Miller Maxstar 300 User manual

Other Miller Welding System manuals

Miller

Miller Spectrum 375 X-TREME User manual

Miller

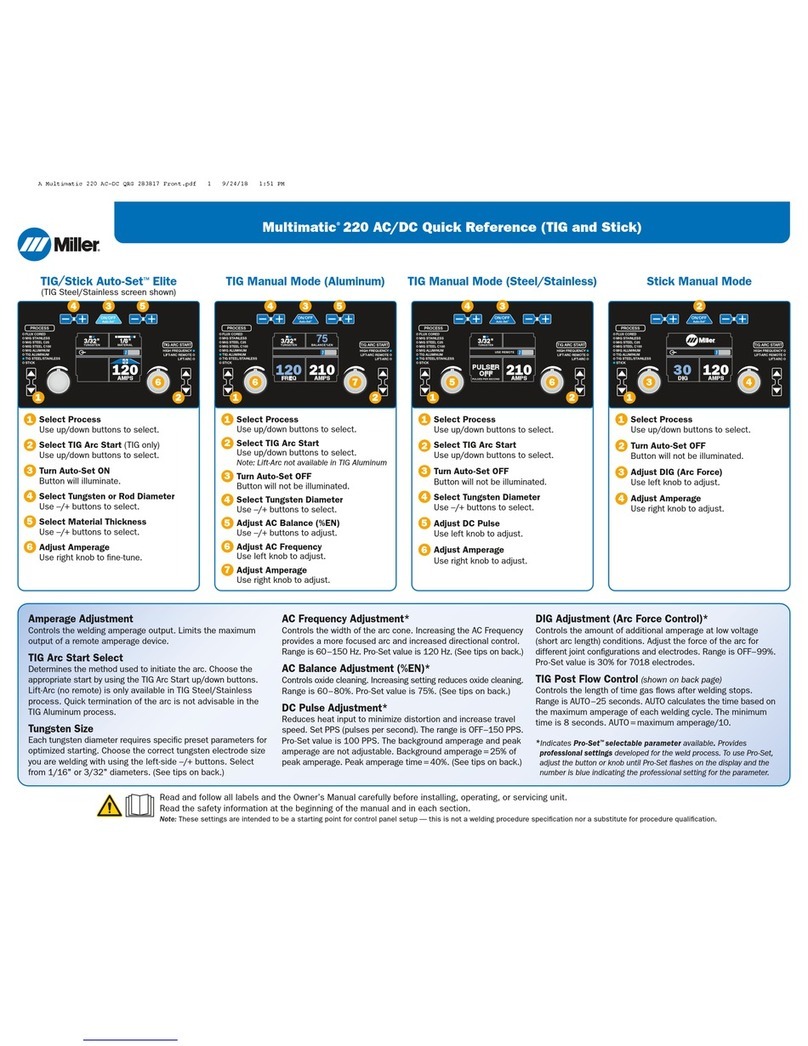

Miller Multimatic 220 AC/DC User manual

Miller

Miller PipeWorx 400 User manual

Miller

Miller MILLERMATIC 70A User manual

Miller

Miller SRH-333 User manual

Miller

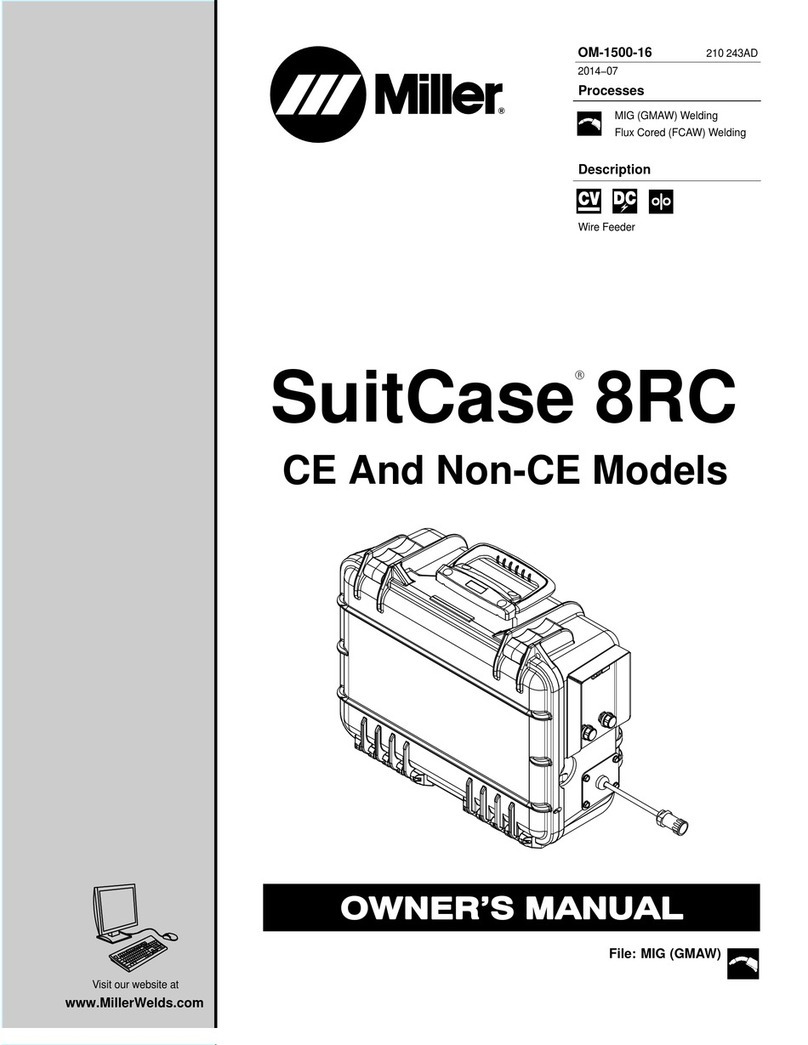

Miller SuitCase 8RC User manual

Miller

Miller Legend 302 User manual

Miller

Miller ST-24w User manual

Miller

Miller Dynasty 400 User manual

Miller

Miller ST 44 Series User manual

Miller

Miller Migmatic 175 User manual

Miller

Miller ALT 304 User manual

Miller

Miller Dynasty 280 DX User manual

Miller

Miller MigMatic 300 User manual

Miller

Miller Coolmate 3.5 CE User manual

Miller

Miller RAD-400 User manual

Miller

Miller AG-BAG G6060 User manual

Miller

Miller EnPak Mechanic OM-240 113H User manual

Miller

Miller MAC TOOLS MW 183ET User manual

Miller

Miller hydracool 270 CE User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual