Meva MevaLite Owner's manual

Technical Instruction Manual

June 2022

MevaLite

ML-2

MevaLite

MevaLite is a modular formwork system that can be either handset or

gang formed. It is suitable for use on residential, commercial, industrial

and highway projects.

The panels are composed of closed profile powder coated aluminum

frames and a high grade alkus composite facing that provides an

excellent concrete finish. Panels are connected with the MEVA assembly

lock which results in fast and ecient assembly with no nuts and bolts.

A complete formwork assembly including accessories weighs about 12

psf. Panels are designed for a maximum lateral concrete pressure of 1350

psf when properly supported.

MevaLite panels are available in 4 different heights (9’, 6', 4’, and 3’) and

in 5 different widths (3’, 2’, 1’-6”, 1’-0”, and 6”). In addition, 2’-6" wide

multi-purpose panels are available in each height. These panels have

multi-adjustment profiles for placing ties or column clamps and are ideal

for forming 90° corners, columns, pilasters, and connections to existing

walls.

Introduction

Available accessories include aluminum fillers (1”, 2”, and 3”), inside

corners (12”x12”), outside corners, push-pull props, and walkway

brackets. Threaded nuts built into the panels allow for easy attachment

of accessories.

Please check here for the most up to date manual:

https://www.meva.net/en-us/tools-downloads/downloads

And please check here for the MEVA YouTube channel:

https://www.youtube.com/user/mevalive/featured

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-3

Safety Rules &

Recommendations:

ÆThis manual contains information and instructions on how to use

MEVA equipment in a safe and ecient manner. All construction

personnel involved with the use of this equipment (“User”) must be

familiar with the contents of this manual.

ÆThe user is responsible for identifying and complying with all

applicable government regulations, codes, and ordinances in the use

of this equipment.

ÆMEVA equipment must be erected, used, and dismantled in

accordance with this manual, safe practices, and all applicable

industry standards developed and published by the American

Concrete Institute (ACI), the American National Standards Institute

(ANSI) and the Occupational Safety and Health Administration

(OSHA). Additional workplace safety precautions should be taken

where necessary.

ÆMost examples shown are standard applications that will occur in

practice most often. For applications not covered in this manual,

please contact your MEVA representative for advice.

ÆMany of the details in this manual show specific conditions and

situations during different stages of assembly and are therefore not

always complete. Any equipment or safety accessories not shown in

the details must still be used in accordance with all applicable rules

and regulations.

ÆIn order to assure proper fit and load capacity, do not combine this

equipment with components of other manufacturers unless directed

by a MEVA representative.

ÆThe user must inspect all equipment before each use. Never use

equipment that is damaged, deformed, or weakened due to wear or

corrosion.

ÆNever oil or wax MEVA assembly locks.

ÆThe user must ensure the stability of all components during all

phases of construction.

ÆFor gang formwork, the user should always establish the number

and location of lift points to equalize load on lift brackets and

ensure that no individual component is overloaded.

ÆIt is the user’s responsibility to adjust the pour rate and placement

methods in accordance with ACI 347 for the concrete mixture and

the specific jobsite conditions at the time of placement so that the

specified maximum lateral concrete pressure is never exceeded.

ÆCertain applications will result in a maximum lateral concrete

pressure lower than the system panel capacity. Refer to specific

sections of this manual, MEVA application drawings, or consult your

MEVA representative.

ÆWhen stripping gang formwork, never use the crane to break the

concrete bond. Instead, use suitable tools such as pry bars or wood

wedges. Secure the lift brackets prior to removal of ties, anchors,

and/or bracing.

ÆDo not nail into aluminum panel frames.

Contents

The MevaLite Panel................................................................................4

Multi-Purpose Panels .............................................................................5

The alkus Sheet......................................................................................6

Panel Connection...................................................................................7

Tie Systems............................................................................................8

System Panel Sizes ..........................................................................9 - 11

Tie Placement ......................................................................................12

Stacking Panels....................................................................................13

90°Corners ...................................................................................14 - 17

Articulated Corners.......................................................................18 - 20

Stripping Corners..........................................................................21 - 27

Columns .......................................................................................28 - 29

Fillers ............................................................................................30 - 31

Intersections ........................................................................................32

Bulkheads ....................................................................................33 - 34

Adjoining Walls....................................................................................35

Pilasters ...............................................................................................36

Pilasters at Corners ..............................................................................37

Wall Offsets.........................................................................................38

Vertical Offsets ....................................................................................39

Horizontal Panels .................................................................................40

Wall Braces...................................................................................41 - 43

Form Walkways ...................................................................................44

Crane Hook .........................................................................................45

Gang Forming...............................................................................46 - 47

Adjustable Shearwall Bracket...............................................................48

Assembly, Erection and Stripping ..................................................49 - 54

Transport .............................................................................................55

Service.................................................................................................56

Notes............................................................................................57 - 58

Product List..........................................................................................59

