Meva Mammut 350 Owner's manual

Technical Instruction Manual

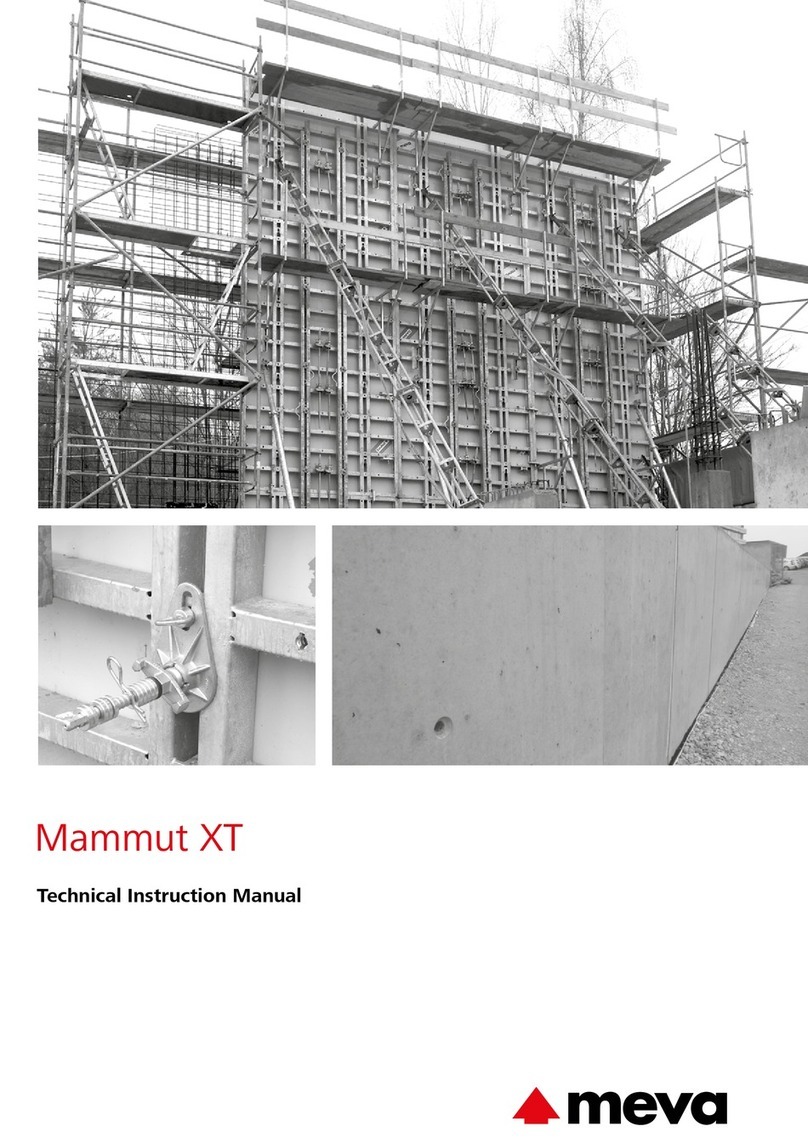

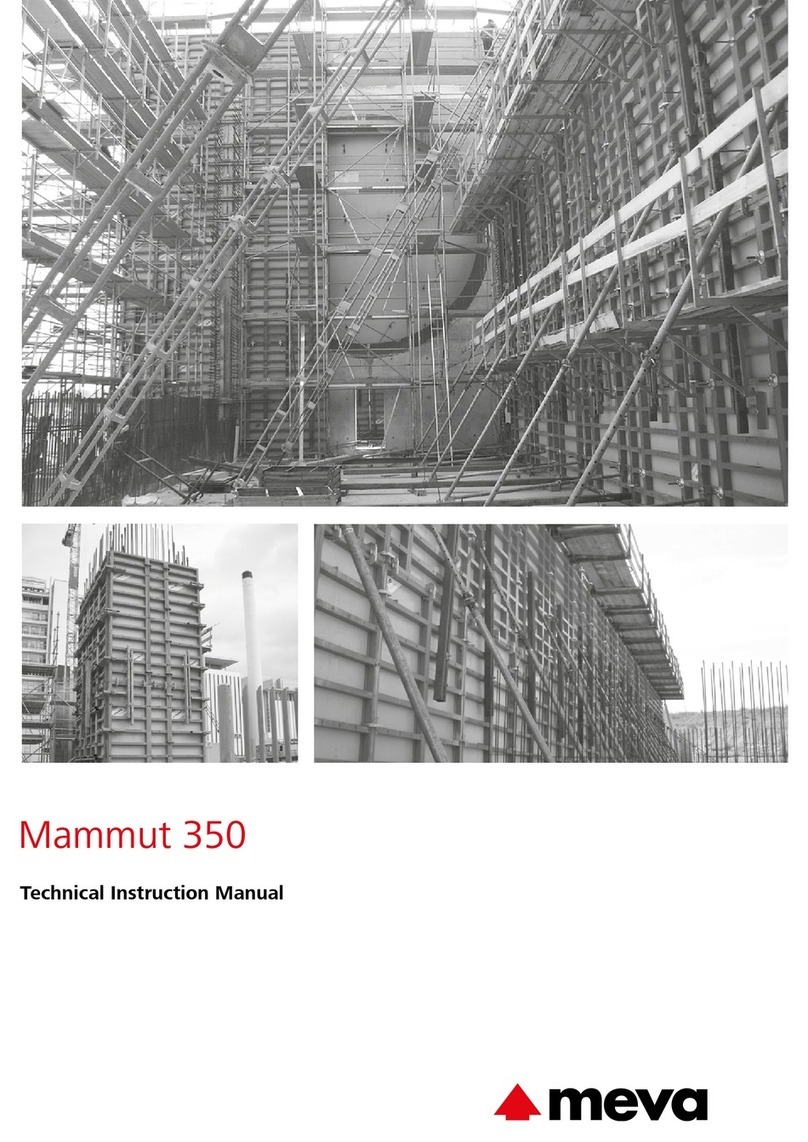

Mammut 350

The Mammut 350 wall formwork is a crane-dependent formwork

system made of steel. It is ideally suited for use in high-rise, public,

commercial and industrial construction as well as civil engineering

projects that require a top architectural concrete surface.

The Mammut 350 has the following characteristics:

ÆSeven multi-function profiles

ÆTie holes at multi-function profile level

ÆBump notches for panels that are 250 and 125 cm wide

ÆSymmetry on the inside and outside

ÆAn even tie hole and joint pattern

ÆCompatible with Mammut XT and Mammut

ÆSame accessories used for Mammut XT, Mammut 350 and

Mammut

The steel frames of the Mammut350 panels are hot-dip galvanised

both internally and externally and post-treated. This ensures improved

corrosion protection, making them durable and easy to clean.

Mammut 350 panels are available with heights 350, 300, 250 and

125cm. A complete formwork set including accessories weighs

approx. 62 kg/m²

The MEVA multi-function profile with welded-in DW-threaded nuts

makes the attachment of accessories easier, for example:

ÆPush-pull props and alignment rails with flange screws

ÆWalkway brackets with integrated self-locking pin

ÆDW tie rods of any length that are used to bridge problem areas.

The Mammut350 panels are equipped with the 20 mm thick alkus

all-plastic facing made of polypropylene and aluminium. The facing

is riveted to the panel on the pouring side. In addition, the facings

are protected with silicone. The tried-and-tested polypropylene and

aluminium composite facing has all the positive properties of plywood

plus important advantages: longer lifespan, greater load-bearing

capacity, better nail-holding ability, fewer and easier repairs, 100%

recyclability.

Product features

The admissible fresh-concrete pressure is 100 kN/m² if DW20 tie

rods with a permissible working load of 160 kN are used (required for

panel widths from 100cm upwards). This high load capacity results in

short pouring cycles, since walls up to a pouring height of 400cm can

be poured without considering the rate of placing. The fresh-concrete

pressure for vertical formwork according to DIN18218:2010-01

can be determined easily and precisely with MEVA’s online concrete

pressure calculator. This and other digital aids are available in the

download area at www.meva.net and in the app MEVAme for iOS

and Android.

Abbreviations, measurements, figures and tables, etc.

The abbreviation M 350 is used for the Mammut 350 system series

and the abbreviation M for the Mammut system series. DIN means

Deutsche Industrie-Norm (German Industrial Standard). E DIN

(E=Entwurf / draft) means that the DIN is in draft status and not yet

approved. Any further abbreviations are explained where they are

used for the first time.

TÜV means Technischer Überwachungsverein. This is the independent

German organisation that tests the safety of technical installations,

machinery and motor vehicles. If a product passes the test, it is

permitted to carry the GS seal. GS stands for Geprüfte Sicherheit

(approved safety).

Measurements: This manual uses the metric system, i.e. m (for metre),

cm (for centimetre) and mm (for millimetre).

Non-defined dimensions are in cm.

The page numbers in this manual start with M350. The figures and

tables are numbered per page. Depending on its product abbreviation,

a cross reference in the text refers to a page, table or figure in this or

in another manual. This is indicated by the product code with which

the cross-reference begins.

M350-2 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Please note

Contents

Formwork assembly and stripping..................................................... 4

The Mammut 350 panel ................................................................... 8

alkus all-plastic facing..................................................................... 10

