ULTRAFLO 2000 INSTALLATION & OPERATING INSTRUCTIONS

4

INTRODUCTION

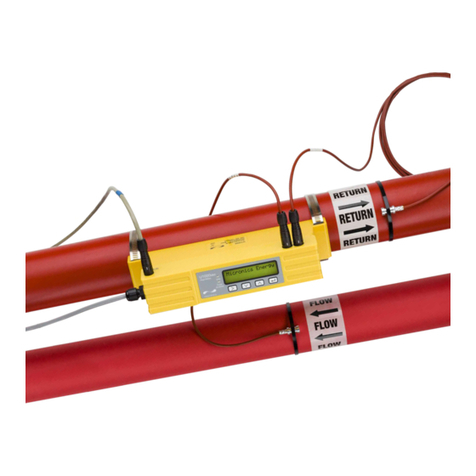

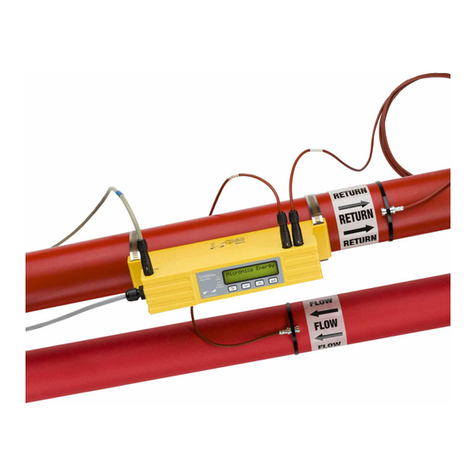

The Ultraflo 2000 is a “Clamp-on” liquid flow meter

that uses the Transit Time method of

measurement to read flow. Using two PT100

temperature probes to measure temperature it

can also be used as a Heat/Energy meter.

The Ultraflo is able to measure the flow of liquid in

any pipe from 13mm to 5000mm, providing the

pipe is flooded and the correct transducers are

used. Units are supplied according to application

data provided by the customer.

The instrument displays volumetric flow rate in

m3/hr, m3/min, m3/sec, g/min, USg/hr, l/min, l/sec

and linear velocity in metres and feet per second.

The total volume of flow will be displayed, up to a

maximum 12-digit number. When supplied as a

Heatmeter, kW, kCal/hr, MJ/hr, MJ/min and

MJ/sec can be displayed, as well as the

temperature differential.

The flowmeter is supplied with electronics,

sensors and all mounting hardware. The

Heatmeter version will also be supplied with

PT100 temperature probes.

HARDWARE

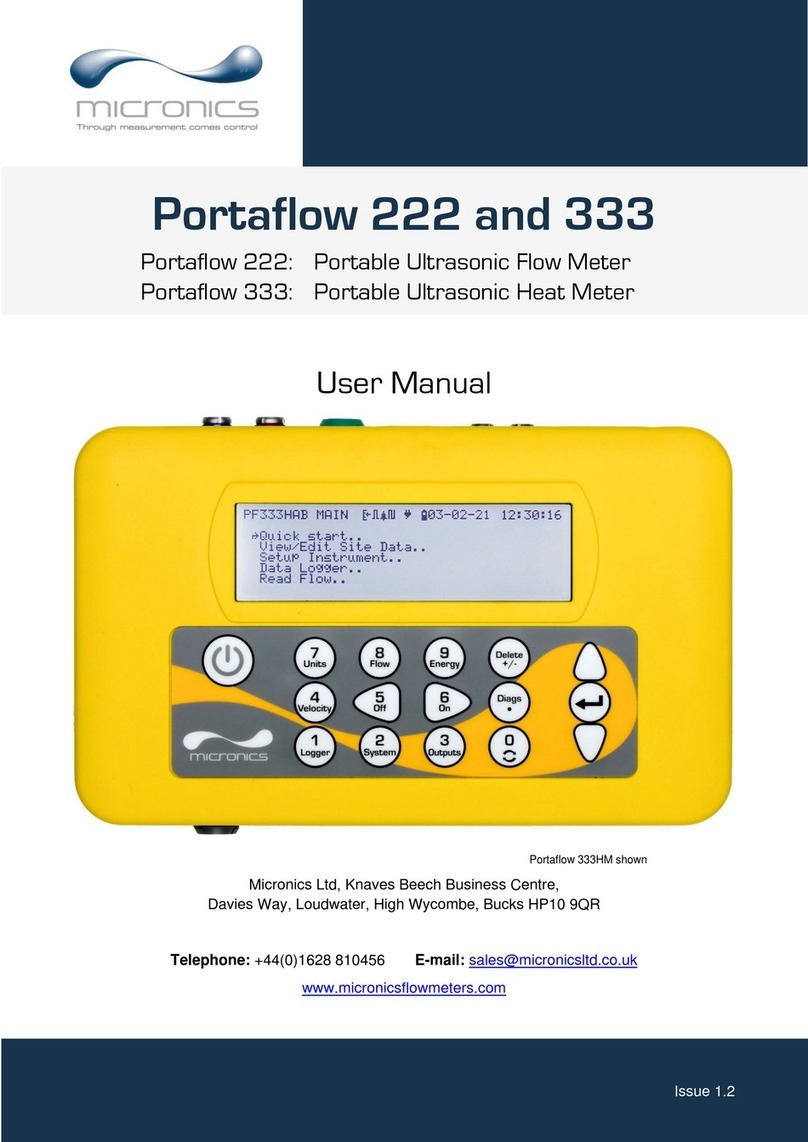

Electronics Housing

An ABS housing with an opaque door contains the

master PCB. The housing is designed for wall

mounting using the brackets provided (see Figure

2 for mounting pattern). Drilling further fixing holes

in the Housing remove the IP67 protection rating

and CE approval.