Wall formwork

Technical Instruction Manual / June 2022

ML-4

MevaLite

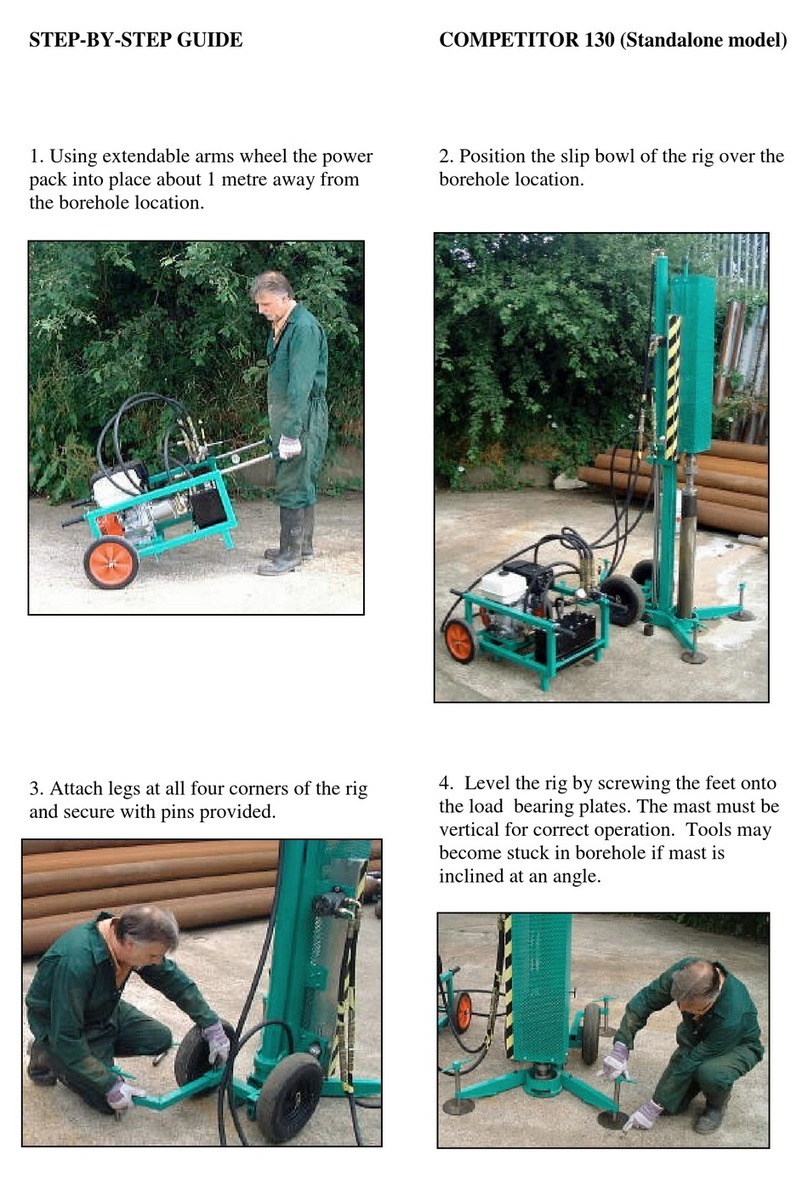

The MevaLite Panel

Fig. 4.1

MevaLite panel

Fig. 4.2

The aluminum frames are

manufactured of closed profiles which

are welded in mitered joints. These

profiles are provided with a groove

and an integrated protection for the

forming face.

Fig. 4.3

Large tie pockets allow for easy

insertion of any tie system (taper ties,

she-bolts, thru-rods).

Fig. 4.4

Pioneering panel connection with

MEVA assembly lock.

Fig. 4.5

The ergonomically designed cross

stiffeners are also made of closed

aluminum profiles. The profiles have

the shape of a bone: they are easy

to grab, and the risk of injuries is

eliminated.

Fig. 4.6

The multi-function profiles have

Dywidag threaded nuts inside which

allow for fast and safe attachment of

accessory parts.

Fig. 4.7

The tie-off bar allows safe working

on the formwork. Under no

circumstances should panels be lifted

or moved using these tie-off bars.

Tie-off bars should only be used with

suitable positioning device systems

as described in OSHA 1926-502(e),

supplied by others.

Or, provided the user adhere to

the guidance set forth in OSHA

1926.502(d)(15), 1926.502(d)(15)(i),

1926.502(d)(15)(ii), and all associated

sections, these tie-off bars may

be used with personal fall arrest

systems that meet the requirements

set forth in OSHA. It is the end

user's responsibility to ensure OSHA

requirements are met.

Fig. 4.1

Fig. 4.6

Fig. 4.5

Fig. 4.4

Fig. 4.3

Fig. 4.2

Fig. 4.7

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-5

Multi-purpose Panels

Multi-function profile

Frame

Standard tie hole

Dywidag-threaded nuts

Holes with threaded nuts in frame at

multi-adjustment profile elevation

Tie-off bar

Ø 1 1/16"

Fig. 5.1

Fig. 5.3

The multi-purpose panels are ideal

for forming 90° corners, columns,

pilasters, bridge abutments and

connections to existing walls.

