© 2014 MIMAKI ENGINEERING CO.,LTD. 1.1.1 P.2

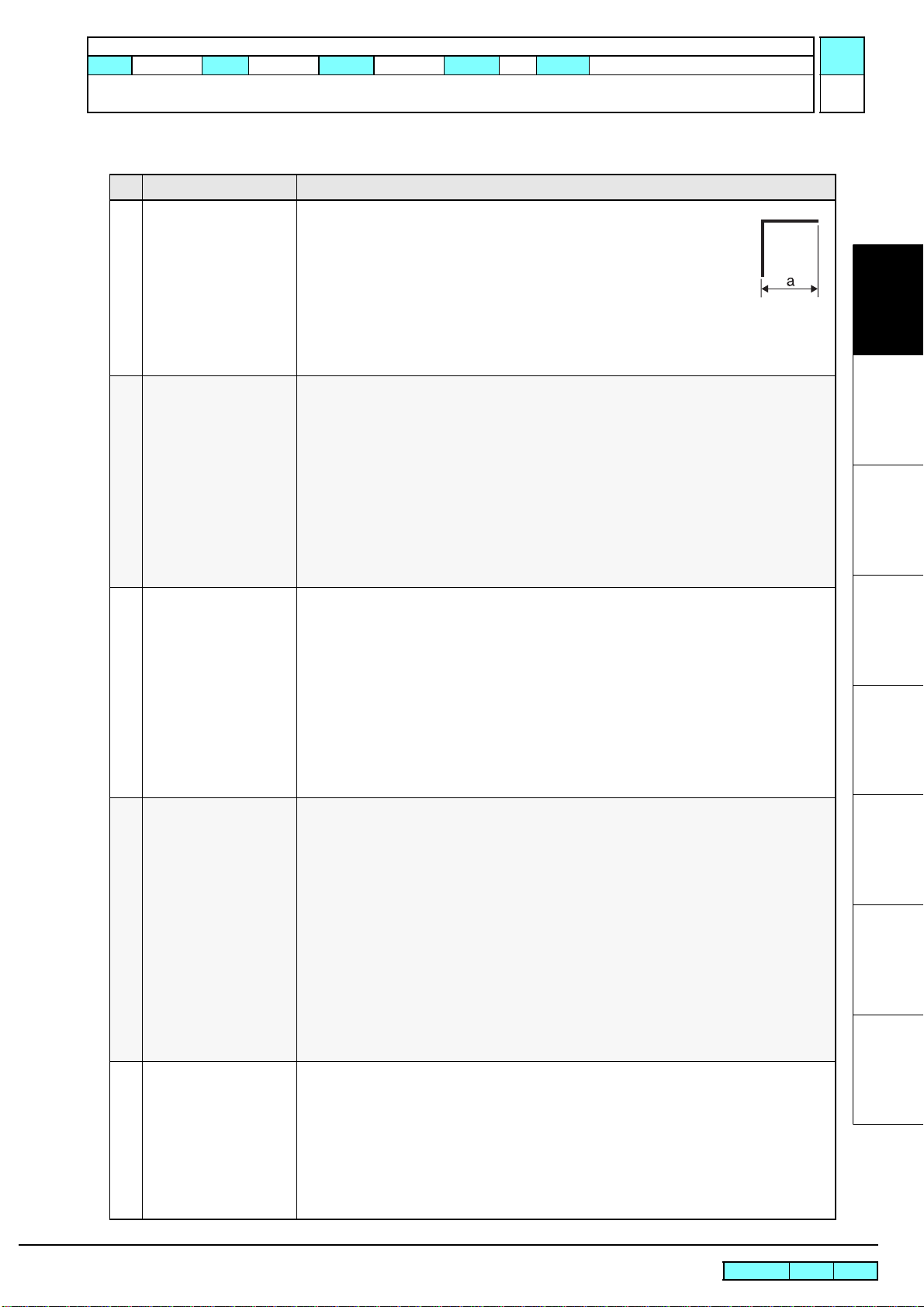

1.1.1 Mark Detection

1

2

3

4

5

6

7

8

5 Searching for horizontal

line of mark (TP1)

1. The head moves in the X-axis upper direction (for type 1) or X-axis lower

direction (for type 2) until the mark sensor turns on and stops.

