Meva Triplex Owner's manual

Technical Instruction Manual

Triplex

TRIPLEX2

triplextimus.pdf 06/2010

Triplex heavyduty braces must only be assembled and dis

assembled by persons with adequate working knowledge.

This manual illustrates the assembly and stripping

procedure of a standard application. For more complicated

or special applications not covered in this manual, please

contact the MEVA experts for advice.

All components have to be subjected to a visual check for

damages before assembly. Damaged parts must not be

used. The assembly sequence illustrated on the following

pages is binding.

Product Characteristics

Triplex is a heavyduty brace (three chords) to align and

brace formwork with heights exceeding 20‘ (6.00 m).

The system consits of modules which are assembled to the

required length on site. The standard components are:

intermediate pieces 300 cm (9‘10 1/8“), 200 cm (6‘6 3/4“),

100 cm (3‘3 3/8“) and 50 cm (1‘7 11/16“) as well as top

units with spindles.

The righthand and lefthand threads of the top units allow

for a precise adjustment.

Triplex is available in two different types:

Triplex R

is a brace for formwork heights of more than 20‘ (6.00 m).

It is attached to the formwork with a connector, and it is

provided with a foot plate to be anchored to the floor slab.

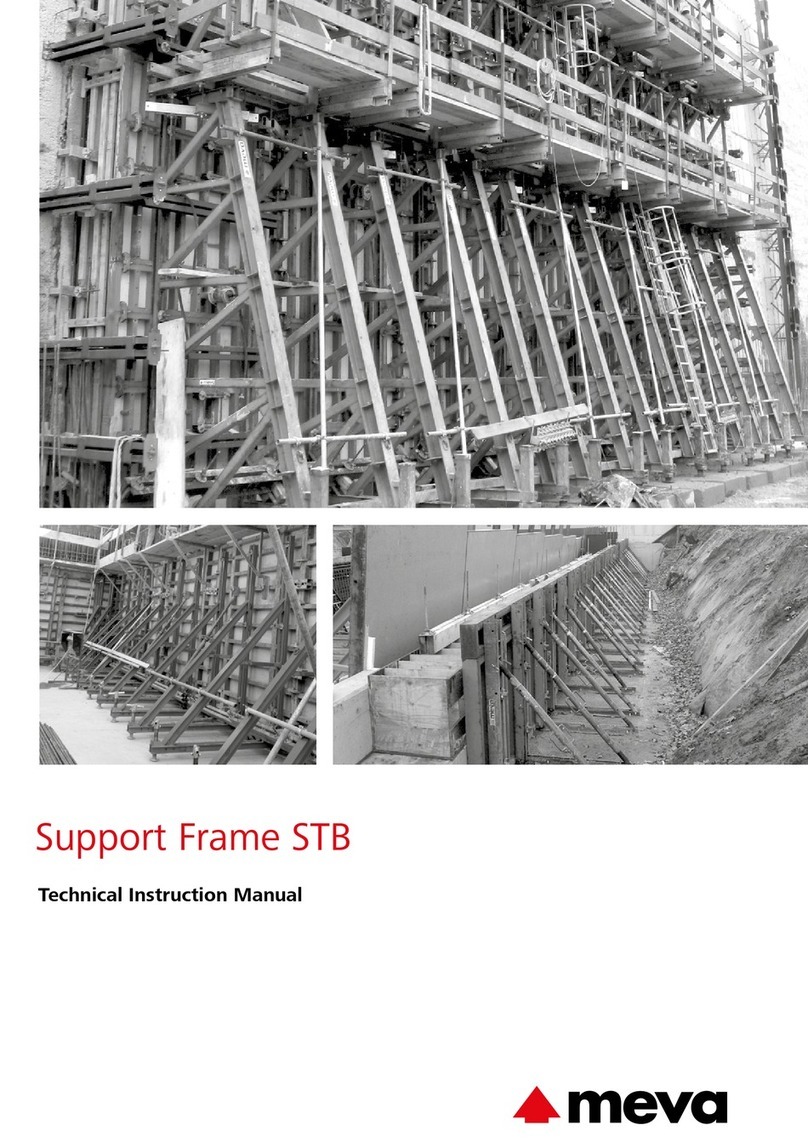

Triplex SB

is a reinforced version of the Triplex R brace (bigger

tubes). It is also used as an additional support for support

frames STB 450 with height extensions 150 when single

sided walls of more than 20‘ (6.00 m) are formed.

