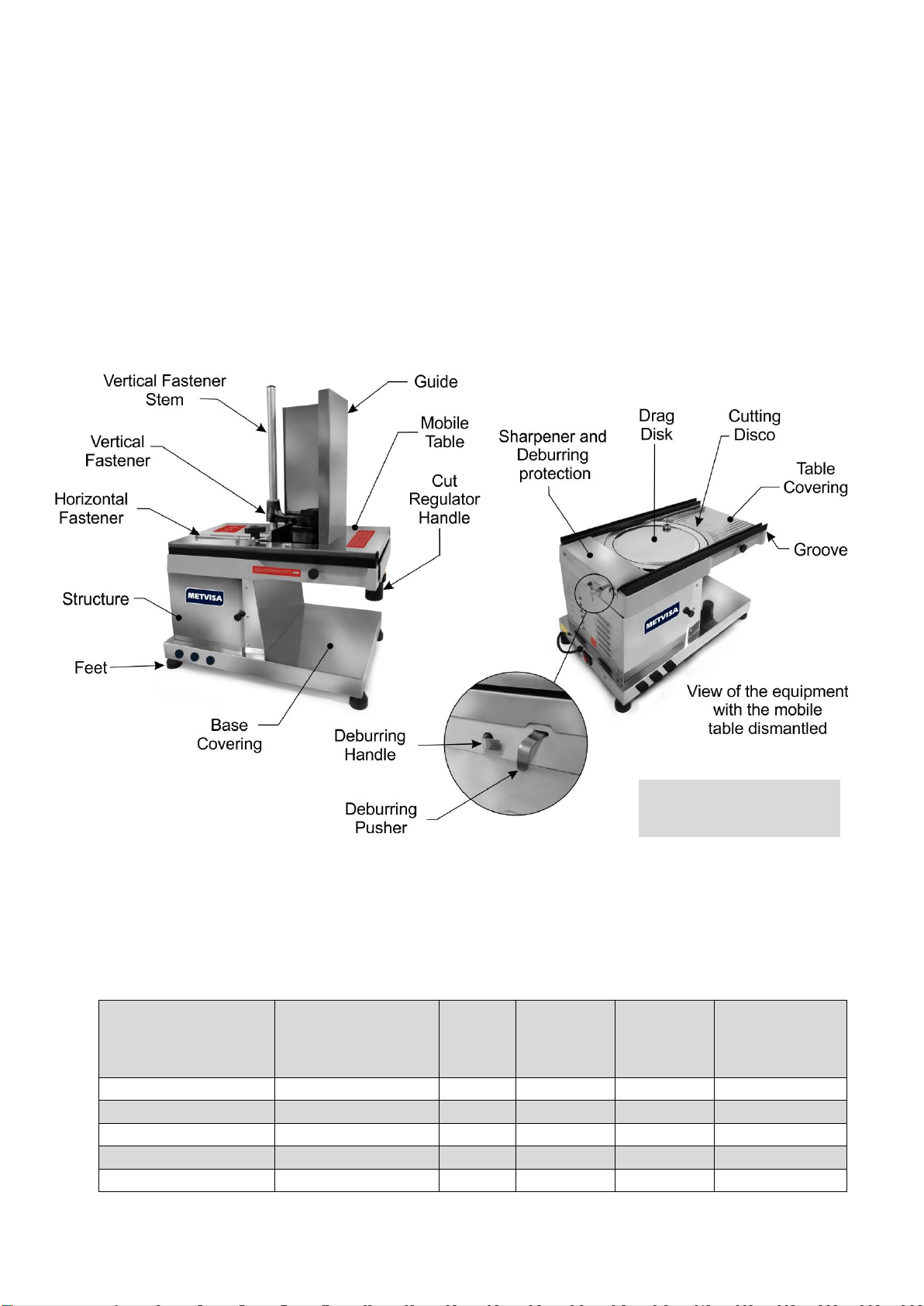

2.1 Main Components

For the equipment described in this manual, safety in use, cleaning, maintenance and

maximum hygiene are guaranteed by the project and special design of all parts and also by using

stainless steel and other materials suitable for contact with food.

7

The equipment was built with the following features:

•Cutting disc and drive disc, made of steel with a hard chrome surface treatment. Its design and

production guarantee perfect cutting precision.

•Movable table, rail, structure, tray, horizontal fastener and base covering are made from 430

stainless steel, which has superior corrosion resistance than other steels. It is a material resistant to

the attack of several corrosive agents;

•Vertical fastener made of ABS plastic. It is non-toxic, durable and resistant to the attack of corrosive

agents.

