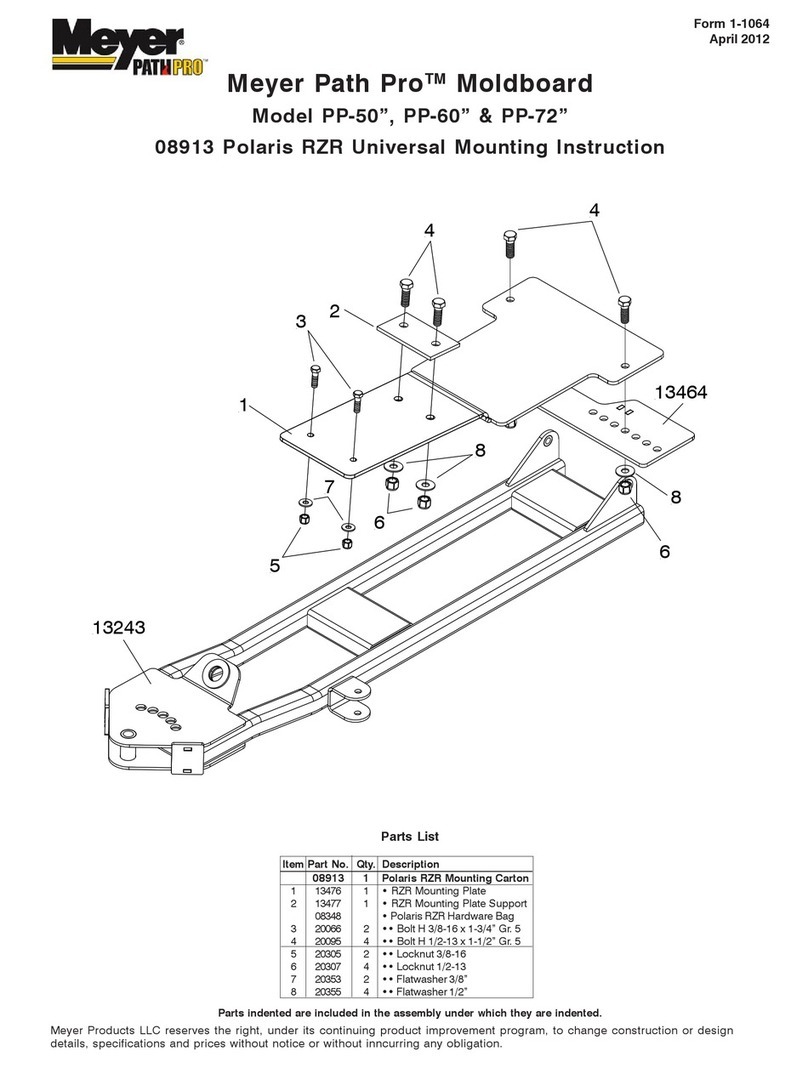

Parts List

Meyer Products LLC reserves the right, under its continuing

product improvement program, to change construction or

design details, specications and prices without notice or without

incurring any obligation.

Parts indented are included in the carton, bag or assembly under which they are indented.