General Advice

June 2010

Triplex

TRIPLEX3

triplextimus.pdf 06/2010

ContentsPlease note:

This technical manual contains information, instructions and

hints describing how to use the Triplex heavyduty braces on

the construction site in a proper, quick and economic way.

Most examples shown are standard applications as they

occur in practice most often. For more complicated or

special applications not covered in this manual, please

contact the MEVA experts for advice.

When using our products, the federal, state and local codes

and regulations must be observed.

The individual, projectrelated assembly instruction, which

has to be prepared onsite, serves to reduce the specific

jobsite risks and must contain the following information:

1. Sequence of operational procedures including assembly

and disassembly

2. Weight of individual components

3. Type, number and spacing of anchors and braces

4. Arrangement, number and dimension of access platforms

(working scaffolds) including the required fall protection

and walkways

5. Attachment points to allow transport by crane

For this, please adhere to the following technical

instructions when applying the Triplex system. Deviations

require engineering calculation and analysis for proper

safety.

Generally, only wellmaintained material may be used.

Damaged parts must be replaced. Apply only original MEVA

spare parts for replacement.

Triplex R System description .........................................4

Triplex SB System description........................................5

Components.....................................................................6

Attachment to Wall Formwork...................................7–8

Attachment to Support Frame STB 450..........................9

Attachment to CaroFalt.................................................10

Attachment to Circo ......................................................11

Stripping.........................................................................12

Storage ...........................................................................13

Transport ........................................................................14

Load Charts .............................................................. 15–16

Services ...........................................................................17

Product List.....................................................................19

TRIPLEX4

triplex-timus.pdf 06/2010

Description . . . . . Ref.-No.

Triplex R 300 right-hand

thread with foot

plate................... 29-407-90

Triplex R 300

left-hand thread.. 29-407-93

Triplex intermediate pieces

R 50.................. 29-407-50

R 100.................. 29-407-55

R 200.................. 29-407-60

R 300.................. 29-407-65

Top units

48 left................. 29-407-80

48 right .............. 29-407-85

Triplex R - System Description

Heavy-duty braces

Triplex R

The Triplex R braces

are used to brace and

align wall and col

umn formwork with

heights of more than

20‘ (6.00 m).

Triplex R braces

are delivered as

several modules

which are assembled

to the required

length on site (see

product list, pages

20ff. for individual

components).

The Triplex R 300 with

righthand thread

comes with a foot

plate 48 (Fig. 4.1).

A bendproof

connection of the

modules is achieved

with always six (6)

bolts at each gusset

plate (Fig. 4.2).

Fig. 4.1 Triplex R 980 Fig. 4.2 Gusset plate

Triplex R 300 righthand thread with foot plate Triplex R 300 lefthand thread

Intermediate piece R 300

∅1.33“ (33.7 mm)

Hole diameter for

connecting bolts

∅0.67“ (17.0 mm)

Foot plate 48

TRIPLEX5

triplextim-us.pdf 06/2010

Triplex

Heavy-duty braces

Triplex SB

The Triplex SB braces

are used to brace and

align high wall and

column formwork

as well as additional

bracing for support

frames STB 450 with

height extensions 150

when singlesided

walls of more than

20‘ (6.00 m) are

formed.

The foot plate 73 can

be attached to the

top unit.

Triplex SB braces

are delivered as

several modules

which are assembled

to the required

length on site (see

product list, pages

23ff. for individual

components). Only

the Triplex SB 630

(Fig. 5.1) comes as

preassembled unit

(w\out foot plate).

A bendproof

connection of the

modules is achieved

with always six (6)

bolts at each gusset

plate (Fig. 5.2).

Description . . . . . Ref.-No.

Triplex SB 630 ......29-407-00

Triplex SB 300

right-hand thread 29-407-15

Triplex SB 300

left-hand thread...29-407-17

Triplex intermediate pieces

SB 50...................29-407-30

SB 100.................29-407-35

SB 200.................29-407-40

SB 300................ 29-407-45

Top units

73 left................. 29-407-25

73 right .............. 29-407-20

Fig. 5.1 Triplex SB 630 Fig. 5.2 Gusset plate

∅1.90“ (48.3 mm)

Hole diameter for

connecting bolts

∅0.67“ (17.0 mm)

Triplex SB - System Description

Intermediate

piece SB 50

Triplex SB 300 lefthand thread

Intermediate piece SB 200

Top unit 73 right

TRIPLEX6

triplex-timus.pdf 06/2010

Description . . . . . Ref.-No.