See below the main components of the equipment:

2.2 Technical Data

Model

Standard

Measures

Length.xHt.xWidth

(mm)

Net

Weight

(kg)

Voltage

(V)

Rate

(A)

Capacity

(slices/minute)

CFH300110M604

620x810x420

48,6

110

5,10

45*

CFH300220M501

620x810x420

46,8

220

2,8

45*

CFH300220M502

620x810x420

46,8

220

2,8

45*

CFH300220M504

620x810x420

46,8

220

2,8

45*

CFH300220M604

620x810x420

48,6

220

2,95

45*

* It may vary due to the user's working speed and according to the quality of the processed product.

Note: For exploded view with

spare parts list, see the

annexes.

8

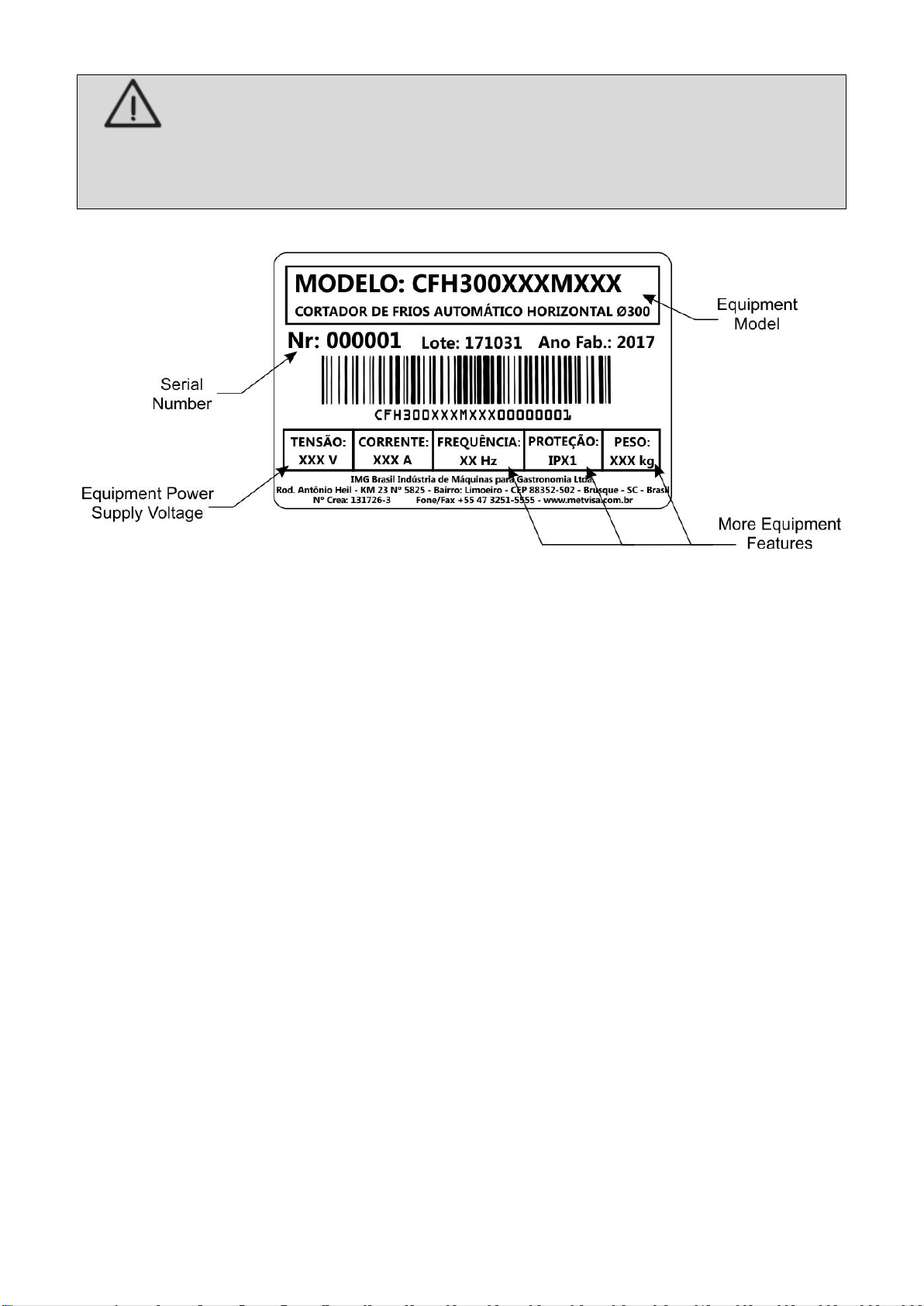

ATTENTION!

