Meva MT 60 Owner's manual

Technical Instruction Manual

Shoring System MT 60

sbava.pdf St. 07/04/16 Printed in Germany

MT2

Shoring System MT 60

Abbreviations, measurements, figures and tables

The abbreviation MT is used for the MT 60 shoring system. Any

further abbreviations are explained where they are used the first

time.

Measurements: This manual uses the metric system and thus m (for

metre), cm (for centimetre) and mm (for millimetre). Dimensions

without a measure are in cm.

The page numbers in this manual start with MT. The figures

and tables are numbered per page. Depending on its product

abbreviation, a cross reference in the text refers to a page, table or

figure in this or in another manual.

Created: 7 April 2016

Product Features

The MT 60 shoring system is a square load tower sized 1.70 m by

1.70 m and allows for safe work in great heights. Fall down acci-

dents are avoided while work performance is increased. The maxi-

mum load capacity is 60 kN per tower post.

Achieve any tower height with only few parts

By using only few different standard parts, the tower can be assem-

bled to achieve almost any height. With the head spindle adjust-

able by up to 62 cm and the base spindle by up to 44 cm, only 3

frame heights (100, 75 and 50 cm) are sufficient to assemble almost

any tower height.

Safe assembly on the ground

The tower is safely assembled on the ground, either in vertical or

horizontal position. The scaffold platforms are self-locking and thus

can also be assembled with the tower in horizontal position.

Long life cycle, few cleaning and maintenance required

All parts are hot-dip galvanized, this results in a long life cycle as

well as minimized cleaning and maintenance efforts.

sbava.pdf St. 07/04/16 Printed in Germany

MT3

Shoring System MT 60

Please observe Contents

This Technical Instruction Manual contains information, instructions

and hints describing how to use the MEVA equipment on the con-

struction site in a proper, quick and economic way. Most examples

shown are standard applications that will occur in practice most

often. For more complicated or special applications not covered

in this manual, please contact the MEVA experts for advice. When

using our products the federal, state and local codes and regula-

tions must be observed. Many of the details shown do not illustrate

the wall formwork system in the ready-to-pour condition as to the

aforementioned safety regulations. Please adhere to this manual

when applying the equipment described here. Deviations require

engineering calculations and analysis to guarantee safety.

Please observe the assembly instructions that your local contractor

or employer has created for the site on which the MEVA equipment

is used. Such instructions are intended to minimise site-specific risks

and must contain the following details:

¢ The order in which all working steps including assembly and

disassembly must be carried out

¢ The weight of the panels and other system parts

¢ The type and number of ties and braces as well as the distance

between them

¢ The location, number and dimensions of working scaffolds

includ ing working area and protection against falling down

¢ Pick points for panel transport by crane. With regard to panel

tranport, please observe this manual. Any deviation will require a

static proof.

Important: Generally, only well maintained material may be used.

Damaged parts must be replaced. Apply only original MEVA spare

parts for replacement.

Attention: Never wax or oil assembly locks.

Product overview .................................................................................4

Integrated safety features ...................................................................6

Planking ................................................................................................7

Basic tower 170 x 170 – Vertical assembly .......................................... 8

Basic tower 170 x 170 – Horizontal assembly flat on the ground ...14

Tower 170 x 340 – Vertical assembly ................................................. 15

Working platform between two towers ..........................................19

Transport by crane .............................................................................20

Transport on wheels ...........................................................................21

Use with slab formwork MevaDec ...................................................22

Use with slab formwork MevaFlex ....................................................23

Disassembly ......................................................................................... 24

Height configurations from 2.51 to 6.42 m ......................................25

Height configurations from 6.84 to 8.46 m ......................................26

Height configurations from 9.65 to 12.54 m ....................................27

Material list – Tower heights from 2.01 to10.76 m .......................... 28

Material list – Tower heights from 10.16 to 18.66 m ....................... 29

Transport and storage ........................................................................30

Important work and handling rules .................................................. 31

Service .................................................................................................32

sbava.pdf St. 07/04/16 Printed in Germany

MT4

Shoring System MT 60

Product overview

The tower is fast and

safe to install.

The few different

parts can always be

assembled from a safe

platform.

Only 4 frames are

required per level.

