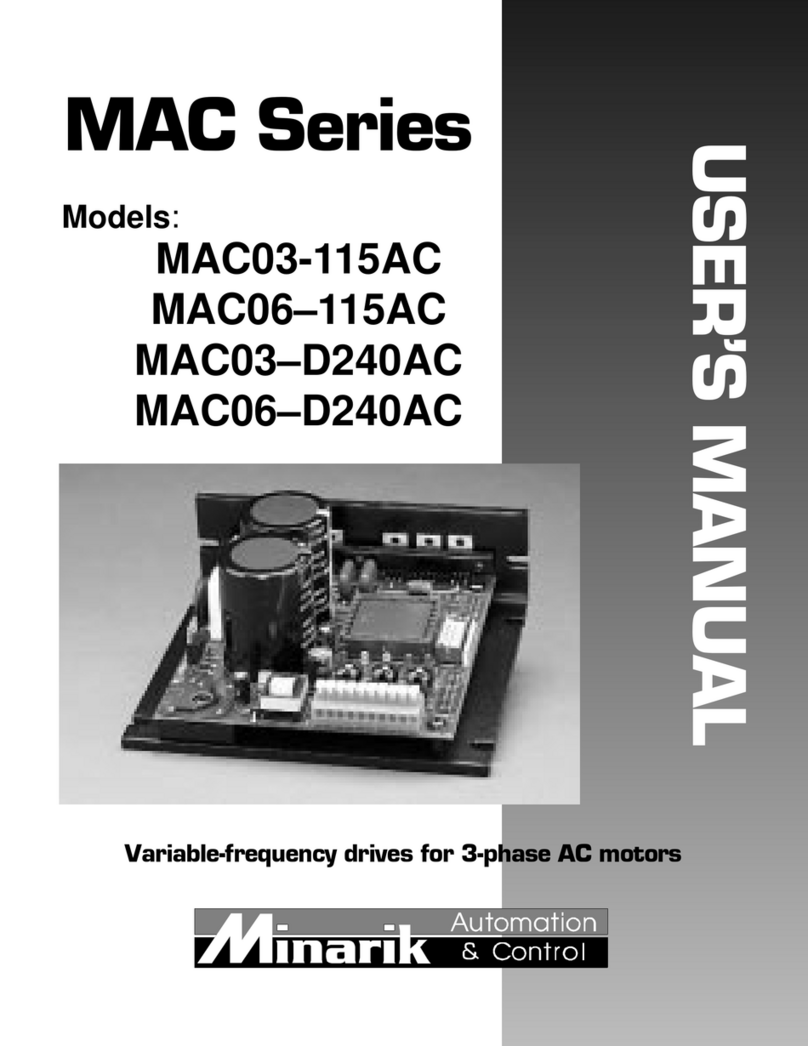

Minarik MAC Series User manual

Other manuals for MAC Series

1

This manual suits for next models

4

Table of contents

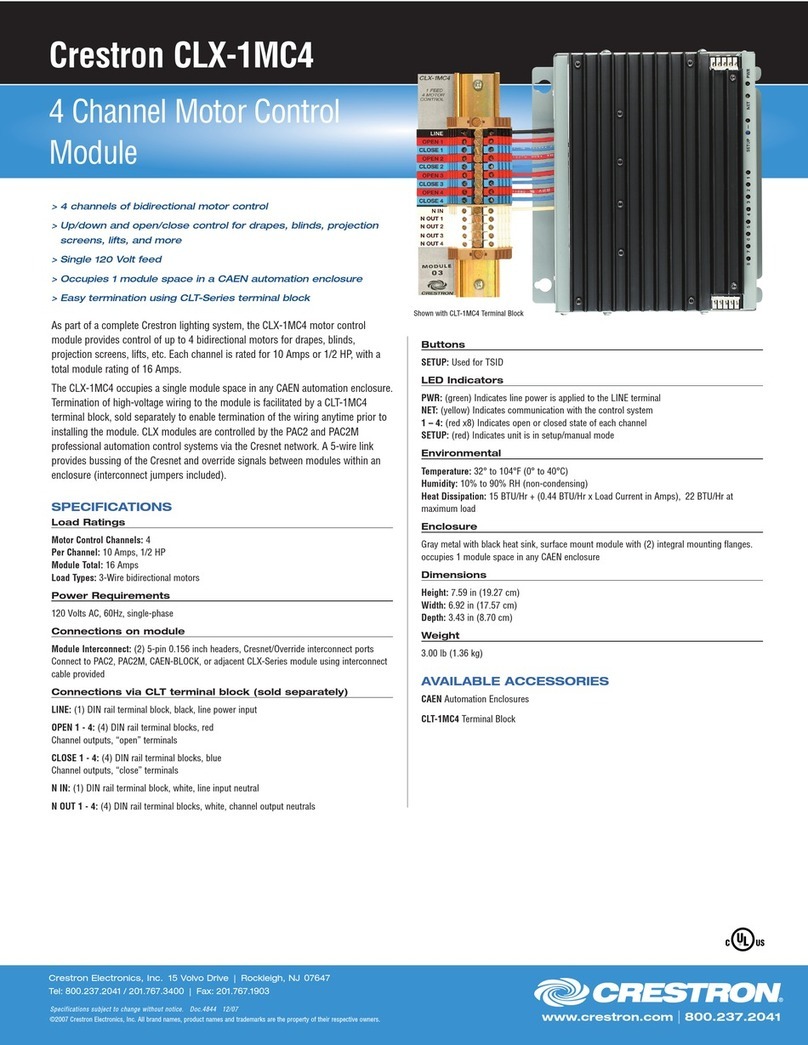

Other Minarik Controllers manuals

Popular Controllers manuals by other brands

Minebea Intec

Minebea Intec Maxxis 5 Original installation manual

Motoman

Motoman XRC Series manual

TOPP

TOPP C160RWA Installation and use instructions

Special Stage Systems

Special Stage Systems MING MECCA user guide