Characteristics like: model, serial number and voltage of the equipment are provided on the

label (figure below). Before installation, check that the power supply voltage of the

equipment corresponds to that of the mains

3. Installation

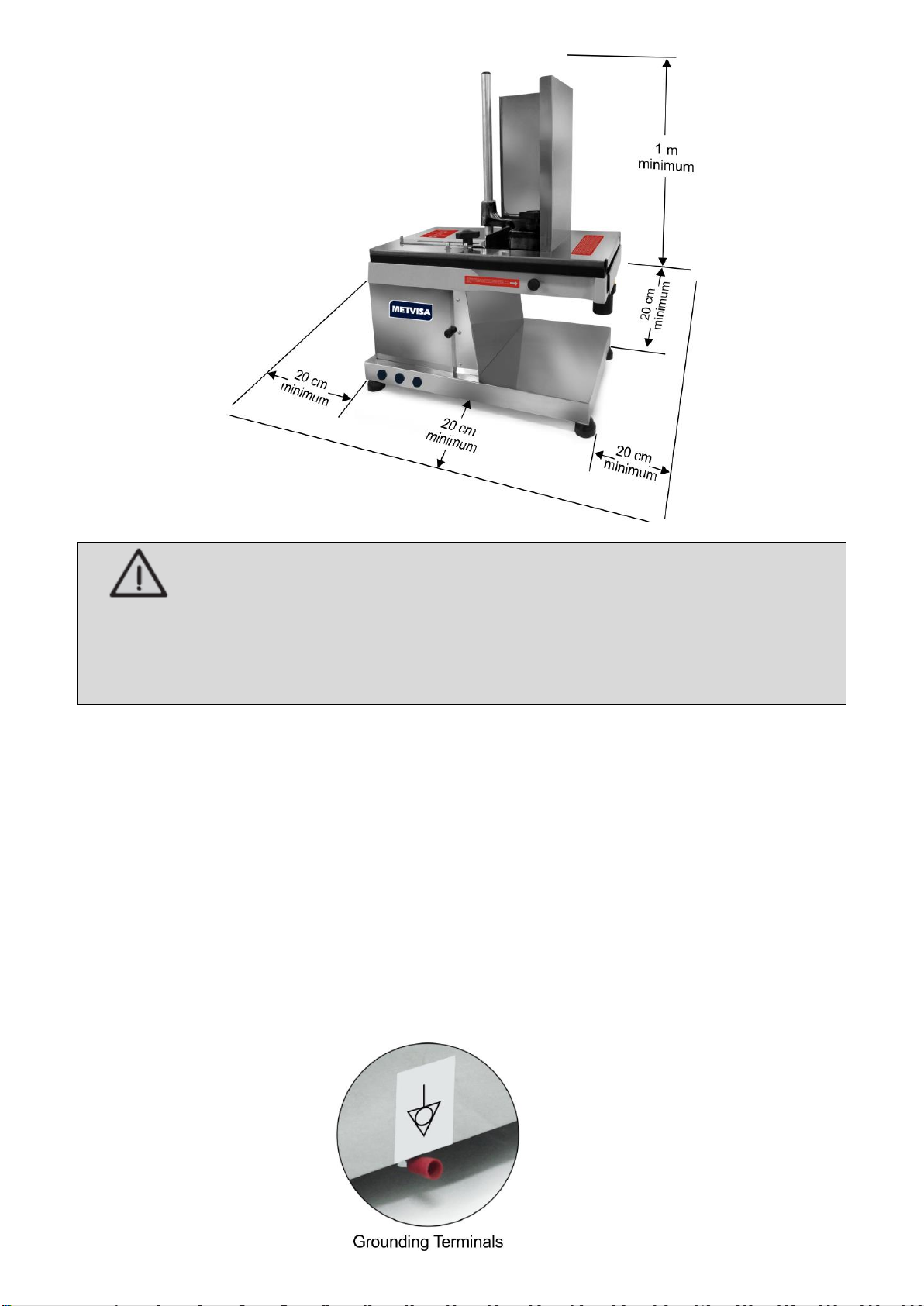

3.1 Equipment Layout

Connection to the electrical main and provision for operation must be carried out by a

qualified professional. Check that the voltage of the equipment is in accordance with that of the

electrical network.

During installation, it is essential to make this manual available to the professionals who will

carry out the installation.

To ensure correct operation and safety, the equipment must be positioned in an airy

environment and on a sufficiently large, well-leveled, dry and stable support surface, away from

sources of heat and water taps, and at an average height. of 80 cm. Install your equipment leaving a

distance of at least 20 cm around it and 1 m in height, so that you have enough space for inspection,

maintenance, cleaning and use.

