Warning and safety instructions

Read the operating instructions before

using this machine for the first time. This

way you will avoid the risk of accidents and

damage to the machine.

Only iron materials with this ironer which

are suitable for machine ironing and

which were washed in water.

This machine must not be operated in the

same room as dry cleaning machines

which use solvents containing PERs or CFCs.

The ironer should only be used in a room

with a low relative humidity level.

Any removable outer panels must be back

in place, and all moving or electrical parts

shielded before the machine is switched on.

Do not damage, remove or bypass the

safety features, fixtures and control ele-

ments of the machine.

Do not use a machine with damaged con-

trols or with damaged cables. These must

be repaired before it is used again.

Repairs to the machine should only be

undertaken by a suitably qualified trained

service engineer to ensure safety. Unauthori-

sed repairs could be dangerous.

Faulty components must only be exchan-

ged for Miele original spare parts. Only

when these parts are fitted can the safety

standards of the machine be guaranteed.

The electrical safety of this appliance can

only be guaranteed when continuity is

complete between the appliance and an ef-

fective earthing system which complies with

local and national regulations. It is most impor-

tant that this basic safety requirement is regu-

larly tested by a qualified electrician.

The manufacturer can not be held respon-

sible for the consequences of an inade-

quate earthing system.

The machine is only completely isolated

from the electricity supply either when it is

switched off at the wall isolator or when the

mains fuse is withdrawn from the distribution

board.

Never allow children to play on or near

the rotary ironer, or to operate it them-

selves.

When the ironer is heated up with the

heater plate in position, there is an acute

danger of burning, if the edge of the heater

plate is touched on the feed-out side.

When ironing double layered items do not

reach in between the layers to straighten

out the fabric. This is extremely dangerous as

you may not be able to extract your hands on

time. The same applies when ironing gar-

ments with pockets.

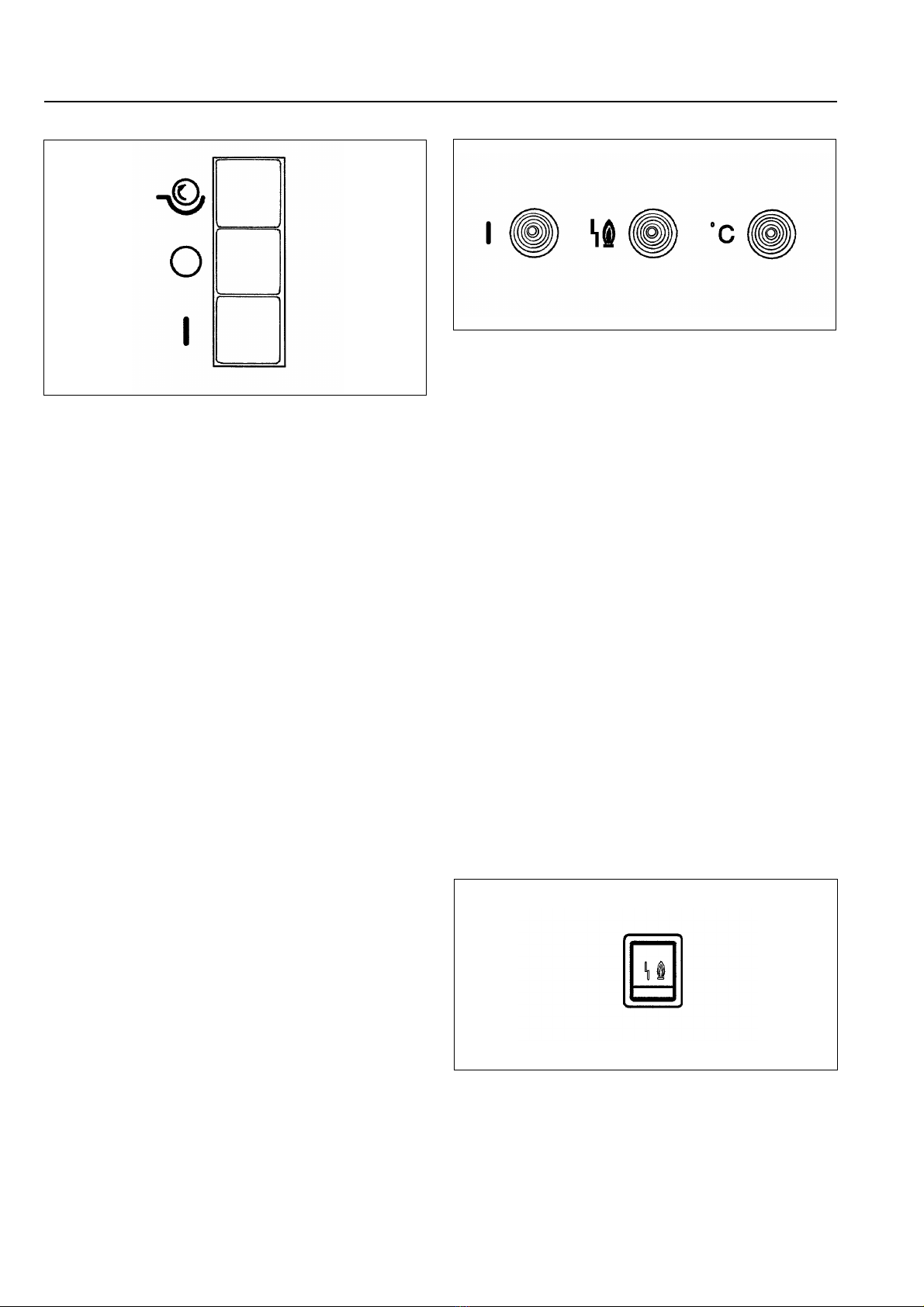

Ironers with belt-feed in:

