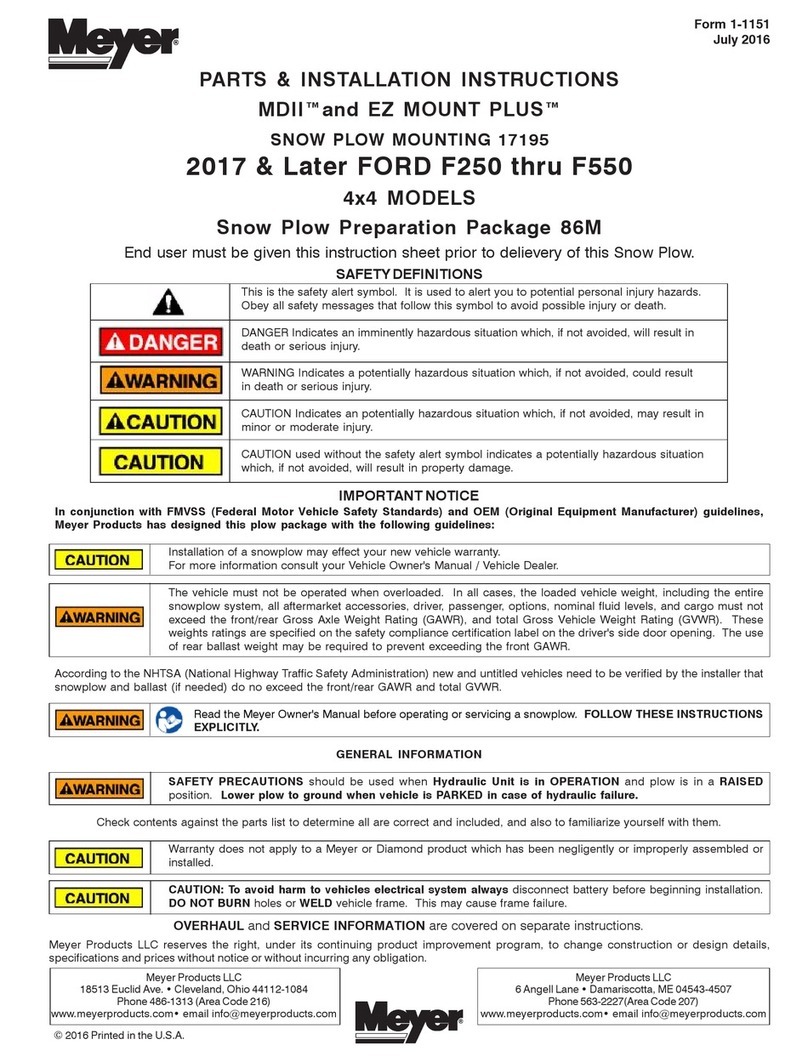

IMPORTANT NOTICE: In conjunction with FMVSS (Federal Motor Vehicle Safety Standards) and OEM (Original Equipment Manufacturer) guidelines,

Meyer Products LLC has designed this plow package with the following guidelines:

CAUTION: Installation of a snowplow may affect your new vehicle warranty. For more information consult your Vehicle Owner’s Manual / Vehicle Dealer.

WARNING: The vehicle must not be operated when overloaded. In all cases, the loaded vehicle weight, including the entire snowplow system, all aftermarket accessories,

driver, passenger, options, nominal fluid levels, and cargo must not exceed the front/rear Gross Axle Weight Rating (GAWR), and total Gross Vehicle Weight Rating (GVWR).

These weight ratings are specified on the safety compliance certification label on the driver’s side door opening. The use of rear ballast weight may be required to prevent

exceeding the front GAWR.

According to the NHTSA (National Highway Traffic Safety Administration) new and untitled vehicles need to be verified by the installer that snowplow and ballast (if needed) do

not exceed the front/rear GAWR and total GVWR.

with certain options and accessories, and it is so stated in vehicle

manufacturer specifications for snow plow application.

WARNING: Deployment of an air bag while using a Meyer Snow

Plow will not be covered under Meyer Products’ warranty.

We also recommend that, for optimum performance, vehicles used for

snow plowing be equipped with:

• Four-Wheel Drive

• Minimum 60 Amp Alternator or larger

• Minimum 70 Amp Battery or larger (550 C.C.A.)