Triplex R intermediate

pieces

R 50. . . . . . . . . .29-407-50

R 100. . . . . . . . . .29-407-55

R 200. . . . . . . . . .29-407-60

R 300. . . . . . . . . .29-407-65

Triplex SB intermediate

pieces

SB 50. . . . . . . . .29-407-30

SB 100. . . . . . . . .29-407-35

SB 200. . . . . . . . .29-407-40

SB 300. . . . . . . . .29-407-45

Top units

48 left . . . . . . . . .29-407-80

48 right . . . . . . . .29-407-85

73 left..................29-407-25

73 right ...............29-407-20

Foot plate 48 .......29-407-75

Foot plate 73 .......29-407-74

Fig. 6.4: Foot plate 48 (Triplex R)

Fig. 6.1: Triplex intermediate pieces R (∅1.33“ / ∅ 33.7 mm) R 300, R 200, R 100 and R 50

and SB (∅1.90“ / ∅ 48.3 mm) SB 300, SB 200, SB 100 and SB 50

Fig. 6.2: Top unit 48 (Triplex R) left and right

Range of adjustment = 15 3/4“ (40.0 cm)

Components

Triplex braces are

delivered in individual

modules which are

assembled to the

required length on

site.

Intermediate pieces

(Fig. 6.1)

Top units

(Fig. 6.2 and 6.3)

Foot plates

(Fig. 6.4 and 6.5)

Please refer to

product list (p. 20ff.)

for individual compo-

nents.

Fig. 6.3: Top unit 73 (Triplex SB) left and right

Range of adjustment = 15 3/4“ (40.0 cm)

Fig. 6.5: Foot plate 73 (Triplex SB)

TRIPLEX7

triplextim-us.pdf 06/2010

Triplex

Detail: Formworkprop connector

Detail: Formworkprop co

Attachment of

Triplex R braces to

wall formwork

The formworkprop

connector is attached

to the formwork panel

by using a flange

screw, while the panel

is still lying on ground.

The Triplex R brace

is attached to the

connector by means of

the head bolt, which

is integrated in the

connector (Fig. 7.1

and Detail).

Triplex R 300 braces

with righthand

thread come with

the foot plate 48

preassembled.

The panels with braces

can be lifted to an

upright position by

using the MEVA crane

hook and 2rope crane

slings (Fig. 7.2).

Make sure to secure

the Triplex braces

safely to the floor slab

or concrete blocks

(dead man) with

adequate dowels or

the like, before you

detach the crane

slings.

Attachment to Wall Formwork

Fig. 7.2

Fig. 7.1

TRIPLEX8

triplex-timus.pdf 06/2010

Attachment to Wall Formwork

Attachment of

Triplex R braces to

wall formwork

The formworkprop

connector is attached

to the formwork panel

by using a flange

screw, while the panel

is still lying on ground.

The Triplex R brace is

attached to the con-

nector by means of

the head bolt, which

is integrated in the

connector.

As soon as the foot

plates are anchored

to the floor slab (Fig.

8.1) or concrete blocks

(dead man) (Fig. 8.2),

the wall forms can be

set plumb with the

Triplex braces.

Attachment of

Triplex R braces to

climbing brackets

Triplex R braces can

be attached to the

climbing scaffold KLK

230 with the adequate

bolts of the KLK

system for singlesided

wall formwork

(Fig. 8.3).

Fig. 8.1

Fig. 8.3

Fig. 8.2

TRIPLEX9

triplextim-us.pdf 06/2010

Triplex

Attachment to Support Frame STB 450

Attachment of

Triplex SB braces to

support frame

STB 450

Depending on

the height of the

singlesided wall

formwork Triplex SB

braces are attached to

the height and base

extensions of the STB

support frames

(Fig. 9.1 and 9.2).

The necessary

connecting bolts

are provided with

the height and base

extensions.

Fig. 9.1

Fig. 9.2.

Fig. 9.1

Fig. 9.2.