9

ATTENTION!

The installation and the place where the equipment will be disposed must comply with the

norms of risk prevention and safety at work (regulatory norm in force in your country).

The manufacturer does not take responsibility for any direct or indirect damages caused by

non-compliance with these rules and other instructions presented in this manual.

3.2 Electrical Connection

The equipment is supplied with a power cord to plug into an electrical outlet. If the power

cord is damaged, it must be replaced with a new one. The exchange must be carried out by the

manufacturer, authorized agent or qualified person, in order to avoid risks.

The type of plug on the power cord varies by country. The installation of the equipment must

be carried out by a technician qualified for this function and observing the current regulations in the

country, especially with regard to grounding connection (if applicable).

Also included with the equipment is an equipotential grounding terminal, located at the rear

of the base covering.

10

The terminal identified in the figure aside is an additional protection to the

grounding that is provided for in the electrical network, it must be connected

to a grounding terminals, regardless of the connection to the electrical

network, and the other products that have accessible metallic parts, and that are stationary,

must also be connected to this bus as well as the service bench itself, if it is made of

metallic material. In this way, all these products will be under the same electrical potential,

avoiding undesirable leakage currents.

The equipment described in this manual is single-phase and single voltage, 110 V or 220 V.

If you need to change the voltage of your equipment, please contact the manufacturer or authorized

dealer.

ATTENTION!

Before turning on your equipment, always check that the mains supply voltage is the same

as the equipment's voltage.

The supply voltage of the equipment is 110 V or 220 V single-phase, as can be seen on the

voltage label affixed to the power cable or as indicated on the nameplate data label located

on the back of the equipment (see figure of this label in item 2.2 of this manual).

Make sure that the voltage of the electrical network where the equipment will be installed is

compatible with the voltage indicated on these labels.

For more details on the rest of the electrical part of the equipment, refer to the electrical

diagram in the manual annexes.

IMPORTANT

The manufacturer does not take responsibility for any direct or indirect damages caused by

non-compliance with these rules and other instructions presented in this manual.

3.3 Safety Procedures and User Instruction

The professional that effects the sale of the equipment must instruct the user about the

correct operation of the equipment and must give the instruction manual.

The user must be informed of the necessary safety procedures and must respect them, as

well as all procedures described in this manual.

Your equipment has mechanical protections (see item 1.2 Mechanical Safety) that prevent

access to moving parts and electrical components. Removing or tampering these safety components

can cause serious risks to the worker's upper limbs.

11

4. Equipment Use

4.1 Utility

This equipment is exclusively intended for slicing different cheeses and hams.

