Technical Information

3

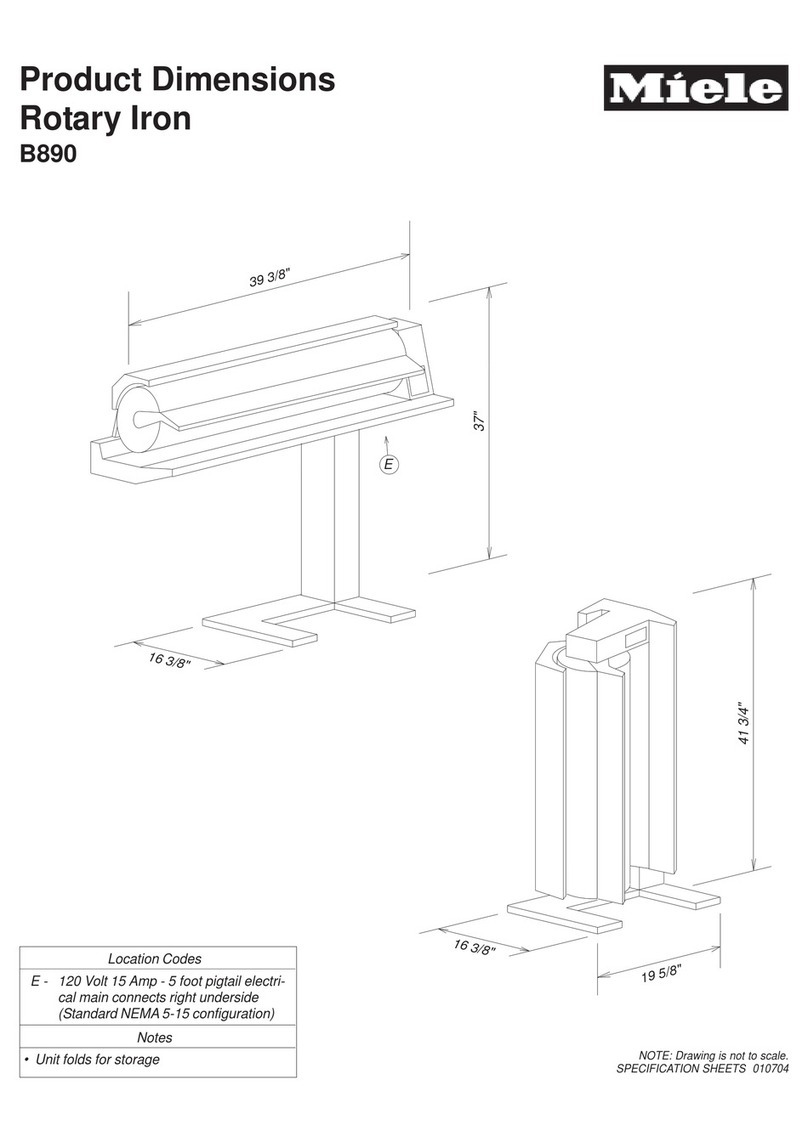

B 890/B 990

4.2Heater Plate Motor (M18) Removal ............................................. 30

4.3Hinge Pressure Spring Setting/Adjustment ................................. 30

035 Lifting Arm .............................................................................................. 32

3Fault Repair ............................................................................................. 33

3.1Emergency Release Does Not Allow Laundry to Be Removed ... 33

3.2Heater Plate Cannot Be Lowered Completely ............................. 33

4Service..................................................................................................... 33

4.1Leaf Spring with Holder Replacement ......................................... 33

040 Roller.......................................................................................................35

3Fault Repair ............................................................................................. 36

3.1Laundry Not Taken In .................................................................. 36

3.2Roller Does Not Turn or Only Turns with Difficulty ...................... 36

3.3Roller Does Not Turn ................................................................... 36

3.4Roller Stops or Heater Plate Does Not Start ............................... 36

4Service..................................................................................................... 37

4.1Roller Removal ............................................................................ 37

4.2Ironing Cloth Replacement .......................................................... 38

050 Roller Motor ............................................................................................ 39

2Function................................................................................................... 40

2.1Roller Drive/Motor........................................................................ 40

2.2Control Electronic ........................................................................ 40