Panel connection ............................................................................ 11

Tie holes......................................................................................... 12

Rules for concrete pouring and rate of placing................................ 13

Flatness of surface .......................................................................... 14

Attachment of accessories .............................................................. 15

Wall braces..................................................................................... 16

Working scaffolds – Folding access platform BKB 125..................... 19

Working scaffolds / walkway brackets ............................................ 20

Working scaffold – Ladder fixture for wall formwork ...................... 21

Working scaffolds – Tilting bracket 40/60....................................... 22

Crane Hook .................................................................................... 23

Inside corner 90° ............................................................................ 24

Outside corner 90° ......................................................................... 25

Height-extended 90° outside corner ............................................... 26

90° corner with filler....................................................................... 27

90° corner – Combinations ............................................................. 28

Hinged corners ............................................................................... 29

Stripping corner.............................................................................. 31

Stripping panel – For stripping support of short walls ..................... 39

Length compensation ..................................................................... 40

T wall connection ........................................................................... 42

Connection to existing walls ........................................................... 43

Stop ends ....................................................................................... 44

Wall offset...................................................................................... 46

Pilasters .......................................................................................... 47

Differences in height....................................................................... 48

Horizontal panels............................................................................ 49

Substitution of ties.......................................................................... 51

Height extension............................................................................. 53

Crane ganging................................................................................ 55

Column formwork – With standard panels and outside corners ...... 57

Column formwork / column panel .................................................. 58

Panel with filling nozzle / concreting window.................................. 64

Single-sided formwork / climbing formwork ................................... 65

Lifting hook 60 .............................................................................. 66

Transport ........................................................................................ 67

Services .......................................................................................... 68

Product list ..................................................................................... 71

This Technical Instruction Manual contains information, instructions

and tips that describe how to use the MEVA equipment on the

construction site in a proper, quick and economic way. Most examples

shown are standard applications that will occur in practice most

often. For more complicated or special applications not covered in this

manual, please contact the MEVA experts for advice. They will help

you without delay.

When using our products, the federal, state and local occupational

health and safety regulations must be observed. Please observe the

assembly instructions that your local contractor or employer has

created for the site on which the MEVA equipment is used. Such

instructions are intended to minimise site-specific risks and must

contain the following details:

ÆThe order in which all working steps including assembly and

disassembly must be carried out

ÆThe weight of the panels and other system parts

ÆThe type and number of ties and braces as well as the distance

between them

ÆThe location, number and dimensions of working scaffolds

including the working area and fall protection equipment required

ÆAttachment points for panel transport by crane. With regard to

panel transport, please observe this manual. Any deviation will require

structural verification.

Important: Generally, only well-maintained material may be used.

Damaged parts must be replaced. Use only original MEVA spare parts

for replacement.

Attention: Never wax or oil assembly locks!

M350-3Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Formwork assembly and stripping

Fig. 4.1 Double-sided formwork

Important!

When assembling and stripping

formwork, strictly observe the

local accident prevention rules.

When using our formwork and

systems always observe federal,

state and local codes and

regulations.

Attention

Above a formwork height

of 2.00 m both sides of the

formwork must be secured

against falling.

Planning

If you want to benefit fully from

the ecient and economical

use that the formwork offers,

we recommend you first plan

and prepare its use. Start

planning by determining the

optimum formwork quantity to

be held in stock (the quantity

is usually based on the amount

of formwork required for a one

day‘s work). When determining

the quantity, consider the

following:

ÆThe formwork weight

ÆThe time required for

formwork assembly and stripping

ÆTransport of gangs from one

pour to the next considerably

reduces assembly and stripping

effort and time

ÆCapacity of the lifting devices

ÆA logical cycle plan that

takes into account corner

configurations, reinforcements,

etc.

Once all these aspects have been

considered, the quantities of

formwork items can be specified.

Ground

The ground on which the

formwork is going to be placed

should be clean, even and

capable of bearing the expected

load, as this will help reduce the

time required for the assembly

and stripping.

Panel transport

When unloading panels or

moving panel stacks, make sure

to use appropriate transport

devices that can bear the load.

For detailed information see page

M350-66

The steps required for

assembly

For ergonomic reasons the

outside formwork is usually

assembled and placed first. Start

assembly in a corner or at a

defined position and perform the

following steps:

Step 1 – Place and brace the

outside formwork

Step 2 – Define and mark the

pouring height, install the

reinforcements and boxouts

Step 3 – Place the inside

formwork and tie the outside and

inside formwork

Refer to the following pages for

a detailed description of these

steps including the installation

of the working platform and

formwork stripping.

M350-4 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Fig. 5.1

Formwork assembly and stripping

If the walkway bracket was not

pre-assembled before step 1, you

can now assemble and install the

working platform. Fig.6.2

on page M350-6 shows a

working platform being lifted

with a crane for attachment to a

braced outside formwork.

3. String further panels together

and connect them with M

assembly locks (see page

M350-11).

Panels with a height of 350cm

are usually connected with three

assembly locks. However, outside

corner configurations require

four assembly locks (Fig.5.2).

Step 2

Pouring height,

reinforcements and boxouts

After performing step 1, the

pouring height is defined and

marked. Then the reinforcements

and boxouts, if required, are

installed.

Step 3

Place the inside formwork

and tie the outside and inside

formwork

The inside formwork is placed

after the outside formwork. Then

the inside and outside formwork

are tied firmly with tie rods and

articulated flange nuts.

Step 1

Place and brace the outside

formwork

The following description is

based on an straight wall. Before

starting, keep in mind:

ÆWhen pre-assembling large

panel units on an even surface,

attach the wall braces and the

walkway bracket as well, i.e.

before performing step 1.

ÆWalls of less than 6m require

a filler in the inside formwork

for easy stripping (Fig. 5.3), as

the formwork may otherwise

become wedged and stick to the

concrete when it is stripped.

1. Spray the facing with the

release agent MevaTrenn pro.

2. Place the first panel and

immediately attach it to the

ground or concrete slab with

two brace frames to prevent it

falling over (Fig. 5.1). The foot

plate must be firmly connected

to the ground or concrete slab –

in earth with two ground pegs,

in concrete with two heavy-duty

dowels.

After placing vertical panels,

always reinforce them

immediately with push-pull

props or brace frames so they

can withstand tensile and

compressive forces and are

protected against displacement

and wind. The prop spacing is

determined by the application.

Fig. 5.2

Fig. 5.3

Filler for easy stripping

M350-5Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Formwork assembly and stripping

Working scaffold

The plug-in walkway bracket

(Fig. 6.1) is used to support the

working scaffold. The maximum

bracket spacing for a load of

150kg/m² (platform group 2) is

2.50m as defined in DIN 4420.

