Local regulations regarding regular in-

spection and maintenance of this ma-

chine must be observed. (In Germany this

machine is subject to laundry regulations

UVV (VBG7y), Sections 36 and 37, which

stipulate that washer extractors with a kinetic

energy of more than 1500 Nm must be

checked once a year by a competent per-

son for their operational safety and the re-

sults entered in a test log (book) supplied

with the machine for the German market,

and which must be kept at the place of oper-

ation and be available for inspection.)

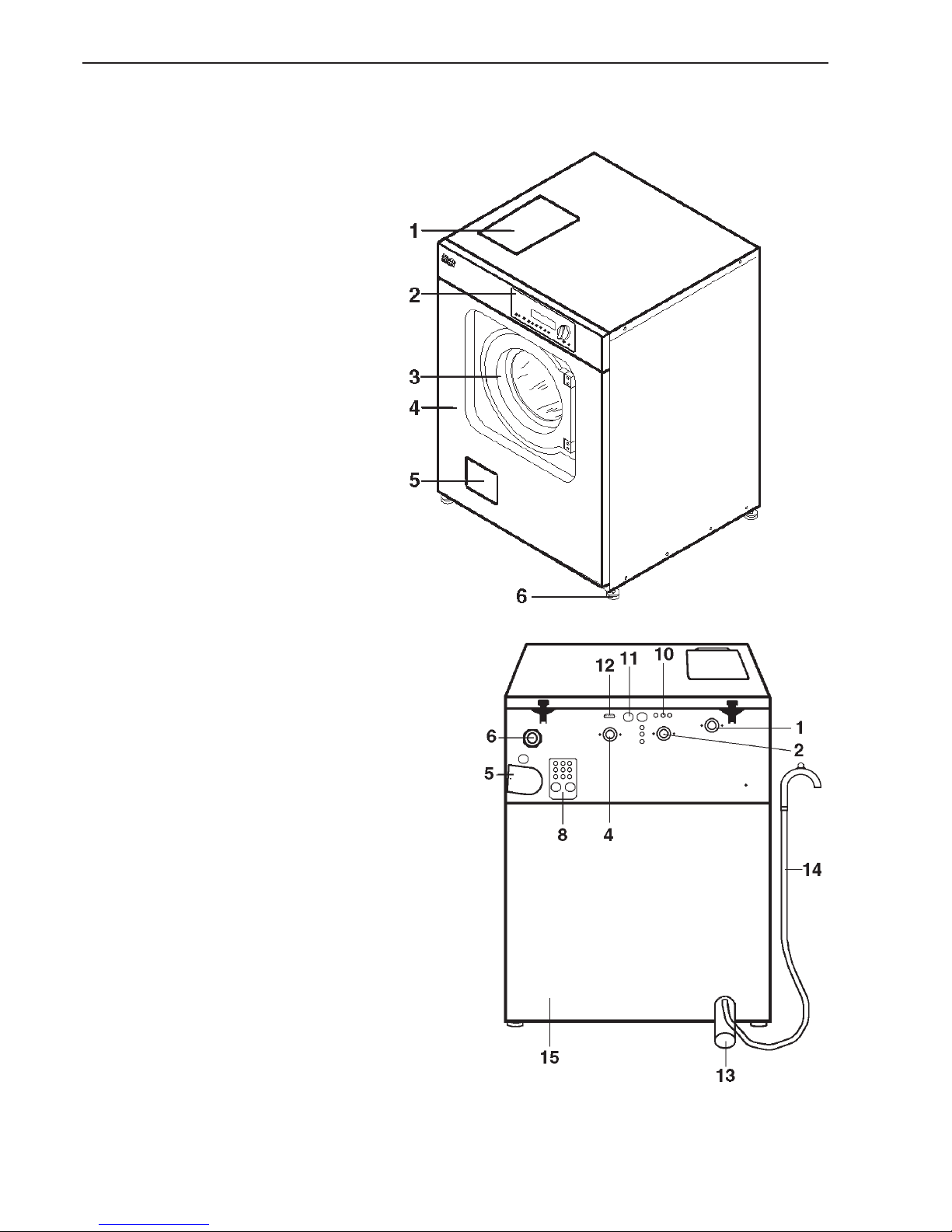

Use of the machine

Never allow children to play in, on or

near the washer extractor, or to operate it

themselves. Please supervise its use by the

elderly or infirm.

Remember that the door porthole glass

can become hot during the operation of

the machine. Do not let children touch it.

When washing with high temperatures

steam can be emitted from the venting

slot behind the machine.

Do not grip between the suspended

drum unit and the seal of the front panel

cut-out during spin.

Always make sure the drum is stationary

before reaching in to remove washing.

Reaching into a moving drum is extremely

dangerous.

Water used for washing and rinsing must

not be used as drinking water. It must be

discharged into a proper sewerage system.

The machine should only be operated

unsupervised when there is a floor drain

(gully) in the direct vicinity of the machine.

To avoid flooding:

If hooking the hose into a sink make sure

that the water can flow away freely to avoid

flooding.

Secure the hose against slipping. The pres-

sure of the water flowing out can push an

unsecured hose out of the sink.

Chlorine or agents containing chlorine

are corrosive, and can under certain

conditions lead to irreperable damage to

components.

Disinfecting and cleaning agents often

have compounds containing chlorides in

them. If these agents dry on to stainless

steel surfaces, the residual chlorides will at-

tack the steel and can cause rusting.

To protect your machine from rust damage,

we recommend only using chloride free dis-

infecting and cleaning agents for washing

and disinfecting programmes and for clean-

ing stainless steel surfaces of the machine

itself.

If you are not sure about a particular agent,

contact the manufacturer of that agent for

advice.

If you accidentally spill an agent containing

chlorides on the machine it should be rinsed

off with water and dried using a soft cloth.

Proprietary dyes, dye removers and

descaling agents may only be used in

this machine if the manufacturer expressly

states that they are suitable for use in a

washing machine. There may be the danger

of fire or explosion.

Always follow the instructions of the

chemical manufacturer when using

cleaning agents and special application

chemicals. Only use such chemicals for the

purpose and in the situation specified by the

manufacturer in order to avoid the danger of

adverse

chemical reactions and material damage.

If in doubt check the suitability of the prod-

uct for use in this machine with the manufac-

turer before using it.

Where a chemical cleaning agent is rec-

ommended on technical application

grounds, this does not imply that the manu-

facturer of the machine takes responsibility

for the effect of the chemical on the material

of the items being cleaned or on the ma-

chine.

Please be aware that changes in formula-

tion, storage conditions etc., which may not

be publicised by the chemical producer, can

have a negative effect on the cleaning result.

Warning and Safety Instructions

M.-Nr. 06 006 850 5