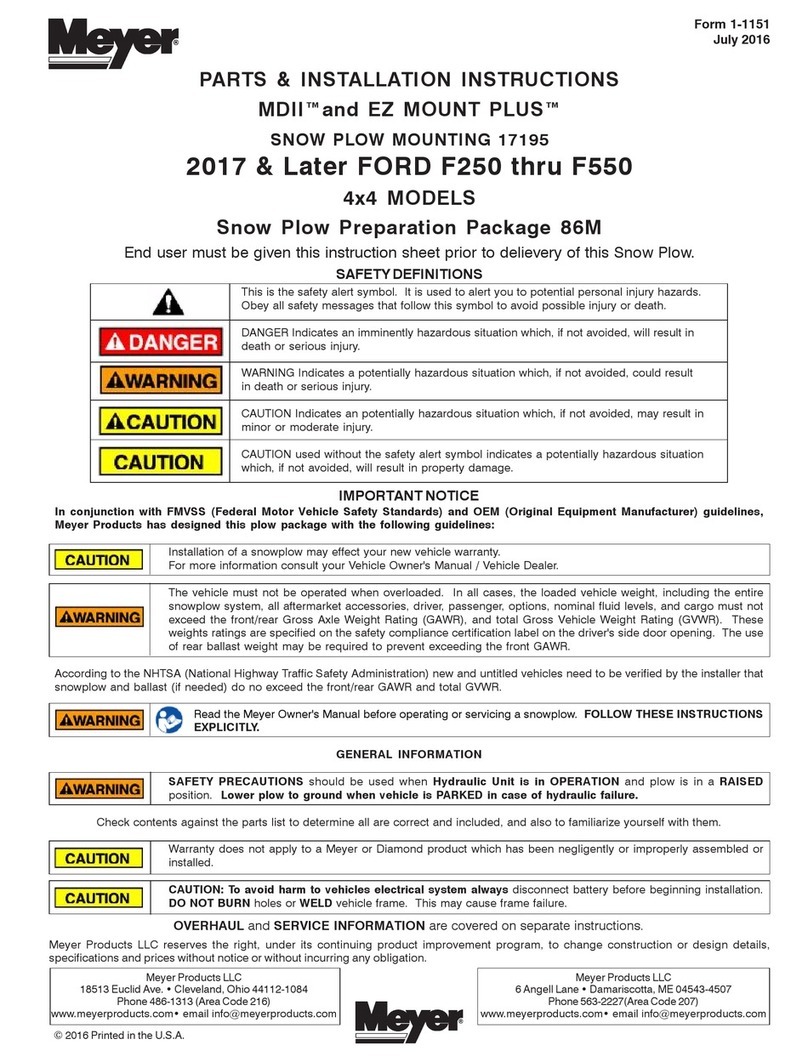

SAFETY DEFINITIONS

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards.Obey all safety messages thatfollow

thissymbol toavoidpossible injuryor death.

DANGER Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING Indicates a potentially hazardous

situation which, if not avoided, could result

in death or serious injury.

CAUTION Indicatesanpotentiallyhazardous

situation which, if notavoided, may result in

minor or moderate injury.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, will result

in property damage.

2

1Never stand or ride on the plow assembly. Keep people and pets at least 25 feet away from the snow plow when in operation. Failure to comply

will result in death

or serious injury.

2Insert and lock locking pin securely before using. Not doing so will result in serious injury or death. It can also result in damage to the vehicle and/or plow.

3Always lower moldboard to the ground when snow plow is being serviced or when vehicle is not in use.

Failure to comply

could result in death or serious

injury.

4The Meyer Utility Plow is for driveway plowing only and should be used on utility vehicles and small SUV’s. Use of this product on larger vehicles is prohibited and can result in

damage to the vehicle or plow.

Failure to comply

could result in death or serious injury.

5NEVER

use the Meyer Utility Plow without rst CAREFULLY reading the Owner’s Manual. It is CRITICAL for your safety to ALWAYS obey EVERY warning in the manual

and follow EVERY instruction EXPLICITLY. Failure to comply

could result in death or serious injury.

6The Meyer Utility Plow should be used by drivers with a valid operator’s license. Keep all body parts inside the vehicle.

Failure to comply

could result in death or serious injury.

7To prevent accidental movement of the plow, always turn o the controller whenever the plow is not in use. Failure to comply

could result in death or serious injury.

8The Meyer Utility Plow should NEVER be used for ANY other purpose other than plowing snow on a driveway, using the Meyer Utility Plow for other purposes could

result in serious injury or death.

9Inspect plow assembly and mounting components and fasteners for wear and damage before and

after each use.Worn or damaged components or fasteners could

allow the plow to drop unexpectedly.

Failure to comply

could result in death or serious injury.

10 Do not change plow position while traveling. You could suddenly lower the plow accidentally. Failure to comply

could result in death or serious injury.

11 ALWAYS wear a seat belt when plowing snow. Hidden obstructions can cause the vehicle to stop suddenly resulting in personal injury. Failure to comply

could

result in death or serious injury.

12 Do not mix dierent kinds of hydraulic uid. Some uids are not compatible and may cause performance problems and product damage Failure to comply

could

result in death or serious injury.

13 NEVER perform any repairs or maintenance with the plow controller turned on and the plow plugged into the vehicle harness and the plow attached to the vehicle.

Failure to comply

could result in death or serious injury.

14

The vehicle must not be operated when overloaded. In all cases, the loaded vehicle weight, including the

entire snow plow system, all aftermarket accessories, driver, passenger,

options, nominal uid levels, and cargo

must not exceed the front/rear Gross AxleWeight Rating (GAWR), and total GrossVehicleWeight Rating

(GVWR).These weights ratings

are specied on the safety compliance certication label on the driver’s side door opening.The use of rear ballast weight may be required to prevent exceeding the front GAWR.

Failure to comply

could result in death or serious injury.

15 Read the Meyer Utility Plow Owner’s Manual before operating or servicing a snow plow. FOLLOWTHESE INSTRUCTIONS EXPLICITLY. Failure to comply

could

result in death or serious injury.

16 SAFETY PRECAUTIONS should be used when Hydraulic Unit is in OPERATION and plow is in a

RAISED position. Lower plow to ground when vehicle is PARKED in case

of hydraulic failure.

Failure to comply

could result in death or serious injury.