Meva MGC-F Owner's manual

MEVA Guided Climber - Foldable

MGC-F

Technical Instruction Manual

May 2022

MGC-F w2Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

MGC is the abbreviation for MEVA Guided Climbing. Guided climbing means

that after each pour cycle the system climbs up the building structure by

one level with the help of guiding profiles and climbing shoes while the

system is lifted by a crane.

The MGC system offers a significant advantage: the entire system including

guiding profiles, ladder extensions, secondary platforms etc. is assembled

from ground level below – maintaining simple, safe and time-saving

conditions.

Another advantage is that the vertical formwork and the work platform are

a single unit. Thanks to the guiding profiles, remains securely attached to

the building structure during building and lifting. Thus, wind velocities do

not affect the building process or endanger worker safety. This is why the

MGC system is ideally suited for high-rise building in areas with high wind

speeds and generally for high buildings since the wind velocity increases

with height. Consult MEVA engineering for the formwork height and MGC

spacing for your project.

The MGC-F bracket was designed specifically for the North American market,

allowing pre-assembly of the platforms to be completed off site and then

transported to the project, where the platforms can be flown off of the

truck and unfolded on the wall.

Product Features

MGC-F w3

Technical Instruction Manual / May 2022

MGC-F

Safety Rules &

Recommendations: Contents:

System overview........................................................................................4

System overview – Top view ......................................................................6

Load details for the platforms ....................................................................7

Minimum and edge distances for the climbing cones.................................8

Installation of the climbing cones...............................................................9

Determining the heights for the climbing cycles.......................................10

Location and installation of the climbing cones........................................11

Ledgers and tension rods.........................................................................12

Access hatch and ladder system............................................................... 14

Ladder to the secondary platform............................................................15

Ladder configuration ...............................................................................16

Assembly Press.........................................................................................18

Disassembly Process..................................................................................22

Service.......................................................................................................24

Notes.......................................................................................................25

This Technical Instruction Manual contains information, instructions

and guidance describing how to use the MEVA equipment on the

construction site in a proper, efficient and economic way. Most

examples shown are standard applications that will occur in practice

most often. For more complicated or special applications not covered

in this manual, please contact the MEVA experts for advice.

When using our products the federal, state, and local codes or

regulations must be observed. Many of the details shown do not

illustrate the wall formwork system in the ready-to-pour condition

as to the aforementioned safety regulations. Please adhere to this

manual when using the equipment described. All applications require

engineering calculations and analysis to guarantee safety.

Please observe the provided instructions for the the MEVA equipment

is used. Such instructions are intended to minimize site-specific risks

and should contain the following details:

£The order in which all working steps including assembly

and disassembly must be carried out

£The location, type, and number of anchors, ties, and

braces.

£The location, number and dimensions of working

platforms including working area and protection

against falling

Important: Only well maintained material may be used. Damaged

parts must be replaced. Apply only original MEVA spare parts

for replacement. Attention: Never wax or oil assembly locks.

MGC-F w4Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

System overview

Setup-of an MGC climbing unit

1MGC-F

2OSHA Planking on Alum. Stringer Beam

3Tension rods consisting of:

Threaded rods LH

Threaded rods RH

Turnbuckle nut M16

Tension rod extension

4MGC Climbing Shoe w/ Swivel Guide

5Access hatch KLK

6Ledger MGC

7Scaffold tube with

Bolt-on couplers & Swivel Joint couplers

8Guiding profile extension MGC

9Ladder system consisting of:

Ladder 243

Extension ladder

Ladder fixture

Safety cage

Ladder connector

Ladder link (set)

Ladder base KLK

Coupling pin 48 LAB

Scaffold tube 48

Ladder fixture (railing)

10 Secondary platform (folding bracket)

11 Railing Clamp 42

Fig. 4.1

11

8

9

7

4

6

1

5

2

3

2

10

MGC-F w5

Technical Instruction Manual / May 2022

MGC-F

Fig. 5.1

11

8

9

7

4

6

1

5

2

3

2

10

System overview

Setup-of an MGC climbing unit

1MGC-F

2OSHA Planking on Alum. Stringer Beam

3Tension rods consisting of:

Threaded rods LH

Threaded rods RH

Turnbuckle nut M16

Tension rod extension

4MGC Climbing Shoe w/ Swivel Guide

5Access hatch KLK (NOT VISIBLE)