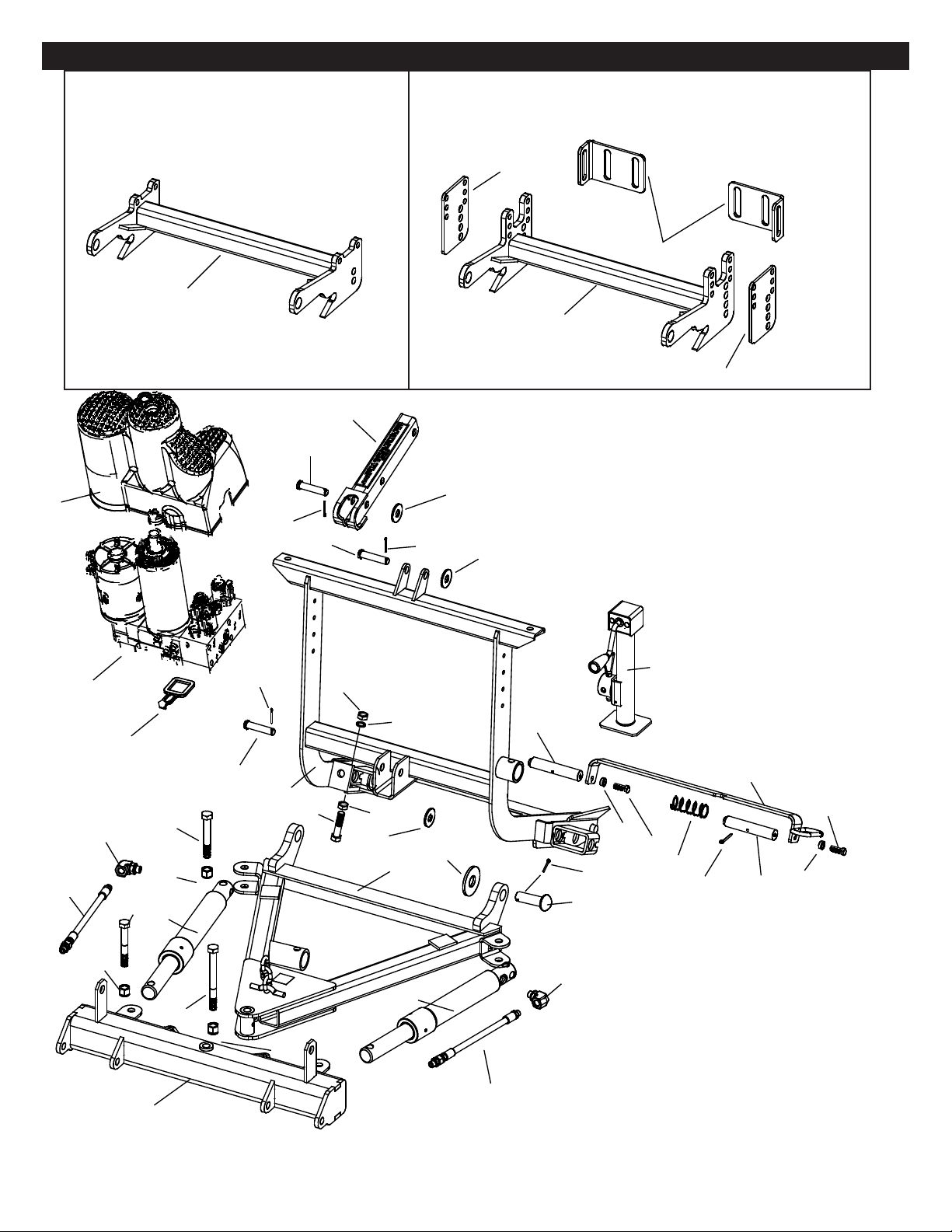

41100 & 41150 E-58H EZ Build

Item Part No. Part No. Qty. Description

41100 --------- 1 DP5.0- 6.8 E58H DP Mount Assy.

--------- 41150 1 DP6.8-7.5 E58H DP Mount Assy.

07620 07620 2 • Ram with Hose & Fittings

1 05877 05877 1 •• Ram (1-1/2” x 10”)

2 22460 22460 1 •• SAE 6 x 90 Degree Elbow

3 22461 22461 1 •• Hose Assy 1/4 x 38” M-6

4 10514 10514 1 • Lift Arm

5 12959 12959 1 • Pivot Bar Drive Pro 6.8

6 13920 13920 1 • A-Frame Drive Pro

7 15630 15630 1 • E-58H Lift Unit Cover

8 15631 15631 1 • Cover Strap

9 15995 15995 1 • Lift Ass’y. (Unit only)

10 19836 19943 1 • Clevis Drive Pro

10190 10190 1 • Lift Frame Assy DP

11 10191 10191 1 •• Lift Frame

12 19775 19775 2 •• Pin

13 19781 19781 1 •• Pull Pin

14 20406 20406 1 •• Cotter Pin 3/16 x 1-1/2”

15 22010 22010 2 •• Bolt H 3/8-16 x 1-1/4”

16 22260 22260 2 •• Poly Washer 3/8”

17 814000005 814000005 2 •• Spring

18 20144 20144 2 • Bolt H 5/8 - 11 x 2-3/4” Gr. 5

19 20147 20147 4 • Bolt H 5/8 - 11 x 3-1/2” Gr. 5

20 20309 20309 5 • Locknut 5/8 - 11

21 20331 20331 2 • Lockwasher 5/8”

22 20357 20357 3 • Flatwasher 5/8”

23 20361 20361 2 • Flatwasher 1”

24 20385 20385 3 • Cotter Pin 1/8 x 1-1/4”

25 20420 20420 2 • Cotter Pin 1/4 x 2”

26 22005 22005 1 • Bolt H 5/8-11 x 5-1/2” Gr. 8

27 22245 22245 1 • Crankstand

28 22436 22436 2 • Pin 1 x 3”

29 22692 22692 1 • Plow Side Harness

30 22719 22719 3 • Pivot Pin 5/8 x 3”