Each frame has an

integrated ladder,

a crane eye and a

self-locking wedge con-

nection.

Frame 100 MT weighs

only 15.6 kg, all other

parts weigh less. This

eases assembly work.

The tower is compat-

ible with slab formwork

MevaDec and MevaFlex.

Each post has 60 kN

load capacity.

The entire tower can

be wheeled from posi-

tion to position if it does

not have more than

5 levels.

Zeichnung Nr. 300506_0006

Stand: 02.03.2016/bhe

bis

44 cm bis 62 cm

100 cm

17

0

170

Fig. 4.1 Shoring system MT 60

Access

sbava.pdf St. 07/04/16 Printed in Germany

MT5

Shoring System MT 60

Product overview

Zeichnung Nr. 300506_0006-1

Stand: 11.01.2016/bhe

Head spindle MT

Transport wheel MT

Base spindle MT

Horizontal brace MT

Ledger 170 MT

Access frame

100 MT

Basic frame 100 MT

Scaffold platform

170/68 with access

hatch MT

Toe board 170 MT

Fig. 5.1

Scaffold plat-

form170/30

The tower is always

assembled with the

same standard parts no

matter how high it is

and what it is used for.

Yet different accessories

can be mounted to the

head spindles to use the

tower to support slab

formwork or concrete

beams or prefab parts.

sbava.pdf St. 07/04/16 Printed in Germany

MT6

Shoring System MT 60

Integrated safety features

The shoring system is

equipped with a series

of features and func-

tions that maximize

safety when assembling,

using and transporting

the tower.

Detail 6.1.A

The two connectors in

the corner area can be

used for accessories or

other parts.

Detail 6.1.B

Each basic frame has a

crane eye.

Detail 6.1.C

Integrated ladder access.

Detail 6.1.D

Self-locking mechanism

at the connecting point

of the MT frames. The

high-tensile connection

allows the tower to be

crane-lifted.

Detail 6.1.E

Self-locking wedge con-

nection.

Zeichnung Nr. 300506_0008

Stand: 11.01.2016/bhe

Zeichnung Nr. 300506_0008_Detail_1

Stand: 08.03.2016/bhe

Zeichnung Nr. 300506_0008_Detail_2

Stand: 12.01.2016/bhe

Zeichnung Nr. 300506_0008_Detail_4

Stand: 13.01.2016/bhe

Detail 6.1.C

Detail 6.1.A

Detail 6.1.B

Detail 6.1.D

Detail 6.1.E

Fig. 6.1

sbava.pdf St. 07/04/16 Printed in Germany

MT7

Shoring System MT 60

Scaffold platform

Bez.: Gerüstbelag 170 / 68 mit Durchstieg

Art.-Nr.: 29-131-30

Gewicht: 14,1 kg

Stand: 04.02.2016

Bez.: Gerüstbelag 170 / 52,5

Art.-Nr.: 29-131-35

Gewicht: 11,1 kg

Stand: 04.02.2016

Bez.: Gerüstbelag 170 / 30

Art.-Nr.: 29-131-40

Gewicht: 8,0 kg

Stand: 04.02.2016

The scaffold platform is

made of wooden planks

inside an aluminium

frame. The maximum

load capacity is 200 kg/

m².

Note that scaffold plat-

forms are required on

every other tower level

so workers can safely

ascend and descend to

and from the tower.

The following scaffold

platforms are available

(the figures indicate

their length and width):

170/68 with access

hatch (Fig. 7.1)

170/30 and 220/30

(Fig. 7.2)

170/52,5 and 220/52,5

(Fig. 7.3)

Installation

The side of the scaffold

platform shown in Detail

7.1.A is plugged onto

the frame MT 100. The

self-locking mechanism

on the other end of

the scaffold platform

encloses the frame

on that end (Detail

7.1.B). The access hatch

(Detail 7.1.C) closes

automatically. All scaf-

fold platforms have a

grab handle on their

underside (Detail 7.2).

Fig. 7.1

Fig. 7.2 Fig. 7.3

Description Ref. No.