6Ledger MGC

7Scaffold tube with

Bolt-on couplers & Swivel Joint coupler

8Guiding profile extension MGC

9Ladder system consisting of:

Ladder 243

Extension ladder

Ladder fixture

Safety cage

Ladder connector

Ladder link (set)

Ladder base KLK

Coupling pin 48 LAB

Scaffold tube 48

Ladder fixture (railing)

10 Secondary platform (folding bracket)

11 Railing Clamp 42

MGC-F w6Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

Cantilever Distance between supports Cantilever

System overview – Top view

Platform with access hatch

1 2x4 Guard railing

2 OSHA Planking & Alum.

Stringer Beam

3 MGC-F Bracket

4 Guiding profile MGC

5 Ledger MGC

6 Access hatch KLK

7Support planks around

opening for access hatch

8Climbing shoe

Secondary platform

12x4 Guard railing

2Railing Clamp 42

3Secondary Platform

(Folding Bracket)

42x4 on flat at 24” max

c/c max with 3/4” plywood

and stringer beam

5Scaffold Tube

6Swivel-joint coupler

48/48

7Ladder fixture (railing)

8Extension ladder

Fig. 6.2

Fig. 6.1

Total platform length

145

Total platform length

8

8

7

7

4

4

6

6

1

1

3

3

2

2

5

5

Cantilever Distance between supports

8ft

Cantilever

MGC-F w7

Technical Instruction Manual / May 2022

MGC-F

Load details for the platforms

An MGC climbing unit consists of a working platform, formwork with

platforms for pouring and a secondary platform. The unit is designed to

support the following loads:

£Working platform

Up to 50psf

£Platform for pouring

Up to 25psf

£Secondary platform

2 workers only

Important

£Unless indicated otherwise, the exterior formwork should be advanced

upward prior to interior formwork, to avoid wind exposure on interior

unbraced forms.

£No workers should be allowed on platforms if wind gusts are expected

to exceed 30MPH. If wind gusts are expected to exceed 70MPH, all

materials not fixed to platform should be removed from platforms.

Platforms should be lowered to a previous lift of concrete, forms tied

back through previous concrete lift, and all decking securely fastened.

If this cannot be achieved, platforms and forms should be removed

from walls and secured on the ground.

£If a hurricane is predicted, all material must be removed from the walls

and the formwork and platforms secured on the ground.

£Lifting eyes on stripping corners are not designed to be used when

lifting large formwork assemblies and platforms. They are included

for handling of stripping corners only

£Global load checks of the forces applied to the permanent structure by

the climbing equipment shown herein, are the responsibility of others.

£Concrete must have attained the the strength specified by MEVA

engineering or the design engineer prior to jumping formwork to

the next position.

£The climbing unit must be kept free from excessive snow and ice.

£The engineer of record should verify the walls that the system will be

mounted to are capable of safely withstanding the imparted loads

from the system.

q=+/- w

25psf

25psf to 50psf

depending on

application

Fig. 7.1

Platform for pouring

Working platform

Secondary platform

2 workers only

MGC-F w8Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

Minimum and edge distances for the climbing cones

Minimum dimensions and

distances must be observed

when installing the climbing

cones – at all openings and

near edges.

The minimum distances

shown apply when using

the MGC climbing brackets

with a maximum load. The

minimum distances can

be reduced if the load is

lower. In this case a separate

engineering analysis is

required.

Fig. 8.3

14“

MIN.

28“ MIN

23“

MIN.

Climbing cycle

Climbing cycle

Fig. 8.1

Climbing cone

Blockout

14“

MIN.

23“

MIN.

14“

MIN.

14“

MIN.

14“

MIN.

14“

MIN.

MGC-F w9

Technical Instruction Manual / May 2022

MGC-F

Installation of the climbing cones

Description Ref. No.

Anchor plate

15/120 ....................... 29-412-30

15/170 ....................... 29-412-35

20/170 ....................... 29-412-37

Climbing cone

15/M24 .......................29-412-70

20/M24 .......................29-412-75

Conical sleeve............. 29-412-95

Positioning disc M24... 29-412-85

Climbing shoe MGC.... 29-011-50

Climbing shoe MGC with

swivel-guide .............. 29-011-60

Washer D40xD26x4, galv.

