INTRODUCTION

The PICPLC16 v7a development system provides a development environment for experimenting with industrial devices. With 16 opto-

inputs and 16 relays (for currents up to 16A), you can develop PIC-based industrial, home or office automation devices the easy way.

We equipped it with our revolutionary new programmer & debugger - CODEGRIP and mikroBUS™ support. We now present you with the

new version 7a that brings so much more, and we hope that you will be thrilled with your new board, just as we are.

PICPLC16 v7a offers amazing

connectivity options. Ethernet, LIN,

and pin headers for each port, you can

connect accessory boards, sensors and

your custom electronics with ease.

Powerful on-board CODEGRIP

USB-C programmer and In-Circuit

debugger will simplify programming

and debugging, whether you’re an

experienced professional or a begginer.

A CONNECTOR FOR EACH PORT EVERYTHING IS ALREADY HERE

Amazing connectivity CODEGRIP on board

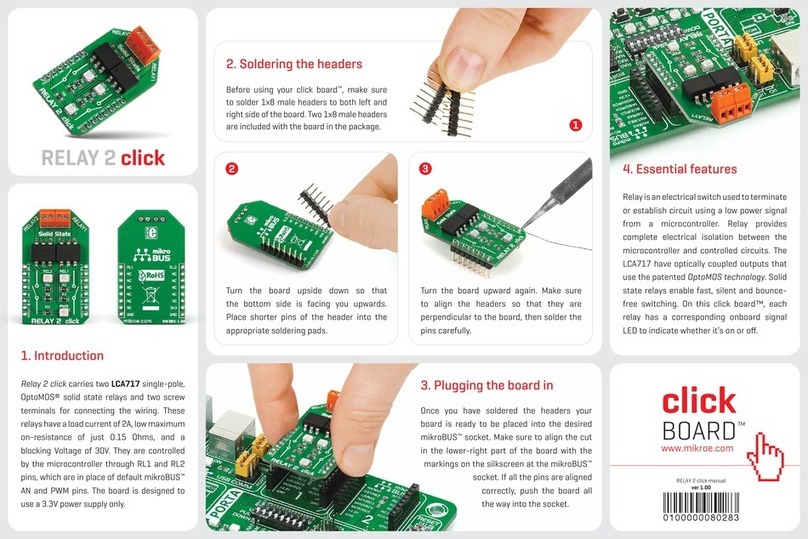

Develop complex industrial, home

or office control systems with 16

optocouplers and 16 relays that

allow you to connect the MCU to high

-powered external industrial (but also

home or office) devices.

INDUSTRIAL CONTROL

Relays and

optocouplers

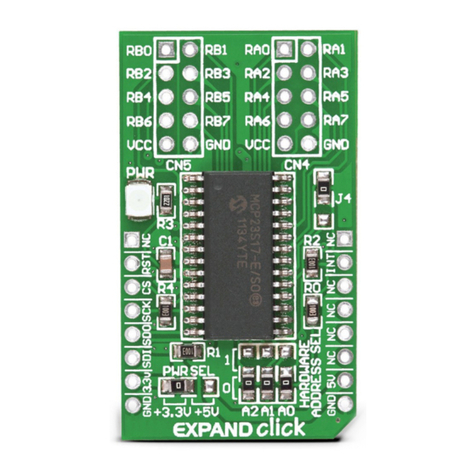

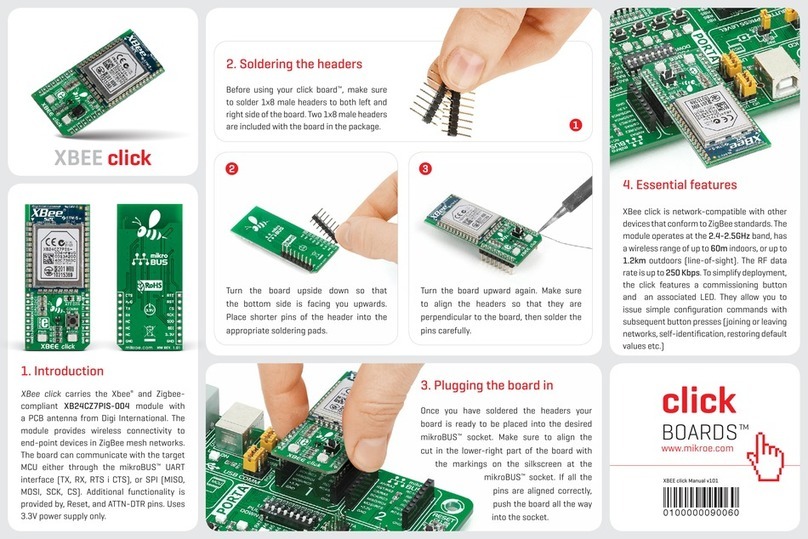

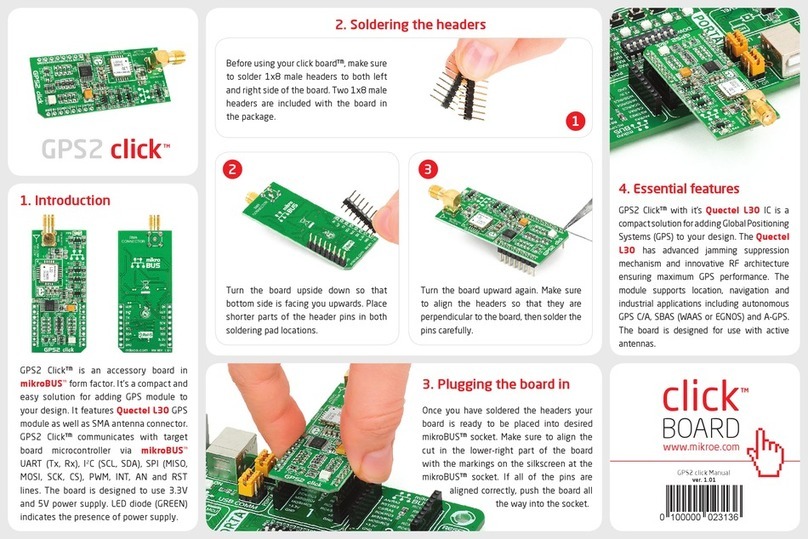

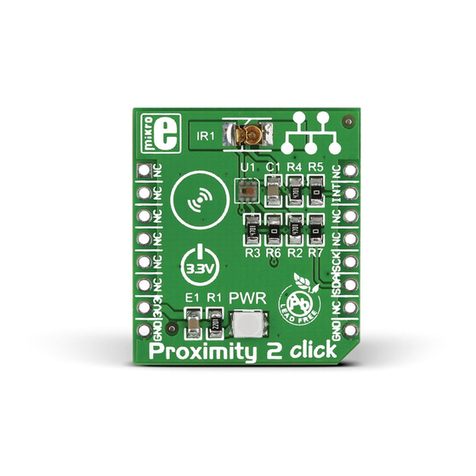

Just plug in your Click board, and

it’s ready to work. We picked up a

set of the most useful pins you need

for development and made a pinout

standard you will enjoy using.

FOR EASIER CONNECTIONS

mikroBUS™support

16