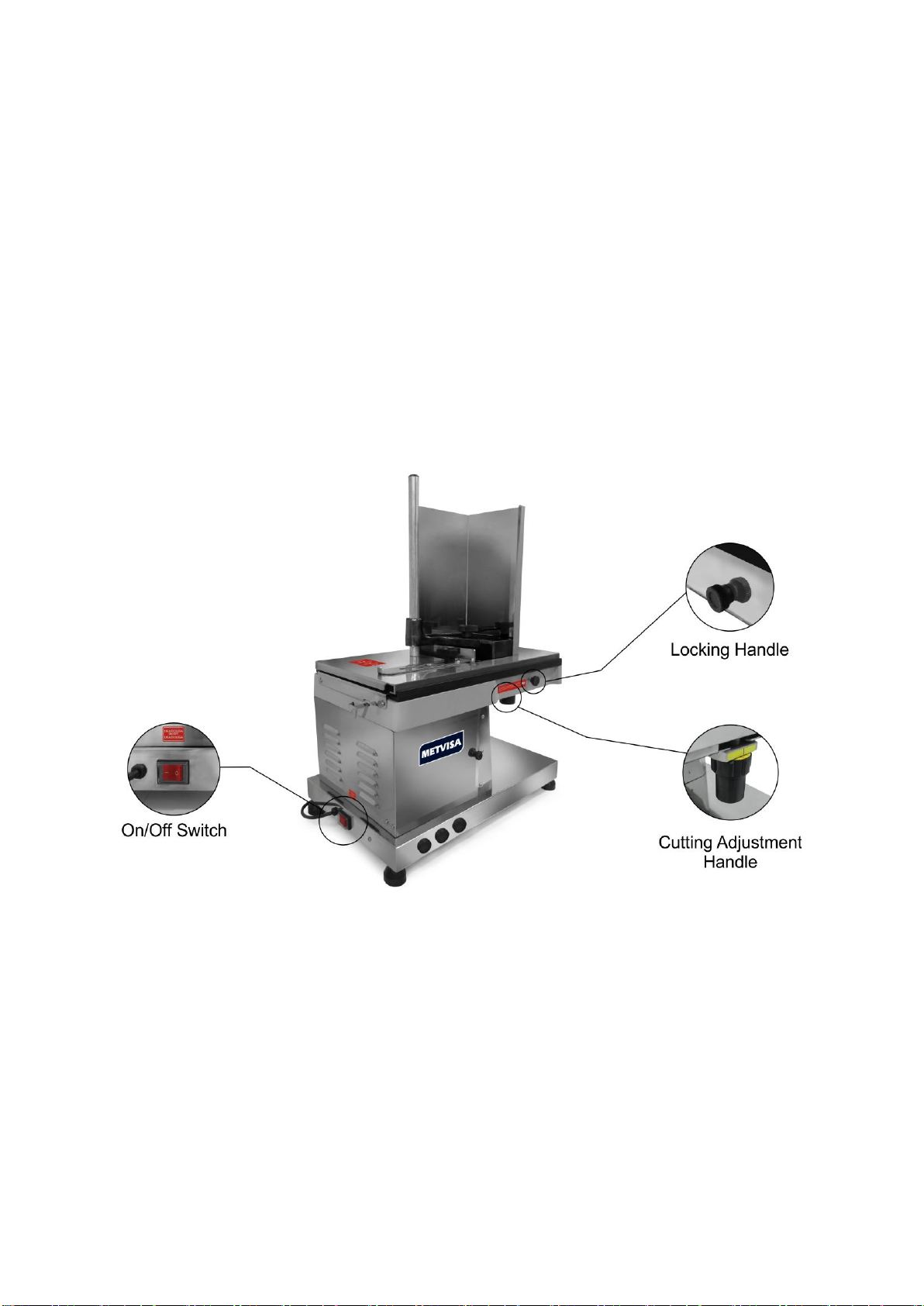

4.2 Commands

The equipment has an on/off button and cutting adjustment handle and locking handle.

The on/off switch is on the left side of the base and the locking handle is located on the front

of the equipment. The cutting adjustment handle is located below the movable table.

See the description of each command below:

•On/Off Button –used to turn the equipment on and off. In position “1” it turns on, in position “0” it

turns off.

•Cutting Adjustment Handle –regulates the thickness of the slice of the product to be cut.

•Locking Handle –locks the table that regulates the thickness of the slice, so that the table does not

move during the process. To unlock, rotate the handle counterclockwise. After adjusting the slice

thickness using the cutting adjustment handle, lock the table by rotating the locking handle clockwise.

12

4.3 Operating Procedures

Before operating your equipment, remove the protective rubber from the cutting disc and

clean the components that will come into contact with the food (fasteners, gutter, base coating,

protection for the sharpener and deburring, etc.), for this, make sure that that the equipment is

disconnected from the mains, only then carry out the disassembly. Follow the cleaning instructions in

item 5 of this manual.

Check the disassembly and assembly procedure described below:

•Disassembly: Disconnect the equipment from the mains. To remove the structure, rotate

the handle (located on the front and back of the equipment) to unlock, then pull the structure out. With

your hands positioned at either end of the movable table, lift the table with both hands at the same

time. Only after removing the mobile table will it be possible to remove the protection of the sharpener

and deburring, where an appropriate tool will be needed to remove the screws.

To remove the drive disc, pull it up through the bearing.

Note: This procedure is used to clean the cutter disk and the tray (fixed inside the cabinet) daily.

•Assembly: The assembly procedure is the reverse of disassembly. Fix the protection of the

sharpener and deburring with the screws. When assembling the moving table, the transverse groove

must be fitted into the bearing located above the drive disc (parts marked in yellow), at the same time

the rail must be fitted into the plastic groove. Make sure the rail is positioned on the same side as the

cut adjustment handle. Finally, fit the structure by rotating the handle to lock it.

13

If the movable table is not secure, it may not have been seated correctly. In this case, repeat

the operation and if not successful, contact technical assistance.

ATTENTION!

Never turn on the equipment with the movable table out of position or with the bearing

disengaged from the transverse groove (picture below), as this could cause accidents.

ATTENTION!

Always make sure the bearing is correctly fitted in the transverse groove (as per the

assembly instructions).

•Operation: The equipment can only be operated after checking that the movable table is correctly

assembled, that the structure is locked with the two handles, and that the voltage of the equipment

complies with that of the mains supply.