3Fault Repair ............................................................................................. 41

3.1Noisy Operation in the Bearing Flange........................................ 41

4Service..................................................................................................... 41

4.1Control Electronic (A1) Removal ................................................. 41

4.2Drive Shaft Removal.................................................................... 42

4.3Bearing Flange Removal ............................................................. 42

4.4DC Motor Removal ...................................................................... 42

List of Figures

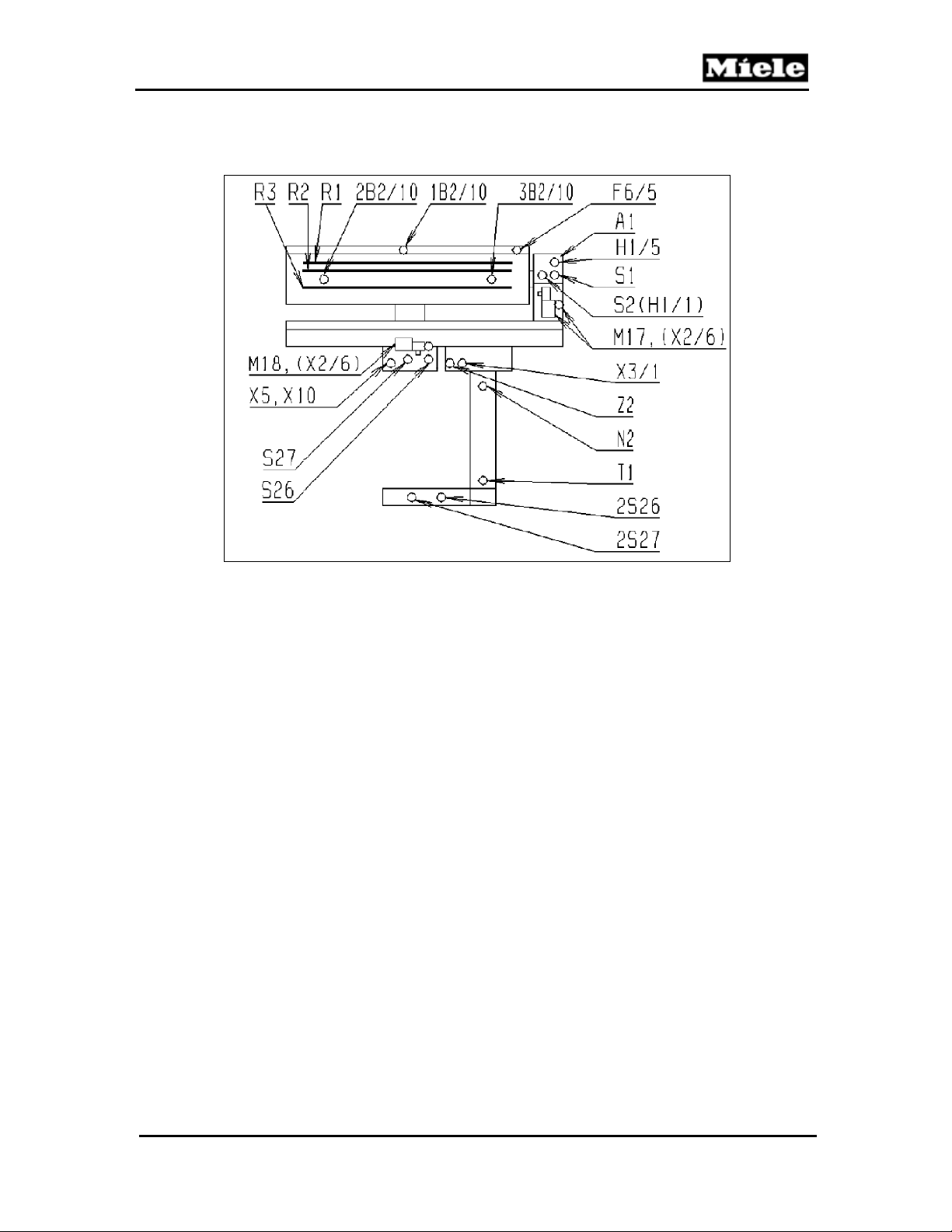

Figure D-1: Layout of Electrical Components ...................................................................9

