Copyright ©2012 Microscan Systems, Inc.

Step 6 —

Connect

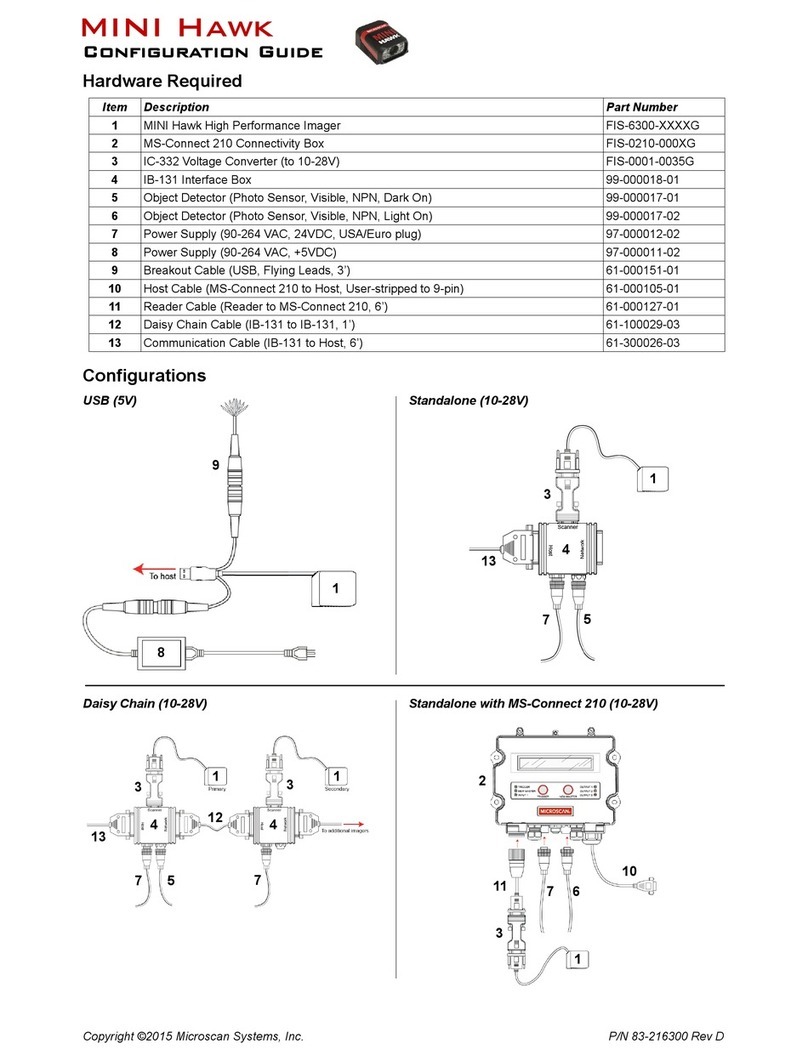

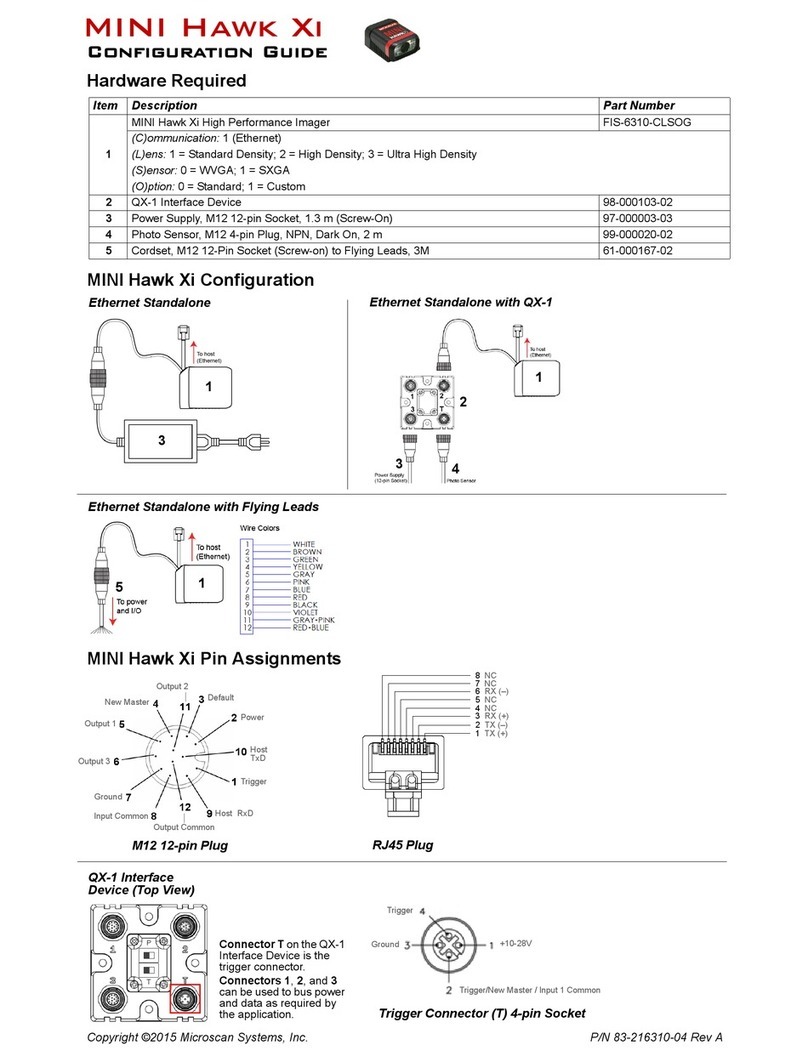

To connect using the Connection Wizard:

• Click Connect on the menu toolbar, and then select Connection Wizard.

• Select the communication interface required by your application.

• Configure settings as required by the application, and click Connect.

• When a connection is established, the green indicator in the status bar at

the bottom right of the screen will be visible:

Important: The imager is in Continuous Read Mode by default. For

best connection results, be sure that no decodable symbols are within the

imager’s field of view while attempting to connect.

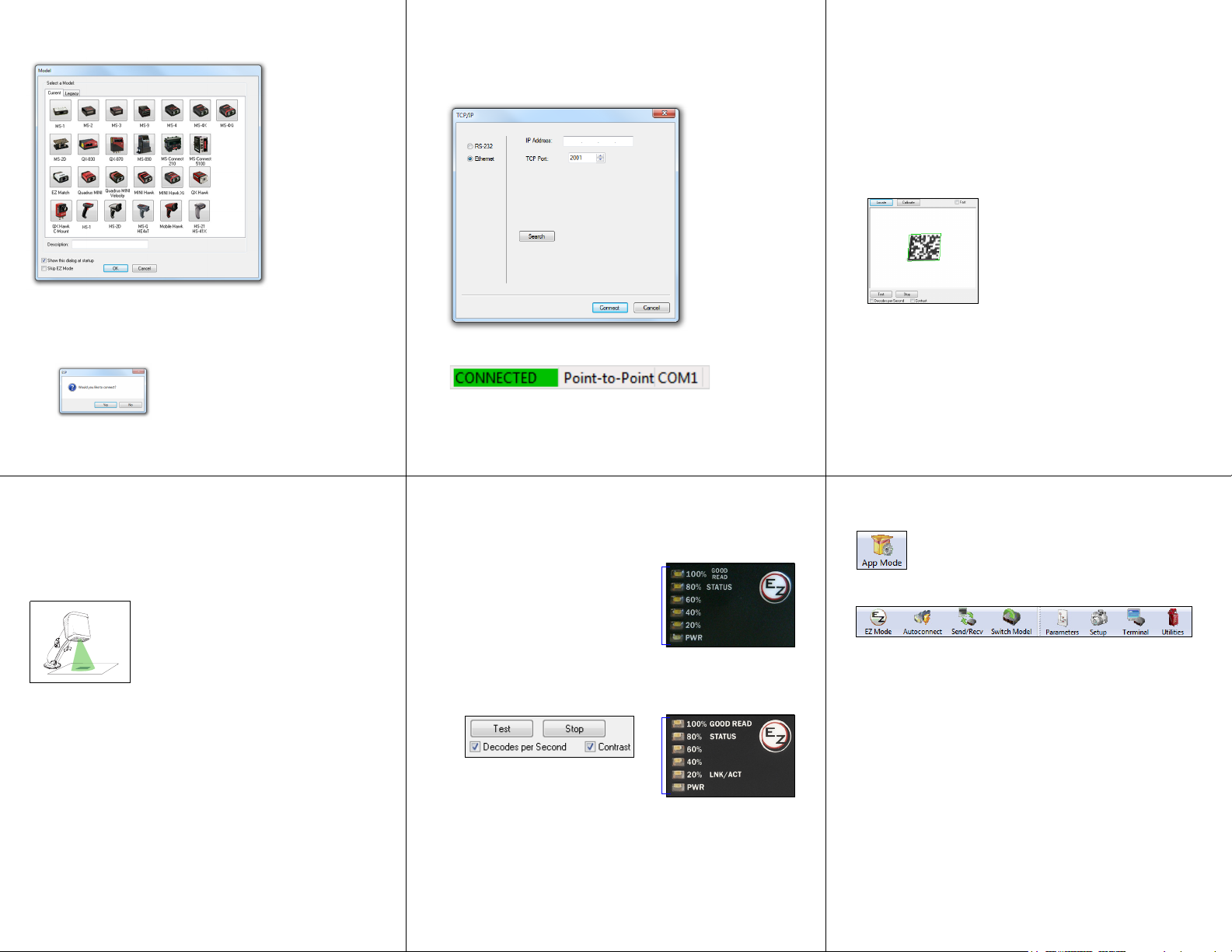

Step 9 — Test Read Rate

Read Rate indicates the number of successful decodes per second

achieved by the imager.