The planking must be at least

4.5cm thick.

The planking and walkway

bracket can be firmly connected.

Do not install any planks before

securing the formwork with

push-pull props or before tying

the inside and the outside

formwork.

Do not forget to attach a side

railing to the working scaffold.

Pouring concrete

Once you have placed, tied,

braced and closed the formwork,

you can start pouring concrete.

When doing so, observe the

permissible rate of placing taking

the setting behaviour and the

consistency of the cement into

account (see page M350-13).

Fig. 6.1

Fig. 6.2

M350-6 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Fig. 7.1

Fig. 7.2

Formwork assembly and stripping

Stripping

Do not start stripping before the

concrete has set to the point

where it can no longer deform.

It is best to start stripping at the

stop ends or at a short corner.

Start stripping with the inside

formwork. Stripping of both the

outside and inside formwork is

performed as follows:

1. Remove the working scaffold.

2. Remove the articulated flange

nuts and tie rods section by

section. Make sure the unbraced

formwork is immediately secured

to prevent it falling over or strip

it immediately.

3. On the formwork panels or

large panel units the assembly

locks are removed at the joints,

and the panels or panel units

are then lifted out by hand or

by crane. Before transporting by

crane, the formwork must be

detached from the concrete!

4. Clean the facing and remove

any concrete. Before the next

use, spray the facing with the

release agent MevaTrenn FT8

(for alkus facings). Observe the

operating instructions for the

alkus facing.

Note

The release agent must not be

stored in galvanized containers.

Please note

When stripping manually, detach

and disassemble the working

scaffold and the brace frames

before stripping the panels.

When transporting large panel

units with a crane, the working

scaffold and wall braces are

moved together with the

panel units. While vertical, all

components are cleaned and

sprayed with release agent

before being lifted together

to the next cycle (see pages

M350-55 and 56).

If there is no further use for the

panel units, the working scaffold

and wall braces are detached

and disassembled in a horizontal

position, and cleaned and

stacked for transport.

M350-7Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Fig. 8.1

Tie hole with conical anchor

sleeve (see page M350-12).

Fig. 8.2

Panel connection with

the M assembly lock (see

page M350-11).

Fig. 8.3

Cross stiffener made of sturdy

closed steel profile.

Fig. 8.4

Quick and secure attachment

of accessories using welded-in

DW 15 threaded nuts (see page

M350-15).

Fig. 8.5

Transport hole to attach the

crane slings 60, allowing fast

loading and unloading of panel

stacks and enabling them to be

moved at ground or slab level

(see pages M350-66 and

-66).

Fig. 8.6

The steel frames are made of

closed hollow profiles with

welded-in mitred joints. The

profiles are provided with a

groove and edge protection.

Panels with a width of 125

and 250 cm are equipped with

four bump notches that are

diagonally welded in, allowing

exact panel positioning without

a hammer.

Note

For a list of the available panels

including their designations and

reference numbers refer to the

Product List.

The Mammut 350 panel

Fig. 8.1

Fig. 8.2

Fig. 8.3

Fig. 8.4

Fig. 8.5

Fig. 8.6

M350-8 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

The Mammut 350 panel

The large-size panels 350/250

(Fig.9.1) and 300/250

(Fig.9.2)

These panels are ideally suited

for vertical and horizontal use.

Since the tie holes are located

inside the panel, the 8.75m²

forming area of the 350/250

panel requires only six ties and

the 7.50m² forming area of the

300/250 panel only four ties.

The panels can be connected to

existing walls without alignment

rails or fillers. They can overlap

by up to 50cm (see page

M350-43).

If 250cm high panels are used

horizontally and mounted on

top of each other, an even joint

pattern with continuous vertical

joints is assured.

Vertical and horizontal panels

can be combined freely.

Panels with a width of 125 and

250 cm are equipped with four

bump notches that are diagonally

welded in, allowing exact panel

positioning without a hammer.

The panels can be positioned in

all directions without a hammer

(M350 Fig.8.6).

Description Ref. No.

M 350 panel AL 20

350/250 ................................ 23-005-05

300/250 ................................ 23-006-05

Fig. 9.2

Fig. 9.1

M350-9Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

alkus all-plastic facing

The tried-and-tested

polypropylene and aluminium

composite facing (Fig.10.3)

has all the positive properties

of plywood plus important

advantages: longer lifespan,

greater load-bearing capacity,

better nail-holding ability,

fewer and easier repairs, 100%

recyclability.

Besides the obvious advantages

such as considerably reduced

cleaning effort, minimum

consumption of release agent

and an excellent, uniform

concrete finish, alkus offers

substantial ecological benefits.

Substituting plastic for wood

saves valuable timber resources.

Also, alkus avoids the release

of highly toxic dioxin that is

released when burning plywood

bonded with phenolic resin.

Used or damaged alkus facings

can be recycled to produce

new facings. They are 100%

recyclable and subject to a global

return policy.