DIN 1440-26................29-412-78

Hexagonal screw M24x60,10.9

black, ISO 4017 ...........63-119-48

Anchor plate

Conical sleeve

Climbing cone 15/M24

Positioning disc M24

Climbing shoe

Facing

Washer D40xD26x4

Hexagonal screw M24x60, 10.9 black, ISO 4017

(DO NOT USE GRADE 8.8 OR LOWER GRADE BOLT)

Fig. 9.5

Fig. 9.2

Fig. 9.1

Possible installation methods of the

climbing cones at the formwork

Installation with M24x60 bolt

(Fig. 9.1 and 9.2)

Use this method when the climbing cones always have

the same location as it ensures a dimensionally

accurate installation.

Installation with positioning disc M24

(Fig. 9.3 and 9.4)

Important

The accurate installation of the anchoring material is mandatory. Inaccurately placed

anchors or anchors that have moved during concreting MUST NOT BE USED.

Hexagonal screw M24/60

Fig. 9.4

Fig. 9.3

Positioning disc M24

1. Screw the M24x60 bolt through the pre-drilled hole (Ø1 inch)

in the form face into the climbing cone.

2. Install the conical sleeve onto the climbing cone. This will

ease unscrewing the climbing cone after stripping the formwork.

3. Screw the anchor plate into the climbing cone.

4. Support back edge of anchor plate by wiring to rebar. (Fig. 9.2)

5. Before stripping the formwork, remove the M24x60 bolt and

detach the formwork from the concrete.

1. Cover the Allen key recess of the positioning disc with tape.

2. Attach the positioning disc with 4 nails to the facing. (DO NOT

USE DOUBLE HEADED NAILS)

3. Screw the climbing cone onto the positioning disc.

4. Install the conical sleeve onto the climbing cone. This will ease

unscrewing after stripping the formwork.

5. Screw the anchor plate into the climbing cone (Fig. 9.3).

6. Support back edge of anchor plate by wiring to rebar.(Fig. 9.4)

7. After stripping the formwork, unscrew the positioning disc

from the climbing cone using an appropriate Allen key.

wire loop

for support

wire loop

for support

8

8

8

7

7

4

4

6

6

6

1

1

1

1

3

3

3

3

2

2

2

5

5

MGC-F w10 Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

Determining the heights for the climbing cycles

The first pour must have a

minimum height of 10‘ 6“.

The heights of the

subsequent cycles

determine the lengths

of the guiding profile

extensions.

Fig. 10.2

Fig. 10.1

Minimum height for the first and second pouring

cycle depends on the guiding profile extension

required.

Minimum height for the first pouring cycle

depending on the used climbing bracket MGC

10’-6”

MGC-F w11

Technical Instruction Manual / May 2022

MGC-F

10’-6”

10’-6”

Climbing bracket e

MGC-F Varies, usually

= 8‘-0“

Table 11.1

Recommended distance e1

Fig. 11.3

Fig. 11.4 Fig. 11.5 Fig. 11.6

23“

Climbing shoe MGC

Climbing shoe MGC with swivel-guide

(The climbing shoe can also be remove

from below. In this case the climbing shoe

MGC without swivel-guide will do.)

23“

10’-6”

1

1

2

2

2

2

MGC

h =

Distance e

Fig. 11.2

23“

10‘ 6“ mm

Location and installation of the climbing cones

1st pour

The upper level is always

located 23“ minimum

below the top of the pour.

Depending on the pour

height and the climbing

bracket equipment,the lower

level is located at distance

from “e “ from the upper

climbing cone.

(Table 11.1).

Climbing shoe MGC with

swivel-guide

This type of climbing shoe is

used on the of the first two

shoe levels, see fig. 11.2

through 11.4. The platform

unit is suspended there.

The swivel-guide allows the

guiding profile extension to

be swivelled in.

Climbing shoe MGC

The pour 2 climbing shoe

MGC can be rigid or swivel.

see fig.11.2.

Reference Ref. No.

Climbing shoe MGC.... 29-011-50

Climbing shoe MGC with

swivel-guide .............. 29-011-60

Guiding profile extension

MGC 400.....................29-007-60

MGC 325.....................29-007-50

MGC 80.......................29-007-30

MGC 55.......................29-007-25

MGC 30.......................29-007-20

Washer D40xD26x4, galv.,

DIN 1440-26................29-412-78

Hexagonal screw M24x60,10.9

black, ISO 4017 ...........63-119-48

2nd pour

Climbing cones are required

on two levels in order to

make sure the climbing

brackets are guided in the

climbing shoes (Fig. 15.3).