Test Read Rate by EZ Button

1. To start the Read Rate test, hold down

the EZ Button about three seconds

until you hear three short beeps. The

20%

,

40%

, and

60%

LEDs will illuminate.

While the object is being inspected, the

Read Rate LEDs will indicate the read

rate percentage on the back of the unit.

2. To end the Read Rate test, press the

EZ Button and quickly release.

Test Read Rate by ESP

1. Click the Test button to start the Read

Rate test and Stop to end it.

If a symbol has been successfully

decoded, its data and related features

will be presented in the field below the

image display window. Also, while the

object is being inspected, the Read

Rate LEDs will indicate the Read Rate

percentage on the back of the unit.

2. To end the test, click the Stop button.

Note: Read Rate can also be tested using the Read Rate interface in

Utilities.

Test Read Rate by Serial Command

You can also start a test with the <C> or <Cp> command and end it with the

<J> command.

MINI Hawk Xi Read

Rate LEDs and EZ

Button

MINI Hawk, Quadrus

MINI, Quadrus MINI

Velocity Read Rate

LEDs and EZ Button

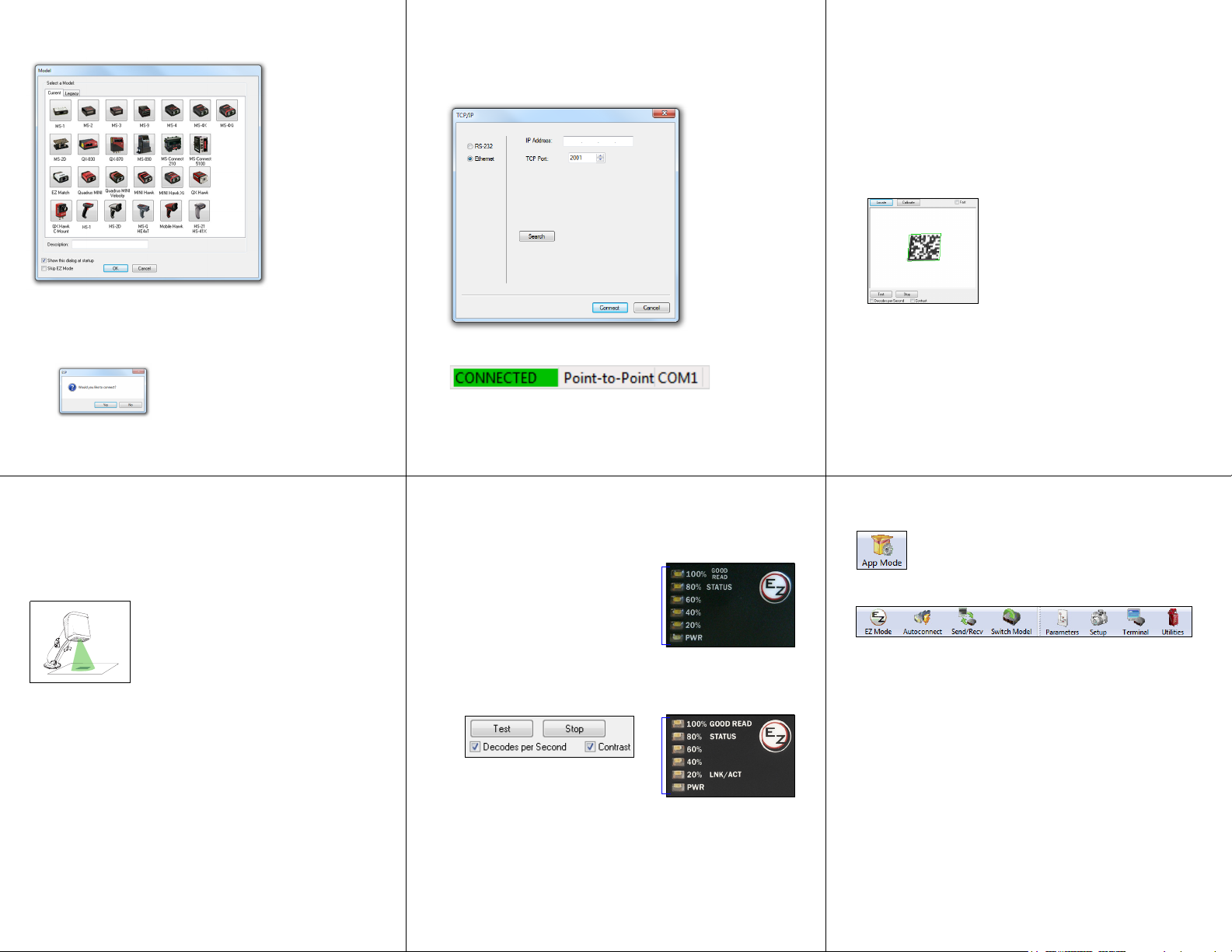

Step 7 — Locate the Symbol

Locate by ESP

•InESP’s EZ Mode, click the Locate button to enable the blue target

pattern.

The symbol in the field of view will appear in the video view beneath

the

Locate

and

Calibrate

buttons, and you will see the blue target

pattern

projected

from the front of the imager.

• Center the target pattern on the symbol.

At 2 to 3 inches, the pattern resembles an X. At 3 to 6 inches, the

pattern resembles a V.

Important: The entire symbol should fall within the field of view (FOV)

of the imager. The field of view is what appears in

ESP

’s

Locate/Calibrate

window in EZ Mode.

• Click the Stop button to end the Locate function.

Locate by EZ Button

If you are not connected to a host computer, the EZ Button allows you to

locate the symbol in the imager’s field of view.

• Hold down the EZ Button for about one second and release when you

hear one short beep. The amber 20% LED will illuminate, and you will

see the blue target pattern projected from the front of the imager.

• Center the target pattern on the symbol.

Note: To end all EZ Button functions, press the EZ Button once and

quickly release.

Step 10 — Configure and Save

Click the App Mode button to make configuration changes to the imager.

The following modes are accessible by clicking the buttons at the top of

the screen:

• Click the EZ Mode button to return to EZ Mode.

• Click the Autoconnect button to establish communication.

• Click the Send/Recv button to send or receive commands.

• Click the Switch Model button to open the model menu, or to return to

a previous model.

•

Click the

Parameters