14

After checking these items, follow the equipment operation procedure below:

•Connect the power cord to the electrical main;

•With the product to be cut, lift the vertical fastener by the handle and place the product

vertically in the guide, then, to secure it, lower the fastener;

•Loosen the handle of the horizontal fastener and adjust according to the measurement of

the product, leaving a distance of 3 to 5 mm between the fastener and the product, in order to keep

the product in a vertical position, but without preventing it from descending by gravity;

•Unlock the locking handle and through the slicer adjust the slice thickness. Then lock the

locking handle again;

•Turn the power switch to the “1” (on) position. At that moment, the equipment will perform

the cutting movement automatically;

•After the end of the process, turn off the equipment by pressing the on-off button in position

“0” (off).

ATTENTION!

Always keep the structure mounted and locked by the handles and constantly empty the

tray located on the inside of the structure, in this way, excess food is prevented from

overflowing and leakage from the motor, causing accidents and damage to the equipment.

15

ATTENTION!

If you notice that the equipment is unable to cut the product or that it stops cutting, observe

the consistency of the product. Very hard or frozen products can impair the speed and

performance of the motor, cutting disc, and the life of the equipment.

Never use frozen products.

For a good performance of the equipment, it is recommended to periodically sharpen and

deburr the disc. See item 5.2 of this manual for instructions on the sharpening process.

Failure to observe these guidelines will be considered an unsafe act and abusive use of the

equipment.

ATTENTION!

Never remove the mobile table and structure with the equipment on, as well as shouldn't

you place your fingers, hands or objects (such as spoons and knives) on the cutting disc, as

this could cause accidents.

Always use the product fastener for cutting, never use your hands to hold the product

during operation, as the moving table will be in motion.

In case of any irregularity, contact the nearest authorized technical assistance service.

IMPORTANT

The operator must wear PPE (personal protective equipment). For example: wear a cap on

your hair, preventing it from getting caught in the moving parts of the equipment and

appropriate gloves, which, in addition to guaranteeing hygiene when handling the product,

protect the operator while cutting the food.

5. Cleaning and Maintenance

5.1 Cleaning Procedures and Products Used

Your equipment was built with first-line materials, so use it properly and you will obtain great

satisfaction. Always keep your equipment clean and well-cared for, which will make it much more

durable.

Daily cleaning of the equipment must be carried out for good operation and durability.

ATTENTION!

Before performing maintenance or cleaning, make sure that the equipment is switched off

and that the plug is disconnected from the mains.

16

ATTENTION!

Do not use water jet to clean the equipment.

IMPORTANT

This equipment is not intended to be immersed in water for cleaning.

Follow the instructions below to find out which parts can be immersed and the special care

to be taken with the other parts.

The detachable parts (structure, sharpener/deburring and drive disc) must be removed from

the equipment (as instructed in item 4.3) and washed with water and neutral detergent. Clean the

corners well, eliminating food residues.

The rest of the equipment should be cleaned as often as possible to prevent food residues

from drying out and sticking to the parts. For cleaning, dilute the soap or neutral detergent in warm

water and apply with a soft cloth. With a cloth dampened with water, rinse and then dry the parts with

a soft, dry cloth.

If necessary, the vertical and horizontal fasteners can also be removed to clean the

equipment.

Never use abrasive products or sponges and substances containing acids or chlorine to clean

metal parts, as they can scratch or damage the surface of the parts causing corrosion points. Do not

pour water over the motor and electrical parts for cleaning, otherwise, when turning it on, it may cause

an electric shock or even burn the equipment.

After cleaning the mobile table, it is recommended to always check and keep the rails and the

transverse groove lubricated, avoiding their oxidation and contamination of the stainless parts. Keep

lubricating with white Vaseline oil or other non-toxic products found on the market. Never use oil from

oilseeds or olives, as this may compromise the functioning of the mobile table.

ATTENTION!

Take care when cleaning the cutting disc and the vertical fastener, as they are parts that

have extremely sharp blades. Handle with care, otherwise it may cause accidents. The same

attention applies to any other sharp component of the equipment.

As soon as you finish cleaning the cutting disc, replace the movable table.

Never operate the equipment without the mobile table mounted, as this could cause

accidents.

IMPORTANT

The manufacturer does not take responsibility for possible direct or indirect damage caused

by non-compliance with the rules and instructions presented in this manual.

17

ATTENTION!

It is extremely important that the products used in cleaning ensure maximum cleanliness

and are not toxic.

5.2 Breakdown Maintenance and Procedures

The operator must be instructed to carry out routine inspections, making small adjustments,

cleaning and observing signs of breakdowns that may occur. Examples include: checking for strange

noises; loss of machine power; the non-execution by the equipment to the proposed service; among

others. Actions like these are indispensable to guarantee a longer equipment life.

ATTENTION!