Fig. 10.1 Frame profile with plywood facing:

Negative imprint in the concrete when using

panels with a conventional plywood facing

Fig. 10.2 Frame profile with alkus facing:

Smooth and even concrete surface as there are no

projecting profiles

Fig. 10.3 Design of the alkus all-plastic facing

Plastic layer

Metal or fibres

Foamed plastic core

Metal or fibres

Plastic layer

M350-10 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Fast and ecient connection

of the panels is accomplished

with the M assembly lock

(Fig.11.1) whether the panels

are assembled side by side or

on top of each other (height-

extended). The assembly lock can

be attached at any position on

the panel joint between the cross

stiffeners. Since it weighs only

3kg, it can be easily attached

with only one hand.

Its 5-point contact (Figures11.2

and 11.3) draws the panels

together and aligns them.

Secure connection and perfect

alignment are achieved with

only a few hammer blows. The

assembly lock locks into a fail-

safe position immediately and

automatically.

Panels up to a height of 300cm

are connected with two assembly

locks and panels with a height of

350cm are connected with three

assembly locks.

When pouring walls in SB3

quality (German architectural

concrete class for immaculate

architectural concrete surfaces),

the use of an additional assembly

lock is recommended to connect

panels that are 250cm high or

higher.

Horizontal panel connections

generally require two assembly

locks.

For the quantity of assembly

locks required for outside corners

and columns refer to pages

M350-25 and -26 as well as

M350-57.

Panel connection

Fig. 11.1

Fig. 11.2 Fig. 11.3

= 5-point contact

Description Ref. No.

M assembly lock 29-400-71

M350-11Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Tie holes

The conical anchor sleeve

(Fig.12.1) for DW 15 and DW 20

tie rods is welded to the frame.

The M350 formwork can be

inclined up to 8 cm/m with

DW15 tie rods or 5 cm/m with

DW 20 tie rods (Figures 12.2 and

12.3). Inclined panels require

articulated flange nuts and

must be secured against uplift.

Articulated flange nuts 15/120

are used for DW15 tie rods,

articulated flange nuts 20/140

for DW20 tie rods.

Use a hammer or 27 mm spanner

(Fig.124) to handle articulated

flange nuts 15/120 without

damaging them and a hammer

or 36 mm spanner for articulated

flange nuts 20/140.

When connecting panels with

different widths, always anchor

them through the wider panel

(Fig. 12.6).

All usable tie holes must be

used for tying and non-usable

ones must be closed with plug

D27/30.

Panels can also be tied outside

the panel using a Uni-tie claw

(Fig.12.5).

Description Ref. No.

Tie rod DW 15/90.................. 29-900-80

Tie rod DW 20/120................ 29-900-97

Flange nut 100 ...................... 29-900-20

Uni-tie claw ........................... 29-901-41

Plug D27/30 .......................... 29-902-61

Articulated flange nut 15/120.29-900-10

Articulated flange nut 20/140 29-900-05

Spanner size 27 ......................29-800-10

Spanner size 36 ......................29-800-15

350

55 120 120 55

α=3

28 (DW 15)

17.5 (DW 20)

α=3°

Detail

α=3°

Fig. 12.1

25 mm

33 mm

Fig. 12.2 Fig. 12.3

Fig. 12.4

Fig. 12.5

Fig. 12.6

Right Wrong

Uni-tie claw

M350-12 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

DW tie rod 15 20

d21[mm] 15 20

d22[mm] 17 22.4

Nominal cross-section [mm²] 177 314

Permissible working load according to DIN 18216 [kN] 90 160

Tie rod elongation

when using the permissible working load [mm/m] 2.5 2.35

Specific values of tie rods DW 15 and DW 20

Table 13.3

Rules for concrete pouring and rate of placing

The maximum permissible

fresh-concrete pressure for

Mammut350 is 100 kN/m²

(when using tie rods with a

permissible working load of

160kN).

Rules for concrete pouring

ÆFor the rate of placing of

walls higher than 4.00m refer

to Table13.1 (DW15) and

Table13.2 (DW20).

ÆAccording to DIN 4235,

concrete should be placed in

layers whose thickness can vary

from 0.50 m bis 1.00 m.

ÆConcrete must not be placed

above heights of 1.50 m (or

higher) in free fall.

ÆWhen vibrating the concrete,

which is done layer by layer, the

vibrator must not penetrate more

than 50 cm into the layer below.

ÆA final vibrating step over

the overall concrete height is

not recommended. It does not

provide any advantage, since

concrete that has been vibrated

once cannot be compacted

further. This may result in water

bubbles (shrinkage cavities) on

the concrete surface.

Rate of placing

The permissible rate of placing

can be precisely determined

according to DIN18218:2010-01

by referring to Tables13.1 and

13.2 or using MEVA’s online

calculation programme available

on the MEVA website.

This and other digital aids are

available in the download area

at www.meva.net and in the app

MEVAme for iOS and Android.

Note that you cannot use

Tables13.1 and 13.2 unless you

know the end of setting of the

concrete, tE. This value can be

determined on-site using MEVA’s

ultrasonic SolidCheck measuring

device or knead-bag tests as

described in DIN 18218:2010-

01. Or simply ask the concrete

supplier for the concrete’s end

of setting.

