QX Hawk Industrial Imager User’s Manual iii

Introduction

Table of Contents

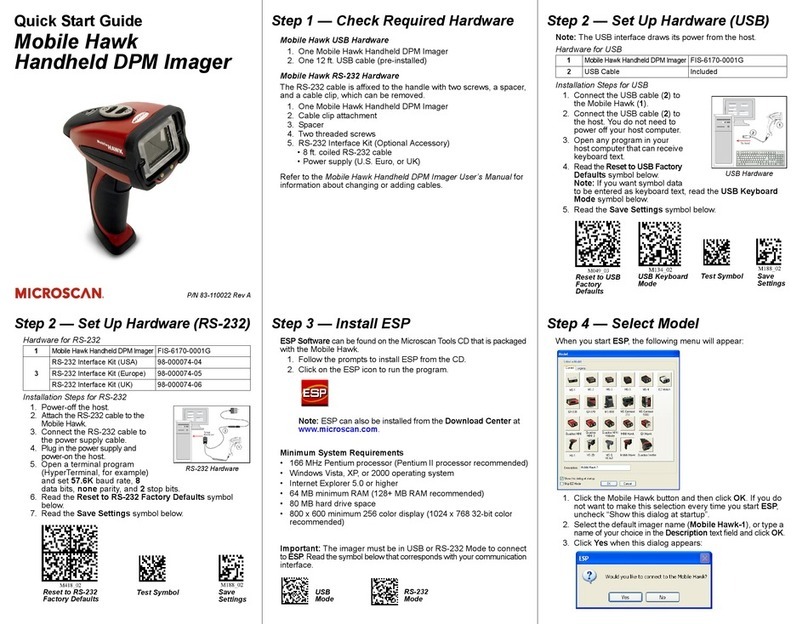

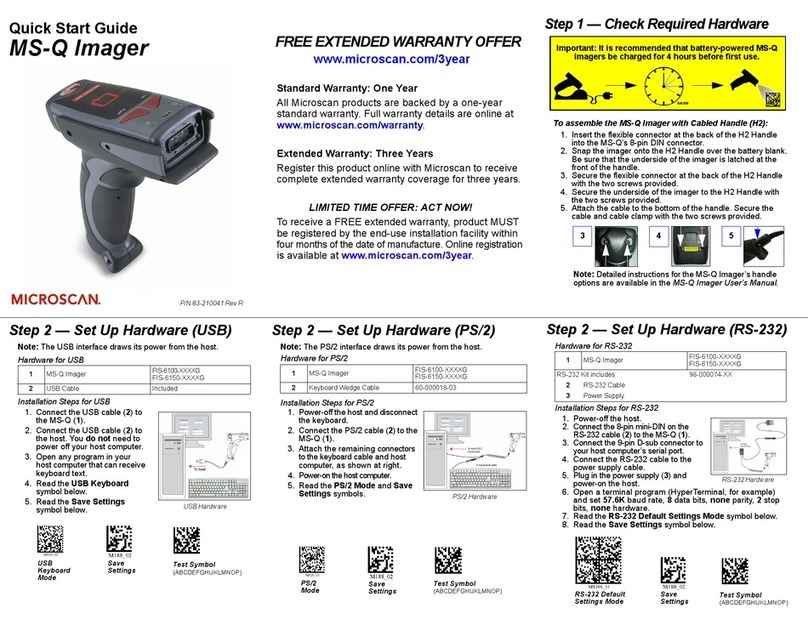

Chapter 1 Quick Start

Step 1 Check Hardware .......................................................................... 1-2

Step 2 Connect the System..................................................................... 1-3

Step 3 Position the Imager ...................................................................... 1-4

Step 4 Install ESP.................................................................................... 1-5

Step 5 Select Model ................................................................................ 1-6

Step 6 Connect........................................................................................ 1-7

Step 7 Locate Symbol .............................................................................1-9

Step 8 Calibrate..................................................................................... 1-11

Step 9 Test Read Rate .......................................................................... 1-12

Step 10 Configure the Imager ............................................................... 1-13

Step 11 Save Changes.......................................................................... 1-14