Item Part No. Part No. Qty. Description

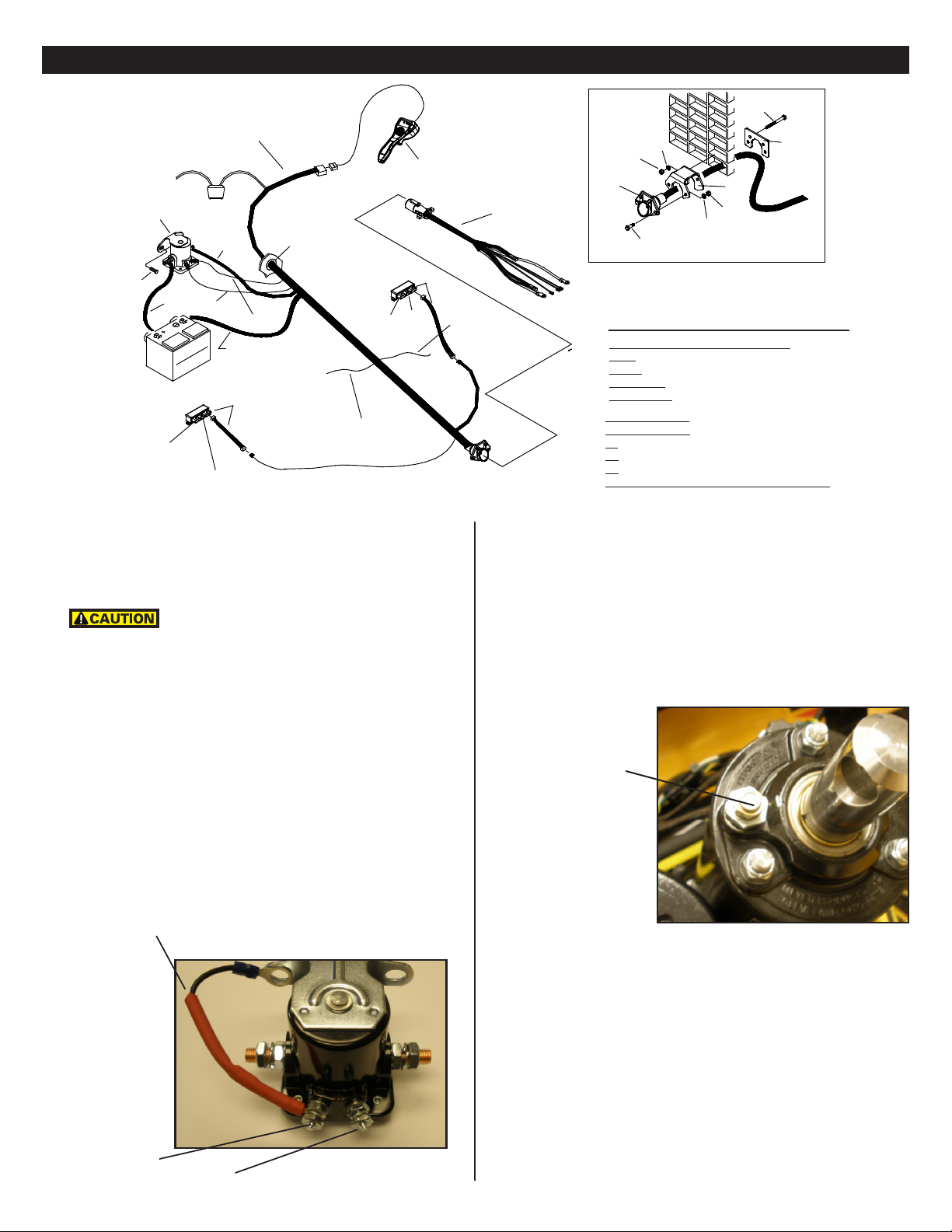

41101 41151 1 • Accessory Box

31 05024 05024 1 •• Power Cable - 36”

32 12978 12978 2 •• Trip Spring

07550 07550 1 •• Nite Saber II Kit

08202 08202 1 •• Plug Bracket Kit

33 19607 19607 1 ••• Plug Bracket

34 19609 19609 1 ••• Plate

35 20027 20027 2 ••• Bolt H 5/16-18 x 1 Gr. 2

36 20326 20326 4 ••• Lockwasher 5/16

37 20525 20525 4 ••• Finish Nut 5/16-18

38 22658 22658 2 ••• Bolt H 5/16-18 x 3 Gr. 2

09917 09917 1 •• Plow Marker Kit

39 08214 08214 2 ••• Plow Marker

40 20027 20027 4 ••• Bolt H 5/16-18 x 1 Gr. 2

41 20304 20304 4 ••• Locknut 5/16-18

42 20352 20352 8 ••• Flatwasher 5/16”

43 15370 15370 1 •• Starter Solenoid - 12 volt

15787 15787 1 •• Hardware Bag

44 21398 21398 2 ••• S. Tap Screw 1/4 - 14 x 3/4”

45 21832 21832 1 ••• Split Bushing

46 --------- 19945 2 •• Clevis Spacer

47 --------- 19948 2 •• Clevis Support Bracket

48 22690X 22690X 1 •• Pistol Grip Controller

49 22691 22691 1 •• Universal Truck Side Harness

41102 41102 1 •• Hardware Bag

50 09124 09124 2 ••• Eye Bolt

51 20357 20357 2 ••• Flatwasher 5/8”

52 20385 20385 2 ••• Cotter Pin 1/8 x 1-1/4”

53 22686 22686 2 ••• Trip Bumper

54 22720 22720 2 ••• Pivot Pin 5/8 x 7

55 8501003013 8501003013 4 • Jam Nut 5/8-11

(2)

Parts Diagram