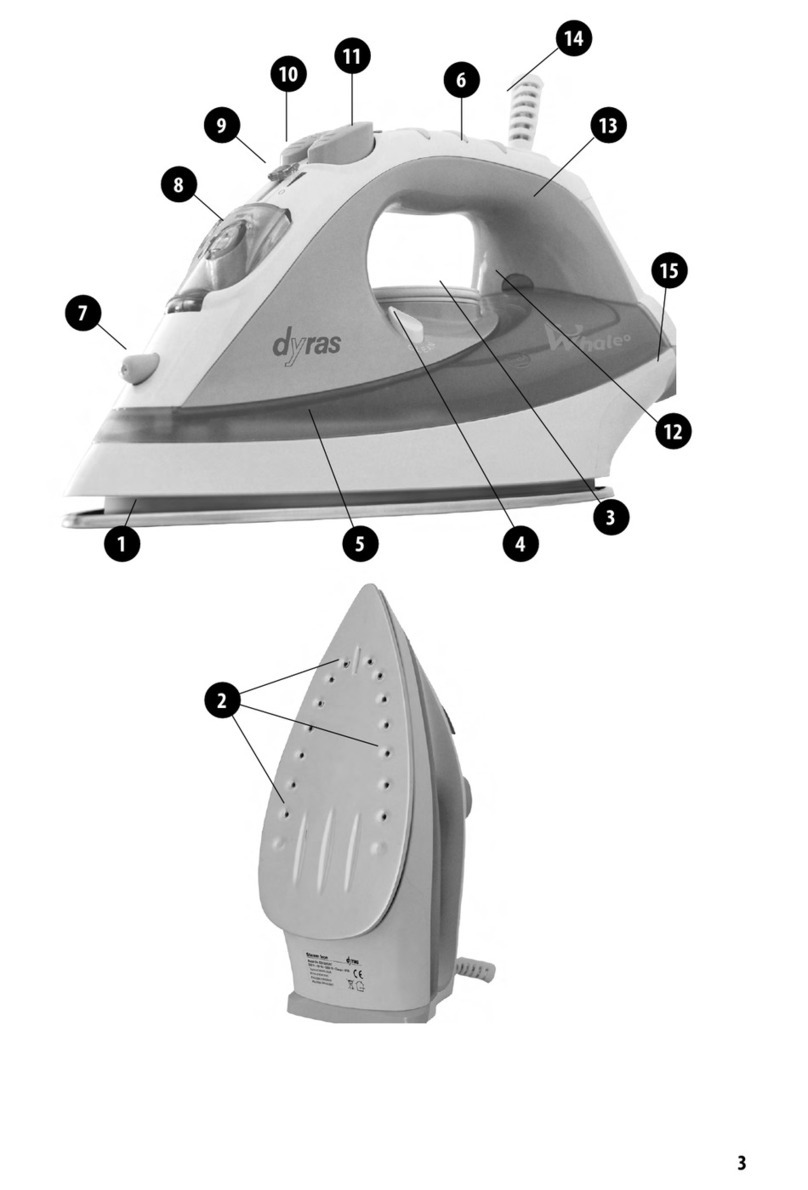

Figure D-2: Overview of Rotary Iron ...............................................................................10

Figure D-3: Overview of (a) B 890 and (b) B 990 Controls .............................................10

Figure 010-1: Main Electronic N2, B 890 ........................................................................ 12

Figure 010-2: Main Electronic N2, B 990 ........................................................................ 13

Figure 010-3: Main Electronic Cover............................................................................... 15

Figure 010-4: Main Electronic Screw .............................................................................. 15

Figure 010-5: Bowden Cable and Plastic Hinge .............................................................18

Figure 010-6: Bowden Cable Holder and Pulley ............................................................. 18

Figure 010-7: Bowden Cable Pin .................................................................................... 19

Figure 010-8: Handle Removal ....................................................................................... 20

Figure 020-1: Heater Electrical Circuit ............................................................................ 22

Figure 020-2: Heater Temperature Control.....................................................................22

Figure 020-3: Finger Guard............................................................................................. 23

Figure 020-4: Handle (Locking Catch) ............................................................................ 24