Calibration 19

Warning! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Max Frequency DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Calibration Procedure Setup for 60 Hz Motors: . . . . . . . . . . . . . . . . . . . . .23

MIN SPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

MAX SPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

TQ LIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SLIP COMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

TQ BOOST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

ACCEL/DECEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Accel Torque Boost Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Application Notes 29

Thermal Protection Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Decelerate to minimum speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Decelerate to minimum with DC injection braking . . . . . . . . . . . . . . . . . . .31

Independent adjustable speeds with . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

FWD-REV switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

RUN/JOG switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Single speed potentiometer control of multiple motors . . . . . . . . . . . . . . .34

Reversing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Troubleshooting 37

Warning! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Before troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

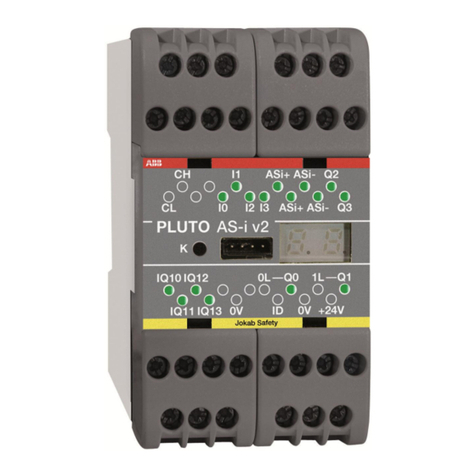

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Clearing LED fault indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Unconditional Warranty inside back cover

250-0262 rev 1.qxd 6/30/99 10:36 AM Page iii