As with the 1st pour, the

upper level is located 23“

below the top of the pouring

height. The location of the

lower level

Climbing shoes should be

as large as possible, and still

allow the MGC-F without the

guide extension to be lifted

while remaining in two guide

shoes. This distance is usually

8‘-0“ or less, depending on

geometry. The smaller this

distance the greater the load

will be on the top anchor.

Note: MGC platforms may be

lifted and remain only in one

shoe level, but this means

a balanced 4 way or crane

compensator will be required

to keep platforms level.

MGC-F w12 Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

After determining the climbing

bracket distances, the position of

the ledgers in the guiding profiles

is determined). In most cases

3ledgers are sucient.

Climbing brackets MGC

The ledgers are attached at

positions and of the

climbing brackets.

Guiding profile extensions

Ledgers can be attached at 3

positions. In most cases only 1

ledger is required and attached

at position on guiding profile

expensions.

Always check for an accurate

position of the ledgers at the

guiding profile extensions.

Guiding profile extensions 80 and

55 usually do not require a ledger.

Ledgers and tension rods

Length calculation of the tension rods

The below formula is used to calculate the length c for the tension rods.

Detail: Tension rod attached to ledger

Distance of climbing brackets

Distance of ledgers

Fig. 12.2

Fig. 12.1

a

b

c

6.6cm

10.5cm 10.5cm

Formula to calculate the tension rod length (c)

a = Distance of brackets – (2 x 6.6 cm)

b = Distance of ledgers – (2 x 10,5 cm)

²b²ac +=

1 2

2

1

MGC-F w13

Technical Instruction Manual / May 2022

MGC-F

Ledgers and tension rod configuration

Adjustment

range

dimension C

(min - max)

(in cm)

Threaded rod Tension

rod

extension

Turn-

buckle

nut

60LH 70LH 80LH 130RH 180RH 230RH 280RH

29-009-10 29-009-15 29-009-20 29-009-40 29-009-50 29-009-60 29-009-70 29-009-90 29-009-

95

192 202 x x x

202 212 x x x

212 222 x x x

212 232 x x 1 x

222 242 x x 1 x

232 252 x x 1 x

232 262 x x 2 x

242 252 x x x

242 272 x x 2 x

252 262 x x x

252 282 x x 2 x

262 272 x x x

262 282 x x 1 x

272 292 x x 1 x

282 302 x x 2 x

282 312 x x 2 x

292 302 x x x

292 322 x x 2 x

302 312 x x x

302 332 x x 2 x

312 322 x x x

312 332 x x 1 x

322 342 x x 1 x

332 352 x x 1 x

332 362 x x 2 x

342 352 x x x

342 372 x x 2 x

352 362 x x x

352 382 x x 2 x

362 372 x x x

362 382 x x 1 x

372 392 x x 1 x

382 402 x x 1 x

382 412 x x 2 x

392 422 x x 2 x

402 432 x x 2 x

Reference Ref. No.

Threaded rod

60 LH ..........................29-009-10

70 LH ..........................29-009-15

80 LH ......................... 29-009-20

130 RH ....................... 29-009-40

180 RH ....................... 29-009-50

230 RH ....................... 29-009-60

280 RH ........................29-009-70

Ledgers

MGC 1,40 m – 2,00 m 29-008-20

MGC 2,00 m – 3,00 m 29-008-30

MGC 3,00 m – 3,60 m 29-008-40

Turnbuckle nut M16 ... 29-009-95

Tension rod

extension.................... 29-009-90

If a length of 432cm is not sucient, further tension

rod extensions can be added.

Each extension adds an additional 20 to 30 cm.

Ledger

Tension rod extension

Threaded rod LH

Turnbuckle nut M16

Threaded rod RH

2

3

4

5

1

1

2

11

2

2

3

6

4

5

Climbing bracket MGC-F+

extension MGC 325

Fig. 13.1

131cm

111

2

2

2

3

4

5

6

3

4

5

6

Climbing bracket MGC-F +

extension MGC 400

Dimension C

Fig. 13.4

131cm

1

2

3

4

5

MGC-F w14 Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

Access hatch and ladder system

Top view onto the main platform with access hatch

The planning and assembly of

the access hatch and ladder

system is done from the

bottom to the top. The layout

of the ladder system depends

primarily on the position

of the secondary platform,

the position of which is

determined by the height

of the pouring cycles and

the position of the climbing

shoes, see p. MGC-18.

