Mounting instructions (Original: de)

8037330

1407a

†‡

Adjusting kit

EADC-E12

Festo AG & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

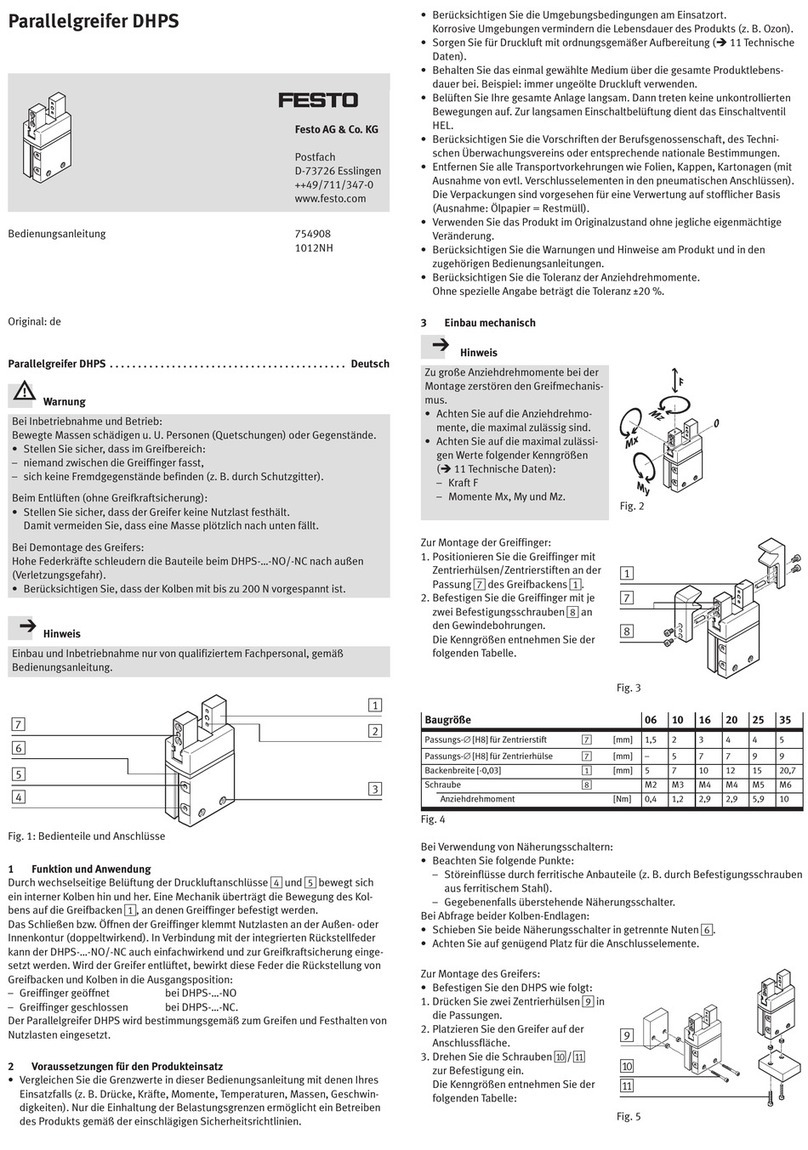

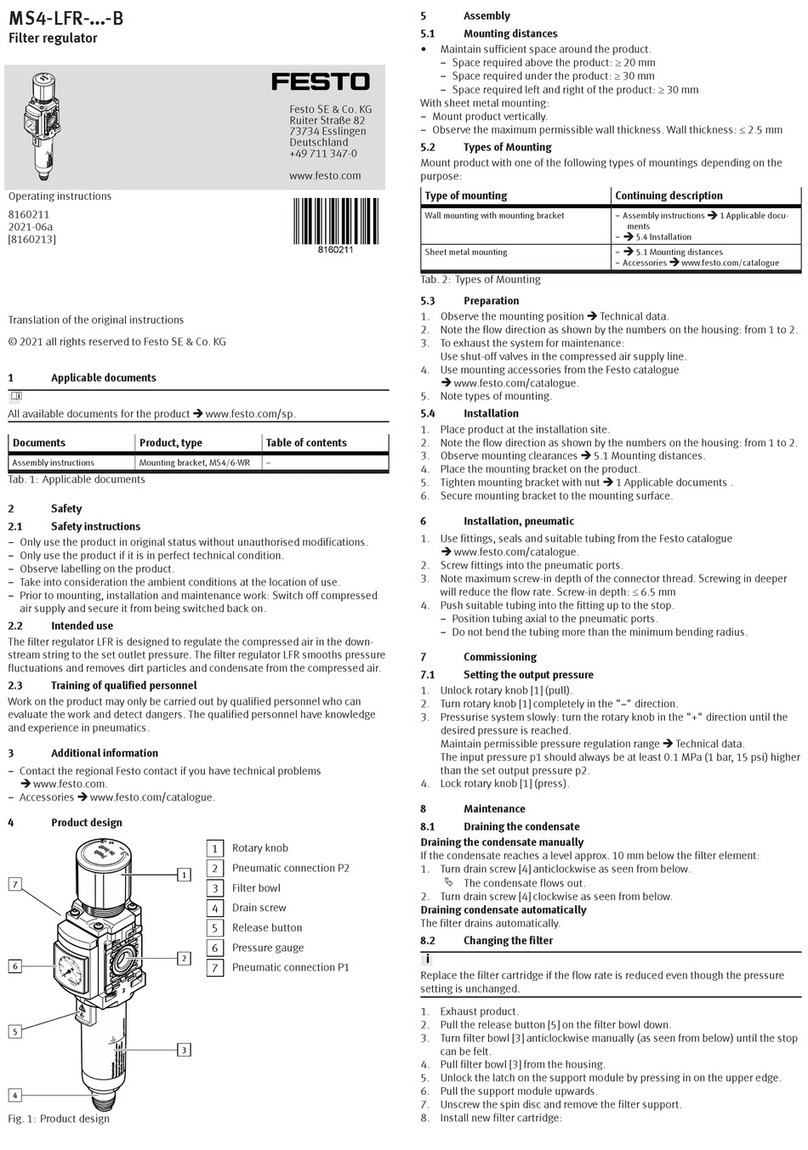

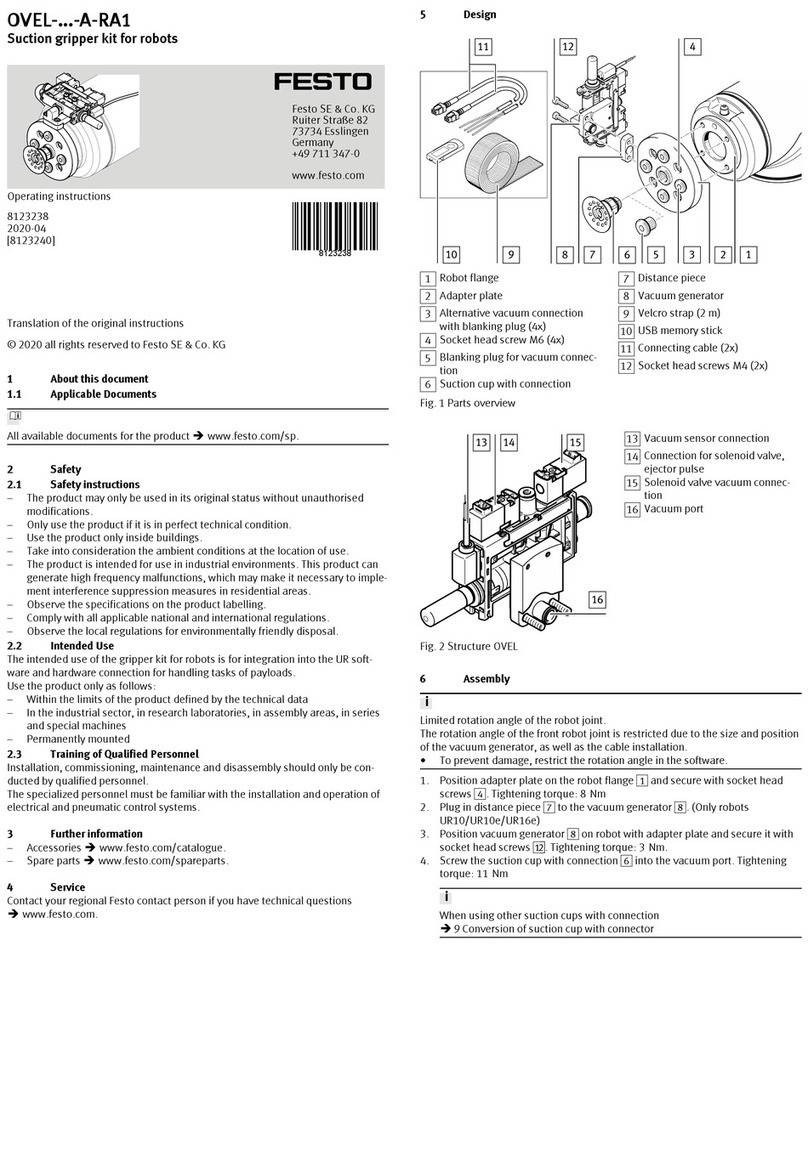

1. Parts list

19344d_1

1Slot nut

2Adjusting plate

3M6x30 screw

4Square nut

5Adjusting bolt

6Washer

7Screw M8x401)

(2x)

(1x)

(2x)

(2x)

(2x)

(2x)

(2x)

19344d_2

Not included in delivery:

8Planar surface gantry

EXCH

(1x)

2. Intended use

Adjusting kit EADC-E12:

Attachment and alignment of the planar surface gantry EXCH. Compensation

of a difference in height of up to 5 mm.

3. Safety instructions and notes on mounting

Caution

Unexpected movement of components.

Injury due to electric shock, impact, squeezing.

Switch off power supply before mounting work.

