Installation and operating instructions for

Brake DT XXX FEA-XXX H-ST

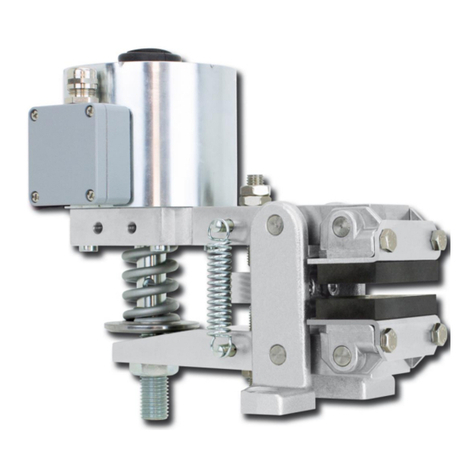

spring activated –electro hydraulically

released

1. General notes

1.1 General safety instructions

Read these installation/operating instructions carefully before putting the brake into operation.

Consider these instructions as well as the drawings in the individual sections.

All work with and on the brake is to be carried out taking into account that "safety is top priority".

Switch the drive unit off before carrying out work on the brake.

Rotating parts (e.g. brake drum) must be secured by the operator against unintentional touching.

1.2 Special safety instructions

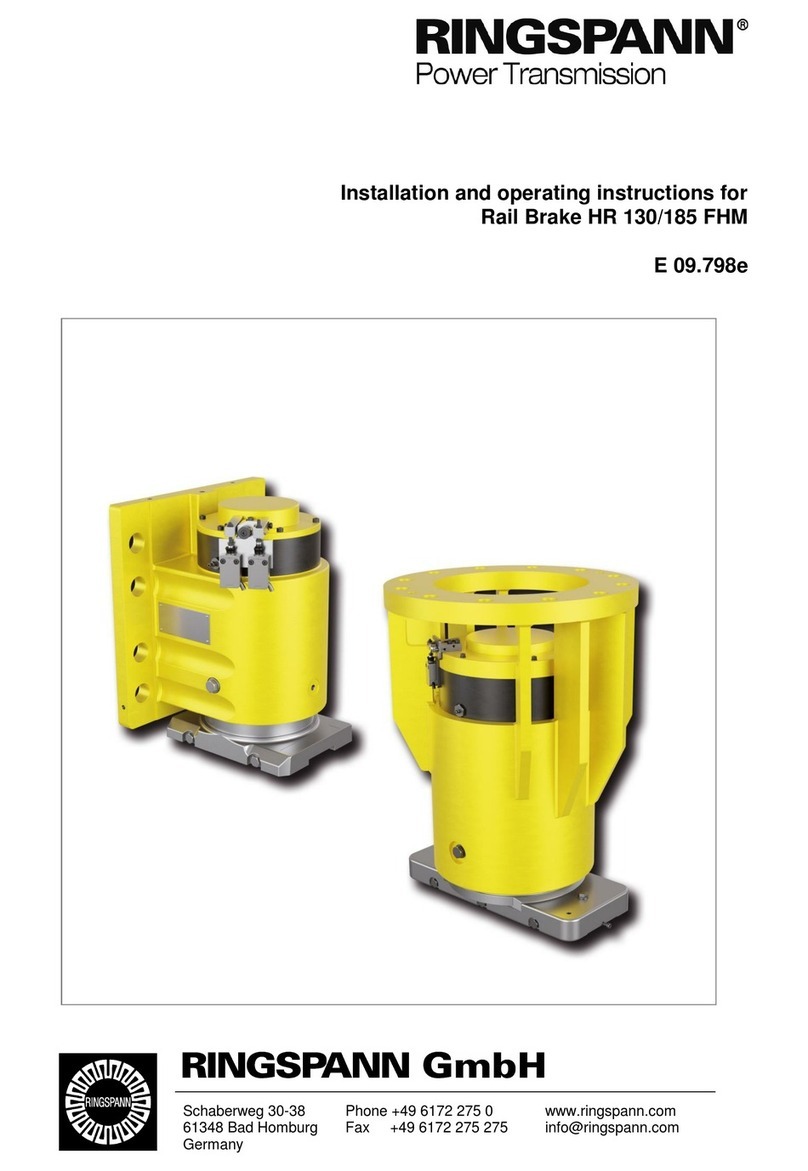

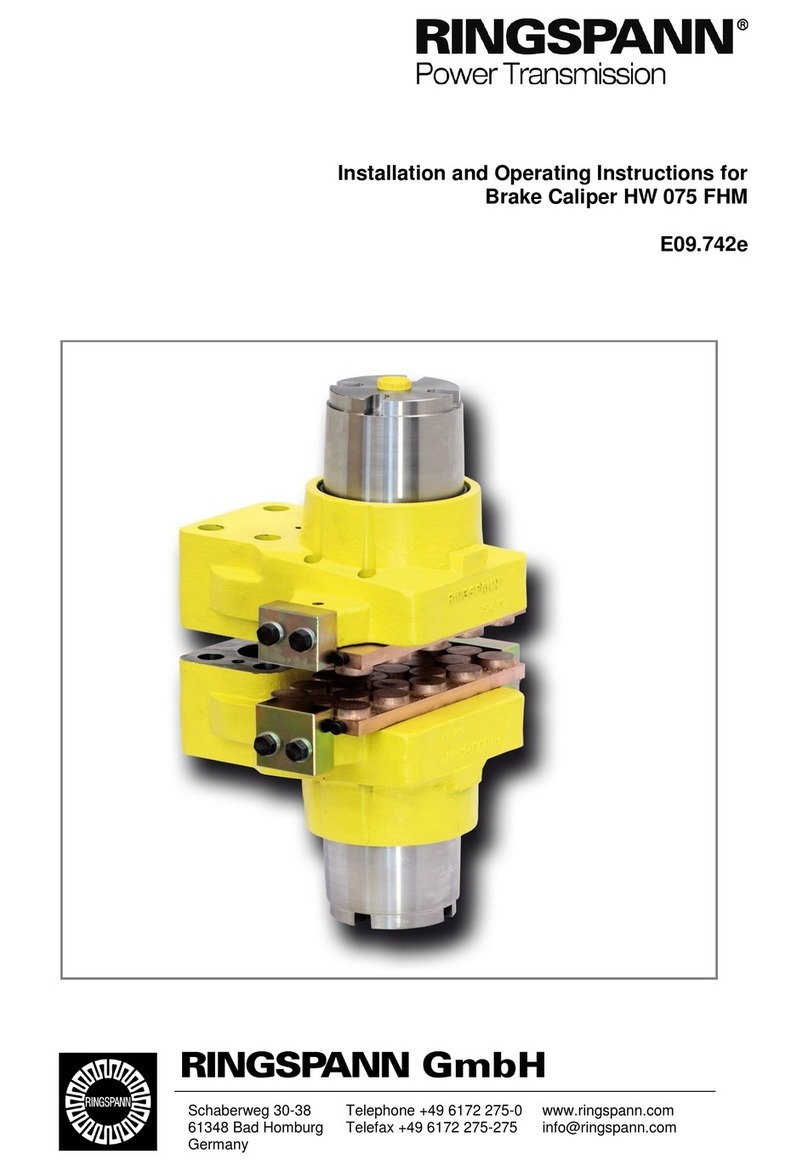

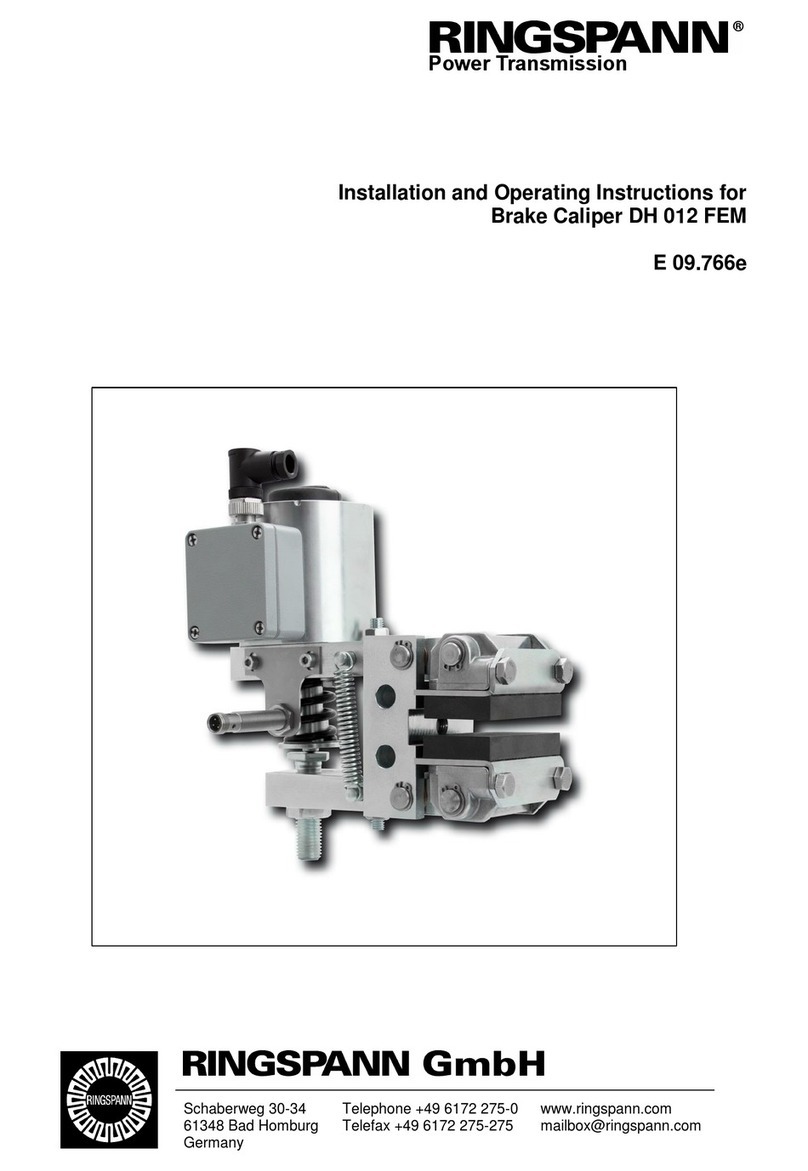

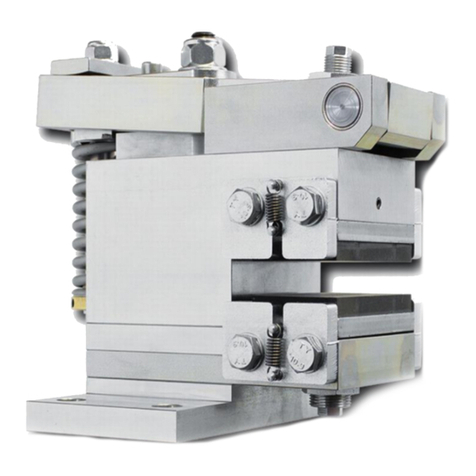

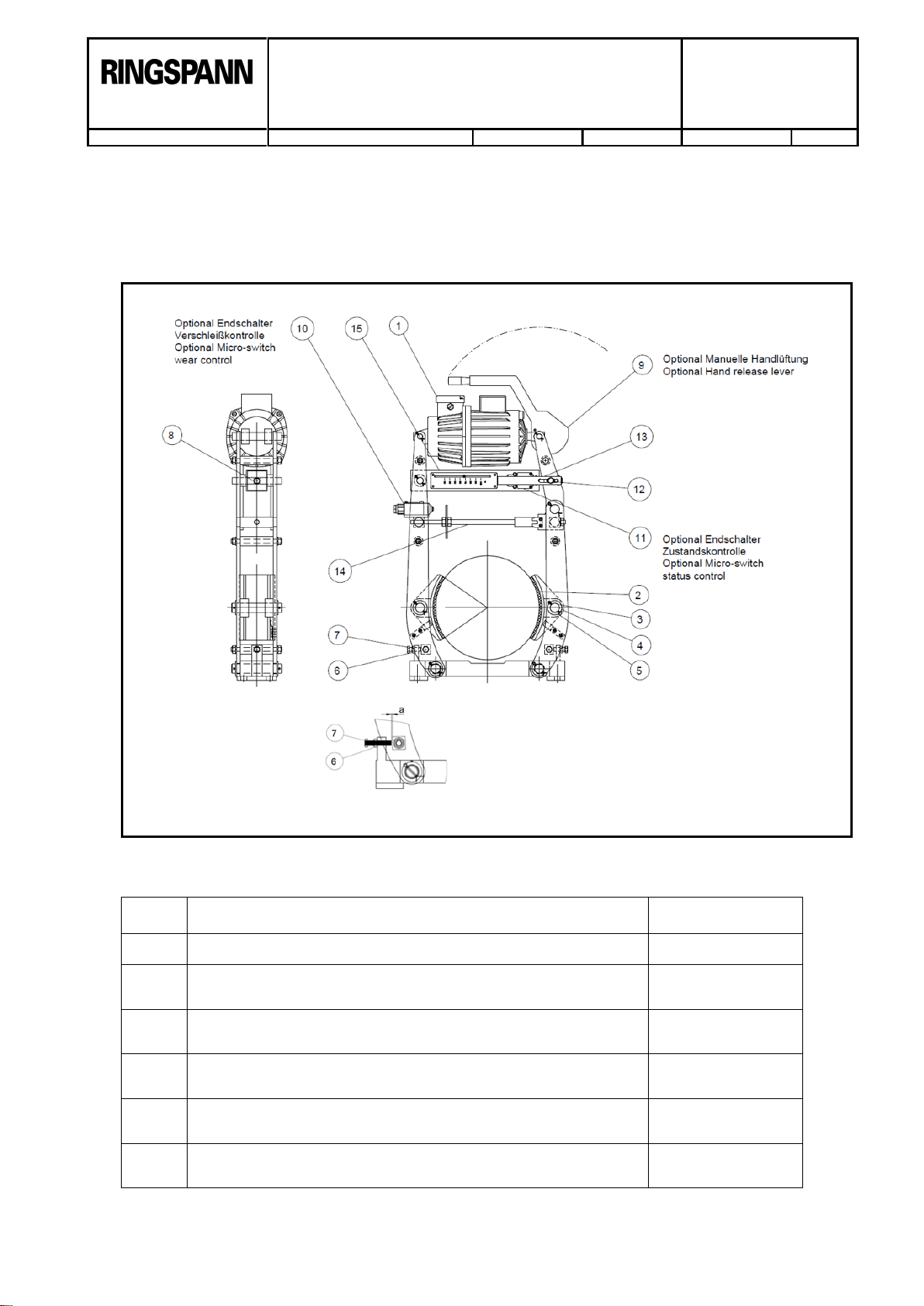