Chapter 2 Using ESP

EZ Mode .................................................................................................. 2-2

App Mode ................................................................................................ 2-3

Menu Toolbar .......................................................................................... 2-4

Navigating in ESP................................................................................. 2-15

Send/Receive Options.......................................................................... 2-16

Chapter 3 Hardware Integration

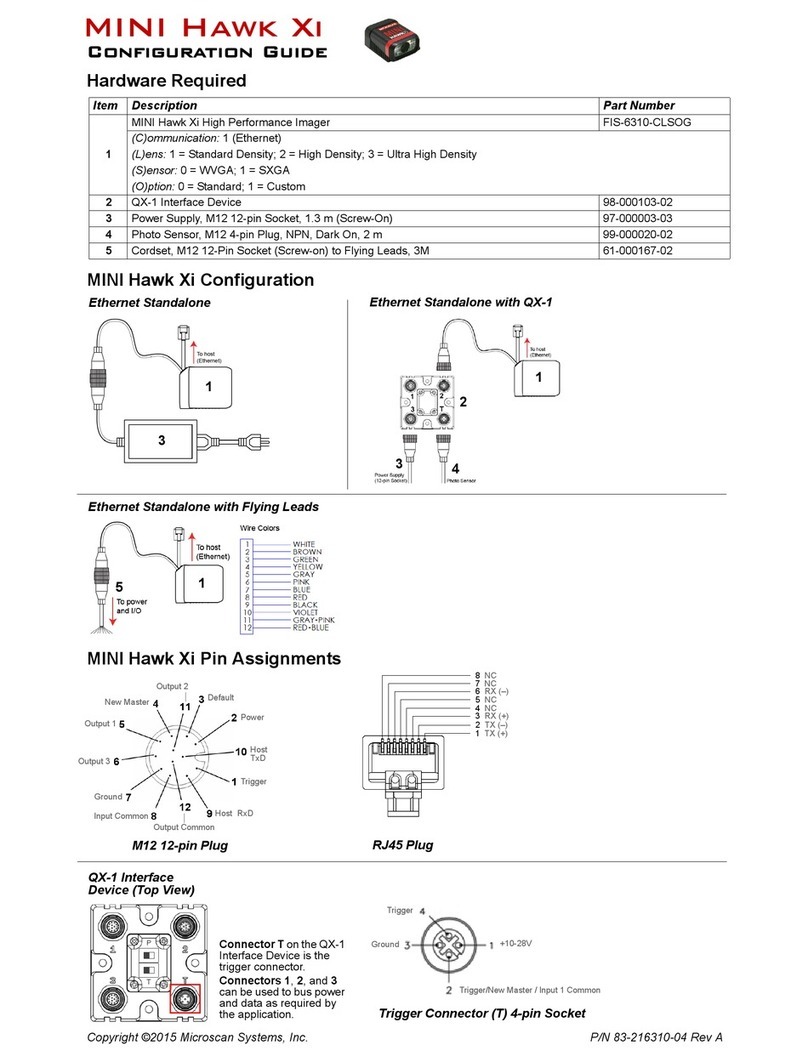

Connectors .............................................................................................. 3-2

Cordsets .................................................................................................. 3-3

QX Hawk and QX-1 Connectors and Pinouts.......................................... 3-4

Power and Trigger Switching................................................................... 3-6

Port Routing............................................................................................. 3-7

Application Examples .............................................................................. 3-8

Chapter 4 Setup

Video ....................................................................................................... 4-2

Evaluation............................................................................................. 4-11

Calibration ............................................................................................. 4-14

Window of Interest ................................................................................. 4-15

Configuration Database......................................................................... 4-17

Ordered Output...................................................................................... 4-24

Output Format ....................................................................................... 4-28

Dynamic Setup ...................................................................................... 4-32

Chapter 5 Parameters

Communication........................................................................................ 5-2

Read Cycle ............................................................................................ 5-40

Symbologies .......................................................................................... 5-61

I/O Parameters ...................................................................................... 5-93

Symbol Quality .................................................................................... 5-155

Matchcode ........................................................................................... 5-162