10

OPERATINGGUIDELINES

5. SetthedesiredairtemperatureusingbuttonsA6andA7.

6. You may start reworking as soon as the desired temperature is

reached.RefertodisplaypanelC3toverify.

7. When reworking is completed, turn off the “SMD Rework”

function switch. The autocooling functionality will commence if

thesystemdetectsatemperaturehigherthan95°C.Itwillblowat

fullspeedtoacceleratethecoolingdownofthehotairgun.The

autocooling functionality will stop when the temperature of the

hot air gun reaches about 95°C or below, as shown from the

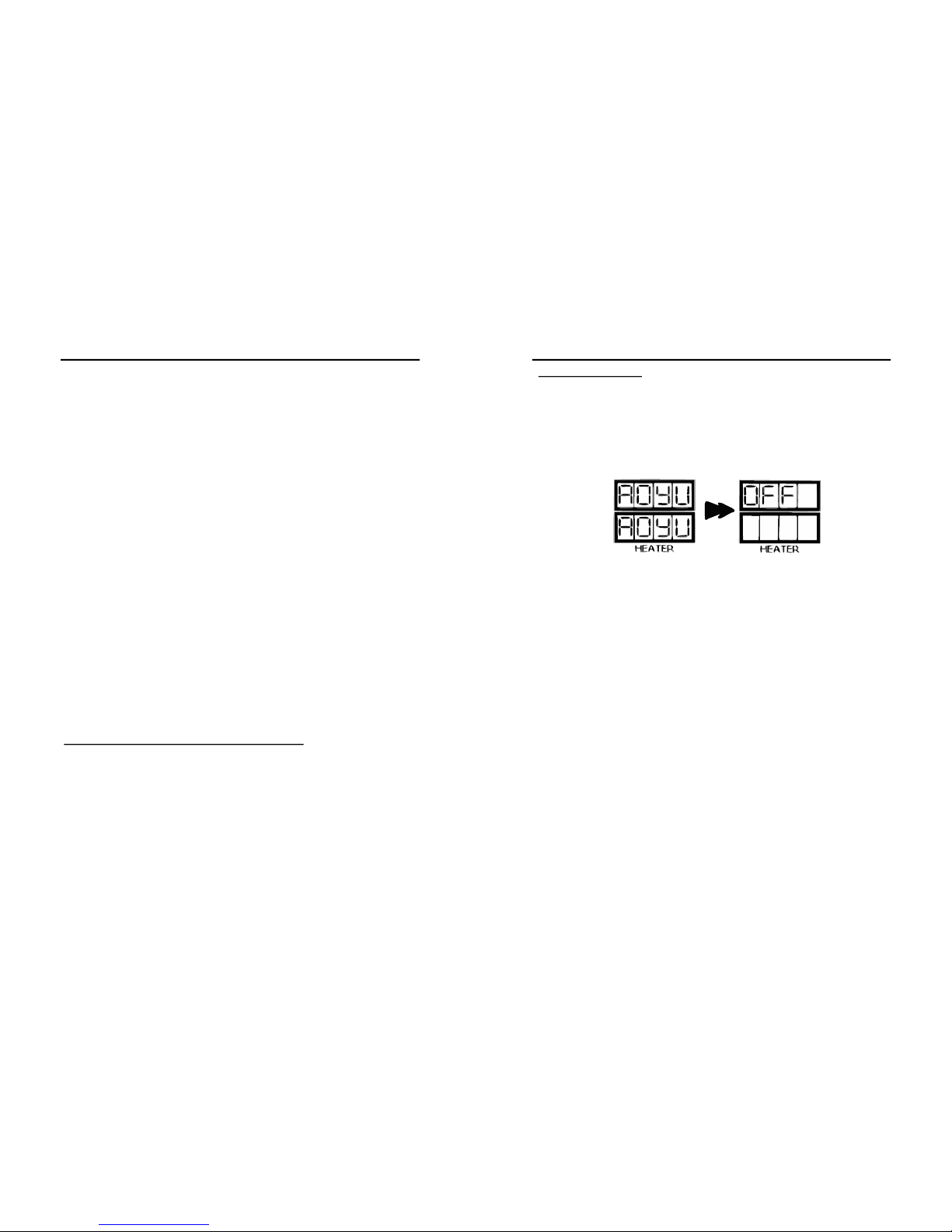

actualtemperaturedisplaypanel,C3.Thesystemwillthenswitch

offanddisplayan“OFF”messagefromuserdefinedtemperature

displaypanel,C2.

NOTE:

MakesurethesmokeabsorptionfunctionalityisswitchedOFFwhen

usingtheequipmentforSMDRework.

SOLDERINGIRON

1. Withtheunitpluggedtothemainpowersourceandmainpower

switch in the ON position, ensure that the soldering iron is

properlyconnectedtothereceptacle,D1.

2. ThesolderingirondisplayA3willshowtheword“OFF”indicating

thesolderingironfunctionisturnoff.

3. TousethesolderingironturnONthe“SolderingIron” function

switch,B1.

4. The soldering iron display A3 will briefly show the current set

temperaturethenswitchtodisplayingtheactualtemperature.

5. When we use the adjustment knob, A3, to set the desired

soldering temperature. The digital display A2 will show the

currentsettemperaturebasedontheknobposition.

11

OPERATINGGUIDELINES

5. Aftera few seconds thedigital display A2willswitchto showing

theactualtemperature.Youmaystartsolderingwhenthedesired

temperaturehasbeenreached.Thesmalldotlocatedattheend

of the number displayed in A2 signifies the heater regulation.

When the small dot starts blinking on and off the system has

reachedthedesiredsettemperature.

6. Afterusageturnoffthesolderingironfunctionswitch.

7. If the soldering iron tip is still higher than 100 degrees, the

soldering iron display will show the word “Hot” indicating the

solderingironisstillhottocautionusers.

8. When the soldering iron tip’s temperature has fallen to

manageablelevelthedisplaywillshowthework“OFF”

9. SwitchONthe“SmokeAbsorber”powerswitch,B2,toactivate

thesmokeabsorptionfunctionality.

NOTE:

Turnthe“SmokeAbsorber”ONonlyafterthesolderingironreached

the desired (set) temperature. This is to avoid affecting the temperature

increaseofthesolderingironintermsofheatingtime.

SOLDERINGIRONSLEEPTIMER

1. The soldering iron has a sleep feature that allows the soldering

iron to go into sleep mode depending on user programmed

duration.

2. Toaccessandenablethesleepfeatureofthesolderingiron:

●TurnSolderingiron,SMDandSmokeabsorberfunctionswitchoff.

●PressandholdthehotairtemperatureincreasebuttonA6.

●The soldering iron display A2 will turn to “t##” ,indicating it is

nowonsleeptimeradjustmentmode.

●Turnthesolderingironadjustmentknobtoselectdesiredsleep

timeinminutes.