Fig. 9.3

Fig. 9.4

TRIPLEX10

triplex-timus.pdf 06/2010

Attachment to CaroFalt

Attachment of

Triplex R braces to

CaroFalt column

formwork

Three Triplex R

braces are attached

to a unit of two

CaroFalt panels

(angle) by means

of formworkprop

connectors (head

bolts are integrated),

while the panels are

still lying on ground.

The third brace serves

as protection against

torsion (Fig. 10.1).

Triplex R 300 braces

with righthand

thread come with

the foot plate 48

preassembled.

2rope crane slings

are used to lift the

complete unit of two

CaroFalt panels,

pushpull props,

Triplex R braces and

CaroFaltplatform to

an upright position

(Fig. 10.2).

Immediately anchor

the foot plate 48 of

the Triplex R braces

to the floor slab or

concrete blocks (dead

man) with adequate

dowels or the like.

Fig. 10.1

Fig. 10.2

Fig. 10.1

TRIPLEX11

triplextim-us.pdf 06/2010

Triplex

Attachment to Circo

Fig. 11.1.

Fig. 11.2

Fig. 11.1

.

Attachment of

Triplex R braces to

Circo circular col-

umn formwork

Triplex R braces

are attached to the

integrated formwork

prop connectors

(incl. head bolts and

cotter pins) of the

Circopanels (half

shell), while these are

still lying on ground.

(Fig. 11.1).

Triplex R 300 braces

with righthand

thread come with

the foot plate 48

preassembled.

Immediately anchor

the foot plate 48 of

the Triplex R braces

to the floor slab or

concrete blocks (dead

man) with adequate

dowels or the like.

As soon as the foot

plates are secured,

the Circo formwork

can be set plumb with

the Triplex braces

(Fig. 11.2).

We recommend to

use stair towers for

a safe access to the

Circoplatforms.

TRIPLEX12

triplex-timus.pdf 06/2010

Stripping

Fig. 12.1

Fig. 12.2

We recommend the

stripping of complete

units (Triplex braces

plus formwork).

After these units are

put to ground, the

Triplex braces can be

dismantled (Fig. 12.1).

Attach the 2rope

crane slings to one of

the chords of a Triplex

brace and remove

all connecting parts.

Then lift the Triplex

brace by crane and

put it aside for clean

ing or stacking

(Fig. 12.2).

Dirt is removed with

a brush or a cloth.

When cleaning the

Triplex braces, do not

use tools which might

cause scratches, and

do not hit the braces

with any tool.

Fig

. 1

2.2

TRIPLEX13

triplextim-us.pdf 06/2010

Triplex

Storage

The components of

the Triplex braces are

stored in stacking

racks, which can be

moved by crane or lift

truck. When a lift truck

is used, slide in the

forks from the long

side (parallel to the

short side) of the

stacking rack (Fig. 13.1

to 13.6).

Transport units per

stacking rack:

20 x R 50 507.1 lbs

17 x R 100 599.7 lbs

10 x R 200 573.2 lbs

10 x R 300 749.6 lbs

20 x SB 50 661.4 lbs

17 x SB 100 826.7 lbs

10 x SB 200 815.7 lbs

10 x SB 300 1,146.4 lbs

The top units 48 and

73 as well as the foot

plates 48 and 73 are

stored and delivered in

storage boxes

(Fig. 13.6).

Depending on the

total weight, either

three stacking racks or

three storage boxes

can be put upon each

other on a truck

(Fig. 13.5 and 13.6).

Fig.13.1 Fig. 13.2

Fig. 13.3 Fig. 13.4

Fig. 13.5 Fig. 13.6

Fig

.13

.1

Fig. 13.2

Fig. 1

3.3

Fig. 13.4

Fig

. 1

3.6

Fig. 13.5

TRIPLEX14

triplex-timus.pdf 06/2010

Transport

Make sure that all

material is secured

properly.

Recommendation

Use one load/cargo

strap per 3 linear feet

of cargo (Fig. 14.1).

Attention

When using our

products, the federal,

state and local codes

and regulations must

be observed.

Fig.14.1

Fig.14.1

TRIPLEX15

triplextim-us.pdf 06/2010

Triplex

Load Charts

Triplex R

The admissible load

capacities for Triplex

R braces in vertical

and horizontal

applications as well as

at an angle of 60° are

shown in table 15.1.

