6Instruction Manual

SECTION 3 - INSTALLATION

3.6 GENERAL INFORMATION

Use piping materials that are resistant to corrosion

by the liquid being pumped. Use care in selection

of materials to avoid galvanic corrosion at points

of connection to the pump liquid end.

Use piping sufciently heavy to withstand maximum

pressures.

Blow out all lines before making nal connections

too pump.

Provide for pipe expansions when hot uids are

to be pumped. Support piping so that pipe weight

is not placed on the pump. Never spring piping to

make connections.

Piping should be sloped in a manner to prevent

tapping of vapor pockets. Vapor present in liquid

end will cause inaccurate pump delivery.

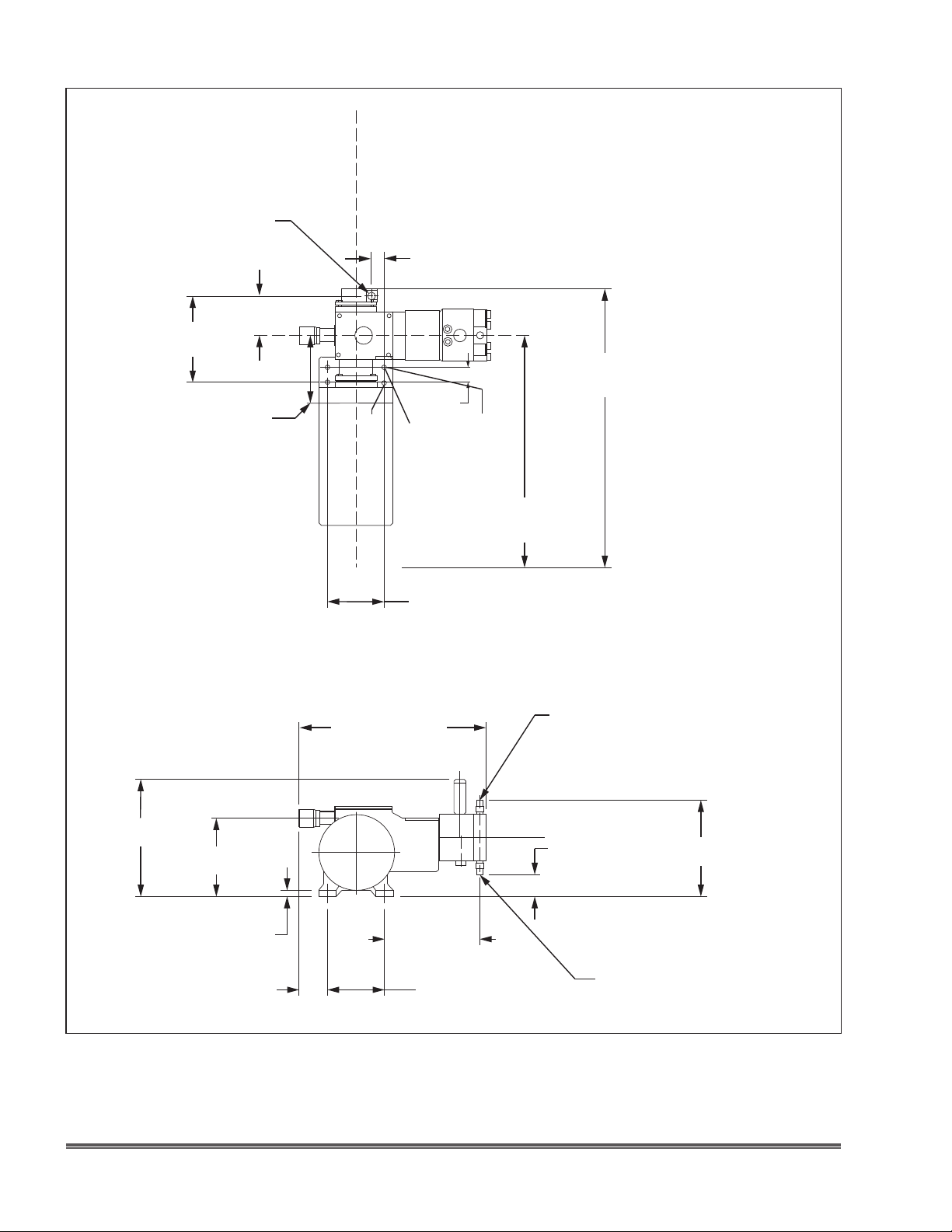

3.7 SUCTION PIPING

If possible use metal or plastic tubing for the suction

line because tubing has a smooth inner surface and

can be formed into sweep bends, thus decreasing

frictional flow losses. Suction piping must be

absolutely air tight to insure accurate pumping.

After installation, test suction piping with air and

soap solution for leaks.

A strainer should be used in the suction line to

prevent foreign particles from entering the liquid

end. Any measures which prevent foreign matter

from entering and fouling the ball checks will give

increased maintenance free service.

It is preferable to have the suction of the pump

ooding by having the liquid end located below the

level of the uid in the supply tank.

When pumping liquids at temperatures near the

boiling point, provide sufcient suction head to

prevent “ashing” of the liquid into vapor when it

enters the liquid end on the suction stroke.

If suction piping is long, particularly at stroke

speeds greater than 70 strokes per minute, the

suction piping should always be larger than tting

size to prevent starving the pump.

Sealed piping, sufcient suction pressure, and

properly adjusted packing are absolutely necessary

for accurate and stable pump operation.

3.8 DISCHARGE PIPING

Install adequate size piping to prevent excessive

pressure losses on the discharge stroke of the

pump. Maximum pressure at the discharge tting

on the liquid end must be kept at or below the

maximum pressure rating as shown on the pump

data plate. The peak ow of this type of pump

during the discharge stroke is approximately three

times the average ow rate (because of harmonic

motion of the plunger) and discharge piping should

be sized accordingly.

The pump will not deliver a controlled flow if

the discharge pressure is less than the suction

pressure. Piping should be arranged to provide at

least 5 psi (34.5 kPa) positive pressure differential

from the discharge side to the suction side.

There are a number of ways to create an articial

discharge pressure, such as the use of a vented

riser or a back pressure valve.

3.9 PIPING CONCENTRATED

SULFURIC ACID

The liquid ends of pumps with plungers less than

5/8” in diameter, designed for 20 gph delivery

or less, are too small to tolerate the sludge in

commercial concentrated sulfuric acid. However,

even these pumps will serve in such applications

if the piping system is modied as follows:

1. Install a sulfuric acid tank, which has an

unused portion below the tank outlet to the

suction line to collect sludge from the system.

(Maximum pressure / sludge trap is 20 psig.)

2. Ensure pump suction is ooded.

3. Use piping material identical to liquid end

material: install steel pipe to steel liquid

end. Never connect iron to steel or serious

galvanic corrosion will occur.