Table 13.1

Maximum rate of placing vb(depending on the concrete's

consistency and end of setting tE)* in m/h

Mammut

(DW 20) tE = 5 h tE = 7 h tE = 10 h tE = 15 h

Consistency

range

F3 5.64 4.72 3.72 2.63

F4 4.71 3.46 2.36 1.38

F5 2.40 1.71 1.20 0.80

F6 1.89 1.35 0.95 0.63

SCC 2.18 1.56 1.09 0.73

* According to DIN 18218:2010-01 (fresh-concrete pressure on vertical

formwork)

tE= End of setting of the concrete

vb= Maximum rate of placing

Maximum rate of placing vb(depending on the concrete's

consistency and end of setting tE)* in m/h

Mammut

(DW 15) tE= 5 h tE=7 h tE=10 h tE=15 h

Consistency

range

F3 3.00 2.43 1.81 1.14

F4 2.53 1.76 1.08 0.47

F5 1.17 0.83 0.58 0.39

F6 0.92 0.66 0.46 0.31

SCC 1.06 0.76 0.53 0.35

Table 13.2

M350-13Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Flatness tolerances of walls and undersides of slabs

(according to DIN 18202, Table 3)

DIN 18202, Table 3, lines 5 to 7

Table 14.1

Fig. 14.2

Column 1 2 3 4 5 6

Distances as limiting values in mm

for distances between measuring points in m

Line Reference 0.1 1* 4* 10* 15*

5 Unexposed walls and undersides of slabs 5 10 15 25 30

6Exposed walls and undersides of slabs, e.g.

plastered walls, panelling, suspended ceilings 3 5 10 20 25

7Like line 6,

but with stricter requirements 2 3 8 15 20

Flatness of surface

The permissible deflection of

formwork parts is defined in

DIN 18202 (flatness tolerances),

Table3, lines 5 to 7 (Table14.1).

Here, the maximum permissible

deflection is defined in relation

to the distance between

the measuring points. The

permissible fresh-concrete

pressure that is in line with the

flatness tolerances as defined

in DIN 18202,Table 3, line 7 is

100kN/m² for full load.

The measuring lath is placed on

the highest protruding points of

the surface and the deflection is

measured at the deepest point

in-between.

The distance between measuring

points corresponds to the

distance between the highest

protruding points.

Line 5

Line 6

Line 7

Distance between measuring points

Tolerances

* Intermediate values can be found in

Fig.14.2. Round up values found to full mm.

M350-14 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

All panels are provided with

multi-function profiles with

welded-in Dywidag-threaded

nuts (Fig.15.1). The difference

between the multi-function

profiles and the cross stiffeners

is that the multi-function profiles

allow accessories to be attached.

Walkway brackets are provided

with integrated self-locking pins

(Fig.15.2) and are mounted on

the multi-function profiles and

secured with a flange screw 18.

Formwork is set vertically using

push-pull props attached to

the panel with formwork-

prop connectors as shown in

Fig.15.4.

Alignment rails should be

attached to the multi-function

profiles with flange screws in

order to stabilise ganged panels

when lifting them by crane,

bridge problem areas and brace

and stabilise the fillers used to

bridge gaps between the panels.

The tie rod holder can

be attached to the multi-

function profile of the vertical

or horizontal panel. It can

hold up to two DW tie rods

with articulated flange nuts

(Fig.15.5).

Fig. 15.1 Fig. 15.2

Fig. 15.3 Fig. 15.4

Fig. 15.5

Attachment of accessories

Fig. 15.6

Description Ref. No.

Tie rod holder Ø35 29-927-05

M350-15Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Wall braces

Description Ref. No.

Braces SRL

SRL 120 ..................................29-108-80

SRL 170 ..................................29-108-90

Push-pull props R

R 160......................................29-109-40

R 250......................................29-109-60

R 460......................................29-109-80

R 630......................................29-109-85

Formwork-prop connector..... 29-804-85

Brace frame 250 with

formwork-prop connector ......29-109-20

Flange screw 18......................29-401-10

Double-jointed foot plate....... 29-402-32

Wall braces Formwork height h (m)

2.50 3.00 3.25 3.50 3.75 4.00 4.25 4.50

Push-pull prop R250+

SRL120

R250+

SRL120

R250+

SRL120

R460+

SRL170

R460+

SRL170

R460+

SRL170

R460+

SRL170

R460+

SRL170

Permissible influence width e (m) 5.78 4.72 4.37 4.13 3.79 3.40 3.23 3.04

Prevailing brace load F1(kN) 5.95 5.57 5.64 5.95 5.65 4.93 5.07 5.02

Prevailing push-pull prop load F2(kN) 11.85 12.08 12.06 11.85 12.01 12.44 12.37 12.37

Lifting force VWind (kN/m) 1.88 2.32 2.49 2.58 2.84 3.27 3.41 3.62

Prevailing dowel force Vdowel 1 (kN) 14.16 14.25 14.25 14.17 14.21 14.38 14.34 14.35

Prevailing dowel force Hdowel 1 (kN) 11.85 11.61 11.62 11.85 11.64 11.15 11.24 11.22

a (m)* 0.275 0.38 0.375 0.275 0.375 0.658 0.625 0.665

b (m)** 1.31 1.54 1.68 1.89 1.97 1.95 2.12 2.24

* Upper pivot point a, distance measured between top edge of formwork and attachment point of the upper formwork-

prop connector

** Distance to the foot plate b, measured from the rear edge of the formwork to the attachment of the foot plate

*** Upper pivot point c, distance measured between top edge of formwork and attachment point of the upper formwork-

prop connector of the individual push-pull prop

**** Distance to the foot plate d, measured from the rear edge of the formwork to the attachment of the foot plate of the

individual push-pull prop

Table 16.1

A push-pull prop or the brace

frame 250 with formwork-prop

connector are attached to the

panel’s multi-function profile

with flange screw 18 (pages

M350-15 and -17).