The panels are provided with multi-

adjustment profiles where column

clamps or ties are mounted.

The panels come with pilot holes

on the back side for drilling

selected tie holes at exact

locations.

Plug the unneeded tie holes with

Plug D27/30.

The 9’ panels have 3 multi-

adjustment profiles, the 6’ and 4’

panels have 2 multi-adjustment

profiles and the 3’ panel has 1

multi-adjustment profile.

Threaded sleeves are also provided

on the frame sides at each tie hole

elevation for tensioning screw

connections.

Description Ref.-No.

ML-multi-purpose panels

9’x2.5’.......................................22-500-25

6’x2.5’.......................................22-501-25

4’x2.5’.......................................22-502-25

3’x2.5’.......................................22-503-25

Plug D27/30 ..............................29-902-61

Multi-adjustment profile

Ø 1 1/16" to Ø 1 1/4" conical

Threaded sleeves

for tensioning

screw connections.

2’-6”

3”

1 ½” 2” 2” 2” 2” 2” 2” 2” 2” 2” 2” 2” 2”

Ø1 1/16”

1 ½”

Fig. 5.2

Wall formwork

Technical Instruction Manual / June 2022

ML-6

MevaLite

The poly-propylene and aluminum

composite forming face has all

the positive properties of plywood

plus important advantages: longer

life span, greater load-bearing

capacity, better nail-holding ability,

fewer and easier repairs, 100 %

recyclability.

Besides the obvious advantages,

such as considerably reduced

cleaning effort, minimum

consumption of release agent

and an excellent concrete finish,

alkus offers substantial ecological

benefits. Substituting plastic

for wood saves valuable timber

resources. Also, the release of

highly toxic dioxin is avoided,

which is released in the process of

burning plywood (that is bonded

with phenolic resin). Used or

damaged alkus plastic sheets can

be recycled into the same product.

It is 100% recyclable, and the

manufacturer guarantees reaccept-

ance.

Fig. 6.3: Composite alkus plastic sheet structure

Frame profile + plywood face Frame profile + alkus sheet

Fig. 6.1: Negative impression in the concrete when using

panels with a conventional plywood face

Fig. 6.2: Smooth and even concrete surface as there is no

projecting profile of the panel frame

Plastic layer

Aluminum layer

Foamed plastic core

Aluminum layer

Plastic layer

The alkus Sheet

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-7

The panels are connected

quickly and eciently with the

EA-assembly lock regardless of

their orientation (Fig.7.1, 7.2).

The lock can be attached on the

frame at any position, and its

5-point contact not only draws

the panels together but aligns

them as well. Only a few hammer

blows are needed to create a

safe connection with perfect

alignment. Since the lock weighs

only 3.3lbs. it can be handled

easily.

Standard lock requirements are

shown in Figure7.4. Additional

locks are required for columns

and outside corners (refer to

respective sections for details).

Panels with aluminum or wood

fillers in between are connected

with the Uni-assembly lock22,

which can accommodate a

maximum filler width of 6.5"

(Fig.7.5).

Panel Connection

Description Ref.-No.

EA-assembly lock .......................29-205-50

Uni-assembly lock 22 .................29-400-85

Fig. 7.1 EA-assembly lock

Fig. 7.2 EA-assembly lock Fig. 7.3 EA-assembly lock

5-point contact

Standard Lock Requirements

Panel Edge Length Number of Locks

9' 4

6' 3

4' thru 1'-6" 2

1', 6" 1

Fig. 7.4 Fig. 7.5 Uni-assembly lock 22

6.5" MAXIMUM

Wall formwork

Technical Instruction Manual / June 2022

ML-8

MevaLite

Tie Systems

Description Ref.-No.

Articuated flange nut 15/120................................29-900-10

5/8" (15mm) Taper Tie Stock Sizes

16/41 - 16" Taper length, 41" Overall ..........2-500-2990131

24/49 - 24" Taper length, 49" Overall ..........2-500-2990133

32/57 - 32" Taper length, 57" Overall ..........2-500-2990135

Description Ref.-No.

Rental

5/8" (15mm) Threadbar 18".........................2-500-2990158

5/8" (15mm) Threadbar 42".........................2-500-2990156

5/8" (15mm) Threadbar 54".........................2-500-2990154

5/8" (15mm) Threadbar 72".........................2-500-2990152

Articuated flange nut 15/120................................29-900-10

Purchase

5/8" (15mm) Plastic Spacer Cone ................. 2-500-2990252

1" Stripping Tool for 5/8" Spacer Cone.........2-500-2990233

3/4" PVC Pipe Sch40 20ft ............................2-500-2990244

Description Ref.-No.

Rental

5/8" (15mm) Pass-Thru She-Bolt x 19"..........2-500-2990173

Articuated flange nut 15/120................................29-900-10

Purchase

5/8" (15mm) Threadbar 19'-1".....................2-500-2990140

5/8" (15mm) Neoprene Waterstop............... 2-500-2990237

Description Ref.-No.