button to show the tabbed tree controls for

Communication,

Read Cycle, Symbologies, I/O Parameters, Symbol

Quality, Matchcode, and Diagnostics.

• Click the Setup button to access a Camera Setup tree control and

Video view, Evaluate image captures, Calibrate the imager, set the

Window of

Interest, load capture settings and processing settings in the

Configuration

Database, set up output filters and parse symbol data in

Ordered Output and Output Format, and control multiple read cycle

functions in Dynamic Setup.

• Click the Terminal button to display decoded

symbol data, and to send

serial commands to the imager using text or macros.

• Click the Utilities button to test Read Rate, request or clear Counters,

enable or disable the imager or send output pulses in Device Control,

determine

the Differences from Default in the current settings, add or

remove master symbol data in Master Database, and verify or update

the imager’s Firmware.

For further details, see ESP Help in the dropdown Help menu.

Step 8 — Calibrate

Imager settings can be adjusted automatically for optimum performance by

either the EZ Button or by ESP.

During the calibration routine, the imager will flash its Read Rate percent

LEDs and illumination LEDs while searching camera settings and determining

the best configuration for decoding symbol data. Upon successful completion

of this routine, a green LED pattern will flash brightly and illuminate the symbol.

If unsuccessful, the imager will emit 5 short beeps and stop searching.

Calibrate by EZ Button

1. Hold down the EZ Button for about two seconds and release when you

hear two short beeps. The 20% and 40% LEDs will illuminate.

2.

The imager will search camera settings to determine the best configuration

for decoding symbol data.

Note: To end all EZ Button functions, press the EZ Button once and

quickly release.

Calibrate by ESP

1. Click the Calibrate button.

2.

The imager will search camera settings to determine the best configuration

for decoding symbol data.

A successful calibration will display a green frame around the symbol,

and the following message will appear: “Uploading all reader parameters.”

After a moment the symbol data will be presented in the field below the

image display window.

Calibrate by Serial Command

Send <@CAL> from a terminal program to begin calibration.

Step 5 — Select Model

When you start ESP, this menu will appear:

1. Click the button showing the imager used in your application.

2. Click OK.

Note: You can also simply double-click the button showing your

imager to make your selection.

3. Click Yes when this dialog appears:

Note: If you need to select another model later, click the Switch

Model button near the top of the screen or use Model > New

Model in the menu toolbar.