• Mud and Snow Tires

• Increased Radiator Cooling

• Automatic Transmission

• Power Brakes

• Power Steering

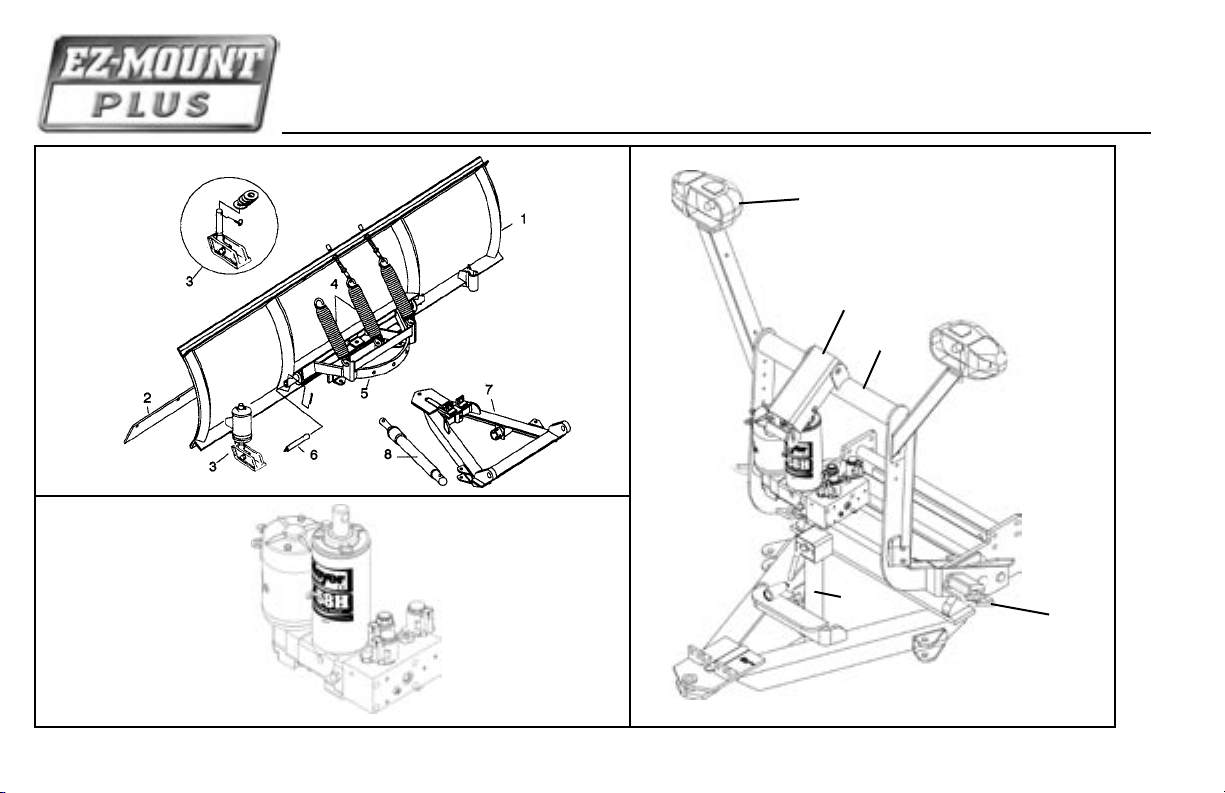

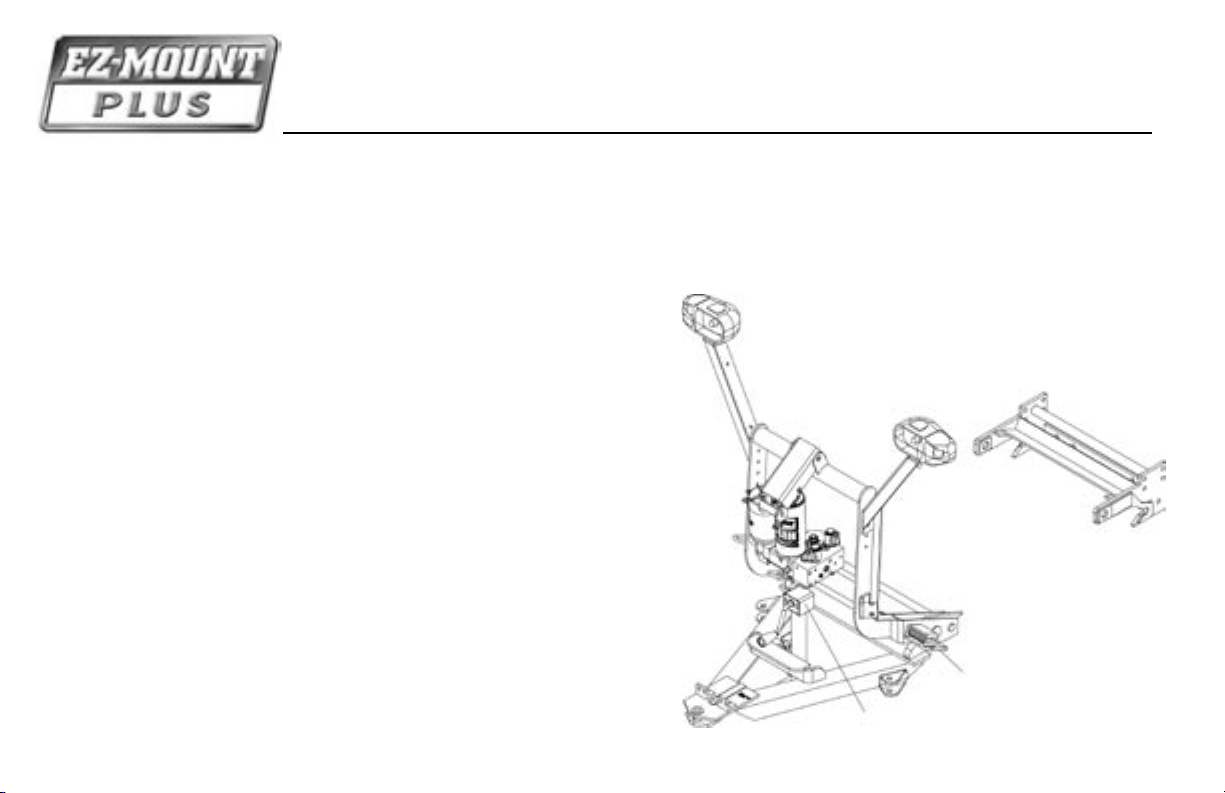

Under the continuing Meyer Product Improvement Plan, Meyer

Products LLC reserves the right to change design details and

construction without prior notice and without incurring any obligation.

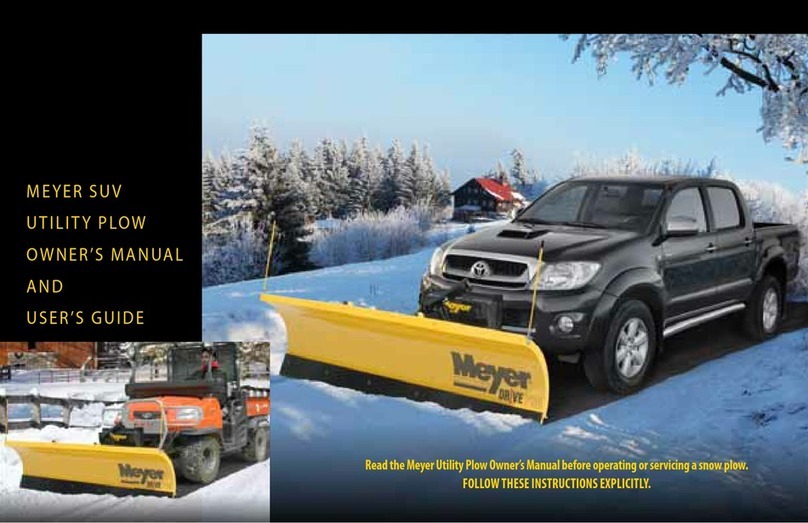

Snow, despite the beauty it may impart to a bleak winter

landscape, poses the dual threat of inconvenience and danger. The

environmental conditions associated with snow, not to mention the

health hazards and economic loss it may impose, seriously endanger

thousands of lives annually. Business and industry suffer, and millions

of snowbelt residents may be affected by a single snowstorm.

Meyer Products LLC has published this manual to help you

get maximum performance from your Meyer Snow Plow and

familiarize you with the features designed for efficiency and

safety; be sure you recognize and understand them. Follow

recommended operation and maintenance instructions, so when

the storm hits, your Meyer Snow Plow will be ready and you will

know how to plow like a pro. DO NOT EQUIP ANY VEHICLE WITH

A SNOW PLOW WITHOUT CONSULTING MANUFACTURERS’

RECOMMENDATIONS.

Vehicles with Meyer Snow Plows installed may be so equipped as

to meet vehicle manufacturers’ specifications and recommended

options for snow plowing use. Most vehicle manufacturers insist

that vehicles which are to be used for snow plowing be equipped

Introduction