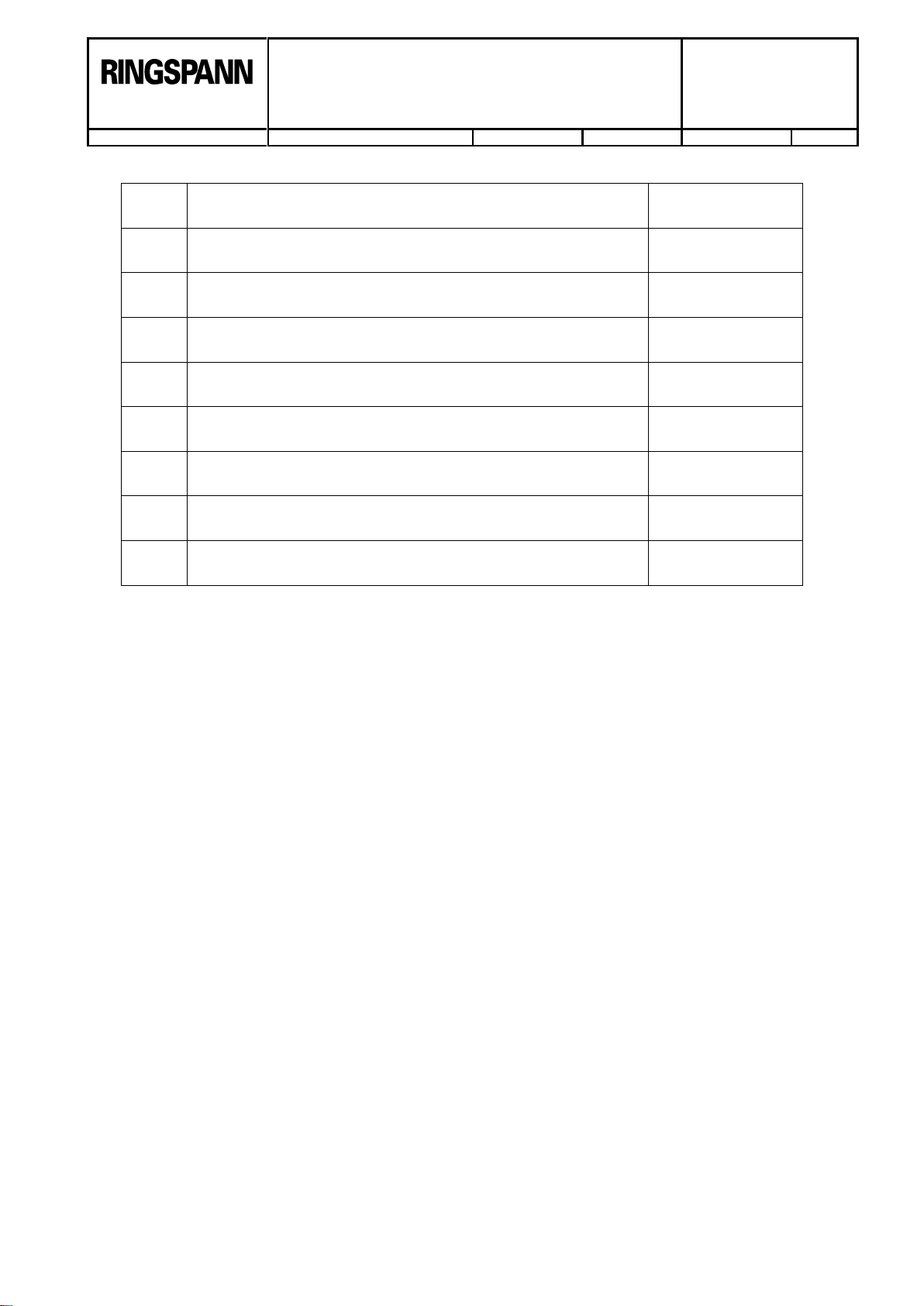

2. Design and function / parts list

2.1 Function

The brake is a machine element with which accelerated masses can be safely slowed down. In

combination with a brake drum, you have a complete brake for the effective safeguarding of

machines and systems. Thanks to its universal design, it fulfils the following functions:

•As a holding brake, it prevents a stationary shaft from starting unintentionally.

•As a stopping brake, it brings a rotating shaft to a halt.

The braking force is produced by springs, and the brake is opened electro hydraulically.

At the standard brake FEA with automatic adjustment if pad wear appears, the automatic

adjustment works and no wear adjustment is necessary to pre-load the springs in the thruster.

The readjustment is only necessary to adjust the gap on each side between the friction pad and

brake drum.

Life-threatening danger!

When assembling, operating and maintaining the brake it is to be

ensured that the entire drive train is secured against being switched on

unintentionally. Moving parts can cause severe injury. Rotating parts

(e.g. brake drum) must be secured by the operator against unintentional

touching.

Strongly pre-loaded pressure springs are installed in the springed

thrusters of the brake. The springed thruster may only be disassembled

by the factory.