Moog Videolarm

Moog Videolarm VLC485 Installation and operation instructions

Autonics

Autonics TF3 Series user manual

EUROSTER

EUROSTER 12 Installation and operation manual

Autonics

Autonics TC4Y manual

Automated Logic

Automated Logic RC642 Technical instructions

Prolon

Prolon C1000 Series quick start guide

Siko

Siko AG25 Translation of the original installation instructions

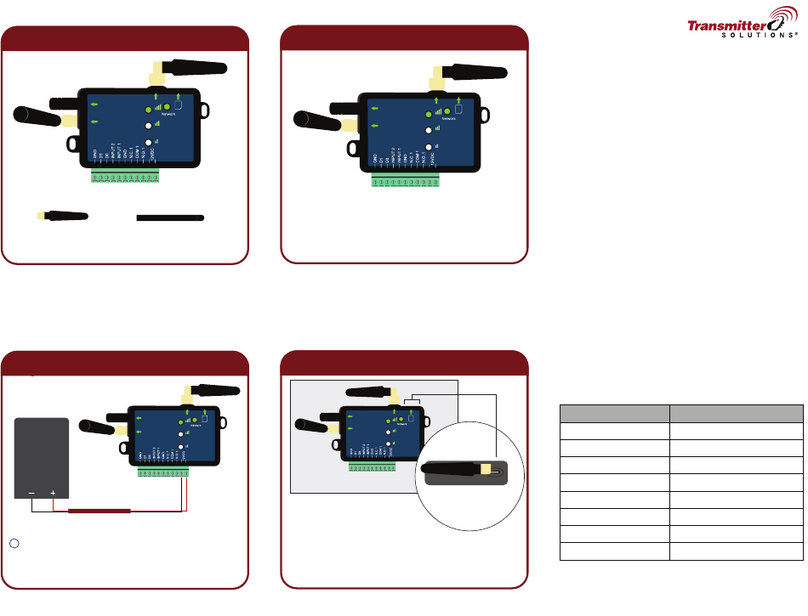

Transmitter Solutions

Transmitter Solutions PAL SPIDER WIEGAND 26 quick start guide