The access hatch is set into

the platform planking. This

requires an opening of 28.7”

x 28.7” in the planking. The

access hatch is positioned

between the platform’s

stringers and the slide

carriages. It must be located

39.5” (minimum) behind the

edge of the guiding profile

to make sure that the hatch

can also be opened when the

formwork is removed from

the wall. Make sure the hatch

cover can be opened towards

the formwork.

Longitudinal planks or

suitable lumber must be

placed on either side of the

opening for the access hatch

MGC

MGC

A

A

2

3

1

7

8

9

10

Access to the secondary

platform

Access hatch KLK

Ladder 243

Safety cage 210

Access to the secondary

platform

Ladder fixture 130

Ladder link set

Extension ladder 210

Safety cage 85

Cantilever Distance between supports Cantilever

Detail: Access hatch

Detail: Ladder link

1

7

2

3

8

9

10

KLK Ladder Hatch

support

MGC-F w15

Technical Instruction Manual / May 2022

MGC-F

Ladder to the secondary platform

Example of a ladder access to the secondary platform

(from top to bottom)

1Access hatch KLK ..........................................29-416-05

2Ladder 243 ...................................................29-416-50

3Safety cage 210 ............................................29-414-85

4Ladder fixture 150.........................................29-416-67

5Ladder connector..........................................29-414-70

6Extension ladder 270.....................................29-416-52

7Ladder fixture 130.........................................29-416-68

8Ladder link set ..............................................29-414-72

9Extension ladder 210.....................................29-416-60

10 Safety cage 85 ..............................................29-414-90

11 Ladder fixture (railing) ...................................29-416-69

12 Coupling pin 48 LAB .....................................29-421-95

13 Extension ladder 90.......................................29-416-60

14 Ladder base KLK ...........................................29-416-70

Connecting material for access hatch:

12 wooden screws 6x45

Connection material for the bottom fixture:

£4 carriage bolts M12x130

£4 washers for wooden assembly

£4 self-locking nuts M12

Detail: Ladder base with

extension ladder

1

2

3

4

5

6

7

8

9

10

11

12

13

14

MGC-F w16 Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

Ladder configuration

The parts required for a ladder system from the secondary to the main platform depend on the distance between

the deck of the secondary platform and that of the main platform. Using this table, you can determine what parts

are required for your ladder system. The ladders are connected with ladder connectors.

Quantities in parentheses ( ) indicate that the article may not be necessary for the configuration.

Ladder configuration Height min.- max. [ft]

min. 21.78 22.76 23.75 24.73 25.72 26.70 27.69 28.67 29.65 30.64 31.62 32.61

max. 22.99 23.98 24.96 25.75 26.93 27.91 28.90 29.88 30.87 31.85 32.84 33.82

Acccess hatch KLK 29-416-05 1 1 1 1 1 1 1 1 1 1 1 1

Ladder 243 29-416-50 1 1 1 1 1 1 1 1 1 1 1 1

Extension ladder 270 29-416-52 1 1 2 1 1 2 2 1 1 2

Extension ladder 210 29-414-60 2 1 1 1 1 2 1 1

Extension ladder 120 29-416-55 2 2 1 1 2

Extension ladder 90 29-416-60 1 1

Ladder base KLK 29-416-70 (1) (1) (1) (1) (1) (1) (1) (1) (1) (1) (1) (1)

Ladder connector 29-414-70 1 2 1 2 1 2 2 2 2 2 3 2

Ladder link set 29-416-72 1 1 1 1 1 1 1 1 1 1 1 1

Ladder fixture 150 29-416-67 1 1 1 1 1 1 1 1 1 1 1 1

Ladder fixture 130 29-416-68 1 1 1 1 1 1 1 1 2 2 2 2

Ladder fixture (railing) 29-416-69 1 1 1 1 1 1 1 1 1 1 1 1

Safety cage 210 29-414-85 1 1 2 2 2 2 2 2 2 2 3 3

Safety cage 85 29-414-90 2 2 1 1 1 2 2 2

Safety cage 40 29-416-90 1 1

Ladder configuration Height min.- max. [ft]

