3

2

6.2. Cleaning

4. Specification

4.1. General Feature

4.2. Electrical Specification

06 0 7 08 0 9 1 0 HYS006689

11

•

•

•

•

•

•

•

•

•

•

•

•

°F

•

•

•

•

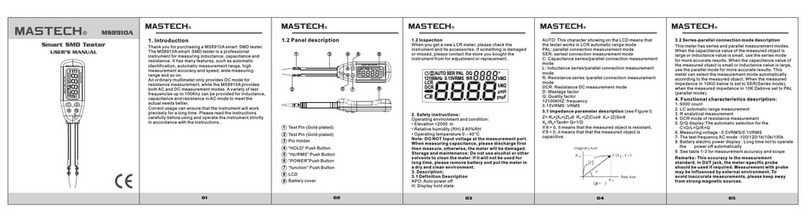

3000 count LCD display.

Full automatic measurement:

Auto scanning the Resistance/Capacitance/Diode.

Function selection by one “FUNC” Push Button

Data Hold function

Continuity Checking function

Over Load Indication ( 'OL')

Low Battery Indication

Power Supply: 3V Lithium Battery (CR2032) , 1pc

Test Pins is Gold-Plated.

Auto Power OFF. If the Tester is idle for more than

10 minutes,

The Tester Automatically Turns The Power Off.

Operating temperature & Humidity: 0 ~ 40°C

(32 ~104 °F) & < 80% RH

Storage temperature & Humidity: -10 ~ 50°C

(14 ~ 122 ) & <70%RH

Safety Class: IEC1010-1, CAT II

EMC: According to CE regulation 89/336.

Dimension (L x W x H) & Weight: 170 x 31 x 17mm,

Approx. 48.6 g

Environmental condition:

(1) Indoor use;

(2) Altitude up to 2000meter.

Function Range Best

Resolution Accuracy

300Ω/3KΩ/

30KΩ/300K

/3MΩ

30MΩ

0.1Ω

Resistance

±(1%rdg+ 2dgt)

±(1.2%rdg+ 3dgt)

3nF/30nF/

300nF/

3uF/30uF/

300uF/3mF

/30mF

±(2%rdg+ 3dgt)

±(3%rdg+ 3dgt)

1pF

Capacitance

Open Voltage:2.8V

Testing Current:2mA

Diode

Check

When the resistance is less than 30Ω, the

Buzzer is sounded.

Continuity

Check

Accessory:

1. Spare Test Pin: 2 pcs

5. Testing Operation

5.1 Scanning Mode

When install the 3V Lithium Battery, the Tester

immediately power ON. In this case, the 'SCAN' and

' - - - - ' sign is displayed on the LCD. This is indicate

the Tester is inter to the auto scanning mode and

automatically identified the resistor, capacitor, diode

and continuity,and then enter to

the corresponding measurement mode.

In the Scanning Mode, when two pins are in touch with

the object being measured, the measured value will be

displayed on the LCD.

Caution

When measuring SMD device on the PCB, You must be

Disconnect power and discharge all high- voltage

Capacitors.

5.2. Resistance Measurement

[1] Auto scanning Mode & Auto range:

300.0Ω - 3.000MΩ

[2] Selected Resistance measurement Mode by the

“FUNC” key:

The range is extended to 30 MΩ, i.e.300.0Ω-30.00MΩ

When over load, the 'OL' symbol will be displayed

on the LCD.

5.3. Capacitance Measurement

[1] Auto scanning & Auto range: 3.000nF - 300.0uF.

[2] Selected Capacitance Mode by the 'FUNC' key:

The range is extended to 30.00mF, i.e.

3.000nF-30.00mF.

Caution

To avoid damage to the Meter or to the equipment

under test, disconnect power and discharge all high

-voltage capacitors before measurement capacitance.

5.4 Diode Check

You can selecting the Scanning Mode or the Diode

Mode by The 'FUNC' push button.

Use the diode test mode to check diodes, transistors

and other semiconductor device. In the diode test

mode sends a current through the semiconductor

junction, and the measure the voltage drop across

the junction. A good silicon junction drop between

0.5V - 0.8V.

For forward voltage drop reading on any

semiconductor component, the test pin(connected

to the 'INPUT' terminal) is in touch with the

component anode and the another test pin is in

touch with on the component cathode. The measured

value show on the LCD.

Reverse the test pin and measure the voltage across

the diode again.

If diode is good, the display shows “OL”.

If diode is shorted, the display shows 0 (zero) in

both direction.

If display shows “OL” in both direction, the diode

is open.

•

•

•

1

5.5. Continuity Check

May selecting Scanning Mode or Continuity Mode by

‘FUNC’ push button.

When the resistance reading is less than 30Ω, the

buzzer generates 2KHz beep to indicate continuity.

6. Maintenance

6.1. Replacing The Battery

When meter display , the battery must be replace

to maintain normal operation.

Open the battery cover on the bottom case

by screwdriver.

Remove old battery and snap new one into

battery holder

1

2

Note:

Lithium Battery type: 3V CR2032

The meter can be cleaned with soft clean cloth to remove

any oil, grease or grim.

Do not use liquid solvent or detergent.