When maintenance occurs (even small adjusts) disconnect the equipment from the electrical

mains.

It is recommended that each 6 months be made preventive maintenance, checking and

adjusting the loose, cleaning the internal parts, and others. Detecting broke parts or without the

correct functionality the worker needs to exchange the parts, always using original parts only.

By carrying out preventive maintenance, the inconvenience of having the equipment stopped

when it is most needed is eliminated, the cost of maintenance is reduced and the risk of accidents is

reduced.

Check the sharpening and lubrication processes described below.

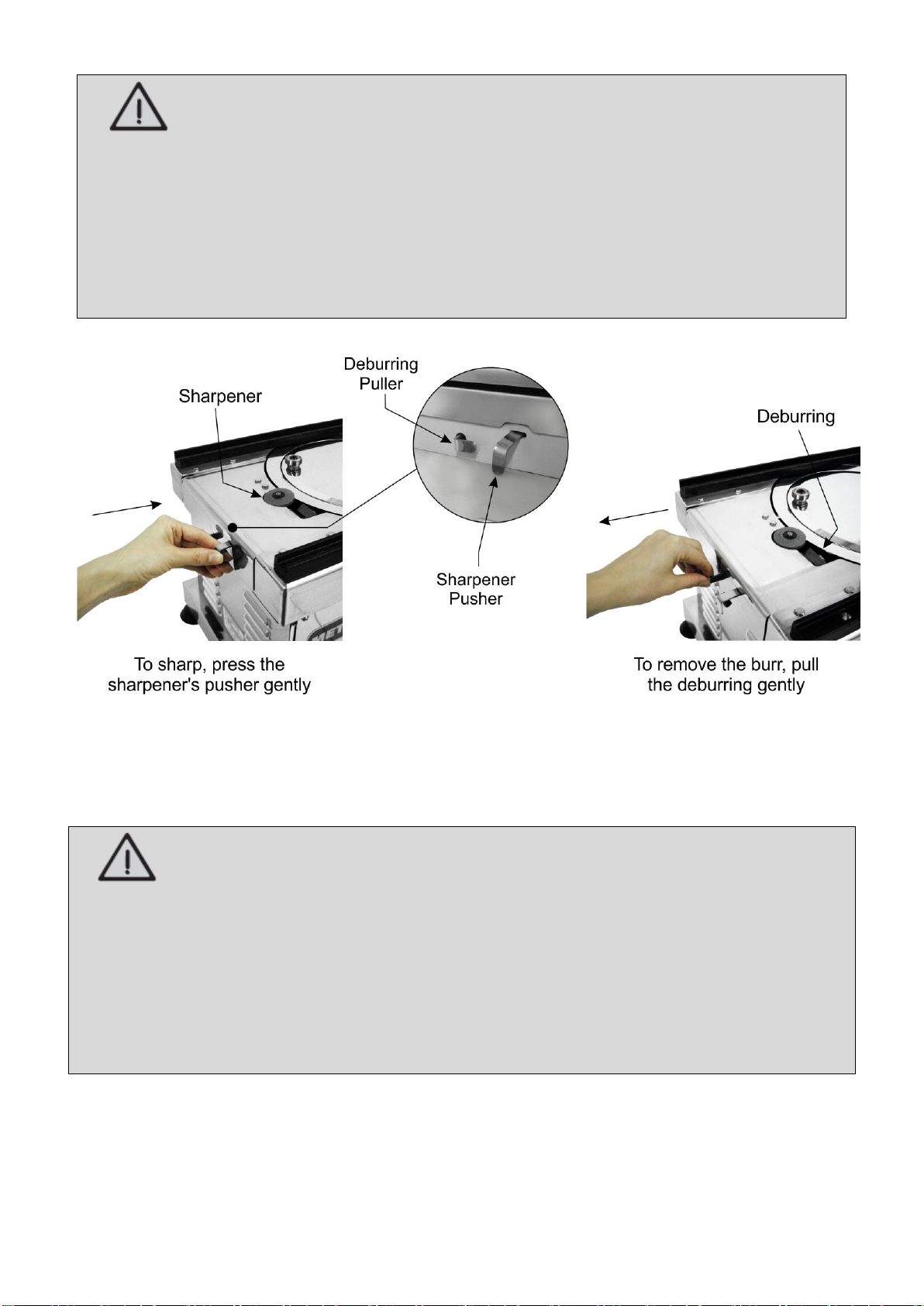

•Sharpening: Sharpening is a very important operation for your equipment. It should be

done whenever the cut does not result in a slice of uniform size and thickness or when the cutting

wheel tends to drag the slice of the product.