Rental

5/8" (15mm) Steel Setting Cone...................2-500-2990180

5/8" (15mm) Threadbar 18".........................2-500-2990158

Articuated flange nut 15/120................................29-900-10

Purchase

5/8" (15mm) Threadbar 19'-1".....................2-500-2990140

5/8" (15mm) Neoprene Waterstop............... 2-500-2990237

Fig. 8.1 - 5/8" (15mm) Taper Tie, 1" to 3/4"

Fig. 8.2 - 5/8" (15mm) Threadbar

Fig. 8.3 - 5/8" (15mm) Pass-Thru She-Bolt

Fig. 8.4 - 5/8" (15mm) She-Bolt Steel Cone

5/8" (15mm) Taper Tie

5/8" (15mm) Threadbar

5/8" (15mm) Pass-

Thru She-Bolt X

19"long

5/8" (15mm) 18"Threadbar

(Reusable)

Articulated

flange nut 15/120

Articulated

flange nut 15/120

Articulated flange nut 15/120

Articulated flange nut 15/120

Neoprene

Waterstop

Neoprene Waterstop

(if needed)

2"

5/8" Spacer

Cone 1 1/2" Cone Depth

3/4" PVC Pipe Schedule 40

Length = Wall Thickness - 2"

5/8" (15mm) Threadbar Inner Tie Rod (Consumed)

Length = Wall Thickness - 4"

5/8" (15mm) Threadbar Inner Tie Rod (Consumed)

Length = Wall Thickness - 4"

5/8" (15mm) Steel

Setting Cone

5/8" (15mm) Taper Tie

SWL = 18.75 KIPS

Factor of Safety = 2:1

5/8" (20mm) Threadbar

SWL = 21.9 KIPS

Factor of Safety = 2:1

5/8" (15mm) Pass-Thru

She-Bolt

SWL = 21.9 KIPS

Factor of Safety = 2:1

5/8" (15mm) She-Bolt Steel Cone

SWL = 21.9 KIPS

Factor of Safety = 2:1

2"

4" Taper

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-9

System Panel Sizes

Panel height: 9’

Panel height: 6’

High degree of flexibility

The formwork is extended in

height using panels assembled

vertically or horizontally on top

of the lower panels. The wide

range of panel heights and widths

ensures:

ÆEconomical height extension

in 6” increments through

combined horizontal and vertical

assembly.

ÆUniform joint grid.

Vertical joints:

For 3’ high panels, you need just

one 5/8” (15 mm) tie.

The 4’ and 6’ high panels require 2

ties and the 9’ high panels require

3 ties.

In general, all tie positions pre-

determined by the system must

be used.

Fig. 9.6 Fig. 9.7 Fig. 9.8 Fig. 9.9 Fig. 9.10

Fig. 9.1 Fig. 9.2 Fig. 9.3 Fig. 9.4 Fig. 9.5

1'-3" 3'-6"

6'

1'-3"

6" 1' 1'-6" 2' 3'

1'-3" 3'-3" 1'-3"3'-3"

6" 1' 1'-6" 2' 3'

9'

9 x 1 9 x 1.5 9 x 2 9 x 3

9 x 0.5

6 x 1 6 x 1.5

6 x 0.5

6 x 2 6 x 3

Wall formwork

Technical Instruction Manual / June 2022

ML-10

MevaLite

System Panel Sizes

High degree of flexibility

The formwork is extended in

height using panels assembled

vertically or horizontally on top

of the lower panels. The wide

range of panel heights and widths

ensures:

ÆEconomical height extension

in 6” increments through

combined horizontal and vertical

assembly.

ÆUniform joint grid.

Vertical joints:

For 3’ high panels, you need just

one 5/8” (15 mm) tie.

The 4’ and 6’ high panels require 2

ties and the 9’ high panels require

3 ties.

In general, all tie positions pre-

determined by the system must

be used.

Panel height: 4’

Panel height: 3’

Fig. 10.1 Fig. 10.2 Fig. 10.3 Fig. 10.4 Fig. 10.5

1'

6" 1' 1'-6" 2' 3'

4'

4 x 1 4 x 1.5 4 x 2 4 x 3

4 x 0.5

1'

2'

Fig. 10.6 Fig. 10.7 Fig. 10.8 Fig. 10.9 Fig. 10.10

1'-6"

6" 1' 1'-6" 2' 3'

3'

3 x 1

3 x 1.5

3 x 2

3 x 3

3 x 0.5

1'-6"

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-11

System Panel Sizes

Multi-purpose panels

The multi-purpose panels are ideal

for forming 90° corners, columns,

pilasters, bridge abutments and

connections to existing walls.

The panels are provided with

multi-adjustment profiles where

column clamps or ties are

mounted.

The panels come with pilot holes

on the back side for drilling

selected tie holes at exact

locations.