Tab 15.1

LOAD CAPACITY OF TRIPLEX R AS VERTICAL SHORE

LENGTH ADJUSTMENT RANGE WEIGHT PRESSURE TENSILE FORCE

ft [m] lbs [KG] kips [KN] kips [KN]

Triplex R 680 21.0 - 23.6 [6.40 - 7.20] 271.2 [123.0] 10.12 [45.0] 10.12 [45.0]

Triplex R 780 24.3 - 26.9 [7.40 - 8.20] 306.4 [139.0] 10.12 [45.0] 10.12 [45.0]

Triplex R 880 27.6 - 30.2 [8.40 - 9.20] 328.5 [149.0] 10.12 [45.0] 10.12 [45.0]

Triplex R 980 30.8 - 33.5 [9.40 - 10.20] 346.1 [157.0] 7.87 [35.0] 10.12 [45.0]

LOAD CAPACITY OF TRIPLEX R AS HORIZONTAL SHORE (Supported at every third of the Triplex)

LENGTH ADJUSTMENT RANGE WEIGHT PRESSURE TENSILE FORCE

ft [m] lbs [KG] kips [KN] kips [KN]

Triplex R 680 21.0 - 23.6 [6.40 - 7.20] 271.2 [123.0] 10.12 [45.0] 10.12 [45.0]

Triplex R 780 24.3 - 26.9 [7.40 - 8.20] 306.4 [139.0] 10.12 [45.0] 10.12 [45.0]

Triplex R 880 27.6 - 30.2 [8.40 - 9.20] 328.5 [149.0] 10.12 [45.0] 10.12 [45.0]

Triplex R 980 30.8 - 33.5 [9.40 - 10.20] 346.1 [157.0] 7.87 [35.0] 10.12 [45.0]

LOAD CAPACITY OF TRIPLEX R UNDER AN ANGLE OF 60°

LENGTH ADJUSTMENT RANGE WEIGHT PRESSURE TENSILE FORCE

ft [m] lbs [KG] kips [KN] kips [KN]

Triplex R 680 21.0 - 23.6 [6.40 - 7.20] 271.2 [123.0] 10.12 [45.0] 10.12 [45.0]

Triplex R 780 24.3 - 26.9 [7.40 - 8.20] 306.4 [139.0] 10.12 [45.0] 10.12 [45.0]

Triplex R 880 27.6 - 30.2 [8.40 - 9.20] 328.5 [149.0] 7.87 [35.0] 10.12 [45.0]

Triplex R 980 30.8 - 33.5 [9.40 - 10.20] 346.1 [157.0] 6.74 [30.0] 10.12 [45.0]

TRIPLEX16

triplex-timus.pdf 06/2010

Load Charts

Tab. 16.1

Triplex SB

The admissible load

capacities for Triplex

SB braces in vertical

and horizontal

applications as well as

at an angle of 60° are

shown in table 16.1.

LOAD CAPACITY OF TRIPLEX SB AS VERTICAL SHORE

LENGTH ADJUSTMENT RANGE WEIGHT PRESSURE TENSILE FORCE

ft [m] lbs [KG] kips [KN] kips [KN]

Triplex SB 630 19.4 - 22.0 [5.90 - 6.70] 315.3 [143.0] 25.18 [112.0] 29.22 [130.0]

Triplex SB 780 24.3 - 26.9 [7.40 - 8.20] 363.8 [165.0] 22.03 [98.0] 29.22 [130.0]

Triplex SB 880 27.6 - 30.2 [8.40 - 9.20] 396.8 [180.0] 17.53 [78.0] 29.22 [130.0]

Triplex SB 980 30.8 - 33.5 [9.40 - 10.20] 429.9 [195.0] 15.29 [68.0] 29.22 [130.0]

LOAD CAPACITY OF TRIPLEX SB AS HORIZONTAL SHORE (Supported at every third of the Triplex)

LENGTH ADJUSTMENT RANGE WEIGHT PRESSURE TENSILE FORCE

ft [m] lbs [KG] kips [KN] kips [KN]

Triplex SB 630 19.4 - 22.0 [5.90 - 6.70] 315.3 [143.0] 25.18 [112.0] 29.22 [130.0]

Triplex SB 780 24.3 - 26.9 [7.40 - 8.20] 363.8 [165.0] 22.03 [98.0] 29.22 [130.0]

Triplex SB 880 27.6 - 30.2 [8.40 - 9.20] 396.8 [180.0] 17.53 [78.0] 29.22 [130.0]