2. The head moves in the X-axis upper direction (for type 1) or X-axis lower

direction (for type 2) by the distance of HM.

3. The head moves in the X-axis lower direction (for type 1) or X-axis upper

direction (for type 2) until the mark sensor turns on and stops.

4. The plotter determines the center of the horizontal line based on the

positions of “1” and “3”.

5. Finally the head moves in the X-axis upper direction by the distance of HM and terminates.

6Searching for vertical line

of mark (TP3)

1. When the distances between the marks are known by the procedure for scale compensation

with the setting value “BEFORE”, the head moves in the X-axis upper direction by

“Distance between marks -Length which is twice the mark size”.

2. The head moves in the Y-axis left direction until the mark sensor turns on and stops.

3. The head moves in the Y-axis left direction by the distance of HM.

4. The head moves in the Y-axis right direction until the mark sensor turns on and stops.

5. The plotter determines the center of the vertical line based on the positions of “2” and “4”.

6. Finally the head moves in the Y-axis left direction (for type 1) or Y-axis right direction (for

type 2) by the distance of HM and terminates.

• If the vertical line is not detected even after a search of the maximum printing range,

[ERROR36-C MARK DETECT] appears.

7 Searching for horizontal

line of mark (TP3)

1. The head moves in the X-axis upper direction (for type 1) or X-axis lower direction (for

type 2) until the mark sensor turns on and stops.

2. The head moves in the X-axis upper direction (for type 1) or X-axis lower direction (for

type 2) by the distance of HM.

3. The head moves in the X-axis lower direction (for type 1) or X-axis upper direction (for

type 2) until the mark sensor turns on and stops.

4. The plotter determines the center of the vertical line based on the positions of “1” and “3”.

5. Finally the head moves upward by HM of the horizontal line of TP3 and to the left (for type

1) or to the right (for type 2) by HM of the vertical line.

• If the horizontal line cannot be detected, the plotter determines that the vertical line

detected above is not part of a mark and repeats the procedure from Step 6.

8Searching for horizontal

line of mark (TP4)

1. When the distances between the marks are known by the procedure for scale compensation

with the setting value “BEFORE”, the head moves in the X-axis upper direction by

“Distance between marks -Length which is twice the mark size”.

2. The head moves in the X-axis upper direction until the mark sensor turns on and stops.

3. The head moves in the X-axis upper direction by the distance of HM.

4. The head moves in the X-axis lower direction until the mark sensor turns on and stops.

5. The plotter determines the center of the horizontal line based on the positions of “2” and “4”.

6. Finally the head moves in the X-axis upper direction (for type 1) or X-axis lower direction

(for type 2) by the distance of HM and terminates.

• If the horizontal line is not found even after a search of a range up to 5 m, [ERROR36-C

MARK DETECT] appears.

• If “no media” is detected at the tail end detection position during a search for a

horizontal line, the plotter performs the tail end detection of the media first and then

continues horizontal line detection.

9 Searching for vertical line

of mark (TP4)

1. The head moves in the Y-axis right direction (for type 1) or Y-axis left direction (for type 2)

until the mark sensor turns on and stops.

2. The head moves in the Y-axis right direction (for type 1) or Y-axis left direction (for type 2)

by the distance of HM.

3. The head moves in the Y-axis left direction (for type 1) or Y-axis right direction (for type 2)

until the mark sensor turns on and stops.

4. The plotter determines the center of the horizontal line based on the positions of “1” and “3”.

5. Finally the head moves in the Y-axis right direction by the distance of HM and terminates.

Processing sequence (2/3)

Step Processing Description

R.1.0

MAINTENANCE MANUAL > Operating Principle > Basic Operation > Mark Detection

Model CJV150/300 Issued 2014.09.15 Revised F/W ver. Remark

1.0