Plug the unneeded tie holes with

Plug D27/30.

The 9’ panels have 3

multi-adjustment profiles, the

6’ and 4’ panels have 2 multi-

adjustment profiles and the 3’

panel has 1 multi-adjustment

profile.

Threaded sleeves are also provided

on the frame sides at each tie hole

elevation for tensioning screw

connections.

Fig. 11.1 Fig. 11.2

Fig. 11.3 Fig. 11.4

1'-3"

2'-6"

1'-3"

1'-3"1'-3"

3'-3" 3'-3"

3'-6"

9'

6'

2'-6"

2'-6" 2'-6"

1' 1'

2'

1'-6" 1'-6"

4'

3'

MPP 9 x 2.5

MPP 6 x 2.5

MPP 4 x 2.5

MPP 3 x 2.5

Wall formwork

Technical Instruction Manual / June 2022

ML-12

MevaLite

Description Ref.-No.

Plug D27/30 ..............................29-902-61

Spanner SW 27..........................29-800-10

1 1/4”

Attention:

The diameter of the hole in the

alkus sheet is 1 1/16”.

Maximum Incline

Tie System Angle [α] Ratio [x:12]

Taper Tie 1" to 3/4" 2° 3/8 : 12

5/8" Threadbar 6° 1 1/4 : 12

Fig. 12.1 Fig. 12.2

α

x

12

Fig. 12.3

Fig. 12.4

Fig. 12.5

Tie Placement

The tie pockets, where the ties can

be inserted, are located adjacent

to the panel frame. The size of

the pockets (Fig.12.4) allow one

or both sides of the wall to be

inclined. On sloping formwork

the articulated flange nuts 15/120

have to be used. These flange nuts

can be easily installed by using

a hammer or a spanner. In order

to secure the formwork against

uplift it has to be anchored to the

ground using shoe plates or other

means.

Please note:

If two panels of different widths

are assembled side by side, the

ties should be placed through

the panel with the larger width

(Fig.12.5), unless otherwise

indicated on MEVA layout

drawings.

When using tie claws, the ties can

be placed at the outside edge of

the panels. For example; when

forming bulkheads, or directly

above the panels when forming

foundations.

Do not use ties as a means of

supporting bulkheads, or in any

other applications where shear

load is applied.

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-13

< 1’

> 1’

Fig. 13.1

Fig. 13.2

Top of concrete

Top of concrete

Stacking Panels

For stacked panel conditions

where the top of concrete is ≤1'

above the panel below it is not

necessary to install ties in the top

panel (Fig.13.1), unless a walkway

bracket is attached or the panel

below is 3' high. If a walkway

bracket is attached to the top

panel, install ties in the upper tie

holes.

For stacked panel conditions

where the top of concrete is >1'

above the panel below (Fig.13.2),

and for all conditions where the

panel below is 3' high, ties must

be installed in all tie holes.

Vertical steel rails must be installed

across stacked panel joints for

lifting gang forms. See the "Gang

forming" section for additional

information.

Wall formwork

Technical Instruction Manual / June 2022

ML-14

MevaLite

90° Corners

The MevaLite inside corner rigid

is provided with tie holes, and

consists of a aluminum frame with

a replaceable alkus face (Fig.14.1).

The length of each side is 1'

(Fig.14.2).

The MevaLite inside corner

elastic is designed to flex to allow

for easier stripping, and the alkus

face is replaceable (Fig.14.3). The

length of each side is 1' (Fig.14.4).

Steel rails or corner angles are

recommended to stiffen the corner

for concrete placement.

ML-alu fillers (1”, 2”, & 3”) are

used to make adjustments for

different wall thicknesses. Steel

rails may be required depending

on the filler/tie configuration (see

the “Fillers” section) and the wall

thickness.

MevaLite Outside Corners

The outside corners (Fig.14.5,

14.6) are connected to adjacent

panels with assembly locks, but

require more assembly locks than

the standard panel connections.

Steel rails may also be required.

See the "Standard Panels and

Outside Corners" section for

specific requirements.

There are two ways to form 90°

outside corners: with standard

panels and outside corners, or with

multi-purpose panels.

Fig. 14.1

Fig. 14.4

Fig. 14.2

Fig. 14.3

Fig. 14.5 Fig. 14.6

4 1/4”

1’

4 1/4”

1’

19/32”

4 1/4”

4 1/4” 15/64”

1’

1’

4 1/4”

4 1/4”

RIC

IC

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-15

Description Ref.-No.

ML-inside corners rigid

9’x1’..........................................22-505-55

6’x1’..........................................22-505-65

4’x1’..........................................22-505-75

3’x1’..........................................22-505-85

ML-inside corners elastic

9’x1’..........................................22-505-60

6’x1’..........................................22-505-70

4’x1’..........................................22-505-80

3’x1’..........................................22-505-90

ML-outside corners

9’...............................................22-505-10

6’...............................................22-505-20

4’...............................................22-505-30

3’...............................................22-505-40

EA-assembly lock .......................29-205-50

Uni-assembly lock 22 .................29-400-85

90° Corners

Standard Panels and Outside

Corners

The connection and rail support

requirements for outside corner

assemblies depend on the wall

thickness.