Triplex SB 980 30.8 - 33.5 [9.40 - 10.20] 429.9 [195.0] 15.29 [68.0] 29.22 [130.0]

LOAD CAPACITY OF TRIPLEX SB UNDER AN ANGLE OF 60°

LENGTH ADJUSTMENT RANGE WEIGHT PRESSURE TENSILE FORCE

ft [m] lbs [KG] kips [KN] kips [KN]

Triplex SB 630 19.4 - 22.0 [5.90 - 6.70] 315.3 [143.0] 22.48 [100.0] 29.22 [130.0]

Triplex SB 780 24.3 - 26.9 [7.40 - 8.20] 363.8 [165.0] 19.11 [85.0] 29.22 [130.0]

Triplex SB 880 27.6 - 30.2 [8.40 - 9.20] 396.8 [180.0] 14.61 [65.0] 29.22 [130.0]

Triplex SB 980 30.8 - 33.5 [9.40 - 10.20] 429.9 [195.0] 12.36 [55.0] 29.22 [130.0]

TRIPLEX17

triplextim-us.pdf 06/2010

Triplex

Service

Rentals

We offer our customers

the option of renting

supplementary material

during peak times. We

also give prospective

customers the chance

to test MEVA formwork

so they can see its

benefits for themselves

in actual use.

RentalPlus

Since MEVA started the

flat rate for cleaning

and repair of rented

formwork systems in

early 2000 more and

more contractors expe-

rience the outstanding

advantages. Ask our

representatives about

the details!

Formwork drawings

Of course, all offices in

our technical depart

ment have CAD facili

ties. You get expert,

clearly represented

plans and work cycle

drawings.

MBS - MEVA Basic

Support

MBS is an addition to

AutoCAD, developed

by MEVA Formwork

Systems in 2000.

MBS is based on

standard programs

(AutoCAD and Excel)

and can be used on

any PC that has these

two programs installed.

It includes pull down

menues for AutoCAD

and applications to

ease forming. It also

includes the possibility

to create takeoffs

Special solutions

We can help with

special parts, custom

designed for your

project, as a supple

ment to our form

work systems.

Static calculations

Generally, this is

only necessary

for applications

like singlesided

formwork where

the anchor parts are

embedded in the

foundation or the

base slab. If request

ed, we can perform

static calculations for

such applications at

an additional charge.