min. 21.78 22.76 23.75 24.73 25.72 26.70 28.67 29.64 30.64 31.62 32.61

max. 22.99 27.91 24.96 29.88 26.93 31.85 29.88 34.80 31.85 36.77 33.82

Access hatch KLK 29-416-05 1 1 1 1 1 1 1 1 1 1 1

Ladder 243 29-416-50 1 1 1 1 1 1 1 1 1 1 1

Extension ladder 270 29-416-52 1 1 2 2 1 1 2

Extension ladder 210 29-414-60 2 2 1 1 3 3 2 2 1

„Hang-in“ ladder 29-414-60 1 1 1 1 1

Ladder base KLK 29-416-70 1 1 1 1 1 1 1 1 1 1 1

Ladder connector 29-414-70 1 1 1 1 1 1 2 2 2 2 2

Ladder link set 29-416-72 1 1 1 1 1 1 1 1 1 1 1

Ladder fixture 150 29-416-67 1 1 1 1 1 1 1 1 1 1 1

Ladder fixture 130 29-416-68 1 1 1 1 1 1 1 2 2 2 2

Ladder fixture (railing) 29-416-69 1 1 1 1 1 1 1 1 1 1 1

Safety cage 210 29-414-85 1 1 2 2 2 (2-3) 2 2 3 3 3

Safety cage 85 29-414-90 2 (2-4) (1-2) 1 (1-2) 2 (2-4) (1-2)

Safety cage 40 29-416-90 1

Table 16.1

Table 16.2

Special case: Extension ladder 210 also used as hang-in ladder

In some cases, the extension ladder 210 is used as a normal hang-in ladder.

Quantities in parentheses

( ) indicate that the number of safety cages may vary depending on the height of the ladder system.

In these cases, the number of required safety cages should be ascertained with drawings during the

planning phase.

MGC-F w17

Technical Instruction Manual / May 2022

MGC-F

Climbing and lifting the platforms

Important

A platform must not be lifted

while a person or material is

on that platform.

All loose parts and tools must

be removed from the platform

prior to lifting it.

We recommend using 4-rope

crane slings when crane-

lifting platforms (one or

more). You can use a chain

jack to balance different

centres of gravity (Fig. 32.1).

Fig. 17.1

AC

B

Detail A

Detail B

Detail C

Do not use for lifting

Lifting point

Lifting point

MGC-F w18 Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

Assembly process

Step 1

For initial placement, set MGC foldable

brackets on flat 4x4 cribbing spaced

1/2” further apart than “A” distance.

Square brackets & attach two (2)

horizontal ledgers that are presized 1

1/2” shorter than “A” distance, to the

guiding profiles. Then attach turnbuckle

cross bracing.

Turnbuckle Bracing Color Code:

60 LH (Yellow-Head Blue)

70 LH (Yellow-Head Red)

80 LH (Yellow)

130 RH (Silver-Head Red)

180 RH (Silver-Head Yellow)

230 RH (Silver-Head Green)

280 RH (Silver)

Step 2

Place two (2) aluminum stringers

on MGC. Once proper cantilever is

established, attach with one (1) beam

clamp per crossing. After clamps are

tightened and the correct spacing/

cantilever is established, the lumber

deck and guardrails can be attached

Step 3

Place pre-assembled MGC foldable

platform near to its desired location.

Confirm that climbing shoe MGC’s

are securely axed to concrete wall -

climbing shoes with swivel-guide are

attached to the first climbing section

to allow for guiding profile extension

to be brought into place.

1

2

3

Attach planks to joists w/ 1/4”X3” Spax

coated powerlags or equal. using T30 Bit

w/ 1/4” Impact Driver

MGC-F w19

Technical Instruction Manual / May 2022

MGC-F

Assembly process

Step 4

Attach crane slings to the crane eyes

at the wall side of the horizontal wailer

MGC w/ slide carriage. Begin lifting on

the one side with just 2 crane slings.

5

6

Safety Catch

Swivel Guides

Guard Railing Post

Retainer Loop

Horizontal Ledger MGC

Guiding Profile MGC

Step 6

Remove (2) pins per lower starter

shoes to allow swivel-guides to open.

Fly the pre-asssembled MGC foldable

platform up to the shoes and rest the

safety catch to the upper starter shoe.

Use a tag line to help maneuver the

MGC assembly into position on all (4)

starter shoes. Close the swivel-guides

and replace the pins.

4

Wall Side

Horizontal wailer MGC

w/ Slide Carriage

Step 5

Continue with lifting the pre-assembled

MGC foldable platform until the guiding

profile MGC is in the vertical position.

MGC-F w20 Technical Instruction Manual / May 2022

MGC-F

Guided Climbing

Assembly process

Step 7

Remove the guard railing post retainer

loop pin & the bottom pin on the GRP.