Mounting the housing into position does not

require the removal of the electronics or the front

display panel.

Figure 2

DO NOT PROVIDE POWER to the instrument

until the service compartment cover has been

replaced.

The electronics are factory set for a particular

supply voltage. Should it be necessary to change

the settings for the power supply see page 7,

Power up.

Having completed the procedure for mounting the

electronics, connecting all cables and checking

the power supply, the power can now be applied.

The Ultraflo 2000 is now ready for programming.

A full programming procedure is described on

page 7.

Before programming the instrument, it is

necessary to attach the transducers to the pipe

wall such that they can be finally locked in the

correct position based on exact data provided by

the instrument.

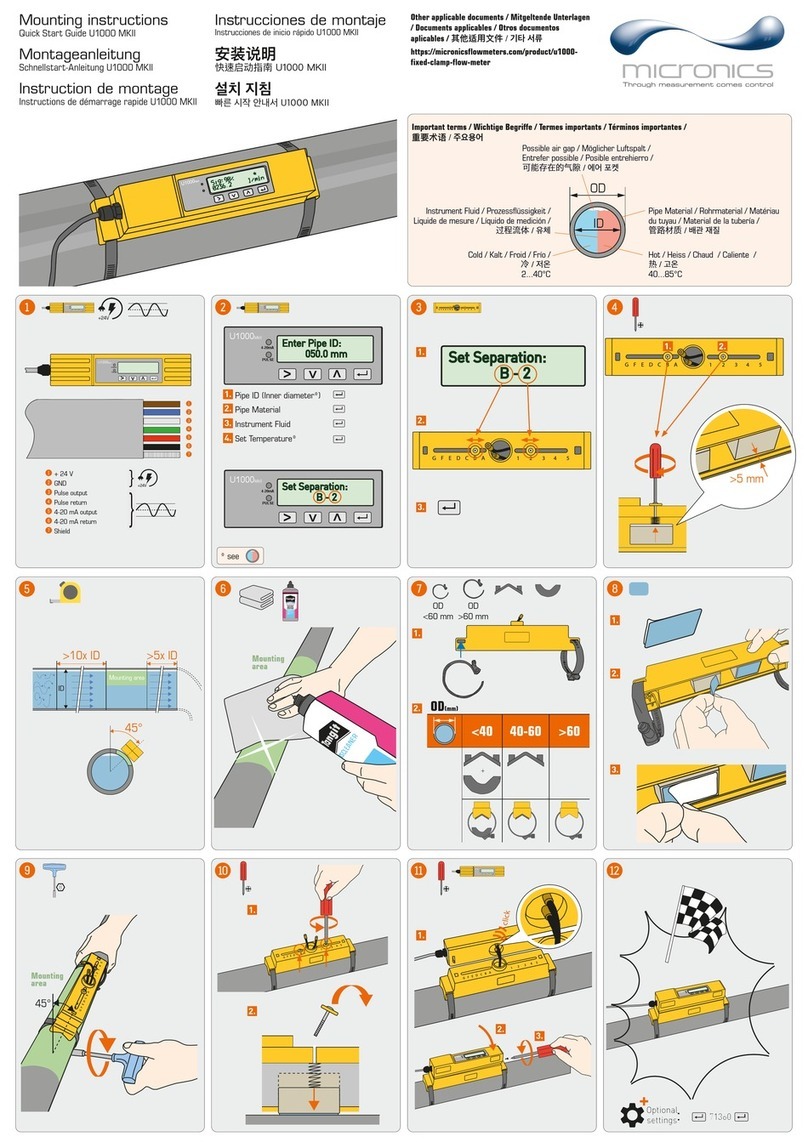

TRANSDUCERS

Each instrument uses two identical transducers,

which transmit and receive the ultrasonic waves.

They are clamped to the pipe surface using the

mounting hardware supplied, as described on

pages 5, 6.

The standard transducers are made from a Peek

material with an aluminium plate supporting the

stud, used to lock the sensor in position. A flying

armoured lead is attached between the sensor

block and the tuning circuit.

Figure 3 – 1MHz Sensors with TNC Coaxial

Connector

Transducers are supplied according to the pipe

size and flow velocity, and are available to meet

an operating temperature range from –20°C up to

+200°C.

Transducer Connections

Transducers are connected to the electronics from

the tuning circuit by TNC connectors. All other

output and input connections are made through

metal glands to the clearly marked terminals.

Only one current output can be used with the flow

meter, but both can be used when the Heatmeter

option is supplied. Connections 5-10 can only be

used when the PT100 temperature probes are

supplied with the Heatmeter.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

+ - + - + - + + - + NC COM NO + L N E

MA1 MA2 HOT COLD RELAY 24VDC AC IN

F

S

Coax sensor connectors

Coax cable

220VAC

24V

110VAC

F