For wall thicknesses ≤12",

additional locks are only required

at the outside corner connections

(Fig.15.1).

For wall thicknesses >12" but

≤18", more locks are required at

the outside corner connections.

Additional locks are also required

on the adjacent panel joints near

the corner (Fig.15.2).

Fig. 15.1 Walls up to 12" thick

Fig. 15.2 Walls >12" but ≤18" thick

Locks required at

outside corner joints:

9' panel - 7 locks

6' panel - 5 locks

4' panel - 4 locks

3' panel - 3 locks

≤12"

2'

2'

IC

OC

Locks required at

outside corner joints:

9' panel - 8 locks

6' panel - 6 locks

4' panel - 4 locks

3' panel - 3 locks

>12" ≤18"

MPP 2.5'

IC

OC

Locks required at all

panel joints within 7' of

outside corner:

9' panel - 5 locks

6' panel - 4 locks

4' panel - 3 locks

3' panel - 2 locks

AF

Locks required

at all panel joints

within 7' of

outside corner:

9' panel - 5 locks

6' panel - 4 locks

4' panel - 3 locks

3' panel - 2 locks

MPP 2.5'

AF

Wall formwork

Technical Instruction Manual / June 2022

ML-16

MevaLite

90° Corners

For wall thicknesses >18" but

≤24", in addition to extra locks

steel rails must also be mounted

at all tie elevations except the

top two, with at least one flange

screw each, and bolted together

at the corner with a flange screw

18 and flange nut 100 (Fig.16.1).

There must be at least one panel

(1' or wider) adjacent to the corner

panels and inside corner.

Flange screws securing rails to

panels shall be tightened by

turning with a hammer claw or

bar until snug, followed by a few

hammer blows (minimum 110

ft-lbs torque).

An example corner elevation for

walls >18" but ≤24" thick is

shown in Fig.16.2.

Outside Corners Without

Reinforcing Rails

When it is not possible or practical

to install corner rail reinforcing

for walls over 18" thick, the

lock configuration shown in

Fig.16.1 can be used at a reduced

maximum allowable concrete

pressure of 1100 psf.

Fig. 16.1 Walls >18" but ≤24" thick

Fig. 16.2 Walls >18" but ≤24" thick - example corner elevation

Locks required at all

panel joints within 9'

of outside corner:

9' panel - 6 locks

6' panel - 4 locks

4' panel - 3 locks

3' panel - 2 locks

>18"≤24"

3'

3'

IC

OC

Flange screw 18 rail

panel connection, typ.

Rail

9 x 3

Corner rails installed at all

tie elevations except the top

two, typ.

Tie thru rail, typ.

OC 9'

1' MIN.

1' MIN.

1' MIN.

1' MIN.

RAIL

RAIL

R 3'

R 3'

Locks required at

outside corner joints:

9' panel - 8 locks

6' panel - 6 locks

4' panel - 4 locks

3' panel - 3 locks

Locks required at all

panel joints within 9'

of outside corner:

9' panel - 6 locks

6' panel - 4 locks

4' panel - 3 locks

3' panel - 2 locks

Flange screw 18 (min. 1 per rail)

Flange screw 18

and flange nut 100

AF

Flange screw 18 with

flange nut 100 rail corner

connection, typ.

Rail

9 x 1 MIN.

x 3 x 1 MIN.

Description Ref.-No.

ML-inside corners rigid

9’x1’..........................................22-505-55

6’x1’..........................................22-505-65

4’x1’..........................................22-505-75

3’x1’..........................................22-505-85

ML-inside corners elastic

9’x1’..........................................22-505-60

6’x1’..........................................22-505-70

4’x1’..........................................22-505-80

3’x1’..........................................22-505-90

ML-outside corners

9’...............................................22-505-10

6’...............................................22-505-20

4’...............................................22-505-30

3’...............................................22-505-40

EA-assembly lock .......................29-205-50

Uni-assembly lock 22 .................29-400-85

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-17

90° Corners

Multi-Purpose Panels

A multi-purpose panel (MPP)

can be used to form 90° outside

corners by connecting a standard

panel with column clamps. The

column clamp is secured with a

flange nut 100 or an articulated

flange nut 15/120. This method

can be used for wall thicknesses

from 6" to 13".

The offset hole pattern in the

MPP allows for wall thickness

changes in 1" increments.

Switching between odd and even

inch increments is accomplished

by simply rotating the MPP 180

degrees.

For wall thicknesses ≤9", the

maximum allowable concrete

pressure is 1350psf (Fig.17.1).

For wall thicknesses

>9" but ≤13", the maximum

allowable concrete pressure is

1100psf (Fig.17.2).

Two multi-purpose panels

connected with tensioning screws

may also be used to form 90°

outside corners for walls from 12"

to 15" thick (Fig.17.3 &17.4).