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Scaffold platform

170/52.5..................... 29-131-35

170/30........................ 29-131-40

220/52.5..................... 29-131-10

220/30........................ 29-131-15

Zeichnung Nr. 300506_0021

Stand: 16.02.2016/bhe

Zeichnung Nr. 300506_0022-1

Stand: 16.02.2016/bhe

Zeichnung Nr. 300506_0022-2

Stand: 26.02.2016/bhe

Zeichnung Nr. 300506_0022

Stand: 16.02.2016/bhe

Detail 7.1.A Detail 7.1.B Detail 7.1.C

Detail 7.2

sbava.pdf St. 07/04/16 Printed in Germany

MT8

Shoring System MT 60

Basic tower 170 x 170 – Vertical assembly

This page and the

following ones show

the vertical assembly of

a standard tower with

3 levels. For a description

of the horizontal assem-

bly see page MT-14. For

height configurations of

towers with more than

3 levels refer to paages

MT-25 through MT-27.

Ground

Check that the ground is

stable enough to sup-

port the tower.

Level 0

1. Start the assembly at

the highest point.

2. Place planks or

another load-distribut-

ing support for the base

spindles.

3. Place the 4 base spin-

dles MT on the planks or

support.

4. Connect the 4 ledg-

ers 170 MT with their

integrated wedges to

the base spindles MT

(Fig. 8.1).

5. Adjust the entire

assembly horizontally by

adjusting the base spin-

dles MT if and where

necessary. Make sure not

to exceed the maximum

spindle length of 44 cm.

6. Tighten the wedges

with a few hammer

blows (Fig. 8.1).

Level 1 (Fig. 8.2)

7. Standing on the

inside, plug the access

frame 100 MT onto the

base spindle at an angle

of 45° and turn it out-

wards until it locks.

Zeichnung Nr. 300506_0009-10

Stand: 15.01.2016/bhe

Zeichnung Nr. 300506_0009-9

Stand: 15.01.2016/bhe

Fig. 8.1

Fig. 8.2

Description Ref. No.

Base spindle MT .......... 29-129-50

Ledger 170 MT ........... 29-122-10

Access frame MT 100 . . 29-121-10

Basic frame 100 MT .... 29-120-10

Position at 45° and

turn outwards

sbava.pdf St. 07/04/16 Printed in Germany

MT9

Shoring System MT 60

8. Attach the frames

100 MT to the other

spindles the way you

attached the access

frame in Step 7 (Fig. 9.1).

9. Attach a horizontal

brace MT between two

frames MT 100 to make

sure the entire frame

construction is rectangu-

lar (Fig. 9.2).

10. Suspend the follow-

ing scaffold platforms

for level 0 at the ledgers

170 MT:

1 scaffold platform

170/68 with access hatch

3 scaffold platforms

170/30

Important

Always suspend the

scaffold platform 170/68

with access hatch in

a way that the access

hatch opens to frame

100 MT and you can

climb up or down the

ladder that is integrated

in the frame.

Level 2

11. Standing on the scaf-

fold platform of level 0,

suspend the frames 100

MT for level 2 (Fig. 9.3).

Zeichnung Nr. 300506_0009-8

Stand: 09.03.2016/bhe

Zeichnung Nr. 300506_0009-7

Stand: 15.01.2016/bhe

Description Ref. No.

Basic frame 100 MT .... 29-120-10

Horizontal brace MT ... 29-127-10

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Scaffold platform

170/30........................ 29-131-40

Fig. 9.1

Fig. 9.3

Zeichnung Nr. 300506_0009-8.1

Stand: 09.03.2016/bhe

Fig. 9.2

Basic tower 170 x 170 – Vertical assembly

sbava.pdf St. 07/04/16 Printed in Germany

MT10

Shoring System MT 60

12. Suspend the scaffold

platforms 170/30 for

level 1 (Fig.10.1).

13. Ascend to level 1

and suspend the scaffold

platform 170/68 with

access hatch (Fig.10.2)

Important

Always suspend the

scaffold platform 170/68

with access hatch in

a way that the access

hatch opens to frame

100 MT and you can

climb up or down the

ladder that is integrated

in the frame.

Zeichnung Nr. 300506_0009-6

Stand: 14.01.2016/bhe

Zeichnung Nr. 300506_0009-5

Stand: 14.01.2016/bhe

Fig. 10.1

Fig. 10.2

Basic tower 170 x 170 – Vertical assembly

Description Ref. No.