Observe safety instructions (applicable documents).

Note

Malfunction and material damage due to incorrect mounting.

If the mounting surface is not made of steel:

Select a different screw 7suitable for the installation situation.

Thread depth ≥14 mm intended on the mounting surface for the

screws 7.

Mount properly (section 4).

Observe tightening torques.

Information

Applicable documents

Description of the planar surface gantry: EXCH (mechanical installation)

–Observe minimum number and distances of the adjusting kits.

–Align planar surface gantry.

Accessories www.festo.com/catalogue: EXCH

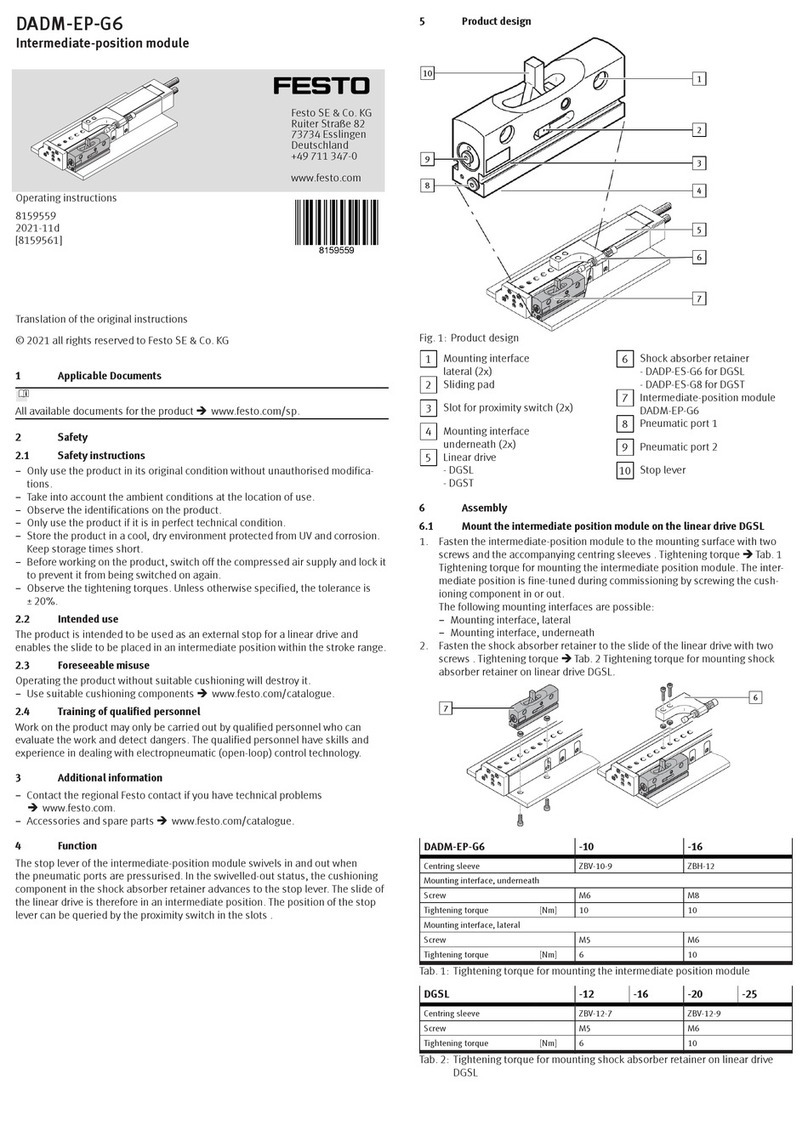

4. Mounting

19344d_3

Place slot nuts 1in the pro-

file slot (A).

Clamp the adjusting

plate 2to the slot nuts 1

using the screws 3.

Position the adjusting

plate 2. Observe minimum

number and distances of the

adjusting kits (Info).

Tighten screws 3.

19344d_8

Screw adjusting bolts 5

flush into the square

nuts 4.

19344d_4

Push square nuts 4includ-

ing adjusting bolts 5into

the slot (B).

19344d_5

Place washers 6under-

neath the screws 7.

Place screws 7in the mid-

dle of the oblong hole.

EADC-E12- 40 60

X [mm] 78 98

Lightly clamp the adjusting

plate 2to the mounting

surface with the screws 7.

19344d_9

Use spanner (C) with

t .5 mm.

With t ,5 mm, the possible

height compensator is smaller

by the difference (t −5).

19344d_6

Align planar surface gantry

(Info). Screw the adjust-

ing bolts 5in or out

(h = 6 … 11 mm).

Observe sufficient screw-in

depth of the screws 7 (for

steel ≥8 mm).

Tighten screws 71). Apply

counter pressure to the ad-

justing bolt 5:

–Do not twist the adjusting

bolt 5.

–Maintain alignment.

Check: alignment of the planar

surface gantry 8.

19344d_7

1)

1) Screw 7and the tightening torque are designed for mounting on steel.

A

B

9.9 Nm _20 %

C

24 Nm _20 %1)

C

C