The maximum allowable concrete

pressure is 1350psf. Additional

locks are required at the panel

joints within 7' of the corner.

Both methods create a tight, rigid

connection.

Fig. 17.1

≤9"

IC

RAIL

RAIL

3" AF

Fig. 17.2

Fig. 17.3 Fig. 17.4

Column

clamp

at each

tie hole

elevation,

typ.

MPP

1.5'

3"AF

MPP

2'

≤13"

12"

15"

1" AF

IC

RAIL

IC

RAIL

3" AF

MPP

MPP

3" AF

Extra panel

joint locks

required

within 7' of

corner per

Fig17.2

IC

3" AF

MPP

MPP

RAIL

3" AF

Extra panel

joint locks

required within

7' of corner per

Fig17.2

Tensioning screw

at each tie hole

elevation, typ.

Maximum allowable concrete

pressure = 1100psf.

Flange nut

100, typ.

MPP

MPP

IC

Description Ref.-No.

ML-inside corners rigid

9’x1’..........................................22-505-55

6’x1’..........................................22-505-65

4’x1’..........................................22-505-75

3’x1’..........................................22-505-85

ML-inside corners elastic

9’x1’..........................................22-505-60

6’x1’..........................................22-505-70

4’x1’..........................................22-505-80

3’x1’..........................................22-505-90

EA-assembly lock .......................29-205-50

Uni-assembly lock 22 .................29-400-85

Wall formwork

Technical Instruction Manual / June 2022

ML-18

MevaLite

Articulated Corners

Acute and obtuse angled corners

are formed using MevaLite

articulated inside and outside

corners. Steel rails are attached

to the multi-function profile with

flange screws at each tie hole

elevation (Fig.18.1 & 18.2). The

rails at the outside corner must

be attached to the panels with at

least two flange screws each, one

in the panel next to the AOC and

one in the adjacent panel. These

rails must also be bolted together

at their intersection with a flange

screw 18 and flange nut 100.

Flange screws shall be tightened

by turning with a hammer claw or

bar until snug, followed by a few

hammer blows.

If wood fillers are needed, the

panel profiles are connected using

Uni-assembly locks.

Side length of articulated outside

corner: 5”

Side length of articulated inside

corner: 1’

Adjustment range: 70º to 220º

(Fig.18.1-18.3).

Description Ref.-No.

ML-articulated inside corners

9’...............................................22-506-10

6’...............................................22-506-20

4’...............................................22-506-30

3’...............................................22-506-40

ML-articulated outside corners

9’ 22-506-60

6’...............................................22-506-70

4’...............................................22-506-80

3’...............................................22-506-90

EA-assembly lock .......................29-205-50

Uni-assembly lock 22 .................29-400-85

Fig. 18.1

Fig. 18.2

AIC

AOC

Wood blocking

Wood filler with

Uni-assembly lock 28

Steel rail

Bolted with flange

screw 18 and flange

nut 100 to provide

rigidity

AIC

AOC

RAIL

RAIL

RAIL

RAIL

RAIL

Note:

See the "90° Corners"

section for lock

requirements at

outside corners

Wall formwork

Technical Instruction Manual / June 2022

MevaLite

ML-19

Articulated Corners

If the inside angle is >100º, steel

rails and wood blocking have to be

used on the inside (Fig.19.1).

To determine the fill distance (y)

between the MevaLite articulated

outside corner and the first panel

where a tie can be used, see the

tables on pages 19 and 20.

Form the fill distance with the

widest MevaLite panel possible

and a wood filler ≤ 6" wide (if

needed). Always locate wood

fillers next to a tied MevaLite

panel.

Description Ref.-No.

ML-articulated inside corners

9’...............................................22-506-10

6’...............................................22-506-20

4’...............................................22-506-30

3’...............................................22-506-40

ML-articulated outside corners

9’ 22-506-60

6’...............................................22-506-70

4’...............................................22-506-80

3’...............................................22-506-90

EA-assembly lock .......................29-205-50

Uni-assembly lock 22 .................29-400-85

α > 100°

AIC

AOC

t

y

Fig. 19.1

Fill Distance, y (inches) for 8" - 15" Wall Thicknesses

Angle, α

(degrees)

Wall Thickness, t (inches)