TRIPLEX18

triplex-timus.pdf 06/2010

Notes

Table of contents

Other Meva Construction Equipment manuals

Popular Construction Equipment manuals by other brands

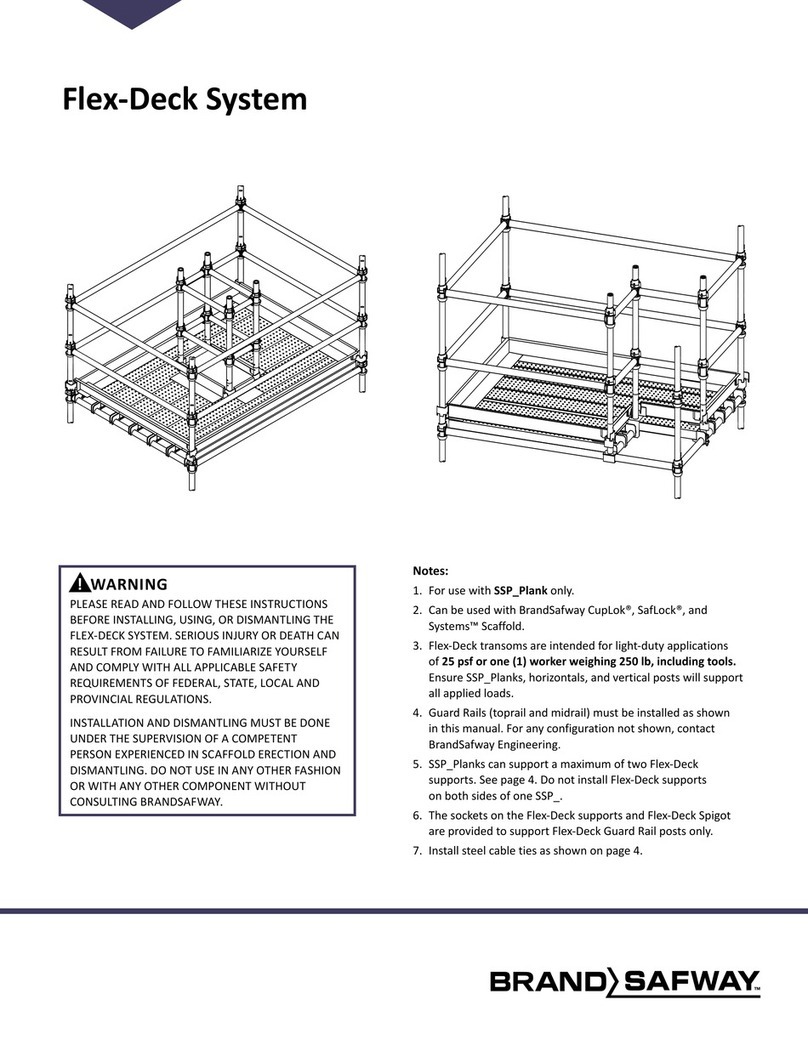

BrandSafway

BrandSafway Flex-Deck manual

Fayat Group

Fayat Group Dynapac CA25 instruction manual

MetalTech

MetalTech M-MFT5710 OPERATIONAL SAFETY AND ASSEMBLY INSTRUCTIONS

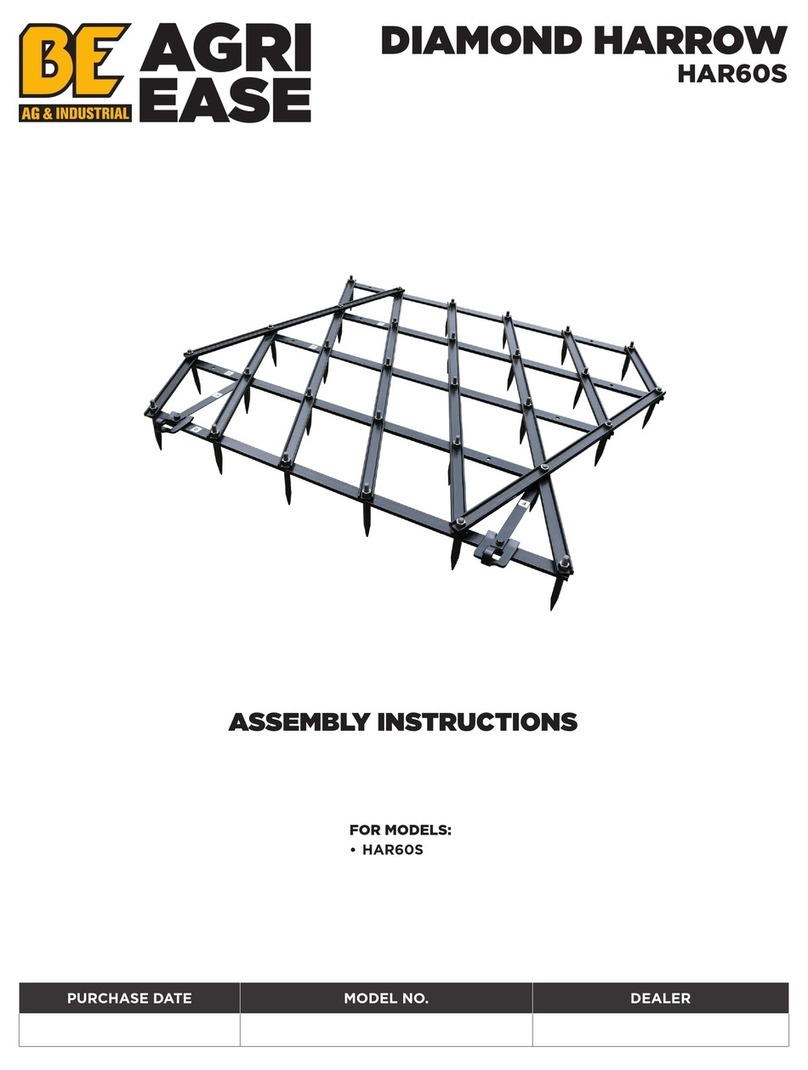

BE Ag & Industrial

BE Ag & Industrial AGRI EASE DIAMOND HARROW HAR60S Assembly instructions

Conmec

Conmec CT436E Operator's manual

SPIERINGS

SPIERINGS AT3 manual