The brace frame 250 is made up

of the push-pull prop R 250, the

brace SRL 120, two formwork-

prop connectors and the double-

jointed foot plate.

If push-pull props or brace

frames are only used to align

the formwork, we recommend

a max. spacing of 4.00m. In

order to withstand wind loads,

refer to Table16.1. For further

applications contact MEVA.

Assumptions for Table16.1

ÆWind loads according to

DINEN1991-1-4

ÆWind zone 2, inland (mixed

profile between terrain

categories II & III)

ÆImpact pressure qP

=0.65kN/m² (Table16.2)

ÆPressure coecient used cP

= 1.8

ÆExposure time factor ψ = 0,7

ÆWind pressure w = qp*cp* ψ

ÆFormwork on upper edge of

terrain

ÆValues are characteristic

values

Wind zone

Impact pressure qpin kN/m² at a

ground elevation within the limits

h ≤10 m 10 m < h ≤ 18 m 18 m < h ≤ 25 m

1 Inland 0.50 0.65 0.75

2Inland 0.65 0.80 0.90

Coast and island in Baltic Sea 0.85 1.00 1.10

3Inland 0.80 0.95 1.10

Coast and island in Baltic Sea 1.05 1.20 1.30

4

Inland 0.95 1.15 1.30

Coast of North Sea and Baltic Sea and island in

Baltic Sea 1.25 1.40 1.55

Island in North Sea 1.40 - -

Wind impact pressure for buildings up to a height of 25 m:

Wall braces Formwork height h (m)

4.75 5.00 6.00 6.50 7.00 7.50 8.25 9.00

Push-pull prop R460+

SRL170

R460+

R250

R460+

R250

R630+

R250+

SRL170

R630+

R460+

SRL170

R630+

R460+

SRL170

Triplex+

R460+

SRL170

Triplex+

R460+

R250

Permissible influence width e (m) 2.79 2.38 2.03 2.68 2.41 2.50 1.81 2.02

Prevailing brace load F1(kN) 4.49 3.95 4.04 3.30 2.94 3.23 2.66 3.60

Prevailing push-pull prop load F2(kN) 12.75 11.73 11.96 13.48 12.80 11.70 12.85 11.96

Lifting force VWind (kN/m) 4.05 4.59 5.42 7.16 7.90 8.51 9.24 10.03

Prevailing dowel force Vdowel 1 (kN) 14.51 14.92 14.74 14.82 15.13 13.65 15.19 14.95

Prevailing dowel force Hdowel 1 (kN) 10.85 9.73 9.97 10.05 9.35 9.08 9.09 9.53

Prevailing push-pull prop load F3(kN) ---8.42 8.97 12.60 6.30 10.73

Prevailing dowel force Vdowel 2 (kN) ---8.47 11.35 15.98 5.45 9.29

Prevailing dowel force Hdowel 2 (kN) ---4.21 4.48 6.28 3.15 5.35

a (m)* 0.923 1.25 1.40 3.28 3.78 4.19 4.20 4.75

b (m)** 2.23 2.19 2.68 1.89 1.69 1.93 2.36 2.48

c (m)*** ---1.05 1.15 1.69 0.92 1.75

d (m)**** ---3.17 3.40 3.37 4.19 4.14

Table 16.2

M350-16 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Fig. 17.2

Formwork-prop connector

Push-pull prop / brace frame

h

a

b

Upper edge

of terrain

60°

FA

F

1

F2

Double-jointed foot plate

Flange screw 18

Note

A restraint mechanism is required

when the lifting force FA= 1.5 x

VWind -0.9 x G x h > 0.

G = dead load of the formwork

(including platforms)

For walls up to 6.00 m we

recommend assembling a brace

frame on-site consisting of the

push-pull props R 460 and R 250.

The required formwork-prop

connectors and double-jointed

foot plates must be ordered

separately.

For formwork heights above

6.50m a brace frame is

assembled on-site consisting of

push-pull prop R 630 and push-

pull prop R 250 or R 460. Above

a formwork height of 8.25 mthe

Triplex brace is also used. It is

especially designed to brace

and align high wall formwork

(seeTable16.1).

Please observe the Triplex

Technical Instruction Manual.

Wall braces

Fig. 17.1

Dowel 1

Dowel 1 Dowel 2

h

a

c

b

Upper edge

of terrain

d

Double-jointed

foot plate

Articulated

foot plate

Formwork-prop connector

Flange screw 18

Formwork-

prop

connector

Push-pull prop /

brace frame

F

1

F2

Push-pull prop

F3

Description Ref. No.

Braces SRL

SRL 120 ..................................29-108-80

SRL 170 ..................................29-108-90

Push-pull props R

R 160......................................29-109-40

R 250......................................29-109-60

R 460......................................29-109-80

R 630......................................29-109-85

Formwork-prop connector..... 29-804-85

Brace frame 250 with

formwork-prop connector ......29-109-20

Flange screw 18......................29-401-10

Double-jointed foot plate....... 29-402-32

FA

M350-17Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

0.5 x e

0.25 x e e (see Table 16.1) e (see Table 16.1) n x e

Fig. 18.3

Fig. 18.1 Double-jointed foot plate

F2

F1

Vdowel

Hdowel

Attachment point for dowel/bolt,

e.g. MEVA quick anchor,

Fischer anchor bolt FAZ II 20/30

or equivalent

The brace is attached to the

double-jointed foot plate

(Fig.18.1) or the foot plate 73

(Fig.18.2) using MEVA quick

anchors or anchor bolts, for

example.