Before sharpening, thoroughly clean the entire equipment and degrease the cutting disc very

well, as instructed in item 5.1.

For the sharpening process, perform the following procedures:

1. Turn the power switch to the “1” (on) position and leave it on for a few seconds. Start

sharpening by pressing the sharpener's pusher gently so that the stone gradually touches the disc;

2. To remove the burr, pull the deburring and gradually place the stone on the cutting disc,

removing the burrs;

3. After finishing sharpening, turn off the equipment by pressing the on-off button in position

“0” (off);

4. Remove the mobile table (follow disassembly instructions –page 12) to have access to

the cutting disc;

5. Clean up;

6. Assemble the mobile table (follow assembly instructions –page 13).

18

ATTENTION!

In the following figure, just as an illustration of the sharpening method, the sharpener and

deburring are seen without the moving table and the protection of the sharpener and

deburring, however, for practical execution, for your safety do not disassemble the

protection and the moving table.

During the sharpening process, the mobile table will be in motion, for your safety, position

your hand so that it does not come into contact with the mobile table.

•Lubrication: Periodically lubricate the sliding parts (grooves, drive disc and transverse groove) with

white vaseline oil. Never use oil from oilseeds or olives, as this may compromise the functioning of the

mobile table.

ATTENTION!

The preventive maintenance must be made by a capacity person.

Make sure that the equipment be disconnected from the electrical mains.

Always that some item referred to safety be removed from the equipment (for example, for

cleaning or maintenance), replace it in place and confirm that it is performing its function

correctly.

Detecting broke parts or without the correct functionality, please contact the nearest

authorized service center.

19

5.3 Prolonged Interruption in Use of Equipment

When leaving the equipment unattended for an extended period of time, unplug it from the

mains, perform a complete cleaning, including the different accessories. It is advisable to protect all

parts of the equipment with white vaseline oil or with suitable commercially available products. The

equipment must also be protected from dust, covering it with a nylon or other material.

6. Problem Analysis and Resolution

6.1 Problems, possible causes and solutions

Products with IMG quality are designed with materials and components that guarantee

longer life to your equipment. However, due to natural wear, improper use or lack of maintenance, the

equipment may have irregularities in its operation.

In the following table, you can check possible causes and solutions:

PROBLEMS

POSSIBLE CAUSES

SOLUTIONS

Equipment do not turn on

- Lack of electricity;

- Check if there is energy in the

electrical network;

- Check for power on the network;

- Check that the on-off switch is in

position “1” (on).

- Voltage different from electrical

mains voltage;

- Send the equipment to the nearest

authorized service station or contact

the factory;

- Bad contact in the internal

electrical connections;

- Problems with the motor;

The disk stops rotating

during operation.

- Lack of electricity;

- Check if there is bad contact in the

connection of the power supply cord

with the electrical network.

- Food locked in disk.

- Follow the disassembly and

assembly procedure (pages 12 and

13).

The equipment turns on,

but rotates at low speed

when in contact with food.

- Defect with the motor start

capacitor.

- Send the equipment to the nearest

authorized service station or contact

the factory;

- Problems with the motor;

- Foods with a very rigid

consistency.

- Observe the consistency of the

product. Never use frozen or very hard

products, as they can impair the speed

and performance of the motor, cutting

disc, and the life of the equipment.

Smell of burning and/or

smoke.

- Device voltage different from the

mains voltage.

- Send the equipment to the nearest

authorized service station or contact

the factory;

- Problems with the motor;

- Problems in the internal or

external electrical circuit of the

device.

Strange noises.

- Mobile table not properly fitted.

- Follow the disassembly and

assembly procedure (pages 12 and

13).

- Poorly fitted parts

- Send the equipment to the nearest

authorized service station or contact

the factory;

20

Damaged electrical cable.

- Transport breakdown;

- Improper use and/or disposal of

the equipment.

- The electric cable must be replaced

by the manufacturer, an authorized

agent or a qualified person, in order to

avoid risks.

Cutting difficulty or

uneven slices.

- Disc with burr or unsharpened.

- Follow the sharpening procedure

(page 18).

Moving parts difficult to

slide.

- Lack of lubrication.

- Follow the lubrication procedure

(page 19).

For more information and clarification, contact your nearest Authorized Service Center.

7. Lifetime of the Equipment and Components

The life of the equipment can vary from 3 to 5 years depending on the proper use, cleaning,

maintenance and quality of its components.

The following is the useful life relationship of the major components:

•On/Off Button: 10000 maneuvers

•Cables and wires: 25 years

•Electrical terminals: 8 years

This manual suits for next models

5

Table of contents

Other METVISA Commercial Food Equipment manuals