))))))))))))))))))))))))))))))))))))))))))))

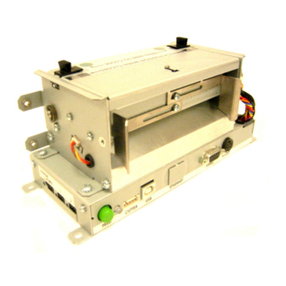

410 ECA Operators Manual

Table of Contents

ListofTables ............................................................. v

ListofFigures............................................................. v

Introduction............................................................... 1

CHAPTER 1: FEATURES AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 FEATURES ................................................... 3

1.2 BARCODES................................................... 3

1.3 FONTS ...................................................... 3

1.4 PRINTING .................................................... 4

1.5 INTERFACECOMMUNICATIONS.................................. 4

1.6 PHYSICAL.................................................... 4

1.7 ENVIRONMENT ............................................... 4

1.8 ELECTRICAL.................................................. 4

1.9 OPTIONS .................................................... 4

1.10 APPROVALS.................................................. 4

CHAPTER2:BASICOPERATION............................................. 7

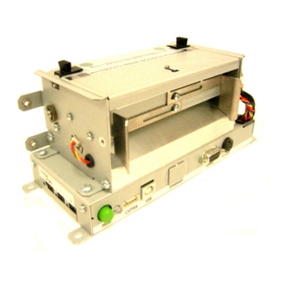

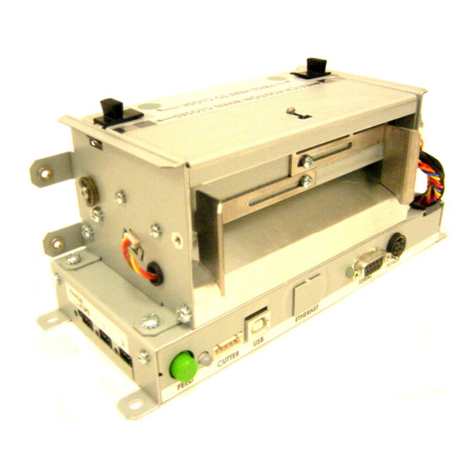

2.1 UNPACKINGTHE410ECAPRINTER .............................. 7

2.2 FRONT PANEL SWITCH AND STATUS LIGHTS . . . . . . . . . . . . . . . . . . . . . . 7

2.2.1 NORMALMODE ......................................... 7

2.2.2 BATCHMODE........................................... 7

2.2.3 STATUSMODE.......................................... 7

2.2.4 PAPER-OUTMODE ...................................... 8

2.3 THESTATUSLIGHT............................................ 9

2.4 LOADINGPAPER .............................................. 9

2.4.1 NORMAL AND TAG/TEAR MODES . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 CLEANINGINSTRUCTIONS..................................... 10

CHAPTER3:COMMUNICATIONS............................................ 11

3.1 CABLEPINOUT............................................... 11

3.2 PRINTERCABLES ............................................ 11

CHAPTER4:DESIGNINGTAGSUSINGLDS................................... 12

4.1 CONTROLCHARACTERS ...................................... 12

4.2 GETTINGSTARTED........................................... 12

4.2.1 PCCONNECTION(SERIAL)............................... 12

4.2.3 LEARNINGLDS......................................... 13

4.3 FORMATTINGTAGS:ANOVERVIEW ............................. 13

4.4 TAGHEADER ................................................ 14

4.4.1 A SAMPLE SESSION WITH A TAG HEADER . . . . . . . . . . . . . . . . . . 18

4.5 TAGFIELDS ................................................. 18

4.5.1 A SAMPLE SESSION WITH A TAG FIELD . . . . . . . . . . . . . . . . . . . . 25

CHAPTER5:PRINTERCOMMANDS ......................................... 26

5.1 SPECIAL PRINTER CONTROL CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2 PRINTERENQUIRIES.......................................... 27

5.3 SENDING^DPRINTERCOMMANDS.............................. 28

5.3.1 SOFTWARE DIP SWITCHES AND EEPROM COMMANDS . . . . . . . 29

5.3.2 PRINTINGCOMMANDS .................................. 34

5.3.3 AUTO-SIZINGCOMMAND ................................ 35

5.3.4 REAL-TIMECLOCK ..................................... 36

5.3.5 SERIALNUMBERCOMMANDS ............................ 38

5.3.6 TAGHEADERCOMMANDS ............................... 40

5.3.7 SAVING FORMAT FILES COMMANDS . . . . . . . . . . . . . . . . . . . . . . . 41