Warning! Do not iron articles with

fringes/tassles, thin straps, ties etc. They

could cause the belt feed-in mechanism to fail

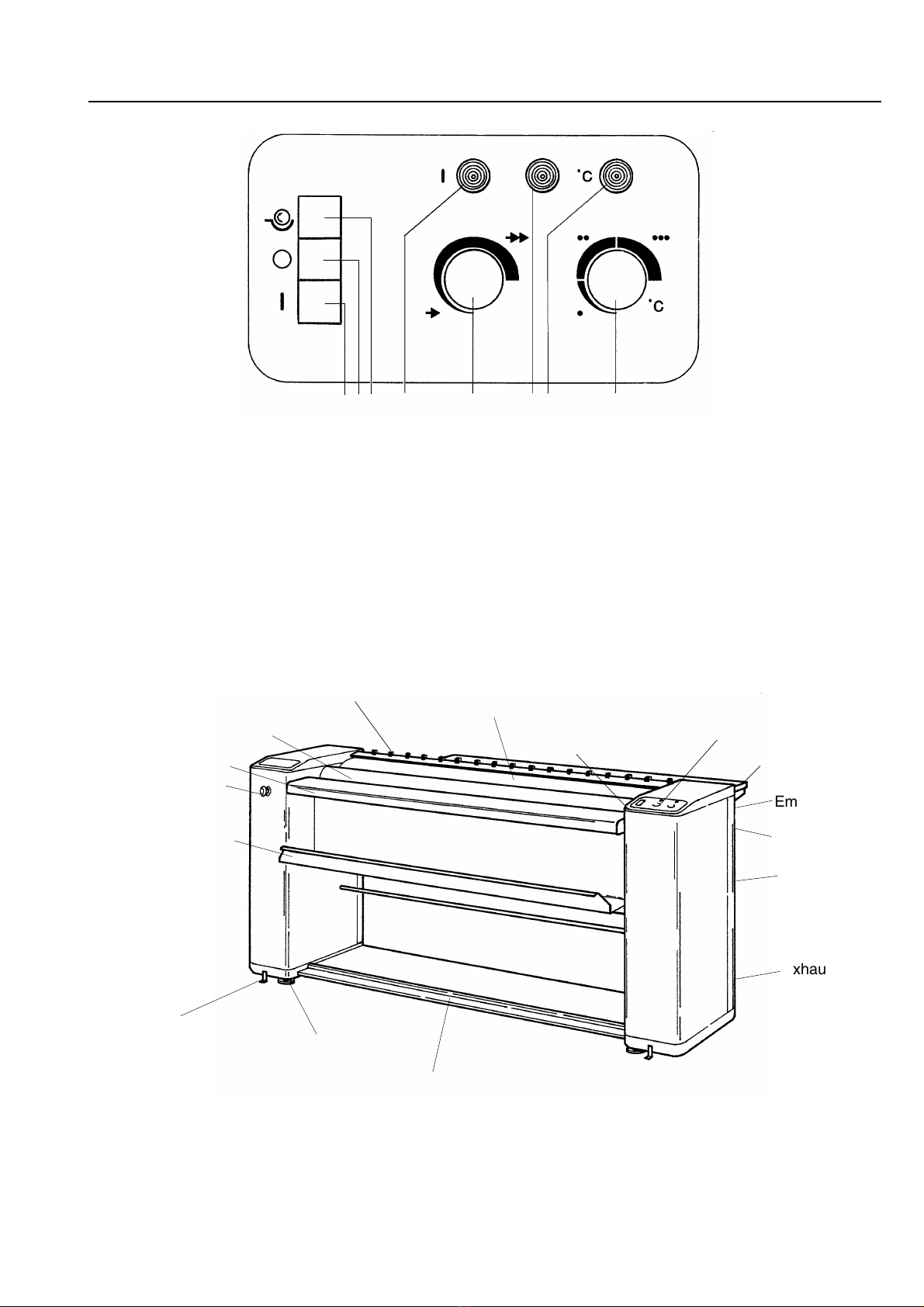

Always keep a fire extinguisher accessi-

ble in the rare event of textiles igniting.

Accessories

Accessory parts may only be fitted when

expressly approved by Miele. If other

parts are used, guarantee, performance and

product liability claims may be invalidated.

M.-Nr. 05372840 4