8 9 10 11 12 13 14 15

70 18.4 19.9 21.3 22.7 24.1 25.6 27.0 28.4

75 17.4 18.7 20.0 21.3 22.6 23.9 25.2 26.5

80 16.5 17.7 18.9 20.1 21.3 22.5 23.7 24.9

85 15.7 16.8 17.9 19.0 20.1 21.2 22.3 23.4

90 15.0 16.0 17.0 18.0 19.0 20.0 21.0 22.0

95 14.3 15.2 16.2 17.1 18.0 18.9 19.8 20.7

100 13.7 14.6 15.4 16.2 17.1 17.9 18.7 19.6

105 13.1 13.9 14.7 15.4 16.2 17.0 17.7 18.5

110 12.6 13.3 14.0 14.7 15.4 16.1 16.8 17.5

115 12.1 12.7 13.4 14.0 14.6 15.3 15.9 16.6

120 11.6 12.2 12.8 13.4 13.9 14.5 15.1 15.7

125 11.2 11.7 12.2 12.7 13.2 13.8 14.3 14.8

130 10.7 11.2 11.7 12.1 12.6 13.1 13.5 14.0

135 10.3 10.7 11.1 11.6 12.0 12.4 12.8 13.2

140 9.9 10.3 10.6 11.0 11.4 11.7 12.1 12.5

145 9.5 9.8 10.2 10.5 10.8 11.1 11.4 11.7

150 9.1 9.4 9.7 9.9 10.2 10.5 10.8 11.0

155 8.8 9.0 9.2 9.4 9.7 9.9 10.1 10.3

160 8.4 8.6 8.8 8.9 9.1 9.3 9.5 9.6

165 8.1 8.2 8.3 8.4 8.6 8.7 8.8 9.0

170 7.7 7.8 7.9 8.0 8.0 8.1 8.2 8.3

175 7.3 7.4 7.4 7.5 7.5 7.6 7.6 7.7

180 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0

MevaLite panel

Wood filler

Wood blocking

RAIL

RAIL

RAIL

Note:

See the "90° Corners"

section for lock

requirements at

outside corners

Wall formwork

Technical Instruction Manual / June 2022

ML-20

MevaLite

Articulated Corners

If the inside angle is ≤ 100º, steel

rails and wood blocking are not

required on the inside (Fig.20.1).

To determine the fill distance (y)

between the MevaLite articulated

outside corner and the first panel

where a tie can be used, see tables

on pages 19 and 20.

Form the fill distance with the

widest MevaLite panel possible

and a wood filler ≤ 6" wide (if

needed). Always locate wood

fillers next to a tied MevaLite

panel.

Description Ref.-No.

ML-articulated inside corners

9’...............................................22-506-10

6’...............................................22-506-20

4’...............................................22-506-30

3’...............................................22-506-40

ML-articulated outside corners

9’ 22-506-60

6’...............................................22-506-70

4’...............................................22-506-80

3’...............................................22-506-90

EA-assembly lock .......................29-205-50

Uni-assembly lock 22 .................29-400-85

α≤ 100°

AIC

AOC

t

y

Fig. 20.1

Fill Distance, y (inches) for 16" - 24" Wall Thicknesses

Angle, α

(degrees)

Wall Thickness, t (inches)

16 17 18 19 20 21 22 23 24

70 29.9 31.3 32.7 34.1 35.6 37.0 38.4 39.8 41.3

75 27.9 29.2 30.5 31.8 33.1 34.4 35.7 37.0 38.3

80 26.1 27.3 28.5 29.6 30.8 32.0 33.2 34.4 35.6

85 24.5 25.6 26.6 27.7 28.8 29.9 31.0 32.1 33.2

90 23.0 24.0 25.0 26.0 27.0 28.0 29.0 30.0 31.0

95 21.7 22.6 23.5 24.4 25.3 26.2 27.2 28.1 29.0

100 20.4 21.3 22.1 22.9 23.8 24.6 25.5 26.3 27.1

105 19.3 20.0 20.8 21.6 22.3 23.1 23.9 24.6 25.4

110 18.2 18.9 19.6 20.3 21.0 21.7 22.4 23.1 23.8

115 17.2 17.8 18.5 19.1 19.7 20.4 21.0 21.7 22.3

120 16.2 16.8 17.4 18.0 18.5 19.1 19.7 20.3 20.9

125 15.3 15.8 16.4 16.9 17.4 17.9 18.5 19.0 19.5

130 14.5 14.9 15.4 15.9 16.3 16.8 17.3 17.7 18.2

135 13.6 14.0 14.5 14.9 15.3 15.7 16.1 16.5 16.9

140 12.8 13.2 13.6 13.9 14.3 14.6 15.0 15.4 15.7

145 12.0 12.4 12.7 13.0 13.3 13.6 13.9 14.3 14.6

150 11.3 11.6 11.8 12.1 12.4 12.6 12.9 13.2 13.4

155 10.5 10.8 11.0 11.2 11.4 11.7 11.9 12.1 12.3

160 9.8 10.0 10.2 10.4 10.5 10.7 10.9 11.1 11.2

165 9.1 9.2 9.4 9.5 9.6 9.8 9.9 10.0 10.2

170 8.4 8.5 8.6 8.7 8.7 8.8 8.9 9.0 9.1

175 7.7 7.7 7.8 7.8 7.9 7.9 8.0 8.0 8.0

180 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0

MevaLite panel

Wood filler

RAIL

RAIL

Note:

See the "90°

Corners"

section for lock

requirements at

outside corners

Wall formwork

Technical Instruction Manual / June 2022

Table of contents

Other Meva Construction Equipment manuals