Basic frame 100 MT .... 29-120-10

Horizontal brace MT ... 29-127-10

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Scaffold platform

170/30........................ 29-131-40

sbava.pdf St. 07/04/16 Printed in Germany

MT11

Shoring System MT 60

Zeichnung Nr. 300506_0009-4

Stand: 14.01.2016/bhe

Zeichnung Nr. 300506_0009-3

Stand: 14.01.2016/bhe

Fig. 11.1

Fig. 11.2

Basic tower 170 x 170 – Vertical assembly

Description Ref. No.

Basic frame 100 MT .... 29-120-10

Horizontal brace MT ... 29-127-10

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Scaffold platform

170/30........................ 29-131-40

Level 3

14. Standing on the

scaffold platform of

level 1, install the frames

100 MT for level 3

(Fig. 11.1)

15. Remove the scaffold

platform with access

hatch from level 1 and

install it on level 2

(Fig. 11.2).

16. Descend to level 0.

sbava.pdf St. 07/04/16 Printed in Germany

MT12

Shoring System MT 60

17. Remove the from

level 1 and install them

on level 2 (Fig.12.1).

18. Climb up to level 2

using the ladder inte-

grated in frame MT 100

(Fig.12.2).

Zeichnung Nr. 300506_0009-2

Stand: 14.01.2016/bhe

Zeichnung Nr. 300506_0009-1

Stand: 13.01.2016/bhe

Fig. 12.1

Fig. 12.2

Basic tower 170 x 170 – Vertical assembly

Description Ref. No.

Basic frame 100 MT .... 29-120-10

Horizontal brace MT ... 29-127-10

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Scaffold platform

170/30........................ 29-131-40

sbava.pdf St. 07/04/16 Printed in Germany

MT13

Shoring System MT 60

Zeichnung Nr. 300506_0009

Stand: 14.01.2016/bhe

19. Plug the 4 head spin-

dles MT into the frame

posts and adjust them

(Detail 13.1.A)

20. Toe boards are

always installed at

the highest working

platform (Fig.13.1).

Attach the toe boards

170 MT as shown in

Fig. Detail13.1.B.

21. Attach the 4 trans-

port wheels MT to the

base spindles MT and to

the frames MT of level 1

(Fig.13.2 and Detail 13.2)

Important

Plankings for working

platforms need to be

installed on every second

level to allow for a safe

ascent and descent.

Attention

Depending on its

height and the load it

is exposed to, e.g. wind

load, the tower needs

to be anchored to an

existing building. Sev-

eral towers need to be

connected with diagonal

braces and ledgers. Fol-

low the details provided

by the stress analyst.

A

Zeichnung Nr. 300506_0011

Stand: 18.01.2016/bhe

A

Zeichnung Nr. 300506_0011

Stand: 18.01.2016/bhe

Fig. 13.1

Fig. 13.2Detail 13.2

Zeichnung Nr. 300506_0009_Detail_1

Stand: 09.02.2016/bhe

Detail 13.1.A

Zeichnung Nr. 300506_0009_Detail_2

Stand: 09.02.2016/bhe

Detail 13.1.B

Basic tower 170 x 170 – Vertical assembly

Description Ref. No.

Head spindle MT ......... 29-129-55

Toe board 170 MT ...... 29-126-15

Transport wheel MT .... 29-129-90

sbava.pdf St. 07/04/16 Printed in Germany

MT14

Shoring System MT 60

Basic tower 170 x 170 – Horizontal assembly flat on the ground

The horizontal assembly

on the ground is done

with the same material

and in the same way as

the vertical assembly. For

further details see the

cross-references to the

vertical assembly section.

Ground

The ground must be

flat to allow for a

trouble-free assembly

(Fig.14.1).

Level 0 and 1

(vertical assembly)

1. Assemble level 0 and 1

with frames 100 MT

and an access frame as

described on pages MT-8

and MT-9.

2. Turn the assembled

construction by 90°

(Fig. 14.1). Level 2 and

all other levels are now

assembled and added

horizontally and the

assembled tower will be

erected when all levels

have been added.

Level 2 until final

height (horizontal

assembly)

3. Assemble the frames

for all other levels –

always at an angle of

45° and from the inside

to the outside (Fig. 14.2).