The permissible influence width

of the bracing (e) is reduced at

the edge of the formwork as

shown in Fig. 18.3.

Æe = permissible influence

width (see TableM350-16.1)

Wall braces

Fig. 18.2 Foot plate 73

F

3

Attachment points for dowel/bolt,

e.g. MEVA quick anchor,

Fischer anchor bolt FAZ II 20/30

or equivalent

Vdowel

Hdowel

M350-18 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Working scaffolds – Folding access platform BKB 125

Folding access platform

BKB125

The ready-made folding access

platform BKB 125 with folding

guardrailing provides safe access

and a 125 cm wide working

platform (Fig19.2). It enables

quick and safe installation of

working scaffolds.

The 48 mm thick planks have a

rough surface and a metal lining

at the edges.

Its length of 235 cm allows

the BKB 125/235 to be easily

transported, as it fits crosswise

on any truck. The stacking height

is only 17 cm and the permissible

load is 2kN/m² (200kg/m²).

The guardrailing can be set to

an angle of 90° or 105° (Fig.

19.1). The BKB 125 side railing

is mounted to the platform with

two flange screws 18.

Attention

Do not crane formwork units

when the working platform is

attached to the formwork.

When using our products, the

federal, state and local codes and

regulations must be observed.

Note

MEVA’s SecuritBasic safety

system offers platforms,

ladder access and other

safety equipment for safe and

ecient work at all heights. The

SecuritBasic platforms are fully

compatible with the Mammut

350 wall formwork.

For more information refer to the

SecuritBasic Technical Instruction

Manual.

Description Ref. No.

Folding access platform

BKB 125/140 ..........................29-417-00

BKB 125/235 ..........................29-417-10

BKB 125/300 ..........................29-417-20

Side railing BKB 125................29-417-30

Suspension point

Examples for corner configurations and length compensation

BKB 125 side railing used

as side protection

BKB 125 side railing as rear

protection when using the BKB

125/140 for length compensation

Gap to be closed with a

compensation platform on-site

Residual gap

Fig. 19.1

Fig. 19.5

Fig. 19.3

Fig. 19.4

The access platform is

automatically secured

against dislodging by

the integrated self-

locking mechanism.

Fig. 19.2

M350-19Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Working scaffolds / walkway brackets

Description Ref. No.

Walkway bracket 90...............29-106-00

Guardrailing post 100.............29-106-75

Guardrailing post 140.............29-106-85

Guardrailing post 48/120 UK ..29-106-80

Side railing 90/100..................29-108-20

Swivel-joint coupler 48/48 ..... 29-412-52

Scaffold tube 48/200 ............. 29-412-23

Scaffold tube 48/300 ............. 29-412-26

Scaffold tube 48/400 ............. 29-412-27

Scaffold tube 48/500 ............. 29-412-25

Scaffold tube 48/600 ............. 29-412-28

Working scaffold according to DIN 4420, Part 1

Handrail (min. 15 x 3)

Midrail (min. 15 x 3)

Toe board (min. 10 x 3)

Planking width

Fig. 20.1

Walkway bracket

The pluggable walkway bracket

90 (Fig.20.2) is mounted to a

multi-function profile. To insert

the bracket, turn it by 45°,

then turn it back to the vertical

position and secure it with a

flange screw18 to the multi-

function profile below. The

planks can then be bolted to

the brackets. Maximum bracket

spacing for a load of 150kg/m²

(scaffold group 2): 2.50m

according to DIN4420. The

minimum thickness of the planks

is 4.5 cm and their minimum

width is 24cm.

Guardrailing posts and side

railing

The guardrailing posts and the

side railing (Figures20.3 to 20.5)

are inserted into the walkway

brackets. If the fall height

exceeds 2.00m, a side railing

(Fig.20.5) is required.

Note that this regulation is valid

for Germany.

Always observe the federal,

state and local regulations of the

country where the formwork is

used.

100 ± 5

≤ 47≤ 47

≥ 10

≤ 30

Fig. 20.2

Fig. 20.3 Fig. 20.4

The guardrailing post 48/120UK

can be used to allow scaffold

tubes to be installed as a fall

protection measure. These

guardrailing posts are made of

round tube with a diameter of

Ø48mm. Swivel-joint couplers

for the scaffold tubes are

attached to the guardrailing

posts. The round guardrailing

posts are inserted into the

walkway brackets with their

rectangular adapters (Fig.20.4).

Note

Minimum cross section of

handrail and midrail:

For a post spacing of up to

2.00m: 15x3 cm

For a post spacing of up to

3.00m: 20x4 cm (Fig. 20.1).

Fig. 20.5 Side railing

Side railing

Guardrailing post

integrated in side

railing

Guardrailing post

100 or 140

Guardrailing

post 48/120 UK

Walkway bracket 90

M350-20 Technical Instruction Manual / Status November 2021

Mammut 350Wall Formwork

Other manuals for Mammut 350

1

Table of contents

Other Meva Construction Equipment manuals