Allow the two guard rail posts and

connecting 2x6 railing to drop down

into the horizontal position. Replace

GRP bottom pin once perpendicular

to the horizontal wailer MGC w/ slide

carriage. Remove the (2) top crane

slings and reattach to bottom (2) crane

eyes.

Step 8

Remove bottom pin connecting

horizontal wailer MGC w/slide carriage

& guiding profile MGC. Begin slowly

lifting the bottom end of the horiz.

wailer upwards into the horizontal

position.

Be sure to remove the top pin of

the guiding profile MGC to allow

intersection of these two main pieces.

8

7

Remove pin from this position to allow

horizontal waler MGC w/ Slide Carriage &

Fixed Guard Rail Post to pivot upwards

Swivel Guides

Safety Catch

Pivot Point

Top Pin of Guiding Profile MGC

Guard Railing Post Bottom Pin

Guard Railing Post Retainer Loop Pin

Safety Catch

Swivel Guides

Do Not Remove This Pin - PIVOT PIN ONLY!

Table of contents

Other Meva Construction Equipment manuals

Popular Construction Equipment manuals by other brands

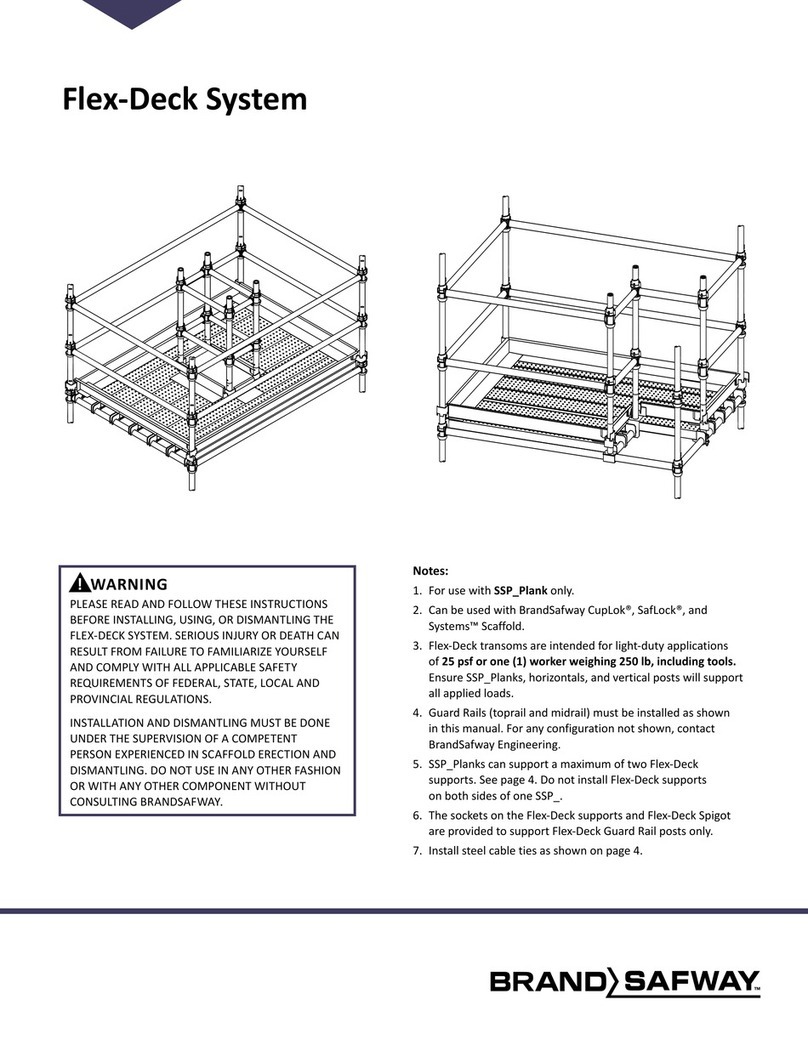

BrandSafway

BrandSafway Flex-Deck manual

Fayat Group

Fayat Group Dynapac CA25 instruction manual

MetalTech

MetalTech M-MFT5710 OPERATIONAL SAFETY AND ASSEMBLY INSTRUCTIONS

BE Ag & Industrial

BE Ag & Industrial AGRI EASE DIAMOND HARROW HAR60S Assembly instructions

Conmec

Conmec CT436E Operator's manual

SPIERINGS

SPIERINGS AT3 manual