4. Install scaffold plat-

forms including access

hatch on every other

level (Fig. 14.3). Since

the scaffold platforms

are self-locking, they will

not tilt or fall off.

5. Attach the head spin-

dles on the last tower

level (Fig. 14.4).

Erecting the tower

1. Attach 4-rope crane

slings to the crane eyes

of the top frame MT

(Fig. 14.5)

2. Erect the tower and

crane-lift it to its place

of use.

3. Align the tower hori-

zontally and vertically.

Attention

Depending on its

height and the load it

is exposed to, e.g. wind

load, the tower needs

to be anchored to an

existing building. Sev-

eral towers need to be

connected with diagonal

braces and ledgers. Fol-

low the details provided

by the stress analyst.

Zeichnung Nr. 300506_0037_1

Stand: 31.03.2016/bhe

Zeichnung Nr. 300506_0037_2

Stand: 31.03.2016/bhe

Zeichnung Nr. 300506_0037_3

Stand: 31.03.2016/bhe

Zeichnung Nr. 300506_0037-4

Stand: 31.03.2016/bhe

Fig. 14.1 Fig. 14.2

Fig. 14.3

Fig. 14.5

Fig. 14.4

Zeichnung Nr. 300506_0037-5

Stand: 31.03.2016/bhe

sbava.pdf St. 07/04/16 Printed in Germany

MT15

Shoring System MT 60

Zeichnung Nr. 300506_0010-11

Stand: 08.03.2016/bhe

Zeichnung Nr. 300506_0010-12

Stand: 09.02.2016/bhe

Zeichnung Nr. 300506_0010.1

Stand: 08.03.2016/bhe

Zeichnung Nr. 300506_0010-10

Stand: 08.03.2016/bhe

Fig. 15.1

Fig. 15.2

Fig. 15.3

Fig. 15.4

Tower 170 x 340 – Vertical assembly

Ground

Check that the ground is

stable enough to sup-

port the tower.

Level 0

1. Start the assembly at

the highest point.

2. Place planks or

another load-distribut-

ing support for the base

spindles.

3. Place the 4 base spin-

dles MT on the planks or

support.

4. Connect the 4 ledg-

ers 170 MT with their

integrated wedges to

the base spindles MT

(Fig. 15.1).

5. Adjust the entire

assembly horizontally by

adjusting the base spin-

dles MT if and where

necessary. Make sure not

to exceed the maximum

spindle length of 44 cm.

6. Tighten the wedges

with a few hammer

blows (Fig. 15.1).

Level 1 (Fig. 15.2)

7. Standing on the

inside, plug the access

frame 100 MT onto

the base spindle at an

angle of 45° and turn it

outwards until it locks

(Fig.15.2).

8. Attach the frames

100 MT to the other

spindles the way you

attached the access

frame in Step 7

(Fig. 15.3).

9. Attach a horizontal

brace MT between two

frames MT 100 to make

sure the entire frame

construction is rectangu-

lar (Fig. 15.3).

10. Suspend the follow-

ing scaffold platforms

for level 0 at the ledgers

170 MT:

2 scaffold platforms

170/68 with access hatch

6 scaffold platforms

170/30

Important

Always suspend the

scaffold platform 170/68

with access hatch in

a way that the access

hatch opens to frame

100 MT and you can

climb up or down the

ladder that is integrated

in the frame (Fig. 11.2

on page MT-11).

Level 2

11. Standing on the scaf-

fold platform of level 0,

suspend the frames 100

MT for level 2 (Fig. 15.4).

Description Ref. No.

Basic frame 100 MT .... 29-120-10

Horizontal brace MT ... 29-127-10

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Scaffold platform

170/30........................ 29-131-40

sbava.pdf St. 07/04/16 Printed in Germany

MT16

Shoring System MT 60

Zeichnung Nr. 300506_0010-9

Stand: 08.03.2016/bhe

Zeichnung Nr. 300506_0010-8

Stand: 08.03.2016/bhe

Zeichnung Nr. 300506_0010-7

Stand: 08.03.2016/bhe

Fig. 16.1

Fig. 16.2

Fig. 16.3

Tower 170 x 340 – Vertical assembly

12. Suspend scaffold

platforms 170/30 and

scaffold platform 170/68

with access hatch for

level 1 (Fig. 16.1).

