M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

LINC 82 ver. 04102003 - pn 15104

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800 Page 6

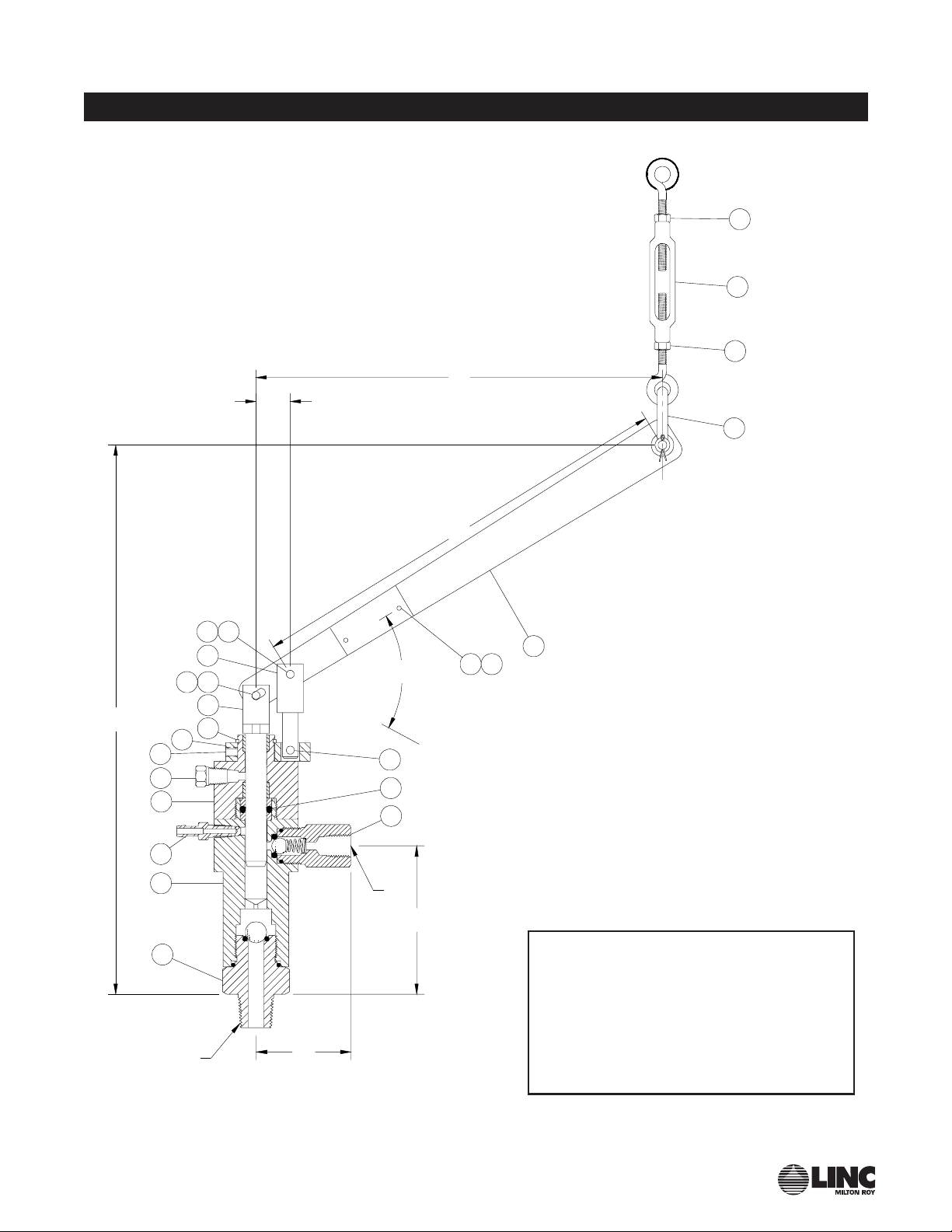

ody (fig. 3, item 1) and "peen"

the all onto the seat to

ensure proper sealing.

6. Install the repaired suction

check valve into the pump

ody. Tighten securely.

7. Reconnect the suction piping.

Discharge Check Valve,

Figure 1, item 15 & Figure 2:

1. Assure that the pump is

isolated from the rest of the

system.

2. Disconnect the piping from

the check valve.

3. Unscrew the check valve

ody (fig. 2, item 1) from the

pump lower housing (fig. 1,

item 13).

4. Remove and discard the

o-rings (fig. 2, items 4 & 5).

5. Inspect the all and spring

(fig. 2, items 2 & 3) for dam-

age. Replace if necessary.

Reassem le the check valve

using new o-rings. If the seat

o-ring is Teflon, install in into

the pump lower housing (fig.

1, item 13) and "peen" the

all onto the seat to ensure

proper sealing.

6. Install the repaired discharge

check valve into the pump

lower housing. Place the all

on the o-ring seat followed y

the spring (small end of the

spring toward the all) and

screw the discharge check

valve ody into the pump

lower housing. Tighten

securely.

7. Reconnect the discharge

piping.

Plunger and Plunger Seal,

Figure 1, item 6 & 16:

1. Assure that the pump is

isolated from the rest of the

system.

2. Remove the pin retainer and

pins separating the plunger

assem ly from the eam (fig.

1, items 4 & 5). Remove the

retaining ring and loosen the

set screw and separate the

swivel ring (fig. 1, items 7, 9

& 8) from the packing lock.

3. Grasp the plunger assem ly

(fig. 1, item 6) and pull up out

of the packing lock (fig. 1,

item 11) to remove. Inspect

the plunger for wear, espe-

cially longitudinal grooves.

Replace the plunger assem ly

if necessary.

4. With a pipe or strap wrench

separate the packing lock

(fig. 1, item 11) from the lower

housing (fig. 1, item 13).

5. Remove the plunger seal and

seal ack-ups, where used,

from the lower housing (fig.

1, items 16 & 13). Carefully

remove the seal ack-up and

seal. Inspect for wear or

deterioration from eing

attacked y the chemical the

pump is pumping.

6. Replace the plunger seal and

plunger seal ack-ups if

needed (see parts lists on

page 9). If the plunger seal

is the o-ring type, it should

e installed with a plunger

seal ack-up on each side of

the o-ring. If the plunger seal

is of the Uniseal type, it

should e installed with the

expander ring down toward

the lower housing. Extreme

care should e taken not to

scratch or distort these parts.

7. After the seal has een

replaced, lu ricate with a light

oil to protect against possi le

damage during assem ly.

8. Screw the packing lock onto

the lower housing and tighten

securely. Slide the plunger

assem ly into the packing

lock and down into place.

Install the swivel ring with the

retaining ring and eam with

the pin and pin retainer. See

step 2 a ove under this sec-

tion.

9. If the leed screw has een

removed, install and tighten

securely.

Plunger and Plunger Seal

Lubrication

1. Remove the plug from the

pump ody (fig. 1, item 10).

2. Add silicone ase lu ricant

(Dow Corning DC-7, part

#10354) or equal into the port

where the plug was removed.

Approximately 0.5cc will e

required for each refill.

Replace the plug.

Note Do not use a grease gun

or any metal tool to insert the lu ri-

cant into the pump to prevent dam-

age to the plunger or plunger seal.

3. Silicone lu ricant should e

added every 4 - 6 weeks

depending upon operation

conditions.

M E T E R I N G P U M P S