13. Install ledger 170

MT und diagonal brace

170/100 MT to brace

both towers (Fig. 16.2).

Bracing with ledger

and diagonal brace is

required on each tower

level.

14. Suspend all other

scaffold platforms

170/30 in level 1.

15. Ascend to level 1

and suspend the scaffold

platform 170/68 with

access hatch (Fig. 16.3)

Important

Always suspend the

scaffold platform 170/68

with access hatch in

a way that the access

hatch opens to frame

100 MT and you can

climb up or down the

ladder that is integrated

in the frame (Fig. 12.2

on page MT-12).

Description Ref. No.

Basic frame 100 MT .... 29-120-10

Horizontal brace MT ... 29-127-10

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Planking 170/30 .......... 29-131-40

Ledger 170 MT ........... 29-122-10

Diagonal brace

170/100 MT ................ 29-125-25

sbava.pdf St. 07/04/16 Printed in Germany

MT17

Shoring System MT 60

Zeichnung Nr. 300506_0010-6

Stand: 08.03.2016/bhe

Zeichnung Nr. 300506_0010-4

Stand: 08.03.2016/bhe

Zeichnung Nr. 300506_0010-5

Stand: 08.03.2016/bhe

Fig. 17.1

Fig. 17.2

Fig. 17.3

Level 3

16. Standing on the

scaffold platform of

level 1, install the frames

100 MT for level 3

(Fig. 17.1).

17. Remove the scaffold

platforms from level 1

in one tower and sus-

pend them in level 2

(Fig. 17.2).

18. Install the bracing

between the two towers

(Fig. 17.3).

Tower 170 x 340 – Vertical assembly

Description Ref. No.

Basic frame 100 MT .... 29-120-10

Horizontal brace MT ... 29-127-10

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Scaffold platform

170/30........................ 29-131-40

Ledger 170 MT ........... 29-122-10

Diagonal brace

170/100 MT ................ 29-125-25

Fig. 16.2

sbava.pdf St. 07/04/16 Printed in Germany

MT18

Shoring System MT 60

Zeichnung Nr. 300506_0010-3

Stand: 18.01.2016/bhe

Zeichnung Nr. 300506_0010-1

Stand: 08.03.2016/bhe

Fig. 18.1

Fig. 18.2

19. Remove the scaffold

platforms from level 1

and install them on level

2 (Fig. 18.1).

20. Ascend to level 2

(Fig. 18.2).

21. Install toe boards

170 MT, head spindles

MT and the bracing

between the towers.

Attention

Depending on its

height and the load it

is exposed to, e.g. wind

load, the tower needs

to be anchored to an

existing building. Sev-

eral towers need to be

connected with diagonal

braces and ledgers. Fol-

low the details provided

by the stress analyst.

Tower 170 x 340 – Vertical assembly

Description Ref. No.

Basic frame 100 MT .... 29-120-10

Horizontal brace MT ... 29-127-10

Scaffold platform 170/68

w/ access hatch ........... 29-131-30

Scaffold platform

170/30........................ 29-131-40

Ledger 170 MT ........... 29-122-10

Diagonal brace

170/100 MT ................ 29-125-25

sbava.pdf St. 07/04/16 Printed in Germany

MT19

Shoring System MT 60

Working platform between two towers

Zeichnung Nr. 300506_0017

Stand: 30.03.2016/bhe

Zeichnung Nr. 300506_0017_2D

Stand: 30.03.2016/bhe

Description Ref. No.

Scaffold platform

170/52.5..................... 29-131-35

170/30........................ 29-131-40

220/52.5..................... 29-131-10

220/30........................ 29-131-15

Toe board

170 MT ....................... 29-126-15

220 MT ....................... 29-126-10

Platform railing

170 MT ....................... 29-128-15

220 MT ....................... 29-128-10

Ledger

170 MT ....................... 29-122-10

220 MT ....................... 29-122-15

Standard post 100 MT 29-123-10

Fig. 19.1

Fig. 19.2

A safe working or walk-

ing area between two

towers can be achieved

by installing either

scaffold platform 170 or

scaffold platform 220

and platform railing 170

or 220 respectively.

The railing is attached

to the frames 100 MT on

both sides (Fig. 19.1).

Make sure to plan and

install an access frame

100 MT towards the

platform in both towers

so that the platform can

be accessed from the

towers (Fig. 19.2).

sbava.pdf St. 07/04/16 Printed in Germany

MT20

Shoring System MT 60

Transport by crane

Zeichnung Nr. 300506_0020_Detail

Stand: 16.02.2016/bhe

Zeichnung Nr. 300506_0020

Stand: 16.02.2016/bhe

The entire tower is

transported in one lift.

The 4-rope crane slings

are attached to the

crane eyes of the frames

MT (Detail 20.1).

Detail 20.1

Fig. 20.1

Table of contents

Other Meva Construction Equipment manuals

Popular Construction Equipment manuals by other brands

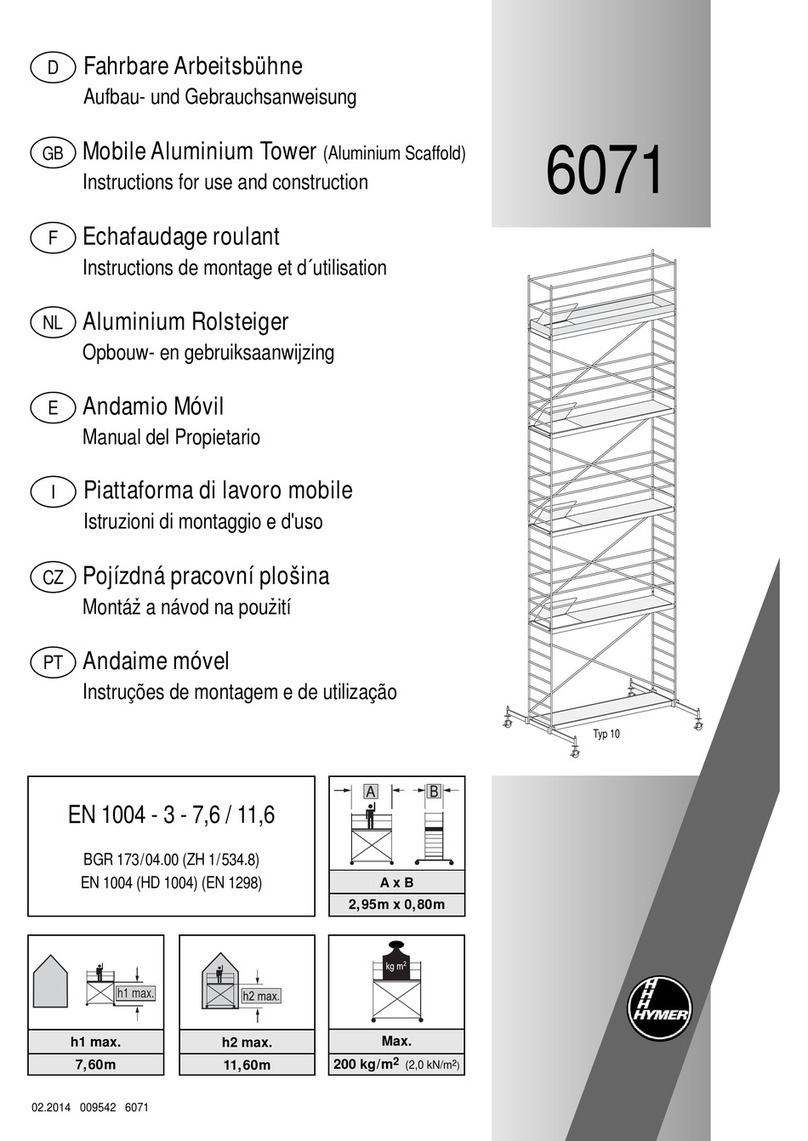

hymer

hymer 6071 Instructions for use

Unimec

Unimec FG3T-35 Operating, maintenance, spare parts manual

Turbosol

Turbosol PRO H CL Instructions for use and maintenance

Jerr-Dan

Jerr-Dan MPL40 Operation and safety manual

MAGIC SCREED

MAGIC SCREED HD6060 Owner's manual & parts book

probst

probst SDH-H-15 operating instructions